Dynamic twin-wire three-arc welding method

A welding method and three-arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as improving the deposition rate, and achieve the effect of eliminating electromagnetic interference and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

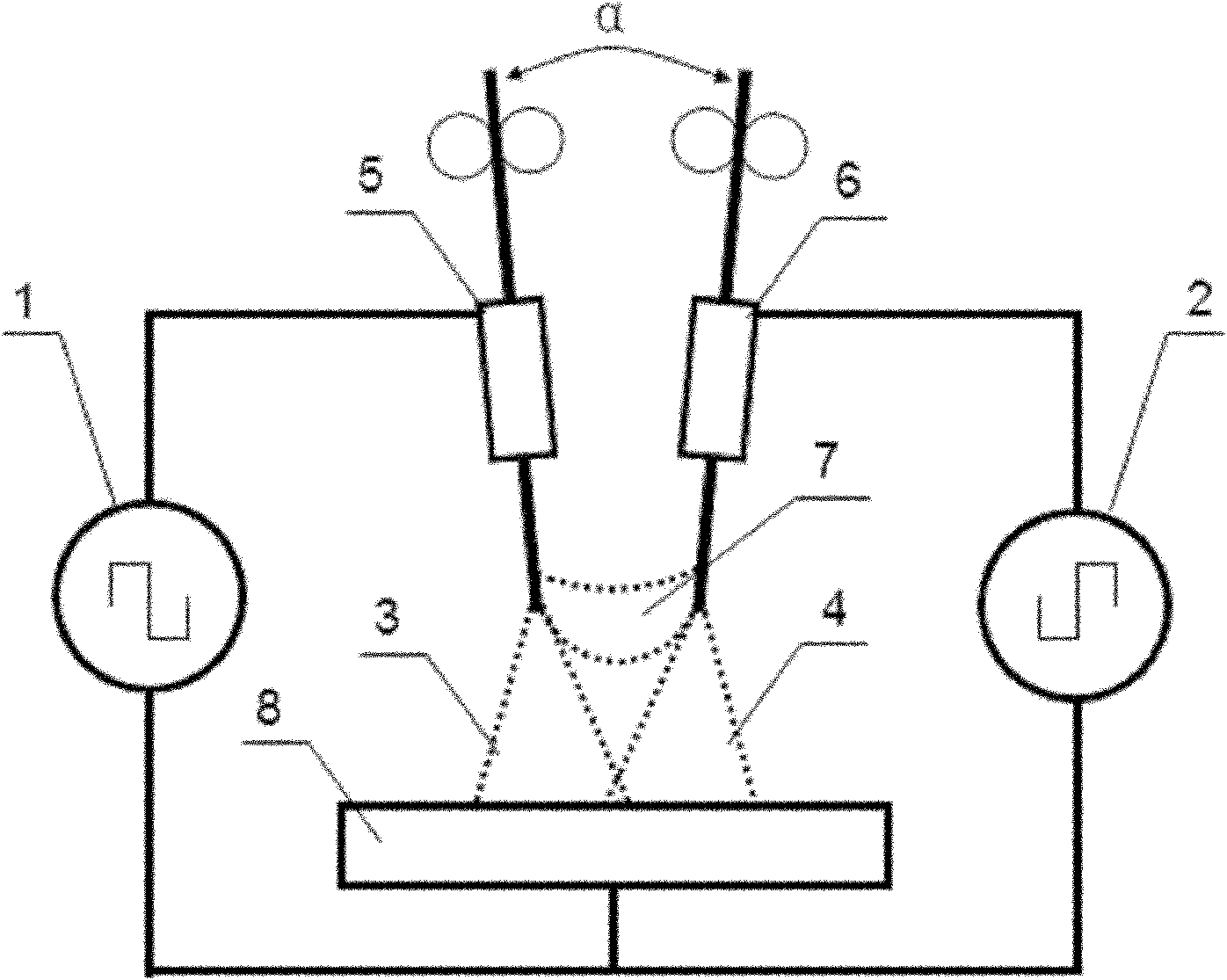

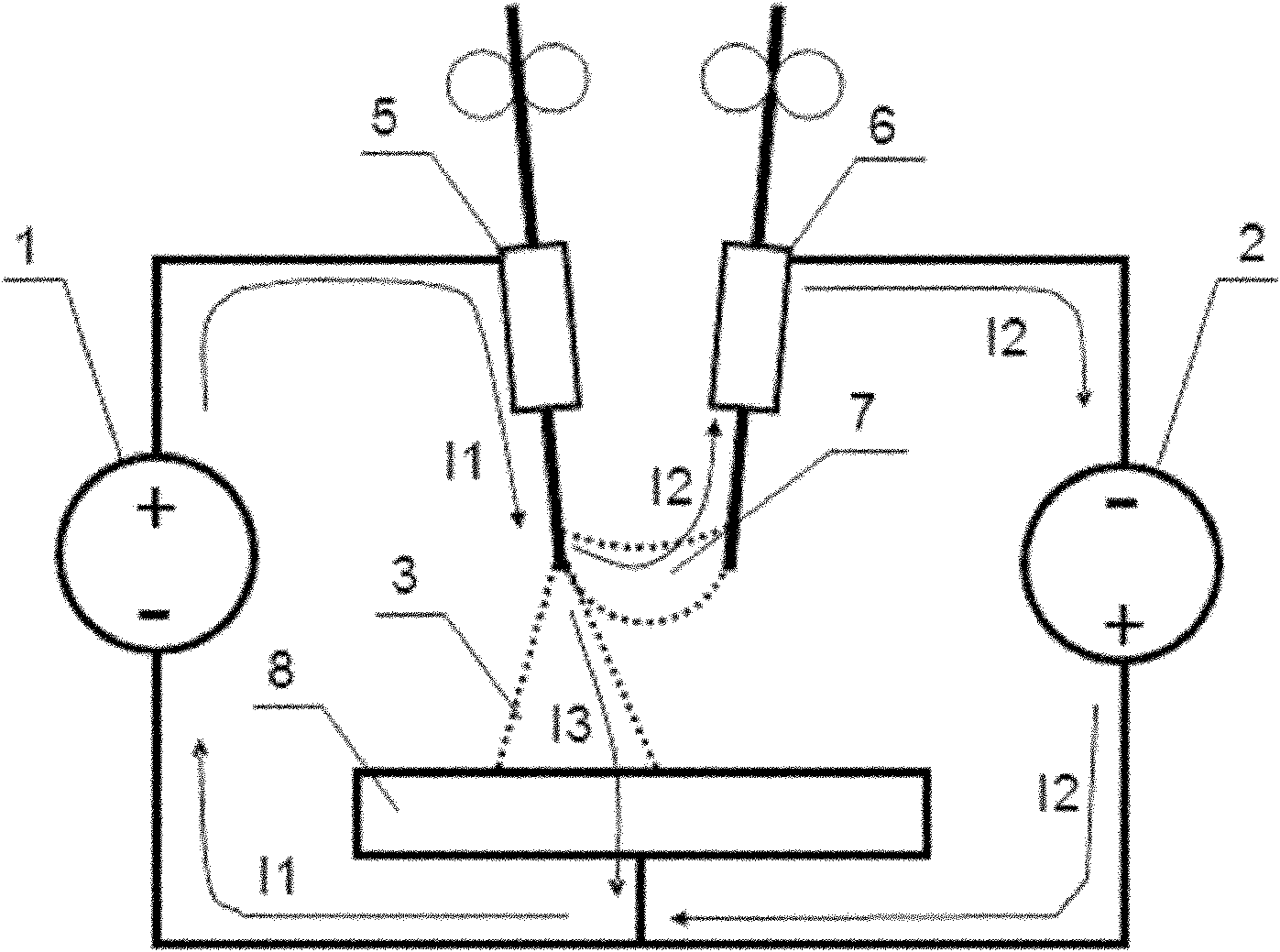

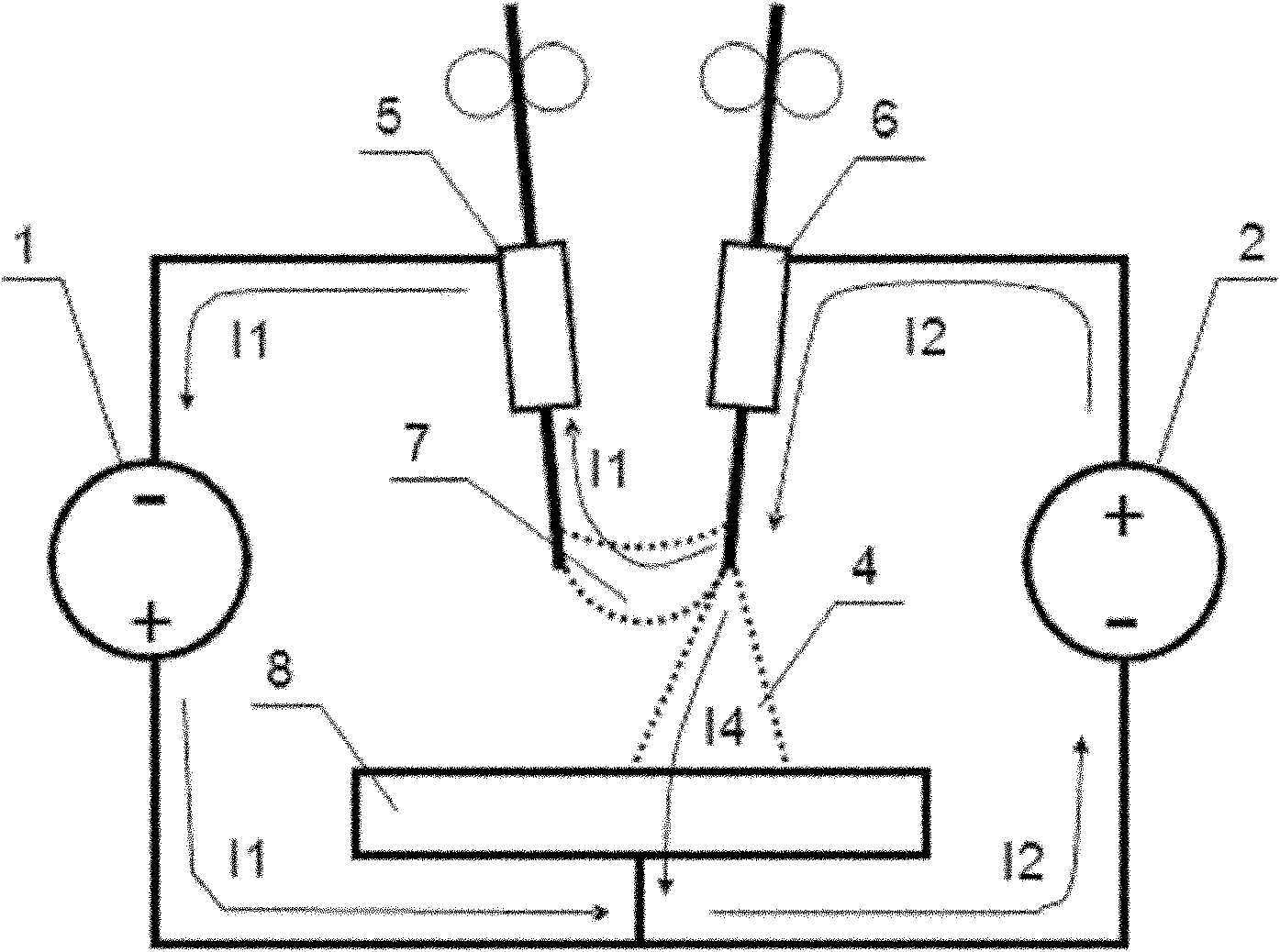

[0014] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, this embodiment uses a wire feeding mechanism to automatically feed the first welding wire 5 and the second welding wire 6 into two welding wire contact tips, and make the angle α between the two welding wires be 0°-90° , one output end of the first variable polarity power supply 1 is connected to a welding wire contact tip, one output end of the second variable polarity power supply 2 is connected to another welding wire contact tip, and the other output of the first variable polarity power supply 1 terminal is connected with the other output end of the second variable polarity power supply 2 and then connected with the workpiece 8 to be welded, the phase difference of the output signals of the first variable polarity power supply 1 and the second variable polarity power supply 2 is 180°,

[0015] The first variable polarity power supply 1, the first welding wire...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is a further description of Embodiment 1. The first variable polarity power supply 1 is a constant current power supply or a constant voltage power supply with adjustable frequency, positive and negative half-cycle time and amplitude. The second variable polarity power supply 2 is a constant current power supply or a constant voltage power supply with adjustable frequency, positive and negative half cycle time and amplitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com