Degradable Mg-Zn-Y-Ca intravascular stent material and preparation method thereof

A vascular stent and alloy technology, applied in the field of degradable Mg-Zn-Y-Ca vascular stent material and its preparation, can solve problems such as organ damage and disorder, achieve improved corrosion resistance, strength and plasticity, and inhibit The effect of battery formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

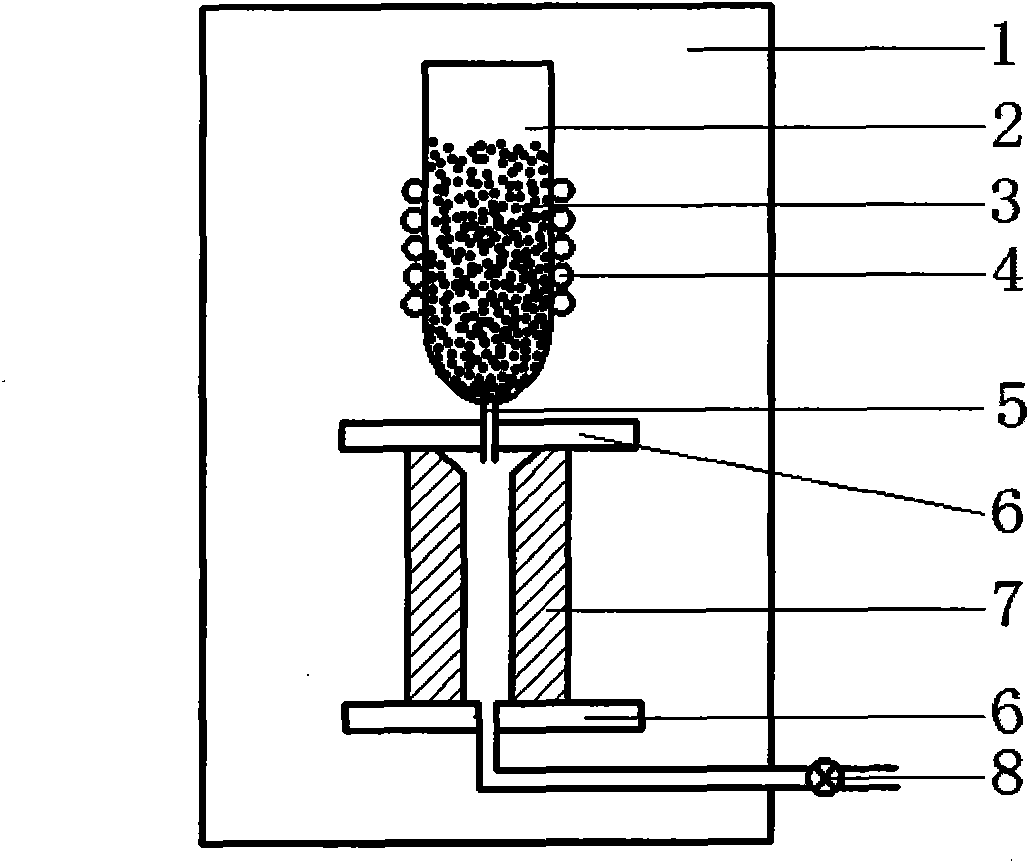

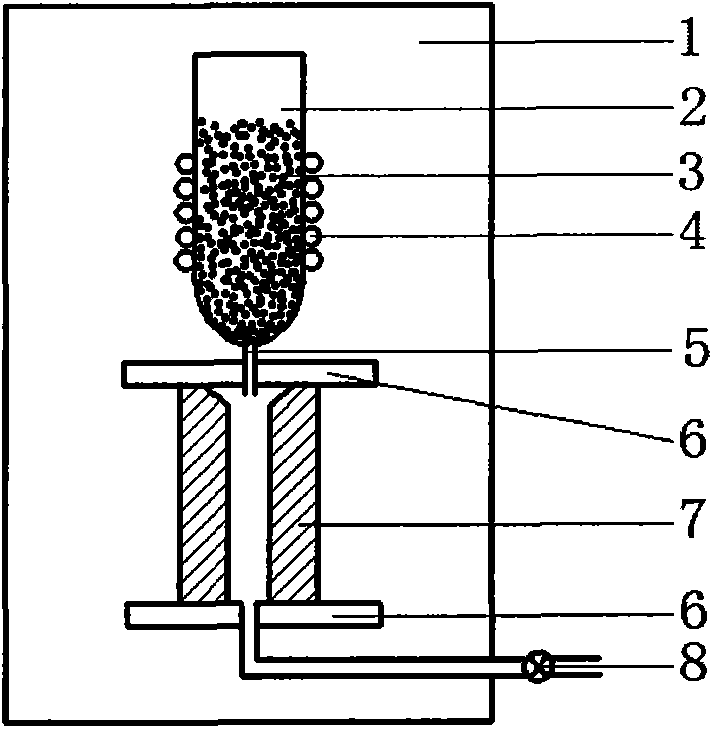

Image

Examples

Embodiment approach 1

[0027] Step 1. Fusion of master alloy ingots

[0028] I. Preliminary preparation

[0029] The raw materials needed for this test are: 1 # Magnesium Ingot, 1 # Zinc ingots, 99.9% pure yttrium and Mg-30% Ca master alloy;

[0030] In order to prevent the oxidation and combustion of magnesium alloys, a protective gas has been passed throughout the melting process. The protective gas used in this test is a mixed gas of carbon dioxide and sulfur hexafluoride, and the flow ratio of carbon dioxide and sulfur hexafluoride is 99%. : 1;

[0031] II. Specific operation process

[0032] a. Set 1 # Magnesium Ingot, 1 #Zinc ingots, 99.9% pure yttrium and Mg-30% Ca master alloy are calculated by mass percentage Wt%: Zn 1.00, Y 0.10, Ca 0.01, and the rest is the proportioning requirement of Mg, and the raw materials are weighed for later use;

[0033] b. Put the crucible into the resistance furnace, and at the same time pass the mixed gas of carbon dioxide and sulfur hexafluoride into t...

Embodiment approach 2

[0040] The composition ratio of magnesium alloy changes as follows: 1 # Magnesium Ingot, 1 # Zinc ingot, 99.9% pure yttrium and Mg-30% Ca master alloy are calculated by mass percentage Wt%: Zn 2.00, Y 0.40, Ca 0.15, the rest is Mg, and others are the same as Embodiment 1.

[0041] The magnesium alloy obtained under this process has a yield strength of 225MPa, an elongation of 22%, and a corrosion rate of 0.25mm / a in a dynamic simulated body fluid, meeting the performance requirements of an ideal vascular stent.

Embodiment approach 3

[0043] The composition ratio of magnesium alloy changes as follows: 1 # Magnesium Ingot, 1 # Zinc ingot, 99.9% pure yttrium and Mg-30% Ca master alloy are calculated by mass percentage Wt%: Zn 3.00, Y 0.70, Ca 0.35, the rest is Mg, and others are the same as Embodiment 1.

[0044] The magnesium alloy obtained under this process has a yield strength of 240MPa, an elongation of 20%, and a corrosion rate of 0.28mm / a in a dynamic simulated body fluid, meeting the performance requirements of an ideal vascular stent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com