Cyclone cylinder flue gas dry-method catalytic desulfurization device and process

A catalytic desulfurization and cyclone technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, separation methods, etc., can solve the problem of huge project investment, low desulfurization efficiency, low desulfurization efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

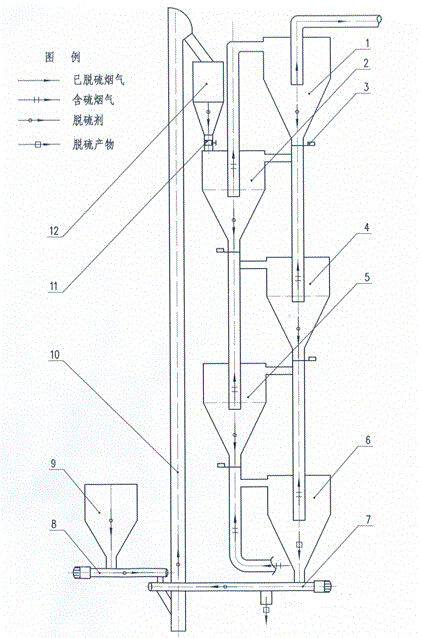

[0062] see figure 1 , the cyclone flue gas dry catalytic desulfurization device includes at least five cyclone bodies, the desulfurization product outlet at the bottom of the cyclone body is provided with a flap valve 3; The inlet of the desulfurization product at the upper part of the secondary cyclone body 2 is connected; the flue gas outlet at the top of the second-stage cyclone body 2 is connected with the flue gas inlet at the upper part of the first-stage cyclone body 1; the smoke at the top of the first-stage cyclone body 1 The gas outlet is connected with the flue gas humidifier and the dust removal system; the desulfurization product outlet at the bottom of the second-stage cyclone body 2 is connected with the desulfurization product inlet at the upper part of the third-stage cyclone body 4; the bottom of the first-stage cyclone body 1 The desulfurization product outlet is connected with the flue gas outlet at the top of the third-stage cyclone body 4; the desulfuriz...

Embodiment 2

[0067] A kind of desulfurization catalyst, it comprises the component of following percentage by weight: V2 o 5 5—10%; MnO 2 15—20%; Fe 2 o 3 30-35%; sodium humate 40-45%.

Embodiment 3

[0069] The cyclone flue gas dry catalytic desulfurization process based on the device described in embodiment 1 is as follows:

[0070] The reaction process of desulfurization agent containing desulfurization catalyst:

[0071] The desulfurizing agent containing desulfurizing catalyst is fed from the desulfurizing agent storage tank, and then sent to the bucket elevator after being metered by the variable-speed screw conveyor, then lifted by the bucket elevator and sent to the high-level tank, and then measured from the high-level tank by the feeder It is sent into the second-stage cyclone body, and after being merged with the desulfurization agent containing desulfurization catalyst that enters from the upper desulfurization product inlet of the second-stage cyclone and is separated from the first-stage cyclone body, it is discharged into the second-stage cyclone body. desulfurization chemical reaction with the sulfur-containing flue gas entering the second-stage cyclone body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com