Brake cylinder seat assembly tool

A technology of brake cylinder and seat group, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of welding deformation, high design requirements of brake cylinder seat drawings, and the inability of brake cylinder seat to meet the size requirements, etc. Achieve the effect of preventing deformation, reducing labor intensity and improving weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

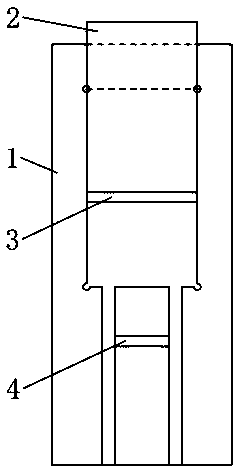

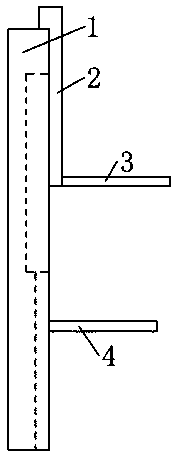

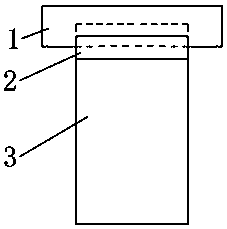

[0032] As shown in the figure, a brake cylinder seat assembly tooling includes a bottom plate 1, a limit plate 2, a first limit block 3 and a second limit block 4;

[0033] There is a rectangular connecting plate fitting groove 101 in the middle of the upper surface of the bottom plate 1, and two parallel seat plate fitting grooves 102 are opened between the connecting plate fitting groove 101 and the end of the bottom plate 1;

[0034] The limit plate 2 is placed on the end of the base plate 1 away from the seat plate assembly groove 102, and the end of the limit plate 2 is integrally connected with an upwardly protruding limit protrusion 201, and the inner side of the limit protrusion 201 is connected to the bottom plate 1 The ends fit together;

[0035] The first limiting block 3 is fixedly connected to the end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com