Multi-power-supply parallel multi-wire high-efficiency electric arc welding device and application thereof

An arc welding and multi-power technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of complex equipment, high cost, difficult processing and replacement, etc., to reduce interference and improve welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

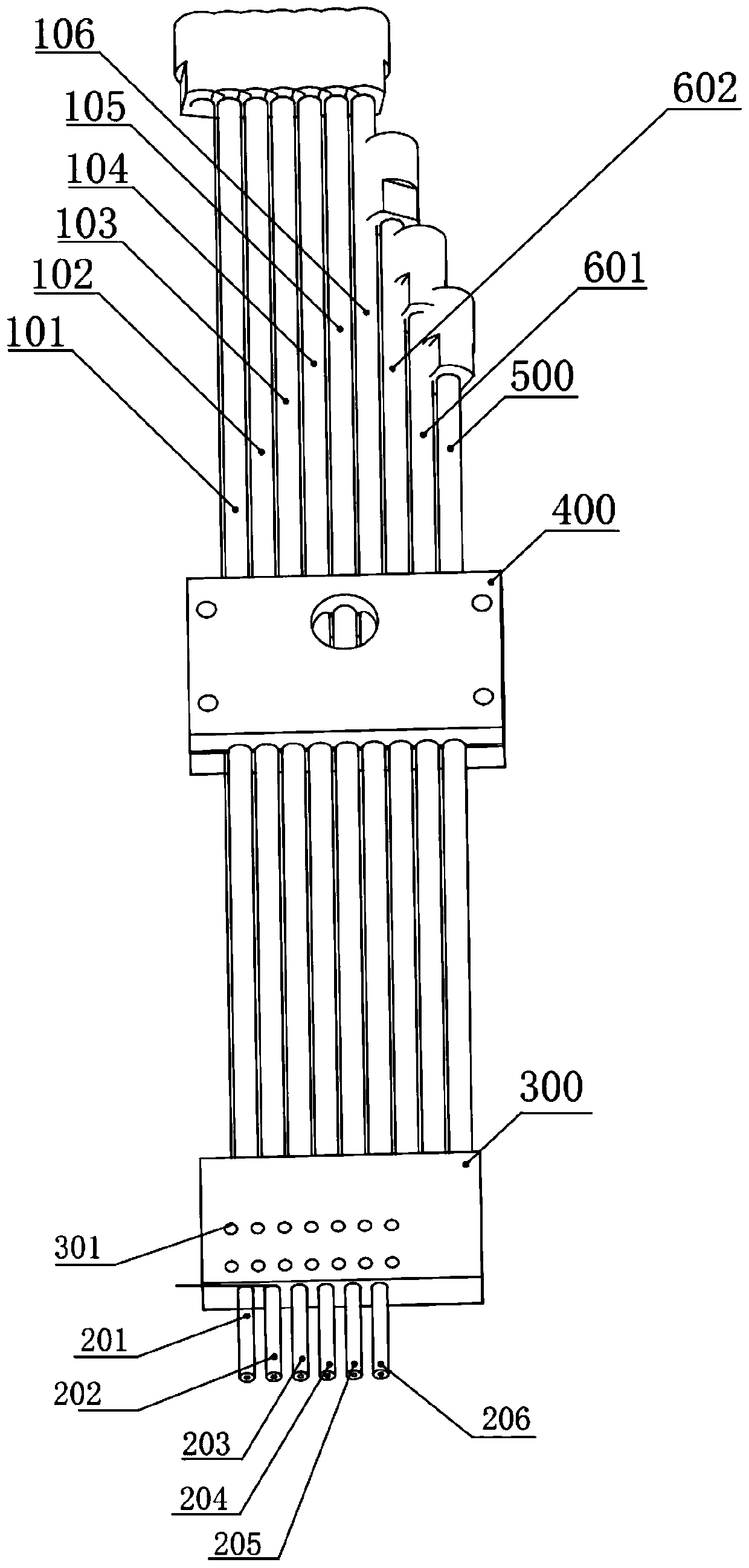

[0031] A multi-power parallel multi-wire high-efficiency arc welding device includes multiple independent welding power sources, multiple independent wire feeding mechanisms, multiple independent wire feeding mechanisms for multiple wire feeders, densely arranged multi-wire welding torches and contact tips.

[0032] The welding power sources of the plurality of independent welding power sources are of constant voltage or constant current characteristics, and the number is at least two.

[0033] The multiple independent wire feeding mechanisms are multiple solid monofilaments and / or multiple flux-cored monofilaments and / or multiple cable-type welding wires.

[0034] The independent wire feeding mechanism of multiple wire feeders can feed each welding wire independently without affecting each other, and each wire feeding mechanism can only feed one welding wire.

[0035] The arrangement of the densely arranged multi-wire welding torches is triangular arrangement, circular arrang...

Embodiment 2

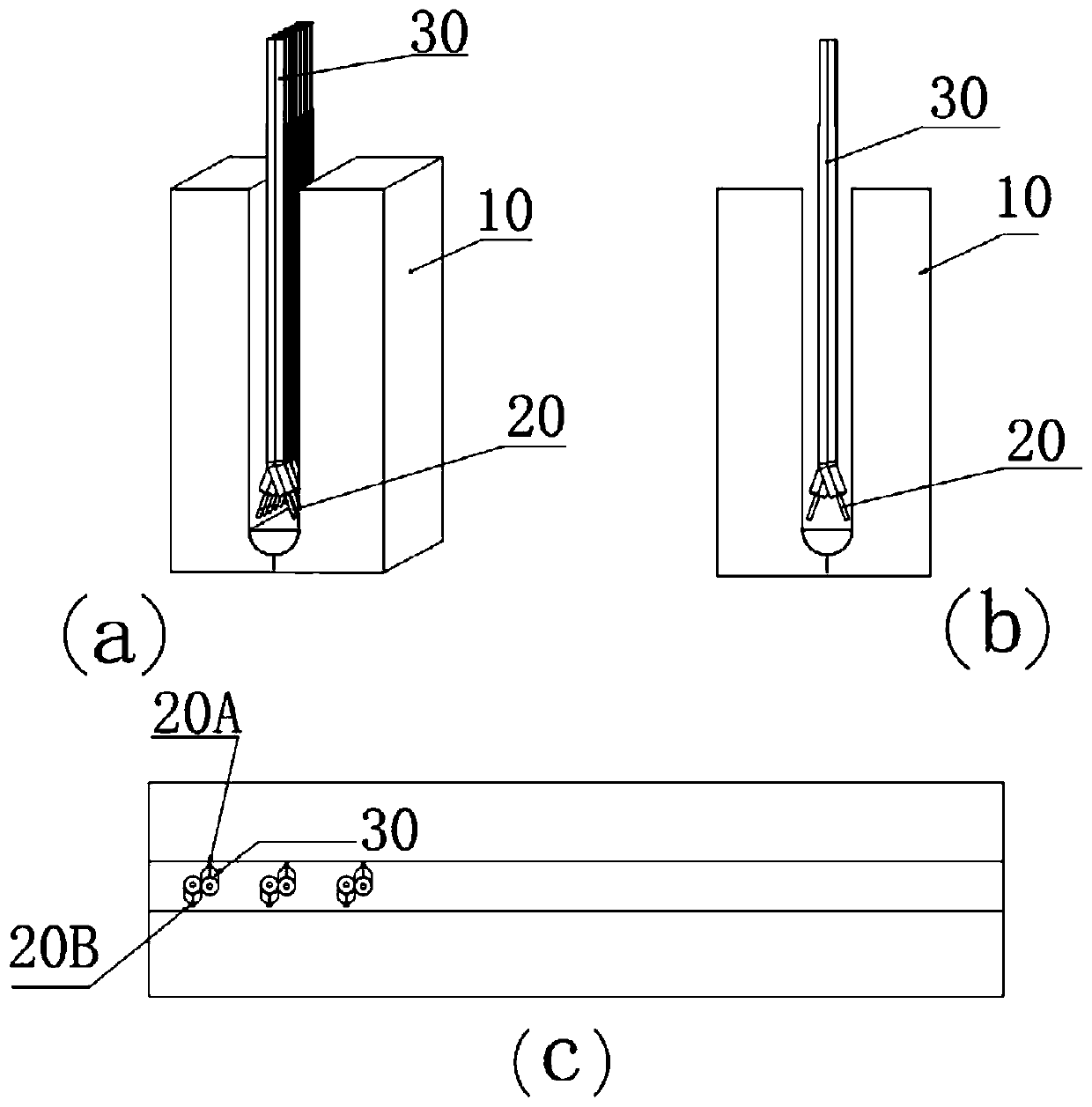

[0045] figure 2 It is a schematic diagram of an embodiment of multi-wire narrow gap welding. figure 2 (a) 10 is the workpiece with narrow gap groove; figure 2 Middle 20 is a curved contact tip with a corner made by utilizing the easy-to-bend feature of the small-diameter special contact tip, so that the welding wire 40 can end the welding wire 40 in a narrow gap space under the condition of using a straight handle wire feeding tube 30. Pointing to the side wall of the welding workpiece, which not only ensures that the welding arc points to the side wall of the welding workpiece, but also ensures the fusion of the side wall of the welding workpiece.

[0046] figure 2 The embodiment of multi-wire narrow-gap welding shown in (b) uses at least two wires, and the contact tip 20 is actually composed of a pair of contact tips 20A and 20B, pointing to the two side walls of the narrow-gap groove respectively. In order to improve welding efficiency, multi-wire narrow-gap welding ...

Embodiment 3

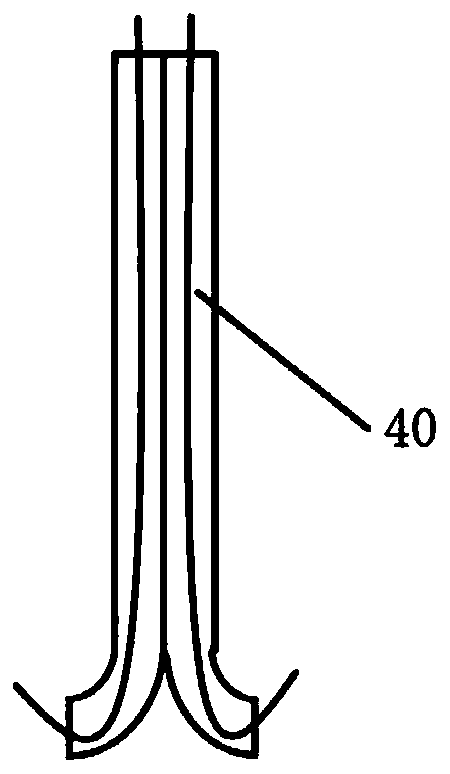

[0049] The current distribution of the phalanx multi-wire arc welding system can be controlled by the wire feed speed of the welding wire 40 . With equal wire feed speeds for all welding wires 40 , the current is evenly distributed on each welding wire 40 . When the wire feeding speeds are not equal: the welding wire 40 with a high wire feeding speed corresponds to a high welding current; the welding wire 40 with a low wire feeding speed corresponds to a low welding current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com