Composite profile control and oil displacement extraction method for thickened oil reservoir through water injection and exploitation

A technology for heavy oil reservoirs and polymers, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problem of level adjustment in the depth of difficult reservoirs, affecting the fluid production capacity of oil wells, and the viscosity of movable gel. It can achieve the effect of expanding the swept volume, alleviating the contradiction of water injection development, and reducing the permeability of water phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

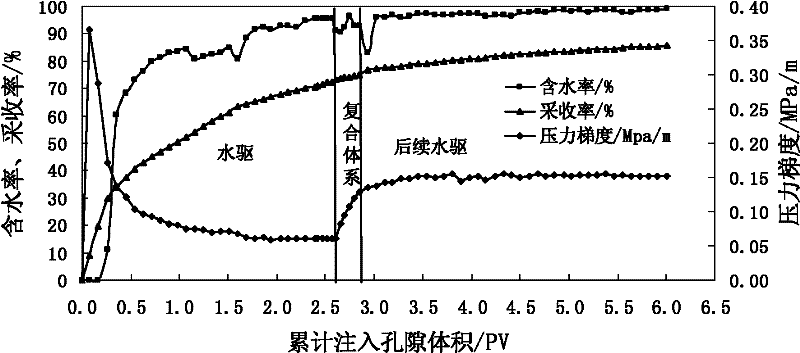

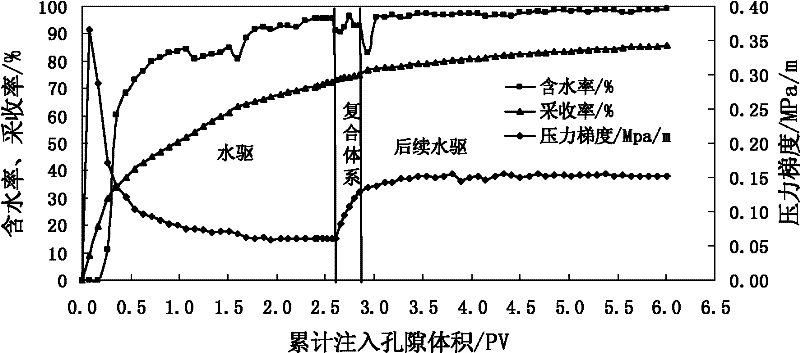

[0038] Example 1 Composite control and flooding system non-uniform man-made core flooding experiment

[0039] Experimental conditions:

[0040] Artificial heterogeneous parallel core model: the permeability is 2000md and 380md respectively.

[0041] Oil used in the experiment: degassed and dehydrated crude oil taken from Block 1 of Liaohe Oilfield, with a viscosity of 75.0mPa.s at 70°C.

[0042] Experimental water: simulated water from Liaohe Oilfield Hai 4 station for dosing sewage, with a salinity of 2286.5mg / L.

[0043] Composite flood control agent: a solution of partially hydrolyzed polyacrylamide (product of Beijing Hengju Chemical Group Co., Ltd.) with a concentration of 3000mg / L and an organic chromium crosslinking agent YG107 with a concentration of 1500mg / L (Shidayu Optical Technology Co., Ltd., Dongying City, Shandong Province) Company product) solutions are mixed and compounded into a polymer gel solution, and the mass ratio of the two is 1:1;

[0044]The concen...

Embodiment 2

[0057] This embodiment is an embodiment of the composite flood control agent in actual production, which includes the following steps:

[0058] (1) Mix the polymer with water to obtain a polymer solution with a concentration of 2500 mg / L and pump it into the storage tank, then mix the cross-linking agent with water to obtain a cross-linking agent solution with a concentration of 1250 mg / L and pump it into the storage tank In the tank, the mass ratio of the two is 2: 1, fully stirred and mixed to obtain a polymer gel solution, which is ready for use;

[0059] (2) Mix the micron-sized movable microgel with water to obtain a movable microgel solution with a concentration of 2000 mg / L, pump it into another storage tank, stir it fully, and set it aside;

[0060] (3) Use a water well pump to pump the polymer gel solution into the water injection well, and the injection amount is 0.01 times of the pore volume of the oil layer;

[0061] (4) Pump the movable microgel solution into the...

Embodiment 3

[0065] This embodiment provides a method for improving the recovery rate of a water flooding reservoir, which includes the following steps:

[0066] (1) When the water content of the reservoir exceeds 80%, first mix the polymer solution with a concentration of 3000mg / L and the cross-linking agent solution with a concentration of 1500mg / L (the mass ratio of the two is 1:1) The polymer gel solution is pumped into the water injection well through a water well pump, wherein the injection amount of the polymer gel solution is 0.01 times the pore volume;

[0067] (2) Then the micron-scale movable microgel solution is pumped into the water injection well through the water well pump, wherein the diameter d of the micron-scale movable microgel is 1-5 μm, and the concentration of the micron-scale movable microgel solution is 2000 mg / L, the injection volume of the micron-scale movable microgel solution is 0.19 times the pore volume of the reservoir.

[0068] The polymer used in this ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com