Golden yellow hfabric for shielding infrared thermal radiation

A heat radiation, golden yellow technology, applied in the field of fabrics shielding infrared heat radiation, can solve the problems of fabrics with no protective effect and fabrics without good shielding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

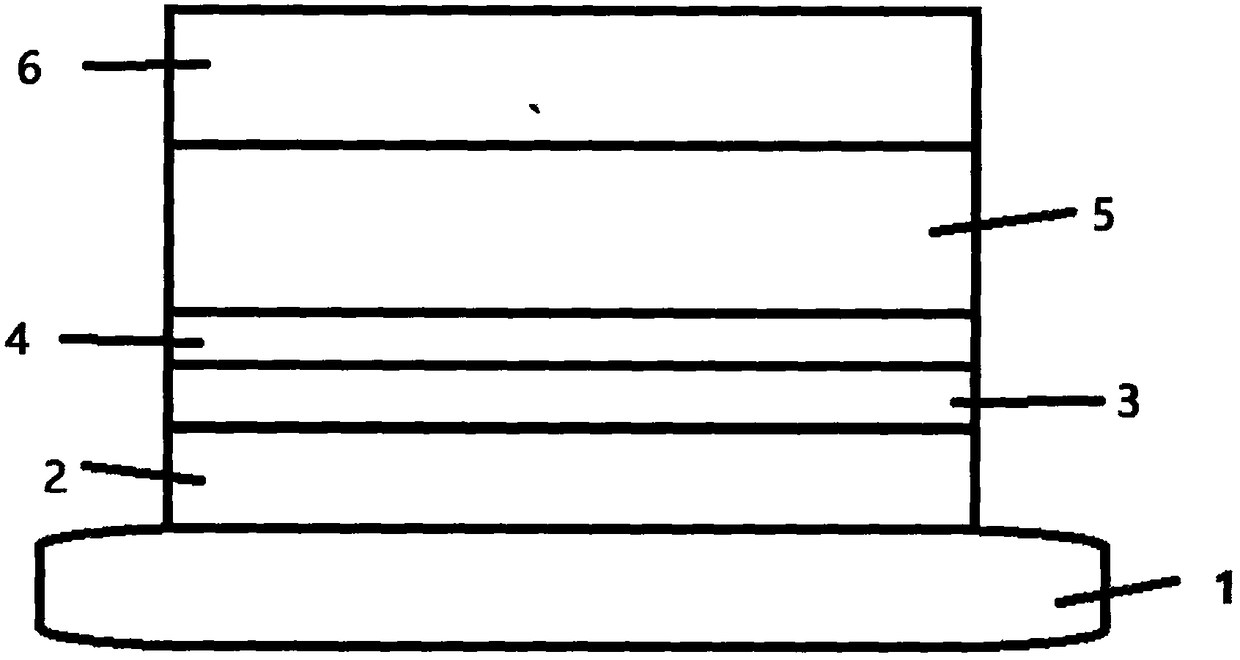

[0018] Example 1: A golden yellow fabric shielding infrared heat radiation.

[0019] The process parameter table is shown in Table 1:

[0020] Table 1

[0021] target

Sputtering pressure mtor

Film thickness nm

Titanium target

3

22

silver target

4

13

copper target

4

10

Nichrome target

Argon

4

3

Si-alumina target

Argon: Nitrogen = 1:2

3

105

[0022] The performance parameter of gained product is as follows:

[0023] The reflectance of visible light is 55%, the color of reflected visible light is a*=5, b*=36, and the emissivity ε=0.06.

Embodiment 2

[0024] Example 2: A golden yellow fabric shielding infrared heat radiation.

[0025] The process parameter table is shown in Table 2:

[0026] Table 2

[0027] target

Sputtering pressure mtor

Film thickness nm

Titanium target

Oxygen: Argon = 10:90

3

4

silver target

Argon

4

4

copper target

Argon

4

7

Nichrome target

Argon

4

4

Si-alumina target

Argon: Nitrogen = 1:2

3

113

[0028] The performance parameter of gained product is as follows:

[0029] The reflectance of visible light is 52%, the color of reflected visible light is a*=4.2, b*=40, and the emissivity ε=0.08.

Embodiment 3

[0030] Example 3: A golden yellow fabric shielding infrared heat radiation.

[0031] The process parameter table is shown in Table 3:

[0032] table 3

[0033] target

Sputtering pressure mtor

Film thickness nm

Oxygen: Argon = 8:92

3

20

silver target

Argon

4

15

copper target

Argon

4

9

Nichrome target

Argon

4

4

Si-alumina target

Argon: Nitrogen = 1:2

3

100

[0034] The performance parameter of gained product is as follows:

[0035] The reflectance of visible light is 58%, the color of reflected visible light is a*=5.5, b*=39, and the emissivity ε=0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com