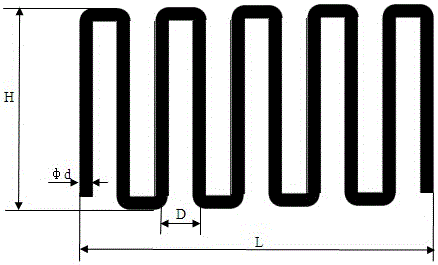

Preparation method of novel thin-walled and special-shaped foamed aluminum part

A technology for foamed aluminum and special-shaped parts, which is applied in the field of porous metal materials, can solve the problems of hindering the industrialization process of thin-walled special-shaped parts of foamed aluminum, complex shapes of special-shaped parts, reducing production efficiency, etc., and achieves high utilization rate of foaming agent and melting time. Short, fast heat-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

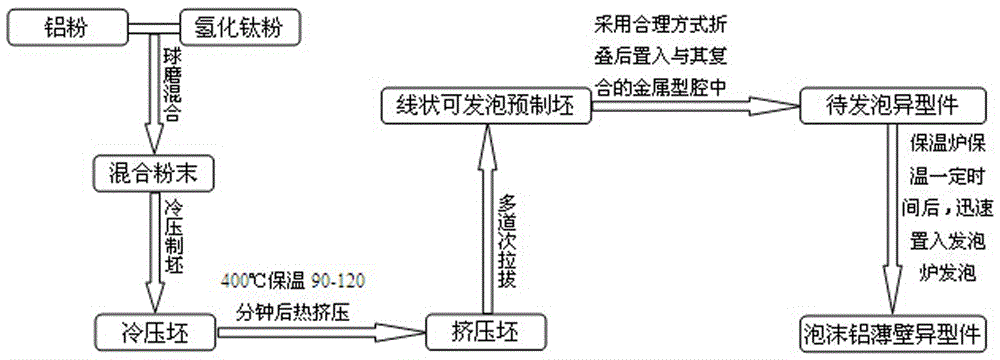

[0030] The present invention is a kind of preparation method of novel foamed aluminum thin-wall special-shaped parts, and the steps of the method are as follows:

[0031] (1) Mixing of powder materials: firstly mix the foaming agent TiH 2 The powder is heated and oxidized in air at 480°C for 120 minutes, and then sieved by a vibrating sieve to select TiH with a particle size below 25 μm 2 The granules are used as a foaming agent, which is added to the matrix aluminum powder in a proportion of 0.1-0.2% by mass, and finally the mixed powder is mixed on a ball mill for 120 minutes.

[0032] (2) Preparation of prefabricated body: The prefabricated body is prepared in three steps: the first step is to press the mixed powder into a high-density cold-pressed billet by means of 500MP cold pressing. The second step is to put the cold compact in the holding furnace and heat it at 400°C for 90-120 minutes, and then quickly transfer it to the extrusion die for extrusion. The extrusion ra...

Embodiment 1

[0039] Preform preparation:

[0040] TiH with a particle size of less than 25 μm after heating and oxidation treatment at 480°C for 120 minutes 2 Powder and aluminum powder were mixed on a drum mixer, and the mixing time was 120 minutes, in which TiH 2 The addition amount is 0.1%, and the balance is aluminum powder. Next, put the uniformly mixed powder into a cylindrical mold, pressurize to 500 MPa, hold the pressure for 10 minutes, and press the mixed powder into a cylindrical cold compact. After demoulding, put the cold compact into a 400°C holding furnace for heat preservation and heating for 120 minutes, and then quickly transfer it to a 30:1 preheated extrusion die for hot extrusion (the preheating of the extrusion die and the indenter The heating temperature is 390°C), and an extruded billet with a diameter of 12mm is prepared. Finally, multi-pass drawing is carried out on the extruded billet. The preform is heated at 400°C for 60 minutes before the first pass and the...

Embodiment 2

[0044] Preform preparation:

[0045] TiH with a particle size of less than 25 μm after heating and oxidation treatment at 480°C for 120 minutes 2 Powder and aluminum powder were mixed on a drum mixer, and the mixing time was 120 minutes, in which TiH 2 The addition amount is 0.2%, and the balance is aluminum powder. Next, put the uniformly mixed powder into a cylindrical mold, pressurize to 500 MPa, hold the pressure for 10 minutes, and press the mixed powder into a cylindrical cold compact. After demoulding, put the cold compact into a 400°C holding furnace for heat preservation and heating for 90 minutes, and then quickly transfer it to a 30:1 preheated extrusion die for hot extrusion (the preheating of the extrusion die and the indenter The heating temperature is 390°C), and an extruded billet with a diameter of 15mm is prepared. Finally, multi-pass drawing is carried out on the extruded billet. The preform is heated at 400°C for 60 minutes before the first pass and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com