Vacuum electron beam welding process for square axle journal and axle pipe of support axle

A technology of vacuum electron beam welding and supporting bridge, which is applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of large deformation and need to be straightened, large environmental pollution, low welding strength, etc., to achieve high production efficiency, The effect of good welding performance and high welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

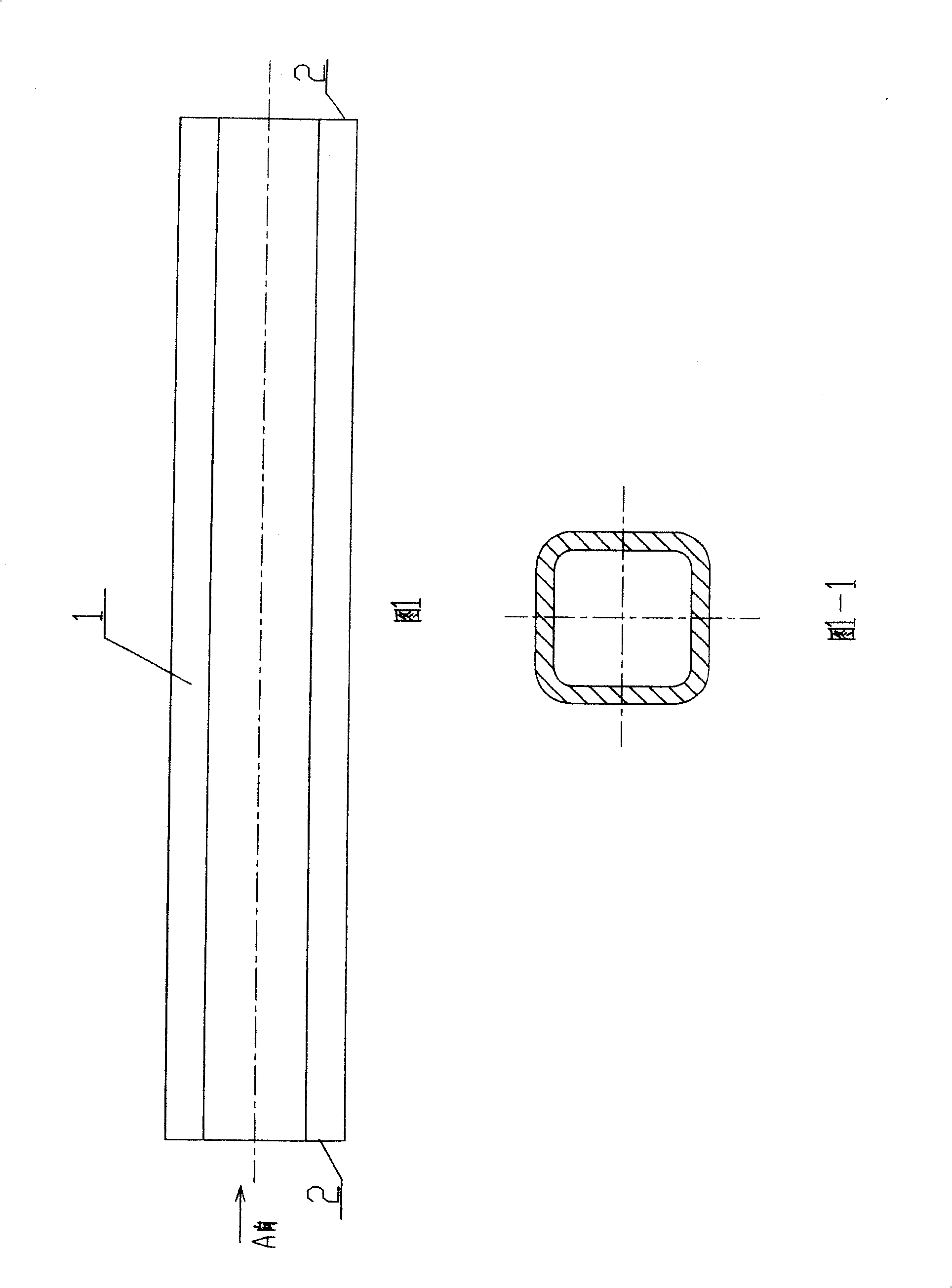

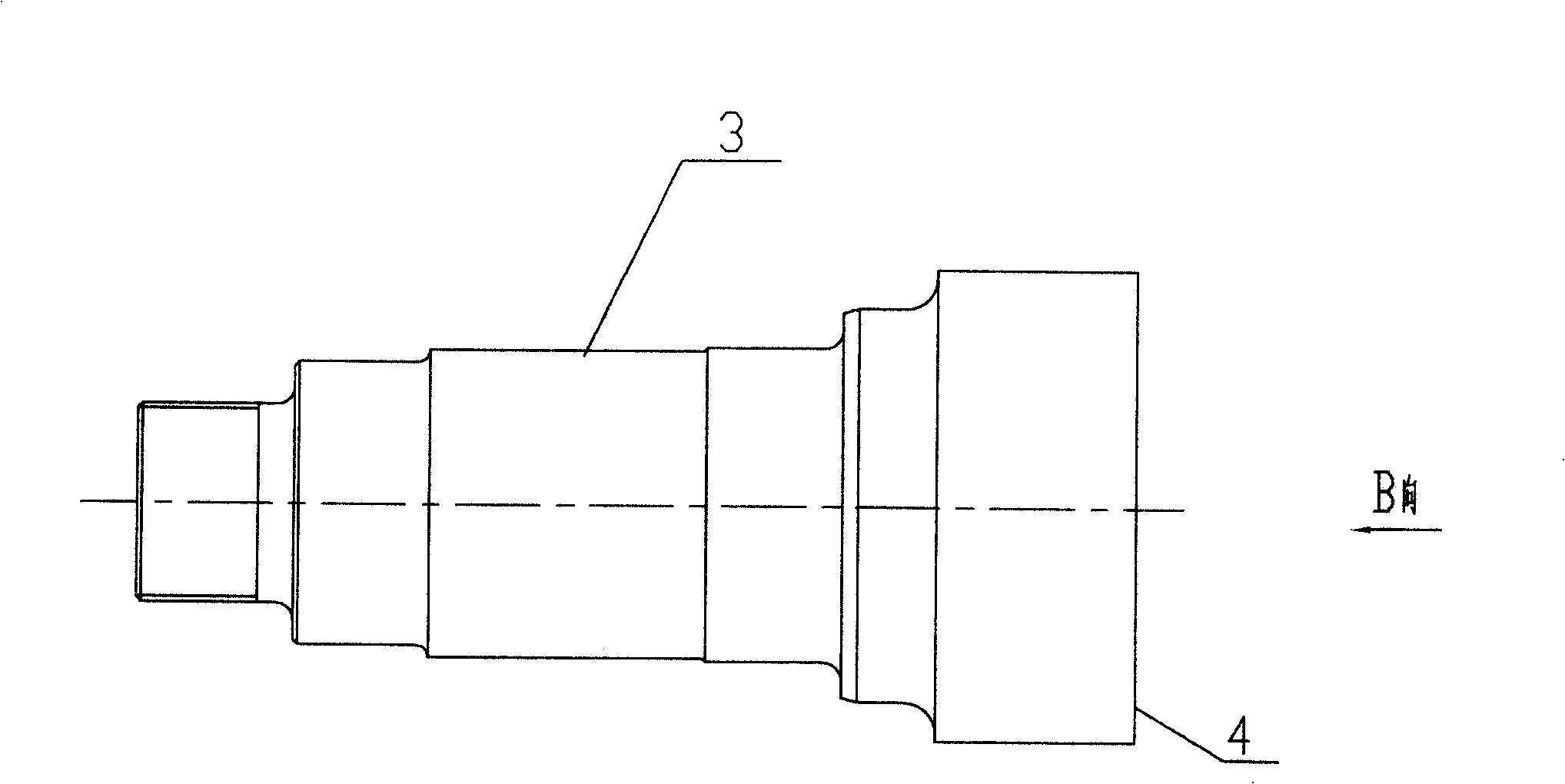

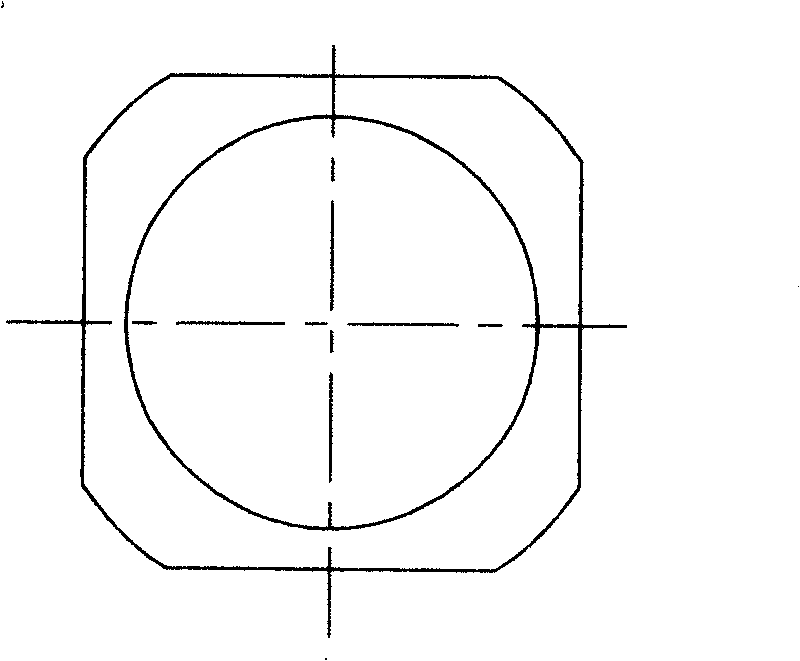

[0025] Firstly, after the square shaft head 3 and the square shaft tube 1 are fixed with tooling, the square shaft head 3 and the square shaft tube 1 are evenly spot welded at four points. Then use the intermediate frequency heating coil to heat the position of the welding seam to 200-250°C, and after heating for about 20-25 seconds, send the shaft head shaft tube into the vacuum chamber for vacuum electron beam welding.

[0026] Use the rotary vane mechanical pump and Roots pump to evacuate the vacuum chamber for about 120 seconds, and the vacuum degree of the vacuum chamber reaches ≥2×10 -1 Pa.

[0027] Set the welding parameters as follows: low point focus is 313mA, high point focus is 317mA, bias voltage is 1800V, filament current is 22A, electron gun high voltage is 80KV, low point beam current is 70mA, high point beam current is 90mA, welding ascending gradient 0.02 seconds, the welding descending gradient is 0.05 seconds, the workpiece rotation speed is 0.8rpm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com