Composite concrete expansion agent

An expansion agent and concrete technology, applied in the field of building material concrete admixtures, can solve problems such as unsatisfactory, and achieve the effect of increasing market value, compensating for early shrinkage and late shrinkage, and having many pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

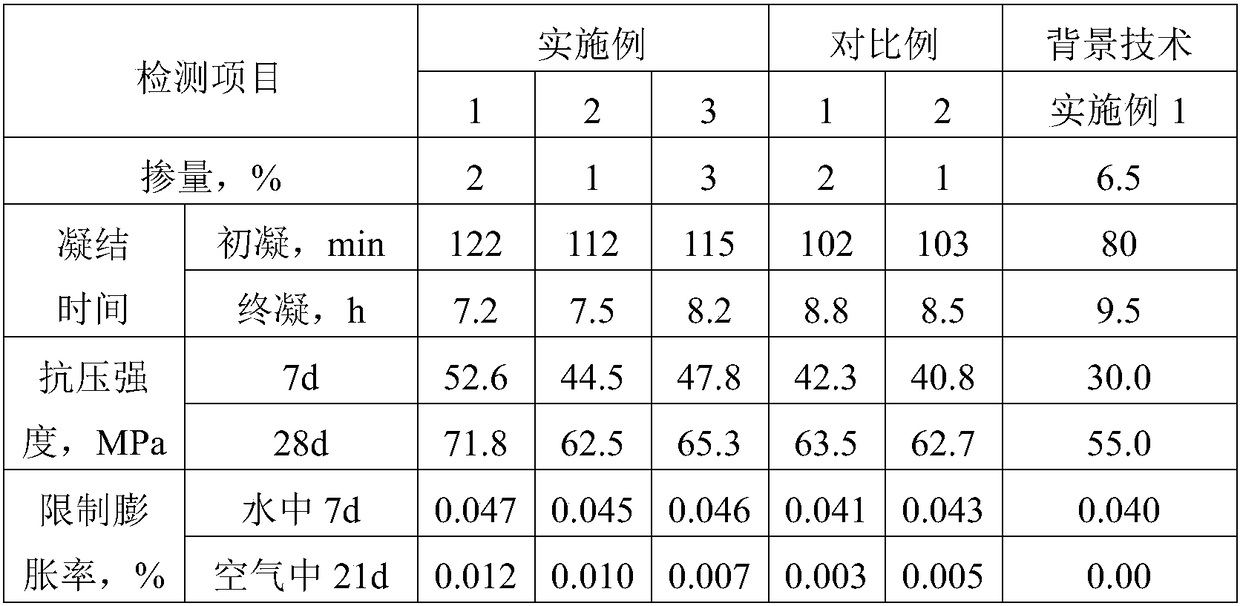

Examples

Embodiment 1

[0027] A composite concrete expansion agent, made of the following components in proportion by weight: 18 parts of calcium aluminosilicate, 28 parts of calcium sulfoaluminate, 25 parts of sulfur-fixing waste residue, 15 parts of red mud, 12 parts of lithium slag, 6 parts of modified calcium oxide, 5 parts of magnesium oxide, 7 parts of sodium methyl silicate, 0.2 parts of azodicarbonamide, 0.6 parts of sodium tripolyphosphate, 3 parts of sodium lauryl sulfate, 0.4 parts of ethylene-acrylic acid copolymer part, 0.8 part of polycarboxylate superplasticizer, and 0.6 part of nanometer calcium carbonate.

Embodiment 2

[0029] A composite concrete expansion agent, made of the following components in proportion by weight: 15 parts of calcium aluminosilicate, 25 parts of calcium sulfoaluminate, 20 parts of sulfur-fixing waste residue, 10 parts of red mud, 10 parts of lithium slag, 4 parts of modified calcium oxide, 3 parts of magnesium oxide, 5 parts of sodium methyl silicate, 0.1 part of azodicarbonamide, 0.4 part of sodium tripolyphosphate, 2 parts of sodium lauryl sulfate, 0.3 parts of ethylene-acrylic acid copolymer part, 0.7 part of polycarboxylate superplasticizer, and 0.5 part of nanometer calcium carbonate.

Embodiment 3

[0031] A composite concrete expansion agent, made of the following components in proportion by weight: 20 parts of calcium aluminosilicate, 30 parts of calcium sulfoaluminate, 30 parts of sulfur-fixing waste residue, 20 parts of red mud, 15 parts of lithium slag, 8 parts of modified calcium oxide, 6 parts of magnesium oxide, 8 parts of sodium methyl silicate, 0.3 parts of azodicarbonamide, 0.7 parts of sodium tripolyphosphate, 4 parts of sodium lauryl sulfate, 0.6 parts of ethylene-acrylic acid copolymer part, 0.9 part of polycarboxylate superplasticizer, and 0.7 part of nanometer calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com