LNG vehicle anti-freezing liquid

A technology of automobile antifreeze and LNG, which is applied in the field of antifreeze, which can solve the problems that the antifreeze performance of antifreeze cannot meet the requirements of LNG heavy trucks, the antifreeze cannot flow normally, and affect the normal use of automobiles, etc., and achieve the effect of inhibiting corrosion and antifreezing Good, the effect of increasing the heat conduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

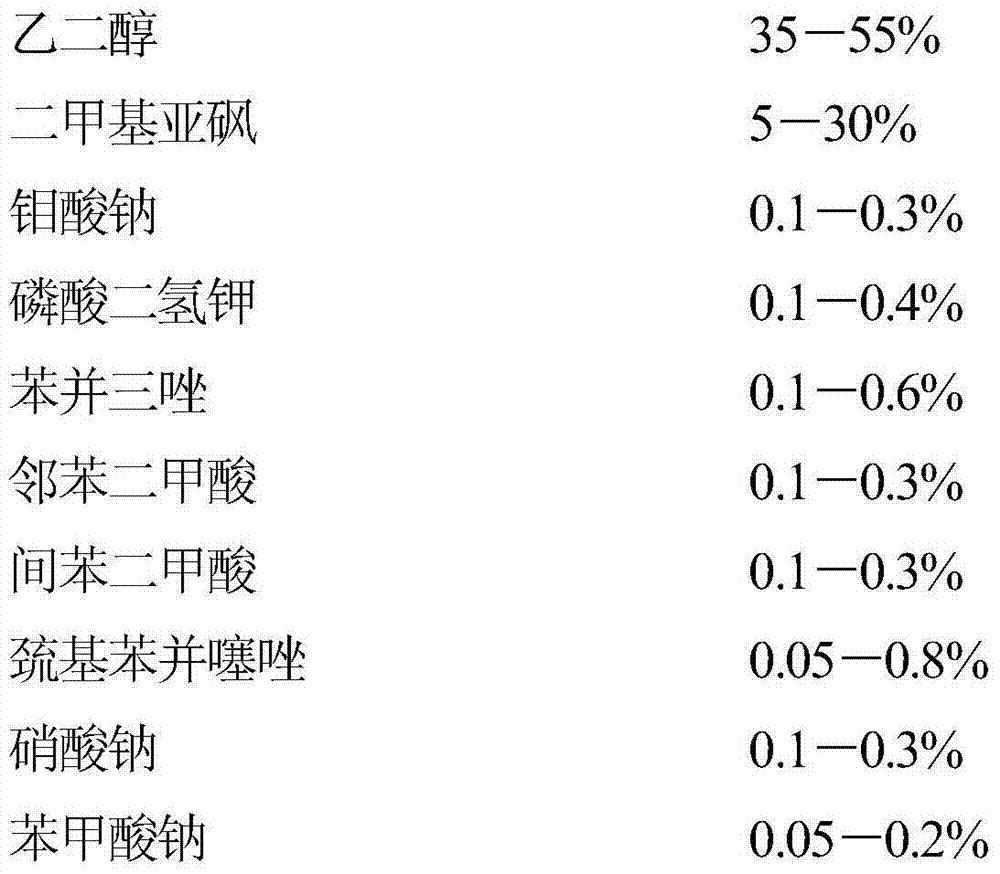

[0010] Example 1: Ethylene glycol 35%; Dimethyl sulfoxide 5%; Sodium molybdate 0.1%; Sodium dihydrogen phosphate 0.1%; Benzotriazole 0.1%; Phthalic acid 0.1%; Isophthalic acid 0.1% %; mercaptobenzothiazole 0.05%; sodium nitrate 0.1%; sodium benzoate 0.05%; sodium hydroxide 0.1%; fluorescein 0.0005%; deionized water balance.

Embodiment 2

[0011] Example 2: Ethylene glycol 55%; Dimethyl sulfoxide 30%; Sodium molybdate 0.3%; Sodium dihydrogen phosphate 0.4%; Benzotriazole 0.6%; Phthalic acid 0.3%; Isophthalic acid 0.3% %; mercaptobenzothiazole 0.8%; sodium nitrate 0.3%; sodium benzoate 0.2%; sodium hydroxide 0.5%; fluorescein 0.0015%; deionized water balance.

Embodiment 3

[0012] Example 3: Ethylene glycol 51.54%; Dimethyl sulfoxide 5.08%; Sodium molybdate 0.11%; Potassium dihydrogen phosphate 0.37%; Benzotriazole 0.28%; Phthalic acid 0.18%; %; mercaptobenzothiazole 0.09%; sodium nitrate 0.11%; sodium benzoate 0.09%; sodium hydroxide 0.37%; fluorescein 0.0008%; deionized water balance.

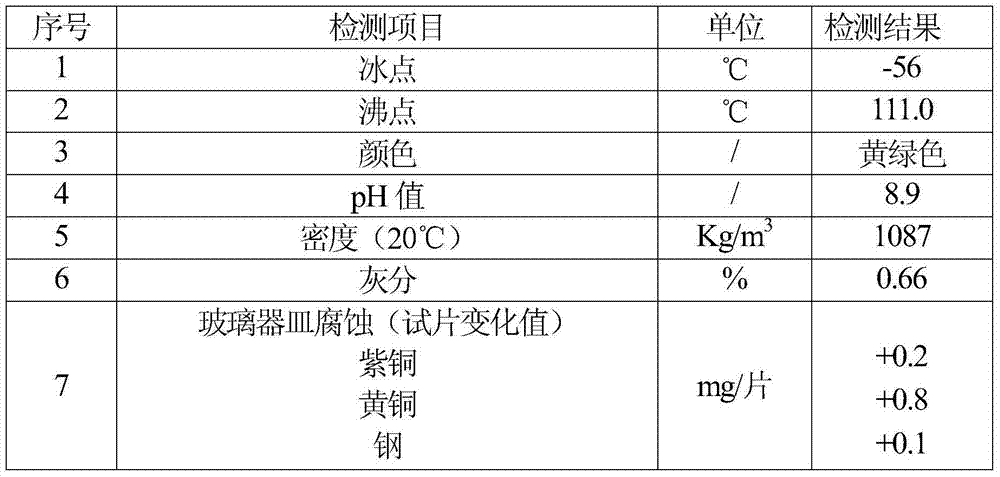

[0013] The test results of the quality index of this kind of antifreeze are as follows:

[0014]

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com