Intelligent real-time temperature control and shape control device and method for thick plate laser welding

A laser welding and intelligent technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as shortening, and achieve the effects of short manufacturing cycle, improved efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

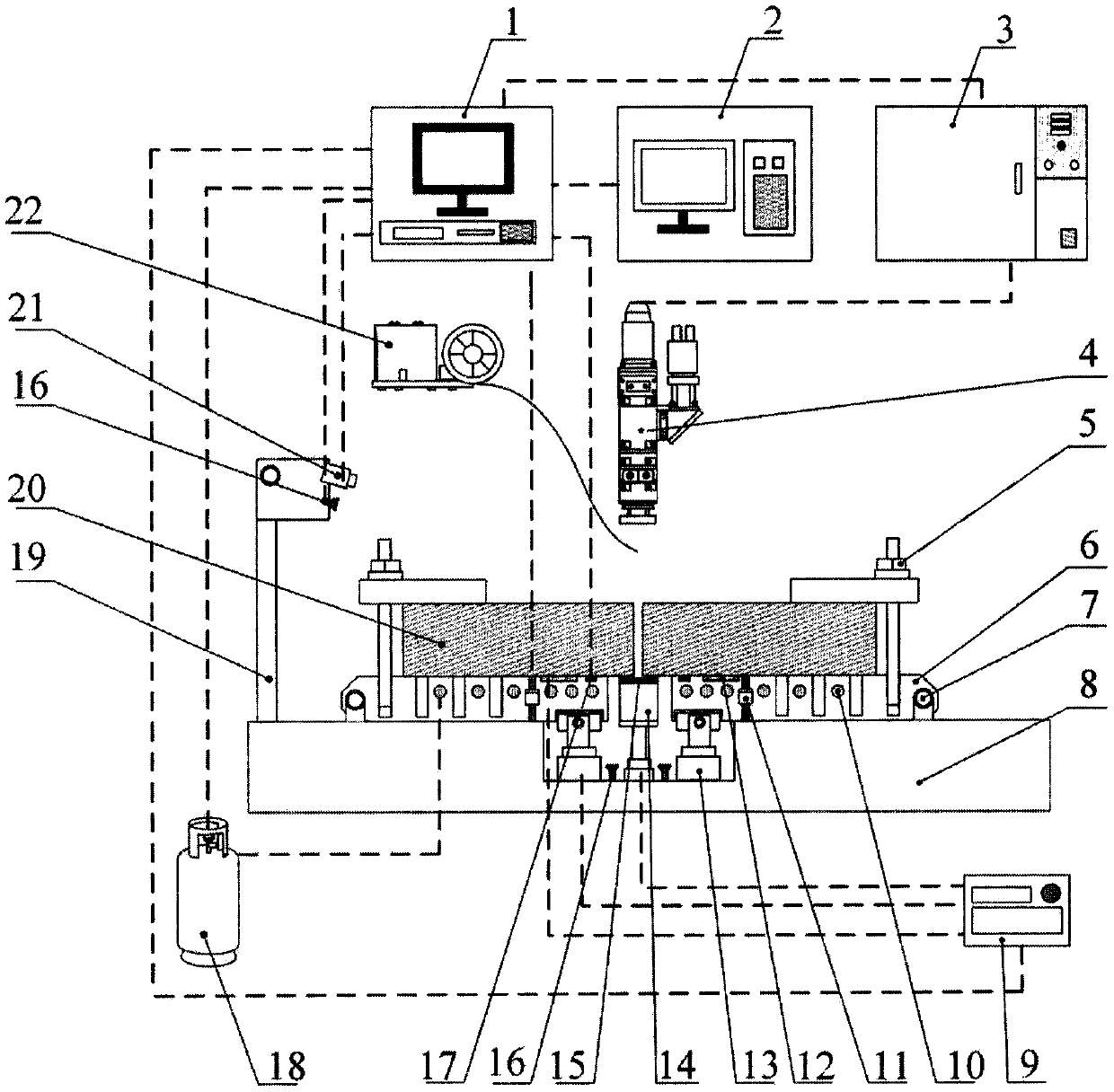

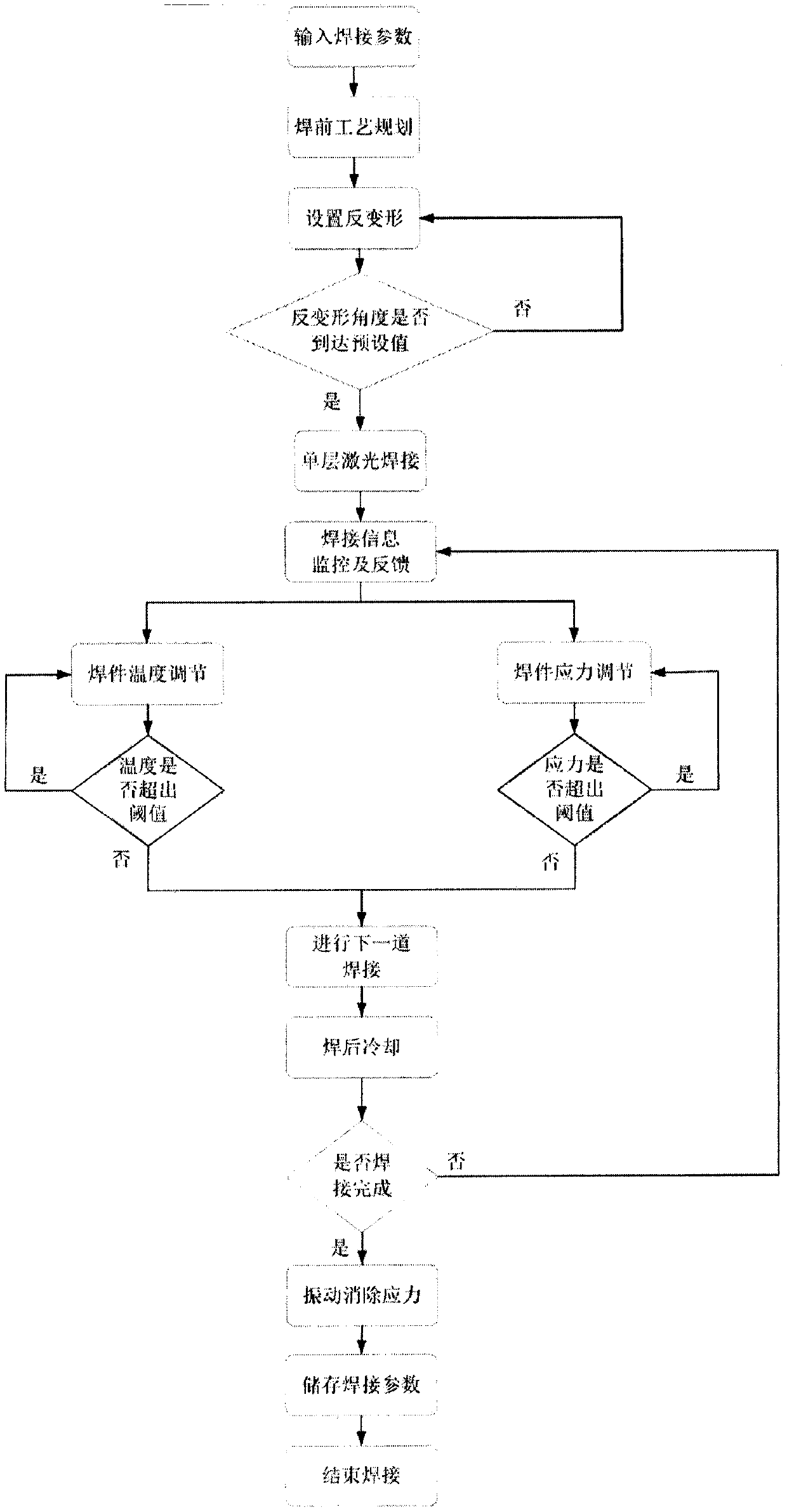

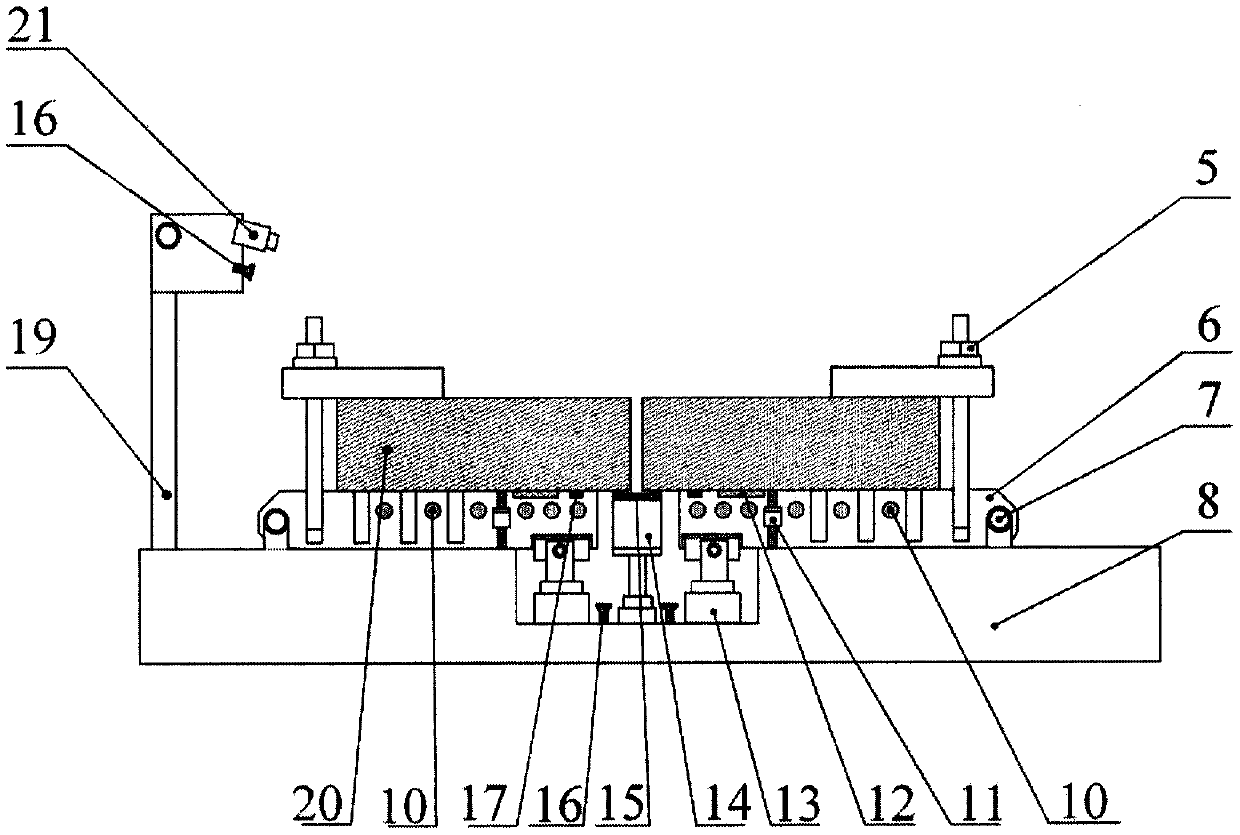

[0041] like figure 1 shown. The invention discloses an intelligent real-time temperature control and shape control equipment for laser welding of thick plates, including a computer control system, a pre-weld planning system, a laser welding system, a monitoring and feedback system, an adaptive water cooling system, an anti-deformation adjustment system and Self-regulating vibration system;

[0042] The computer control system 1 is connected to the pre-weld planning system 2, laser welding system, monitoring and feedback system, adaptive water cooling system, anti-deformation adjustment system and self-adjustment vibration system;

[0043] The pre-weld planning system 2 is used to analyze the input welding information, plan the pre-weld anti-deformation angle, welding laser power and welding speed, and plan the welding temperature range and stress range according to the database information. Finally, the planned welding process information is transmitted to the computer contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com