Potassium metasilicate polymeric alcohol water base drilling fluid

A technology of potassium silicate and drilling fluid, which is applied in drilling compositions, chemical instruments and methods to achieve the effects of good rheology, good lubricity and strong inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: the preparation method of potassium silicate polyalcohol water-based drilling fluid:

[0013] The preparation method of the potassium silicate polyalcohol water-based drilling fluid is: firstly measure 1000 grams of tap water and add 40 grams of sodium bentonite, stir at a low speed for 60 minutes, then stir at a high speed for 30 minutes, maintain at room temperature for 24 hours, then add 40 grams of sodium bentonite under high-speed electric stirring. Add 6 grams of powdery instant potassium silicate FP-V and stir for 5 minutes, add 6 grams of viscosifier HV-CMC and stir for 5 minutes, add 4 grams of fluid loss reducer JT888 and stir for 5 minutes, add 20 grams of polymeric alcohol JLX-B-S and stir for 5 minutes, add 8 grams Stir with KCl for 5 minutes, then slowly add 40% NaOH dropwise to adjust the pH to 11.5, and continue stirring for 15 minutes to obtain the potassium silicate polyalcohol water-based drilling fluid.

Embodiment 2

[0014] Embodiment 2: rheological performance evaluation

[0015] The basic properties of the potassium silicate polyalcohol drilling fluid system before and after aging were evaluated. The potassium silicate polyalcohol drilling fluid system was aged for 16 hours at different temperatures, cooled to room temperature, and then stirred for 5 minutes to measure the apparent viscosity AV and plasticity of the system. Properties such as viscosity PV, dynamic shear force YP and fluid loss, the experimental results are shown in Table 2:

[0016] Table 2 Evaluation of rheological properties of drilling fluids

[0017]

[0018] Remark: Potassium silicate drilling fluid system formula: 4% soil slurry + 4% FP-V + 0.4% HV-CMC + 0.4% JT888 + 1% KCl + appropriate amount of NaOH (concentration is 40%, adjust pH to 11.5), potassium silicate polymerization Alcohol drilling fluid system formula: 4% soil slurry + 4% FP-V + 0.4% HV-CMC + 0.4% JT888 + 3% JLX-B-S + 1% KCl + appropriate amount...

Embodiment 3

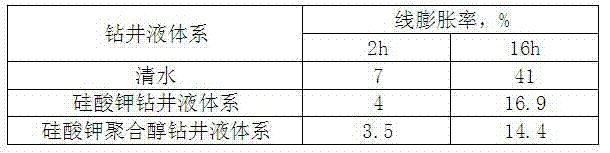

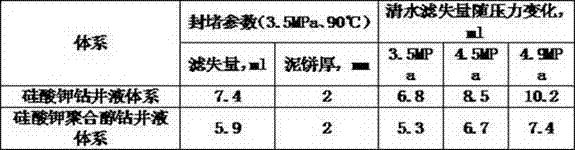

[0020] Embodiment 3: performance evaluation of wall-building by loss of water

[0021] The water-losing wall-building property of drilling fluid is an important performance of drilling fluid, which has a very important influence on the stability of the wellbore wall in loose, broken and water-unstable formations. In this paper, the water loss and wall-building properties of the potassium silicate polyalcohol drilling fluid system were evaluated, and the experimental results are shown in Table 3:

[0022] Table 3 Drilling fluid system loss of water wall building performance

[0023]

[0024] It is not difficult to see from the experimental data in Table 3 that the API dehydration, HTHP dehydration and mud cake thickness of the two systems after aging are all increased compared with those before aging, but after adding polyalcohol, the API dehydration, HTHP and mud cake thickness of the system increased. The dehydration of the cake has improved. It can be seen that the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com