Welding process of nodular cast iron pipe flange pipe

A ductile iron pipe and welding process technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems affecting the quality of ductile iron pipe welding flange pipes, and achieve improved weld strength and savings The effect of time and weld quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] combine Figure 1 to Figure 3 ,as well as Figure 8 Shown is the first specific embodiment of a ductile iron pipe flange pipe welding process of the present invention, the process mainly includes the following steps:

[0025] Step 1): Cut the ductile iron pipe 1 into a certain length with a gantry cutting machine.

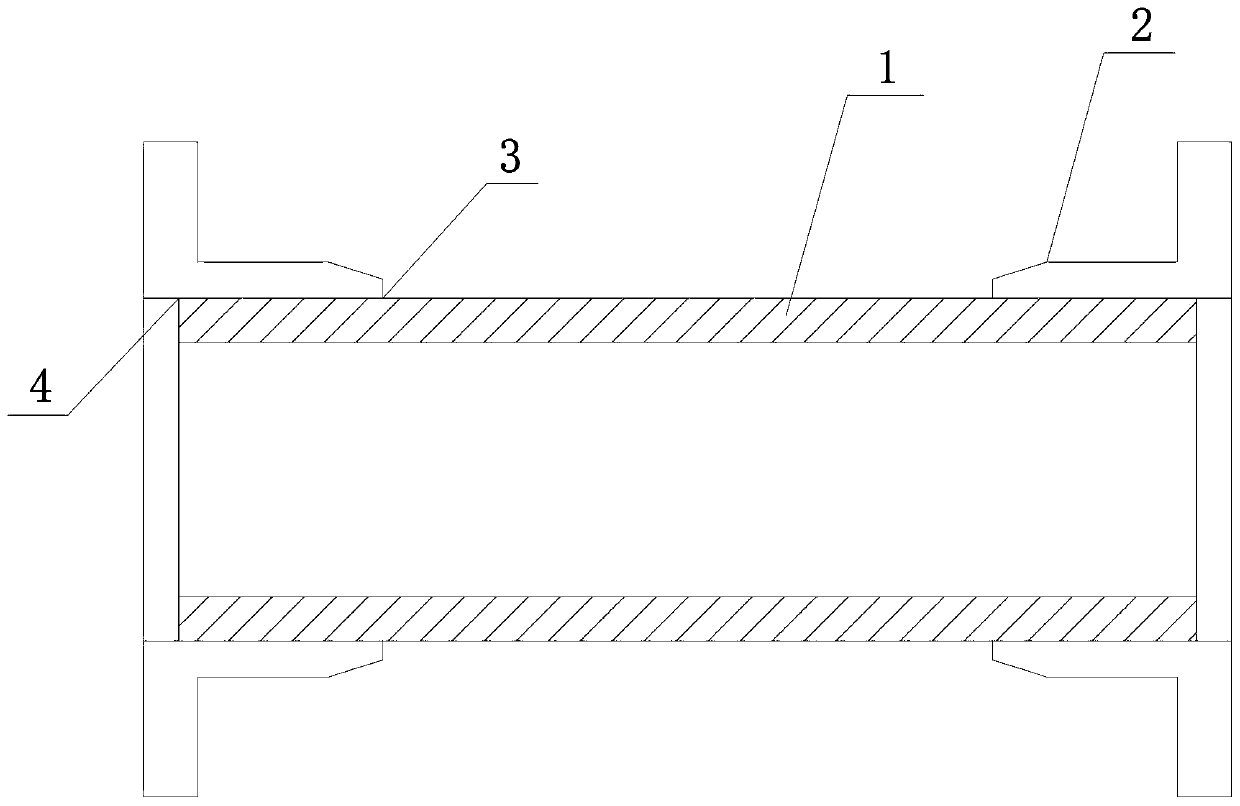

[0026] Step 2): After heating the flange 2 to above 500°C, specifically, it can be heated to 650-800°C, and perform shrink-fit interference fit with the ductile iron pipe 1 to complete the installation. The structural diagram of the installation is as follows figure 1 As shown, there is an outer gap 3 and an inner gap 4 between the ductile iron pipe 1 and the flange 2 .

[0027] Step 3): Using Ar and CO 2 The mixed gas is used as the shielding gas, and the outer gap 3 and the inner gap 4 are welded for the first time with a welding torch, and the welding is carried out at the same time under the condition of 50-60min / turn. In this embodiment, it is specif...

Embodiment 2

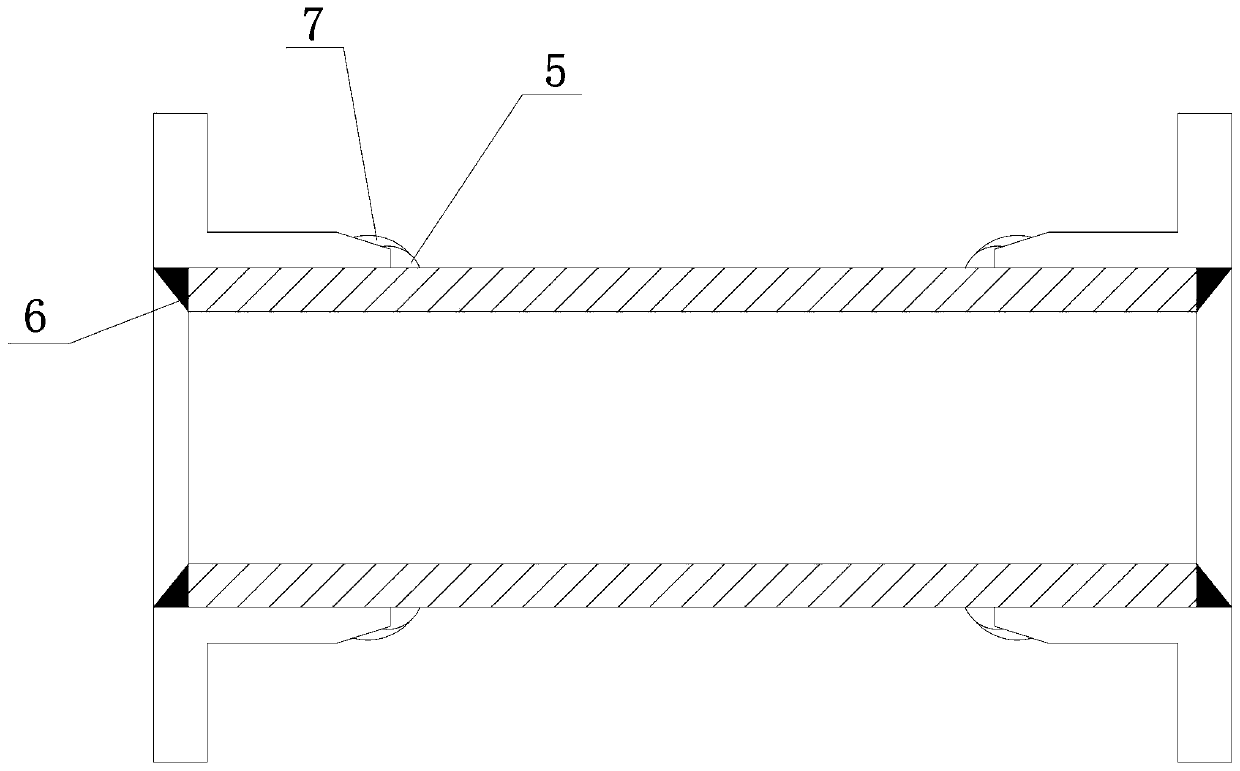

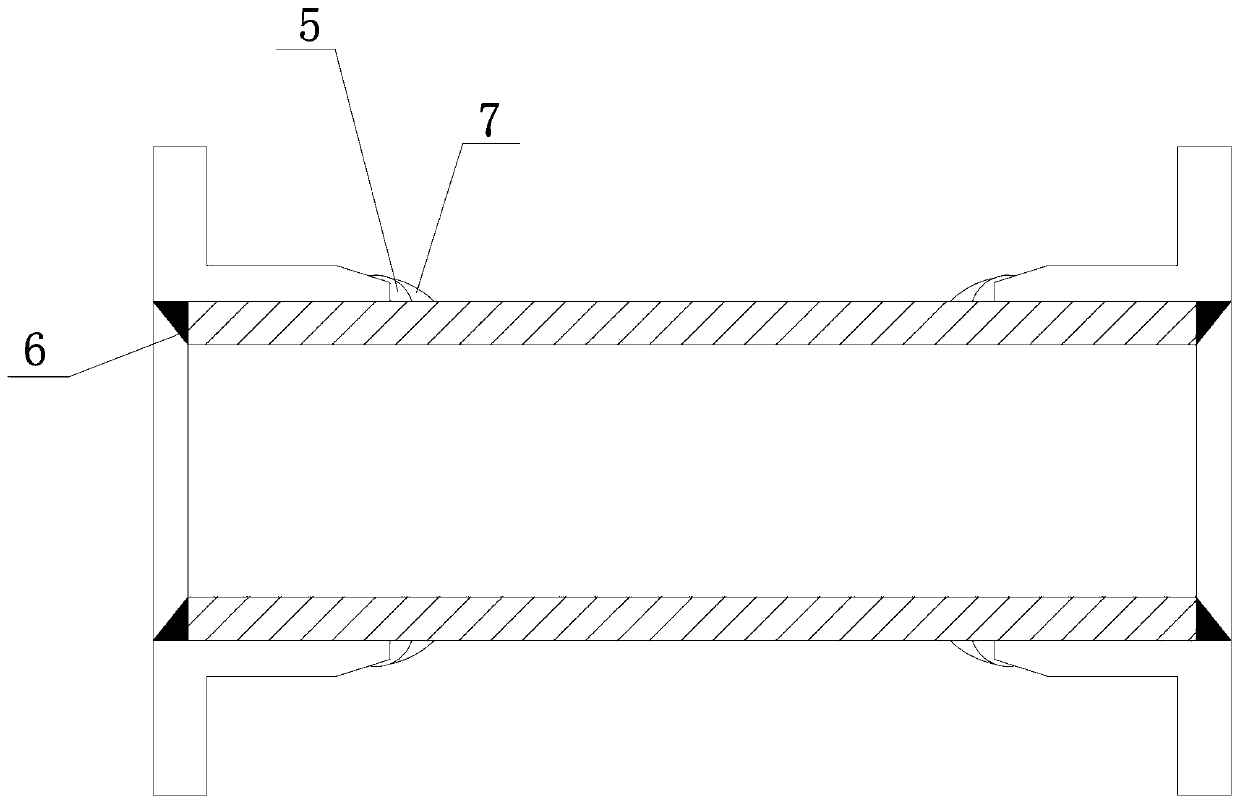

[0031] In this example, combined with Figure 4 to Figure 7 As shown, the difference from the first embodiment is that the second welding also includes a third welding on the outer gap 3 to form a third outer bead 8 .

[0032] Such as Figure 4 Shown is a schematic diagram of the structure of the first product of this embodiment, wherein the third outer bead 8 is bonded to the ductile iron pipe 1 and the first outer bead 5, the second outer bead 7 and the third outer bead 8 Cover the first outer bead 5 from the root of the weld toe to the weld seam.

[0033] Such as Figure 5 Shown is a schematic diagram of the structure of the second product of this embodiment, wherein the third outer bead 8 is bonded to the ductile iron pipe 1, and the first outer bead 5 is bonded to the second outer bead 7, and the second outer bead 7 And the third outer bead 8 completely covers the first outer bead 5 from the root of the weld toe to the weld seam.

[0034] Such as Figure 6 Shown is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com