Twin-wire electrogas welding water-cooled welding torch

A technology of gas-electric vertical welding and welding torch, which is applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc. It can solve the problems of not disclosing the welding torch structure, increasing the amount of welding wire deposition, and increasing the input of welding heat, so as to reduce the amount of welding wire , fast welding speed, reduce the effect of welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

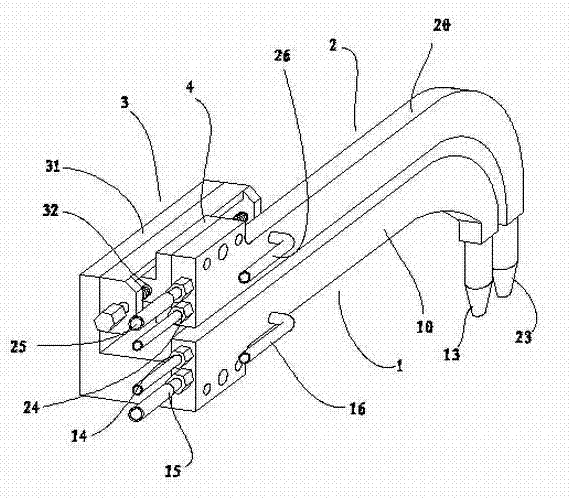

[0025] see figure 1 As shown, the double-wire gas-electric vertical welding water-cooled torch of the preferred embodiment of the present invention includes two mutually insulated first water-cooled torches 1, the second water-cooled torch 2 and the adjusting device 3 of the welding wire spacing, wherein the adjustment of the welding wire spacing The device 3 includes a base 31 and a screw nut 32 mechanism arranged on the base 31, the first welding torch 1 is fixed to the base 3, and the second welding torch 2 is connected to the screw through a fixing plate 4. In the nut mechanism, the nut is fixed, and the second welding torch 2 is located on the upper part of the first welding torch 1, and the two are in the same vertical plane. The front and back distance of the second welding torch contact tip can be adjusted by rotating the screw rod to meet the needs of vertical welding of different plates and different thicknesses.

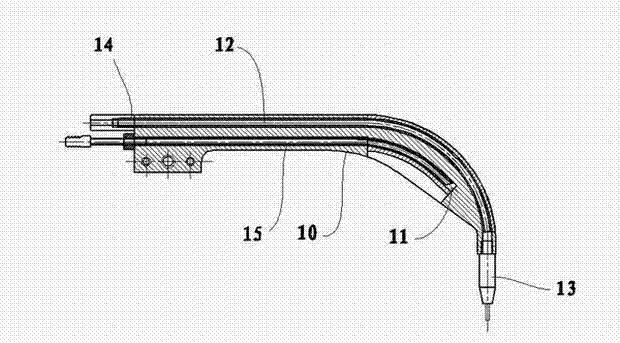

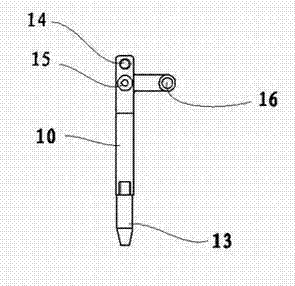

[0026] Such as figure 2 , image 3 , Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com