High-frequency induction brazing method for connection of deep cavity inner conductor of coaxial transmission line

A high-frequency induction brazing and coaxial transmission line technology, which is applied in the direction of connection, welding equipment, line/collector parts, etc., can solve the problems of large investment in equipment, failure to meet high-precision requirements, deformation of inner conductors, etc., and achieve equipment Low investment, guaranteed long-term reliability, and the effect of reducing the limitation of design length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

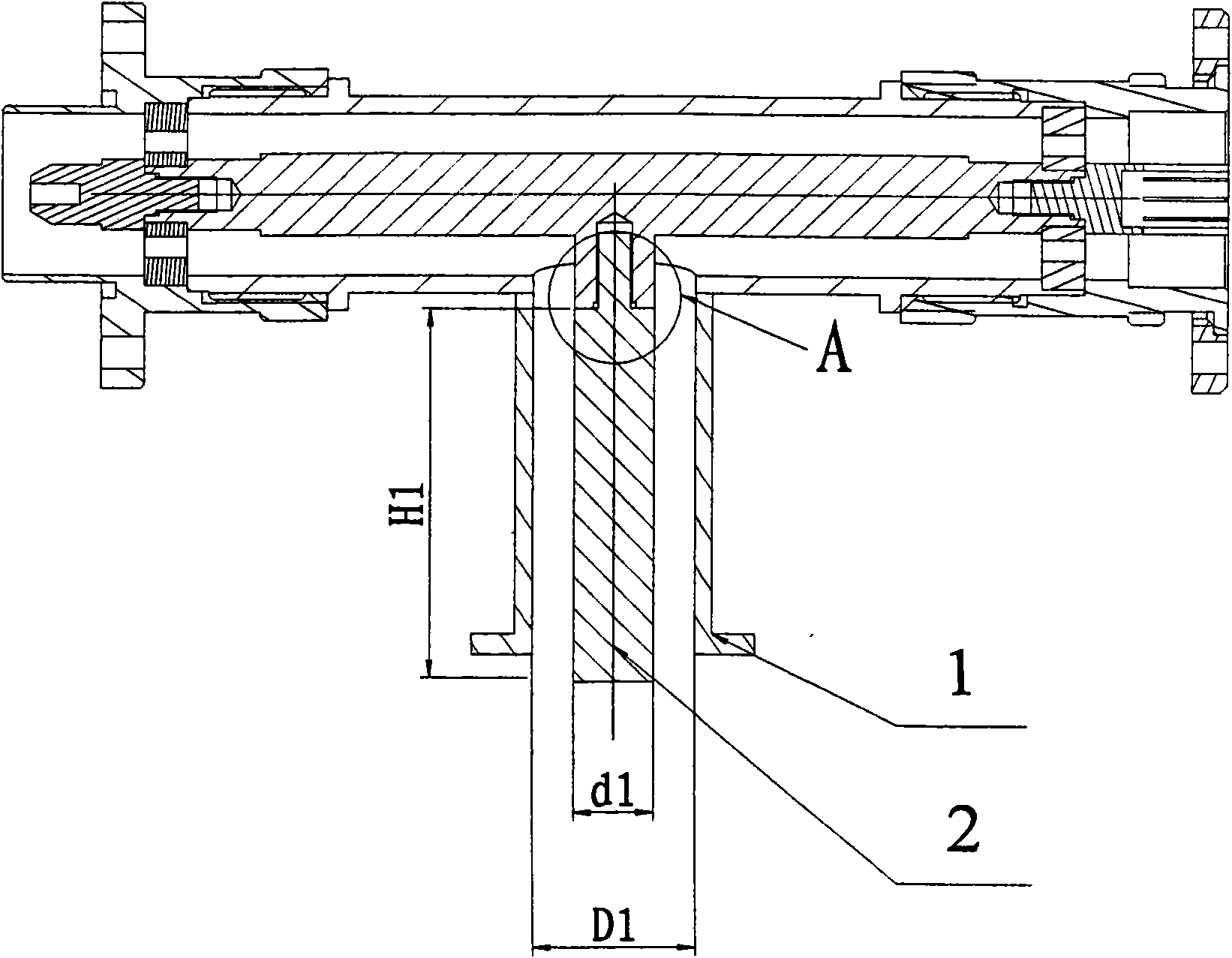

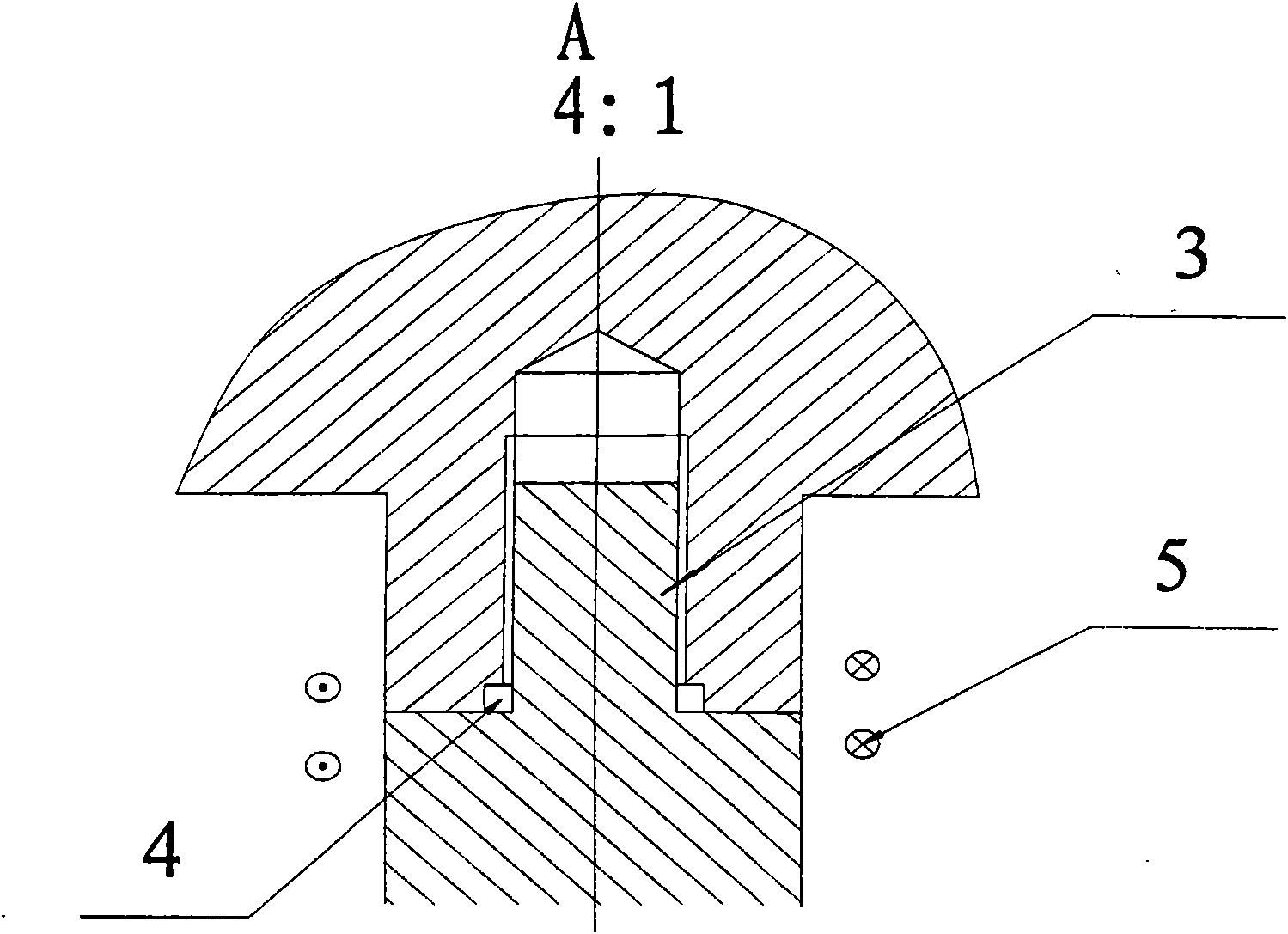

[0031] see figure 1 and figure 2 , for a T-shaped coaxial transmission line, it includes a hollow outer conductor 1 and an inner conductor 2, the deep cavity depth of the hollow outer conductor 1 is H=60mm, and the diameter D=30mm; the inner conductor 2 is composed of two conductors connected to form a T-shaped, two The diameter of the conductor is d=10mm, and the corresponding connecting ends of the two conductors are the correspondingly matched threaded holes and the screw rod 3 respectively, and linear solder is placed in the undercut 4 at the joint of the correspondingly matched threaded holes and the screw rod 3, And the length of the linear solder line is greater than 2.5 times the circumference of the corresponding inner conductor welding; and the two conductors are tightened correspondingly; the ring-shaped induction coil 5 with a diameter of 12 mm is inserted into the deep cavity of the hollow outer conductor 1 , set at the connection of the inner conductor end;

...

Embodiment 2

[0034] see Figure 5 , for the T-shaped structure, the depth of the deep cavity of the hollow outer conductor 1 is H=80mm, and the diameter D=24mm; the diameter of the two conductors is d=10mm, the cavity is deep, and the space is small. The protruding end of the inner conductor is coaxially connected to the auxiliary conductor 6, the diameter of the induction coil 5 is 18mm, and the ring-shaped induction coil 5 is set on the auxiliary conductor 6, and the others are the same as in the first embodiment.

[0035] When the power of the high-frequency generator is 5KW, a wire coil with a diameter of Φ0.5mm is used, and the alloy composition is Sn63Pb37. The induction brazing parameters are set as: power ratio 55%, and welding heating time 80 seconds.

Embodiment 3

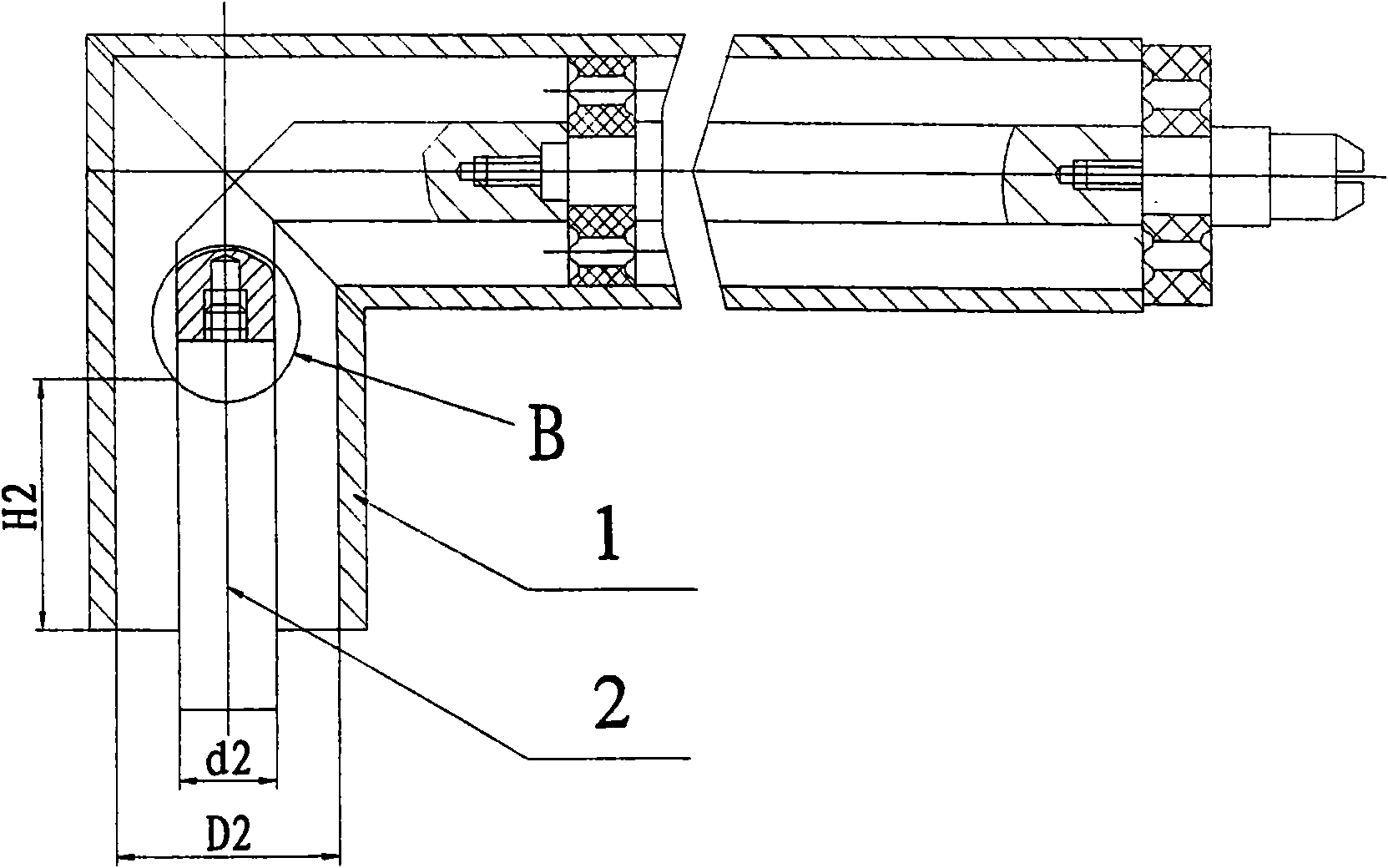

[0037] see image 3 and Figure 4 , for the L-shaped structure, the depth of the deep cavity of the hollow outer conductor 1 is H=60mm, and the diameter D=16mm; the diameter of the two inner conductors is d=5mm, the space is small, and the inner conductor stretches near the connection of the inner conductor end The output end is coaxially connected to the auxiliary conductor 6, the diameter of the induction coil 5 is 10mm, and the ring-shaped induction coil 5 is set on the auxiliary conductor 6, and the others are the same as in the first embodiment.

[0038] In the case of high-frequency generator power 5KW, diameter Φ0.5mm linear solder coil, alloy composition is Sn96.5Ag3.0Cu0.5 induction brazing parameters are set as: power ratio 40%, welding time 35-40 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com