Equipment and method for repairing in-service BOSS weld with defects

A defect and equipment technology, which is applied in the field of repair equipment for in-service BOSS welds with defects, can solve problems such as low repair efficiency, unstable quality, and damage to health, so as to achieve better quality, improve weld quality, and improve the same The effect of axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The application will be described in further detail below in conjunction with the accompanying drawings.

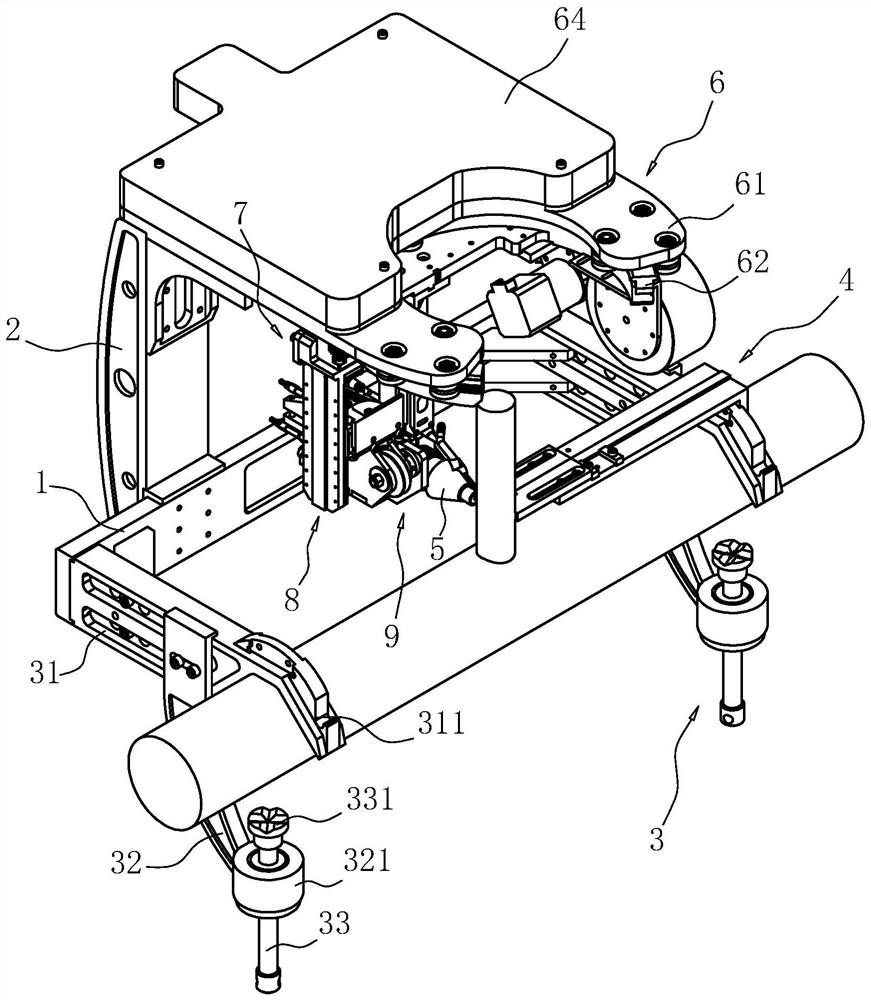

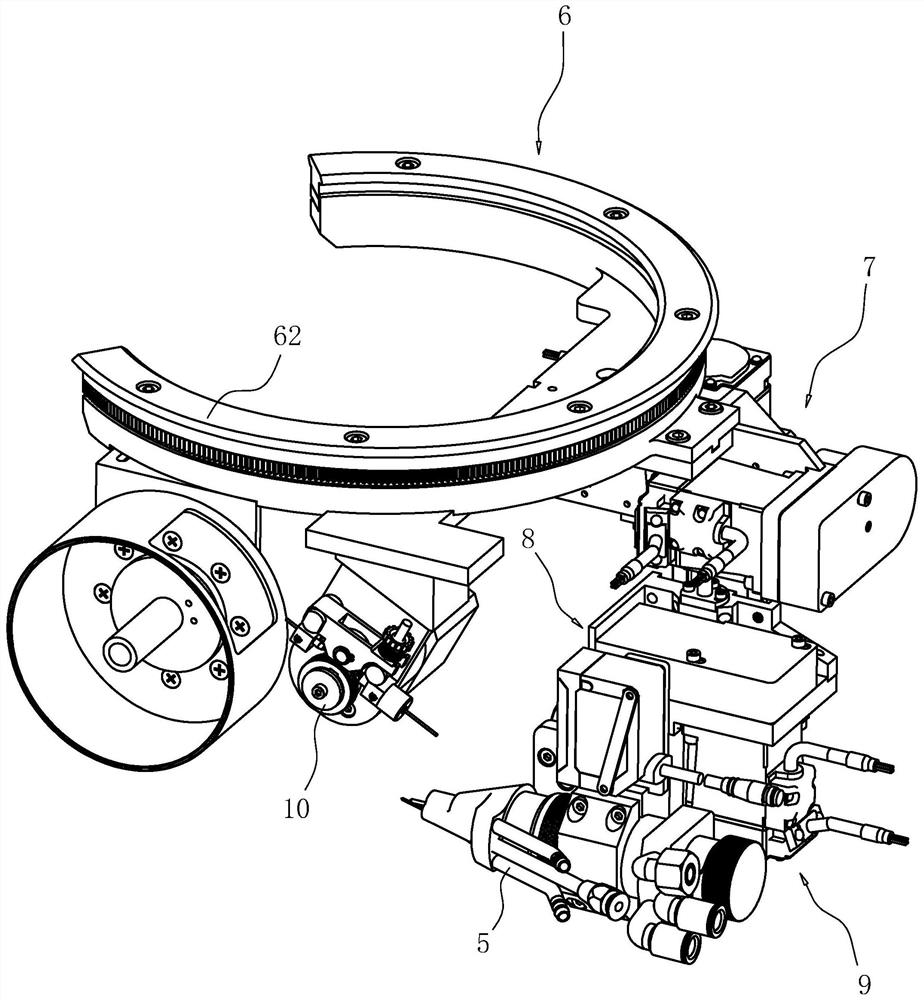

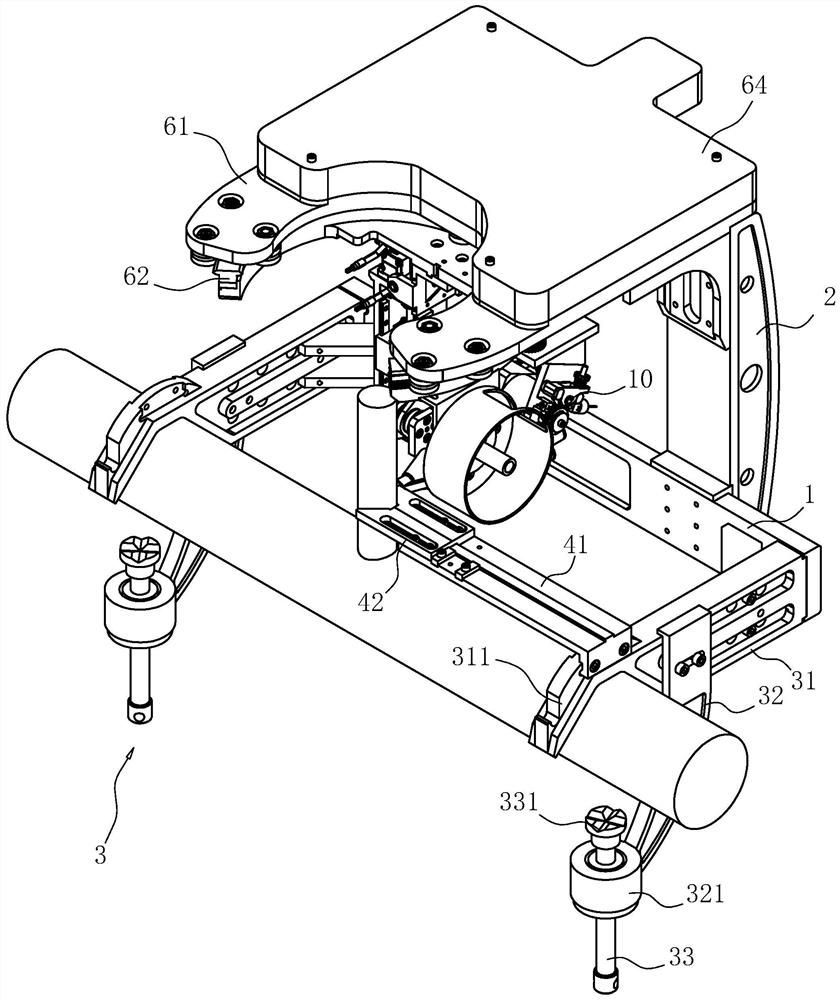

[0047] refer to figure 1 and figure 2 , the present application provides a kind of repair equipment for BOSS welds with defects in service, including a support plate 1 horizontally arranged on the side of the main pipe at the axis level and two support columns 2 vertically fixed on the support plate 1 ; The support plate 1 is provided with a clamping assembly 3 for fixing the support plate 1 on one side of the main pipe; the support column 2 is provided with a horizontal rotation mechanism 6 located above the branch pipe, and the horizontal rotation mechanism 6 is provided with a wire feeder 10 And lateral movement mechanism 7, horizontal movement mechanism 7 is provided with vertical movement mechanism 8, and vertical movement mechanism 8 is provided with turning torch mechanism 9, and turning torch mechanism 9 is provided with welding torch 5; Horizontal moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com