L-shaped part welding clamp capable of avoiding swing of parts to be welded

A part welding and L-shaped technology, which is applied in the field of L-shaped parts welding fixtures, can solve the problems of easy swinging of parts to be welded and poor welding quality, and achieve the effect of avoiding swinging and improving the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

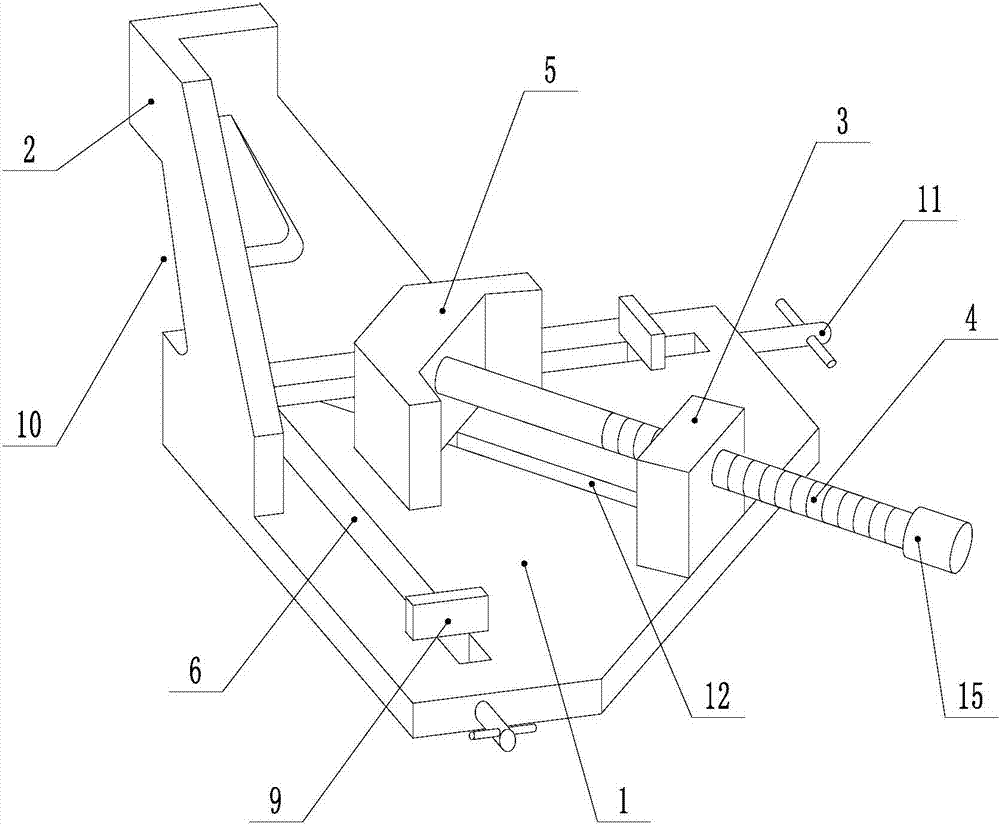

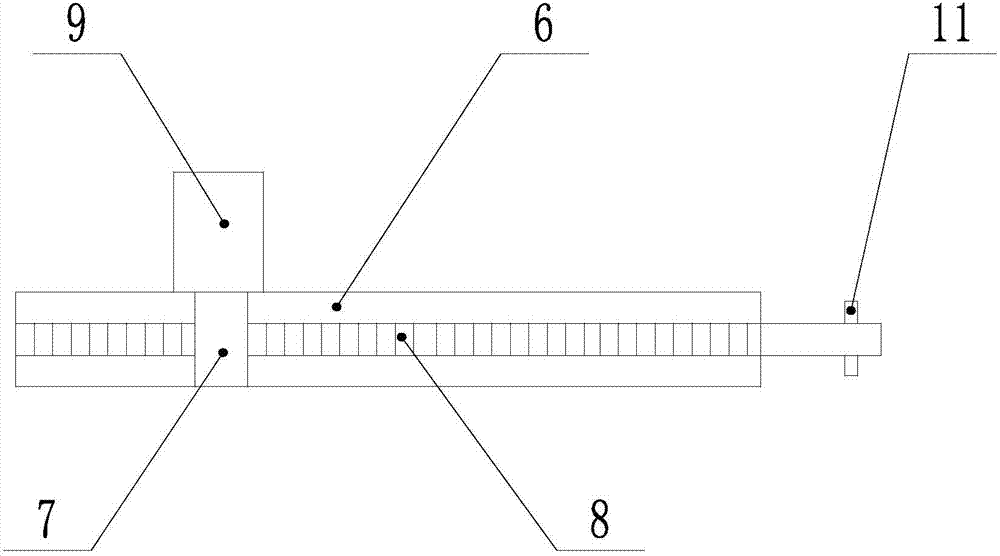

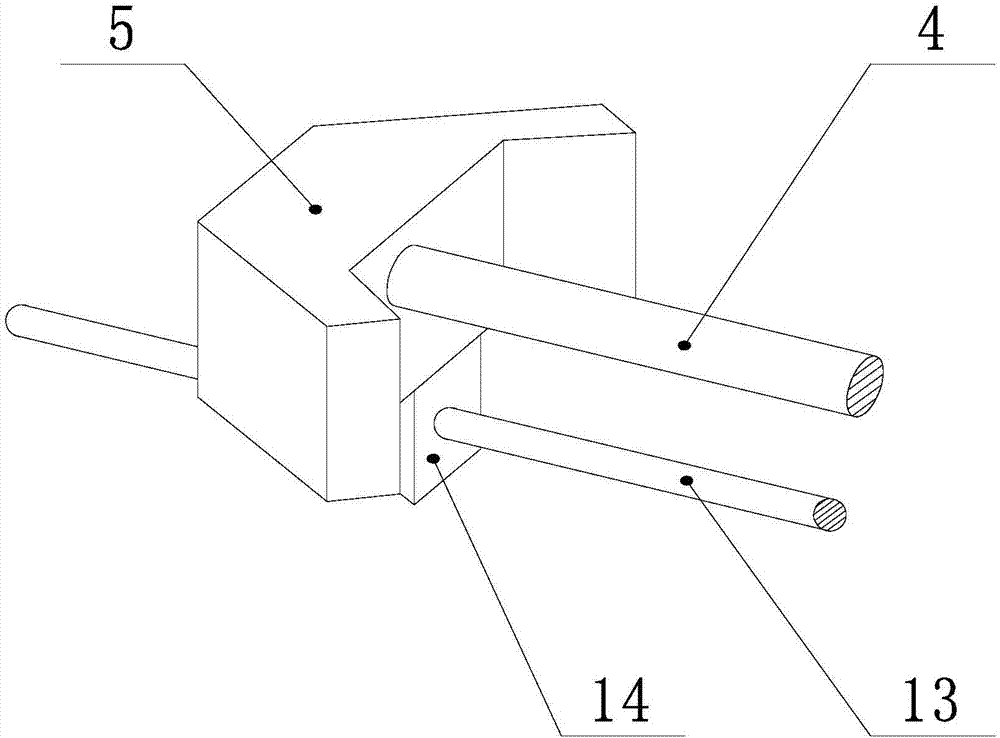

[0024] like Figure 1 ~ Figure 3 As shown, the L-shaped part welding fixture that can avoid the swing of the parts to be welded includes a base 1. Two support plates 2 perpendicular to each other are arranged on the base 1. The end of the base 1 away from the support plate 2 is provided with a mounting plate 3. The mounting plate 5 is located between the two support plates 2, the mounting plate 3 is provided with a threaded hole that matches the screw 4, and the screw 4 is screwed with the mounting plate 3; the screw 1 4 A compression block 5 is provided at one end close to the support plate 2, the compression block 5 is located between the two support plates, and the two sides of the compression block 5 close to the support plate 2 are respectively parallel to the two support plates 2; - 4, the pressing block 5 is close to or away from the support plate 2, thereby clamping or loosening the parts to be welded; the base 1 is provided with two mutually perpendicular grooves 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com