Pipe connecting structure for metallurgical furnace and metallurgical furnace

A connection structure and metallurgical furnace technology, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, furnaces, etc., can solve problems such as separation of welds and weldments, water leakage at welds, and increased operating costs of metallurgical furnaces , to achieve the effect of improving weld quality, increasing connection strength and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

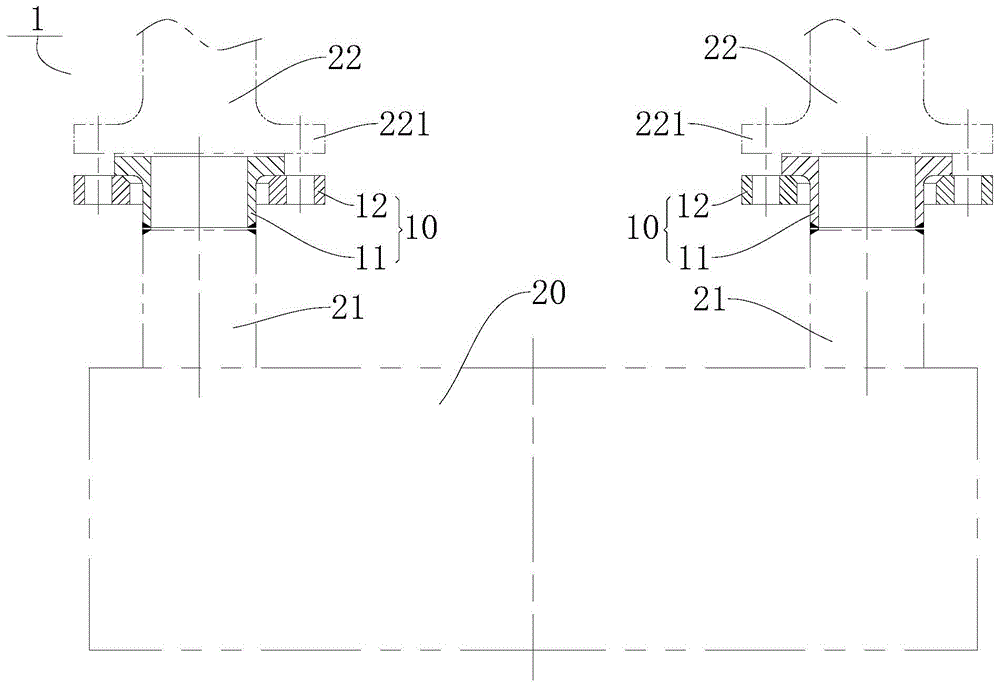

[0034] Refer below Figure 1-Figure 6 The pipe connection structure 10 for the metallurgical furnace 1 according to the embodiment of the present invention will be described in detail.

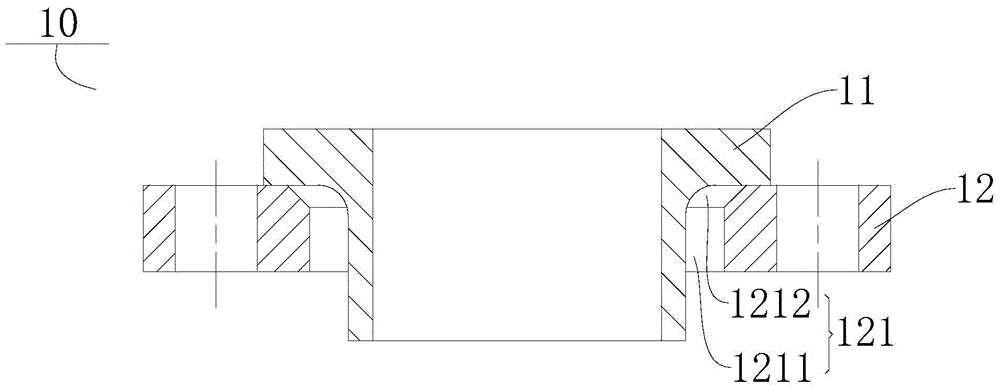

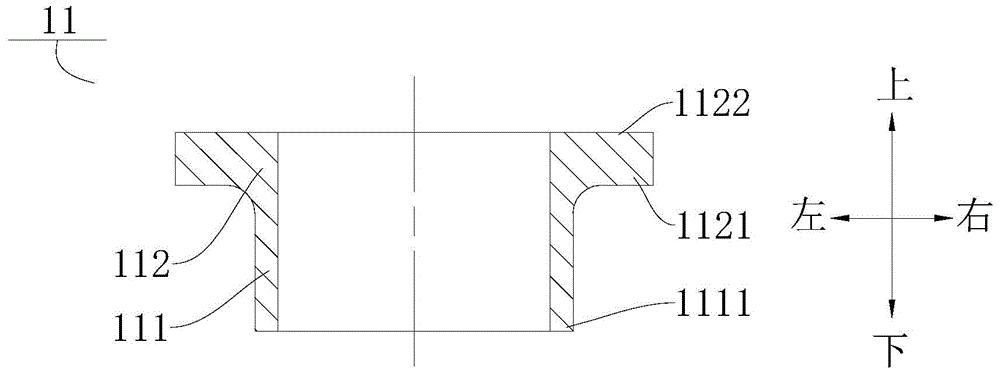

[0035] like Figure 1-Figure 6 As shown, the pipe connection structure 10 for the metallurgical furnace 1 according to the embodiment of the present invention includes: a communication body 11 .

[0036] Specifically, as figure 1 As shown, the communication body 11 can be formed into a tubular shape, and the communication body 11 is suitable for being connected between the first communication pipe 21 and the second communication pipe 22 of the metallurgical furnace 1, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com