High-performance cement expansive material

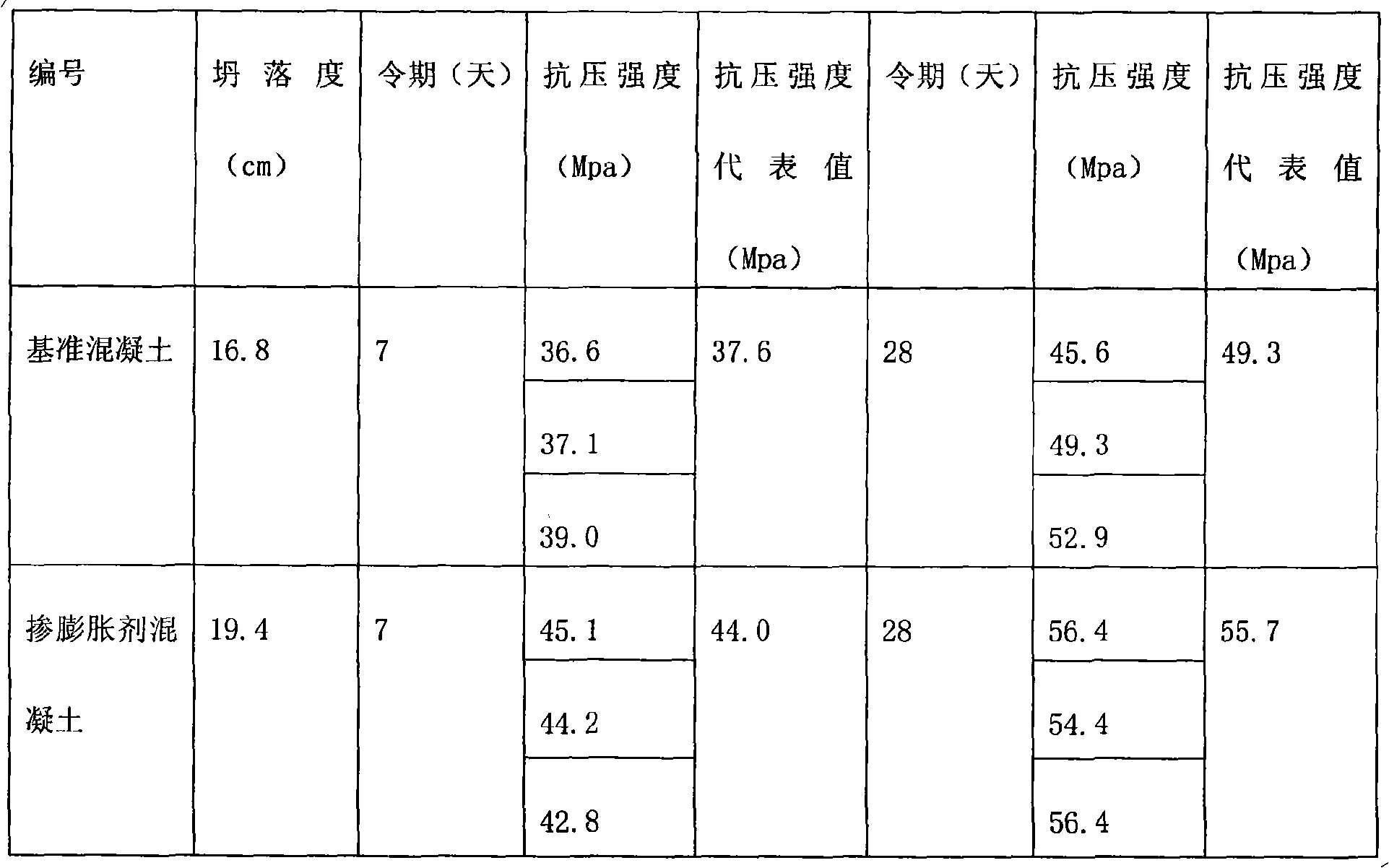

An expansion agent and concrete technology, applied in the field of building materials, can solve the problems affecting the early strength of concrete, large slump loss, etc., and achieve the effects of good expansion effect, reduced shrinkage rate, and enhanced crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

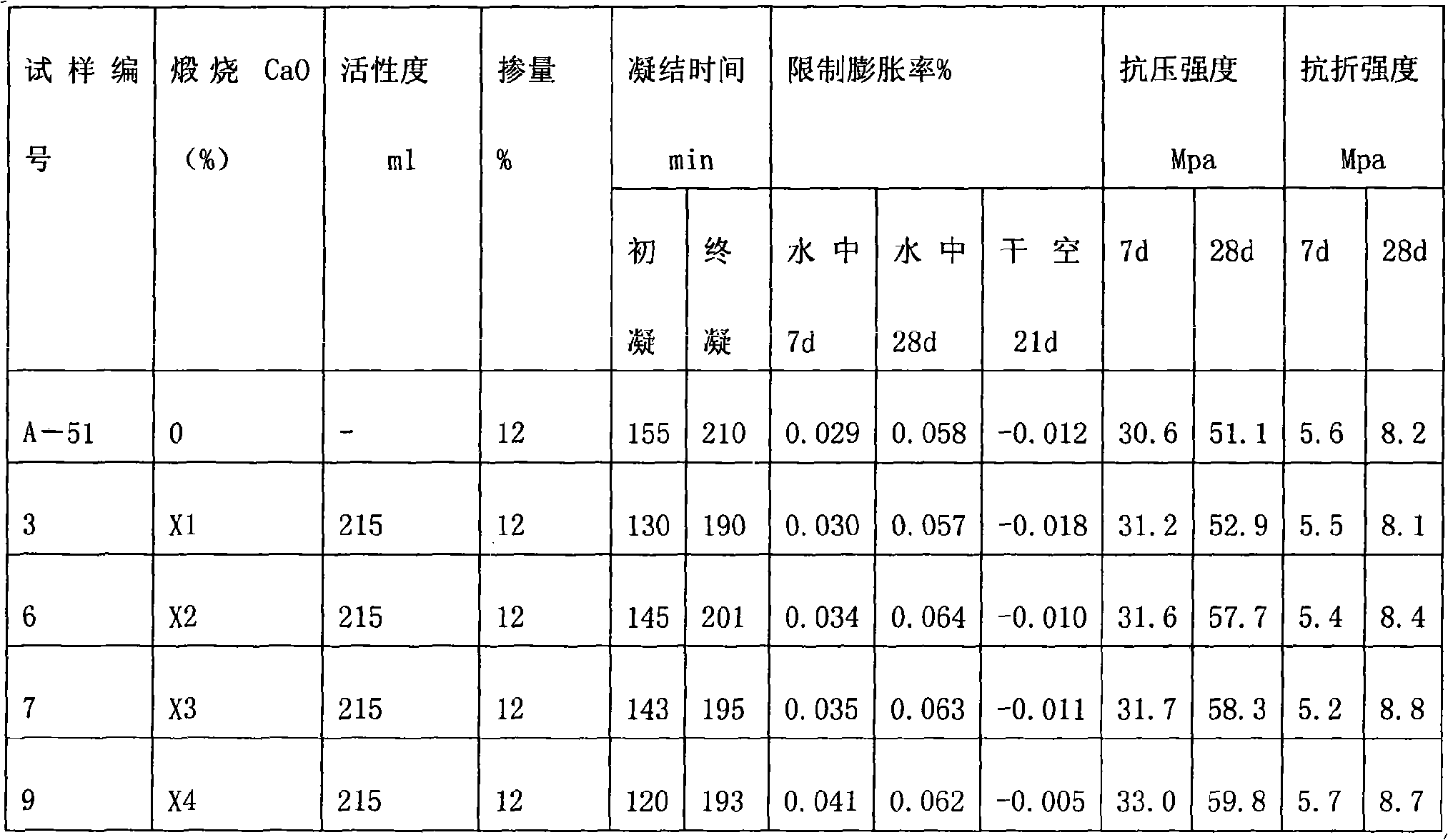

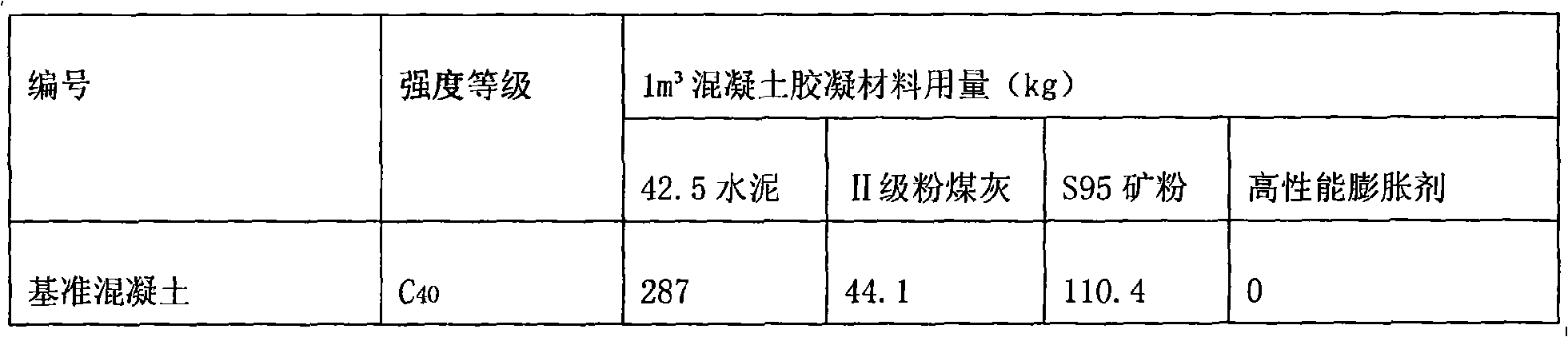

[0051] Embodiment 1: MgO in the calcium clinker is 15%, CaO is 65%; MgO in the expansion agent is 4.5%, MgO and CaO are 10%, and the balance is aluminum material and calcium sulfate, aluminum material and sulfuric acid Calcium forms ettringite. When mixed with cement, the expansion agent accounts for 6% of the total.

Embodiment 2

[0052] Embodiment 2: MgO in the calcareous clinker is 14%, CaO is 70%; MgO in the expansion agent is 4%, MgO and CaO are 11%, and the balance is aluminum material and calcium sulfate, aluminum material and sulfuric acid Calcium forms ettringite. When mixed with cement, the expansion agent accounts for 7% of the total.

Embodiment 3

[0053] Embodiment three: the MgO in the calcareous clinker is 13%, and the CaO is 75%; the MgO in the expansion agent is 3%, MgO and CaO are 12%, and the balance is aluminum material and calcium sulfate, aluminum material and sulfuric acid Calcium forms ettringite. When mixed with cement, the expansion agent accounts for 8% of the total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com