Method for reducing volume shrinkage of photocuring coating by using hollow/porous elastic microspheres

A technology of porous microspheres and volume shrinkage, which is applied in coatings and other directions, can solve problems such as the decline in the comprehensive mechanical properties of materials and affect the use of materials, and achieve the effects of reducing volume shrinkage, reducing the amount of addition, and prolonging the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention can be better understood from the following examples. However, those skilled in the art will readily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in detail in the claims .

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail. Those skilled in the art should understand that the examples are only used to help understand the present invention, and are not intended to limit the present invention.

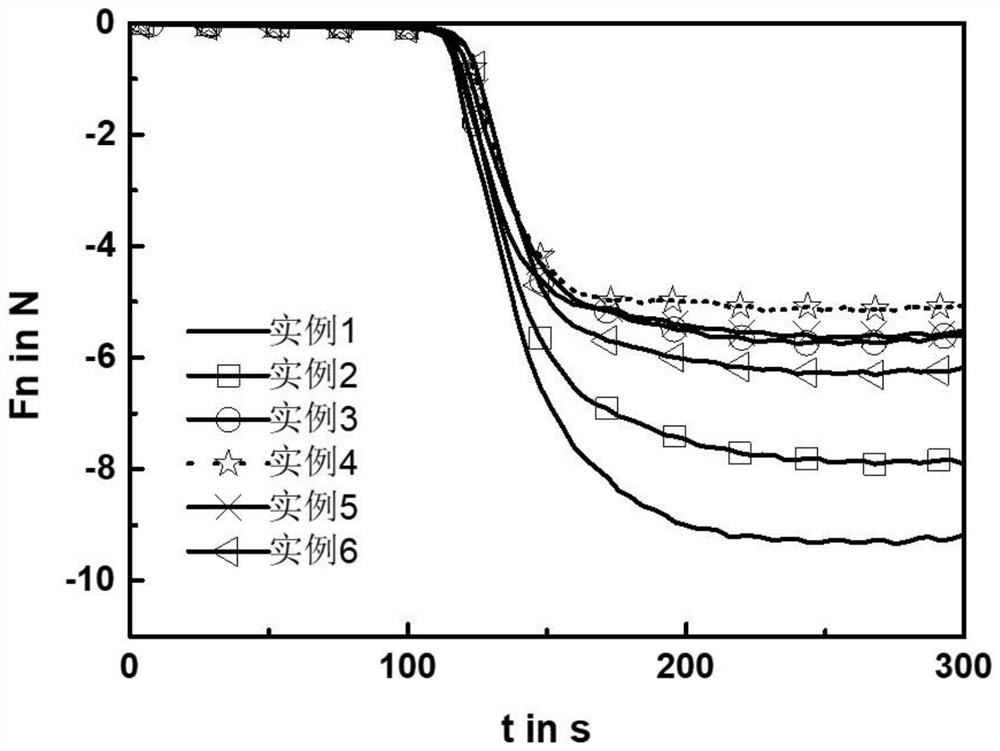

[0037] In order to optimize the scheme, the present invention systematically discusses the influence of the content of elastic hollow / porous microspheres on reducing coating shrinkage when the content of elastic hollow / porous microspheres is added in...

example 1

[0052] Example 1: without adding poroelastic microspheres

[0053] 1. Weigh 10g EA (bisphenol A type epoxy acrylate EA, 10g TPGDA (tripropylene glycol diacrylate) according to the mass ratio of 1:1, mix well and add 0.1g photoinitiator 1173 (2-hydroxy-2- Methyl-1-phenyl-1-propanone), the sample was protected from light and stirred for 6 hours at a stirring speed of 300rmp.

[0054] 2. Put the sample in a vacuum oven to remove air bubbles, then take a small amount of sample and pour it into the mold, and cure it with a crawler-type light curing machine to prepare a tensile sample and a dynamic thermal analysis test sample; take a small amount of sample on the aluminum plate The film is coated on the surface, and cured with a crawler-type light curing machine to obtain a light-cured coating.

[0055] 3. Carry out coating performance, mechanical properties, and infrared-rheological joint tests on the materials.

example 2

[0056] Example 2: Add 0.1g elastic hollow / porous microspheres

[0057] 1. Preparation of modified silica nanoparticles:

[0058] (1-1) First, synthesize silica nanoparticles by sol-gel method, put 2.8mL deionized water, 150mL absolute ethanol and 9.7mL ammonia water into a single-necked flask, raise the temperature to 60°C, and turn on the magnetic stirring, The stirring rate is 300rmp; 4mL of TEOS (tetraethyl orthosilicate) is slowly added dropwise to the above mixture, and after 6 hours of reaction, SiO 2 Dispersions.

[0059] (1-2) SiO to the above step (1-1) 2 Add 200 μL of silane coupling agent MPS dropwise to the dispersion, react at room temperature for 19 hours, and stir at 300 rpm. After the reaction, get SiO 2 - MPS dispersion, washed with ethanol and centrifuged three times, then put into a vacuum oven to dry, and finally obtained SiO2 nanoparticles with double bond modification.

[0060] 2. Preparation of elastic hollow / porous microspheres:

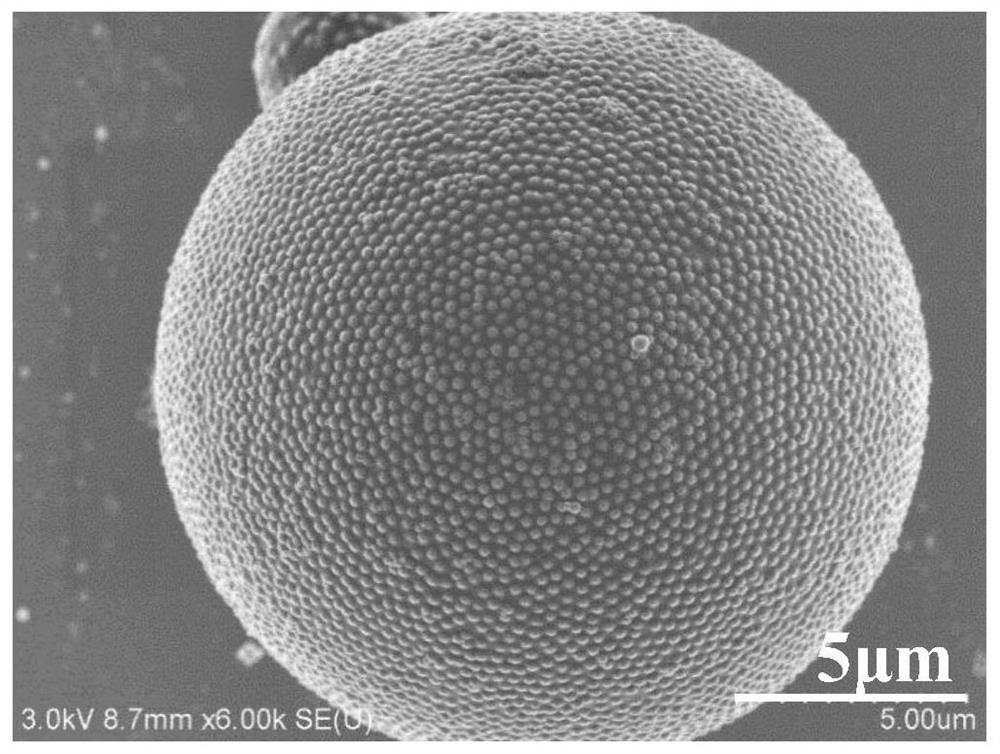

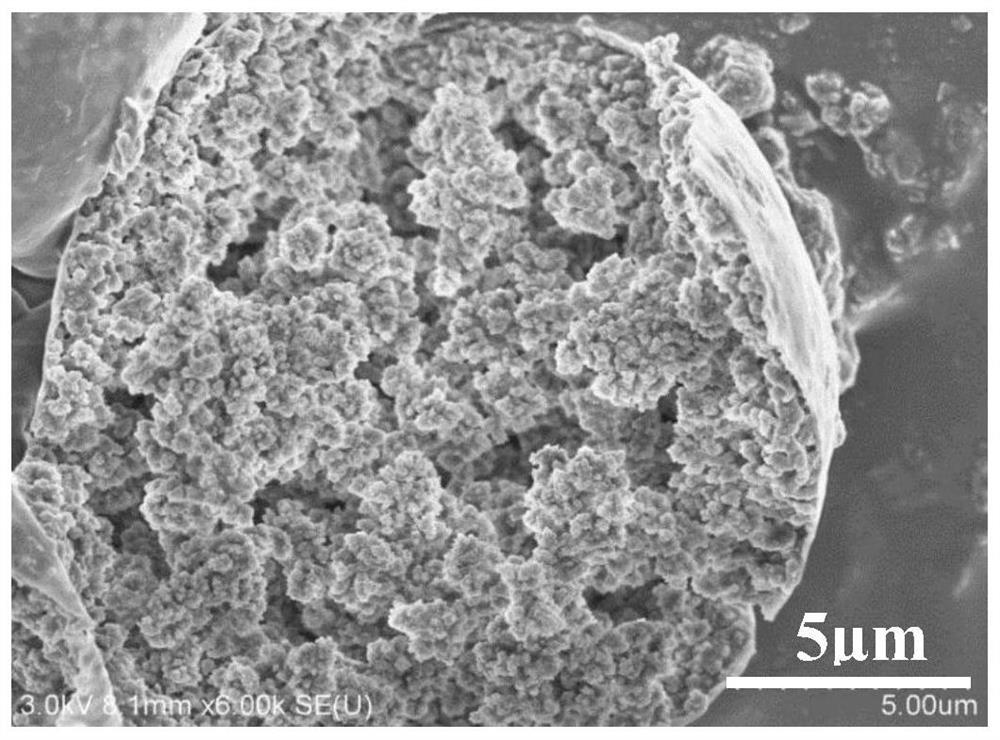

[0061] (2-1) Por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com