Low-temperature multiple-effect evaporation crystallization and filtration process

A multi-effect evaporation and high-efficiency evaporation technology, applied in the low-temperature multi-effect evaporation crystallization filtration coupled with solute recovery process, waste heat utilization and waste liquid emission reduction, multi-effect evaporation crystallization granulation field, can solve the aggravated friction collision of solute particles and easy blockage Corrosion of pipes and discharge ports, pipes, containers, etc., to achieve the effect of high production efficiency, not easy to block pipes, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

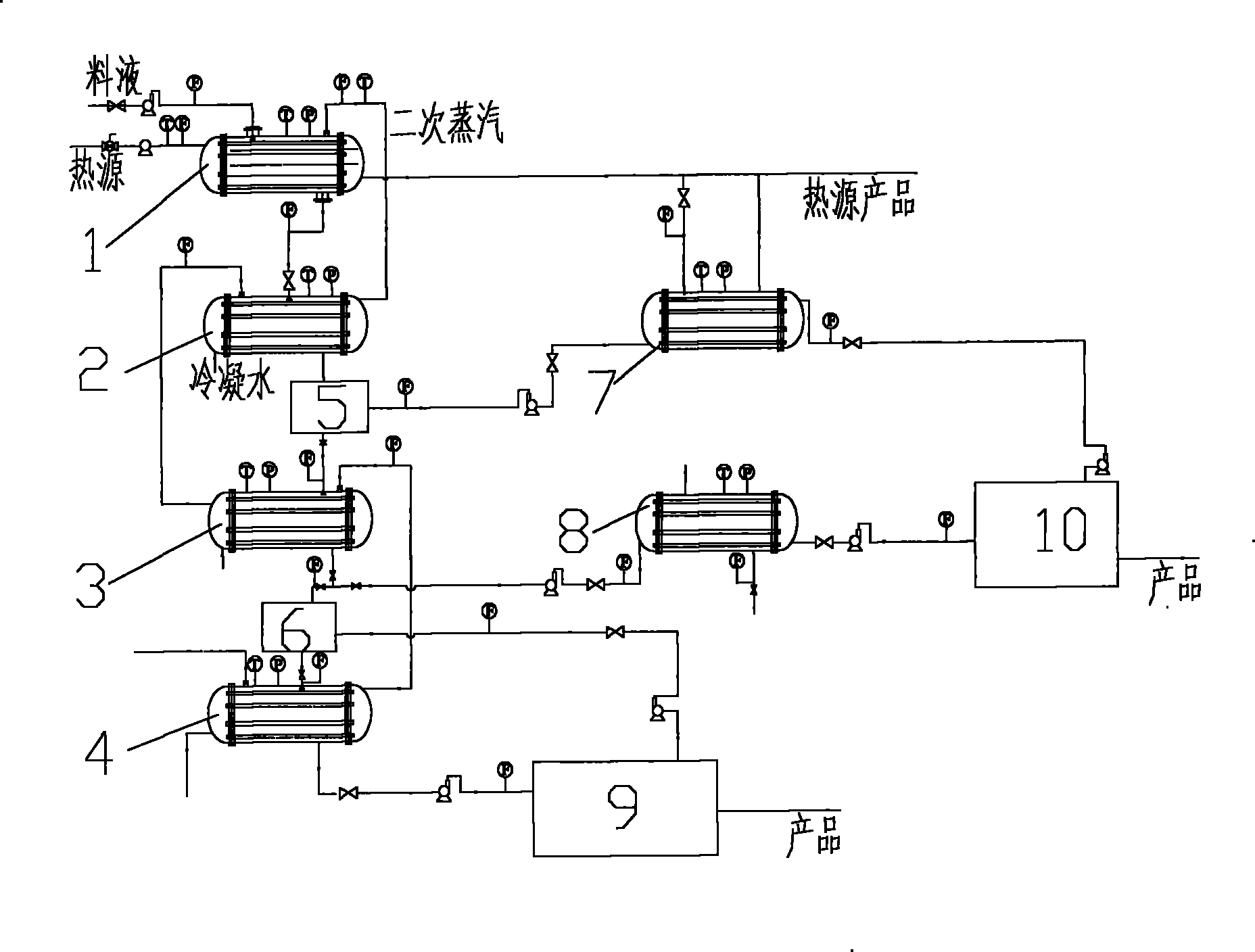

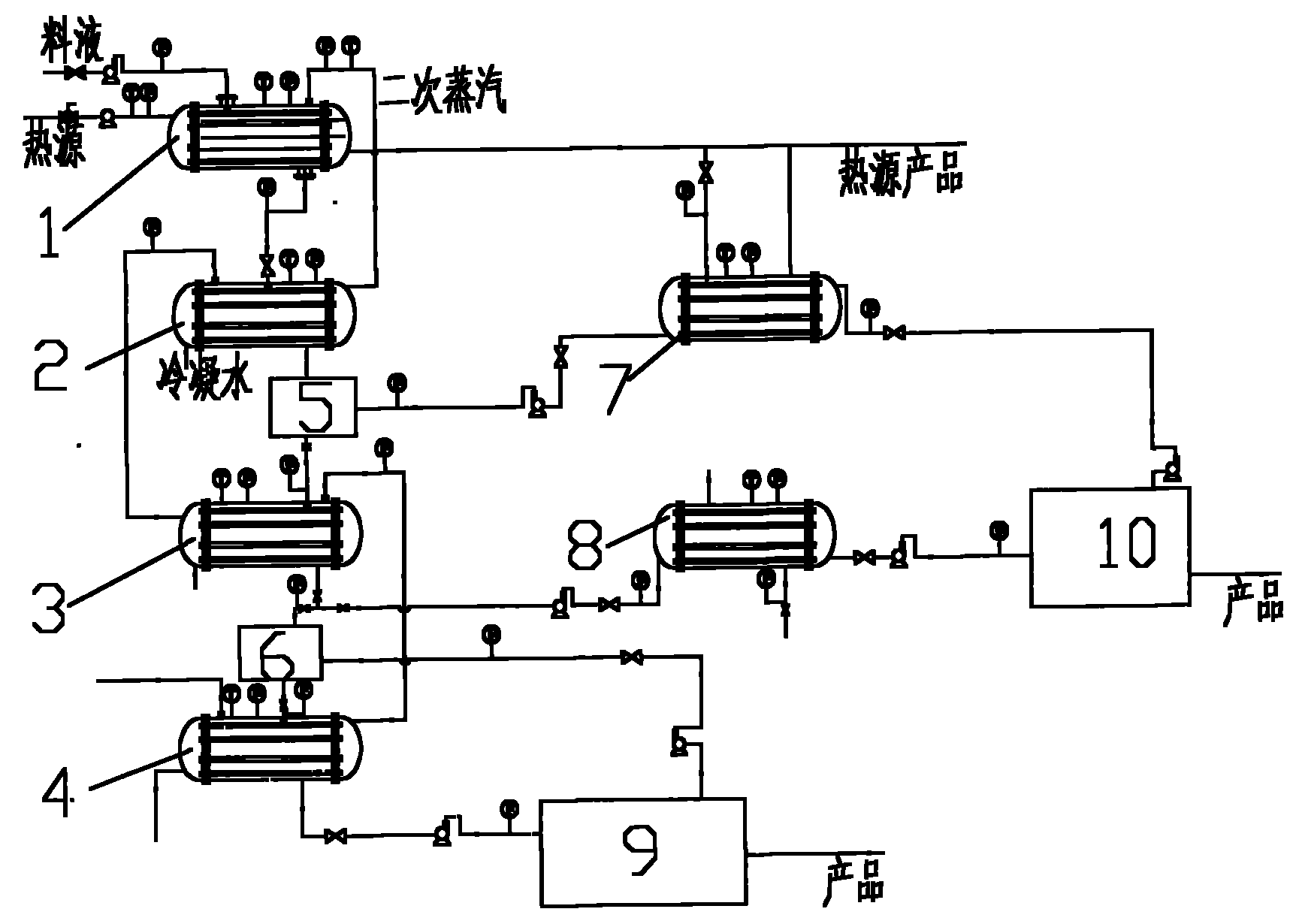

[0010] The specific implementation of the present invention will be described in detail below in conjunction with the technical solution and the drawings, taking ammonium sulfate crystal as an example.

[0011] The ammonium sulfate solution with a concentration of 35% close to the boiling point and a flow rate of 2000kg / h is sent to the one-effect evaporator, and the dichloroethane steam at a temperature of 83.4℃ is used as the heat source to make the solution thicker to 42%. The secondary steam at 75℃ is produced; the concentrated solution enters the second-effect evaporator to continue to evaporate; the heat required for this effect is 212.02kw, and the heat transfer coefficient is 2461.516W / (m 2 ·K), the heat transfer area is 25.18m 2 . In the two-effect evaporator, use the secondary steam generated by the primary effect to heat and evaporate and partially flash the solution to produce a secondary steam at 64.6°C, and the solution is concentrated to 52.4%; the concentrated solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com