Production process of amplitude-stabilized and phase-stabilized cable

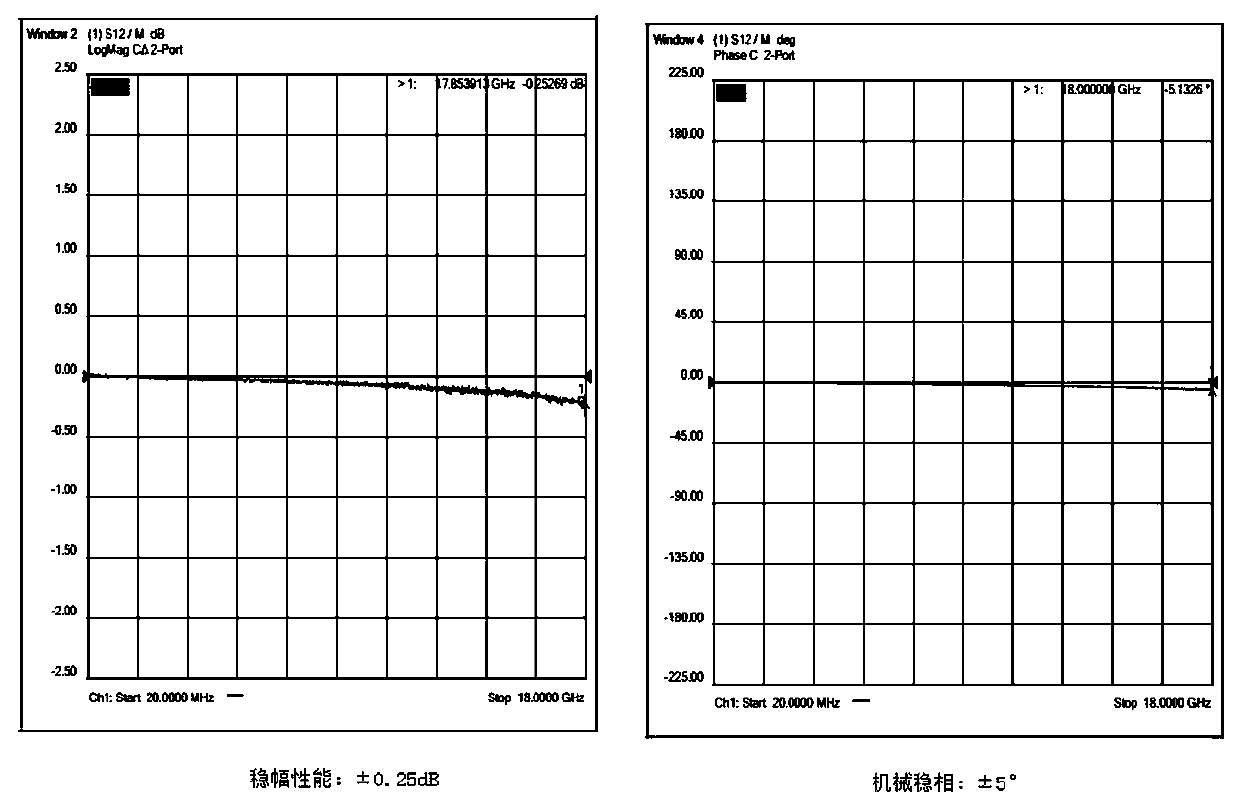

A production process and phase-stable cable technology, applied in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems of large insertion loss, poor amplitude stabilization performance, and high price, and reduce shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

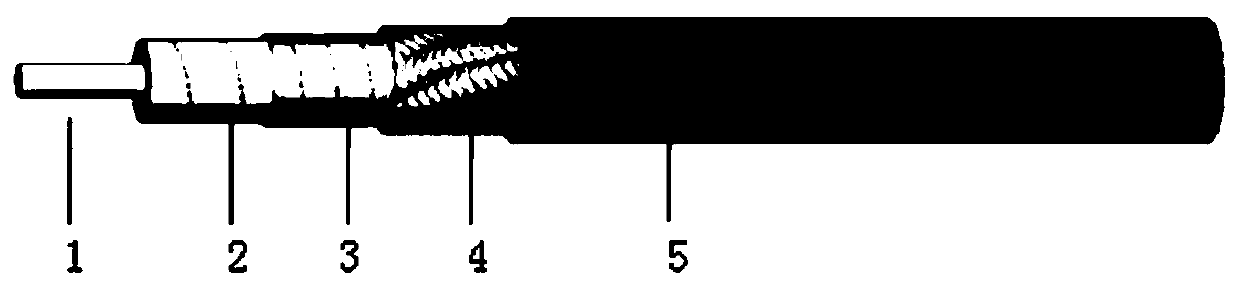

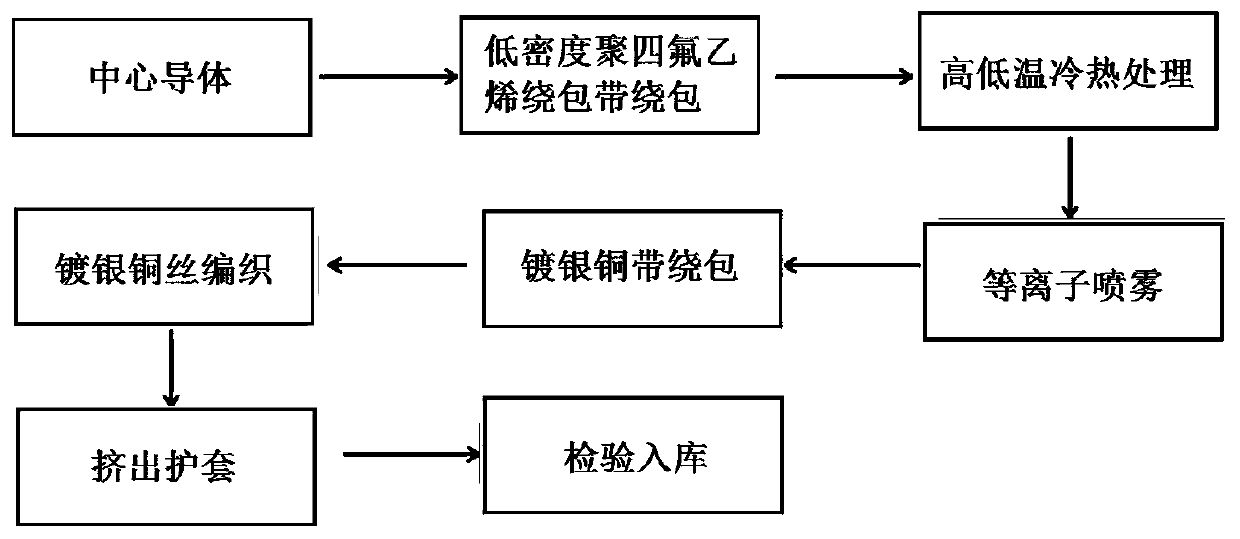

[0023] Embodiment: A production process of a stable amplitude and phase cable, the cable is mainly composed of a silver-plated copper central conductor from the inside to the outside, a polytetrafluoroethylene wrapping dielectric layer, a silver-plated copper tape wrapping inner layer shielding, and a plated copper tape. Silver copper wire braided outer shielding layer and high temperature extruded sheath layer, its production process includes the following steps: use low-density polytetrafluoroethylene tape wrapping process on the center conductor as the insulating medium layer of the cable; The silver tape wrapping process is carried out on the dielectric layer after high temperature setting to form the inner layer shielding of the cable, and the silver-plated copper wire braiding process is carried out on the inner layer shielding layer, which is used as the outer shielding layer and the protective layer of the cable, and then passed through the high temperature fluoroplastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com