Method for producing potassium (sodium) sulfate at low temperature

A technology of potassium sulfate and potassium hydrogen sulfate, applied in the fields of inorganic salt industry and fertilizer industry, can solve problems such as difficulty in single furnace production capacity, large energy consumption, equipment corrosion, etc., and achieve light equipment corrosion, low reaction temperature, and fast reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

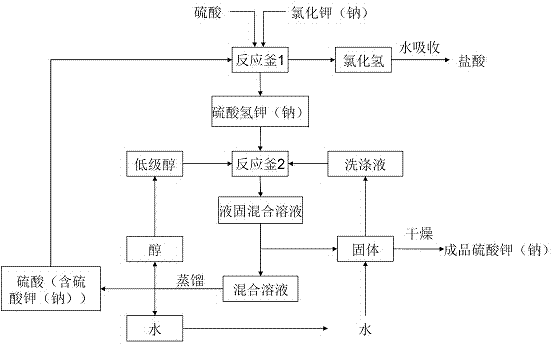

[0026] Example 1: A new method for low-temperature production of potassium sulfate (sodium), technical process reference figure 1 .

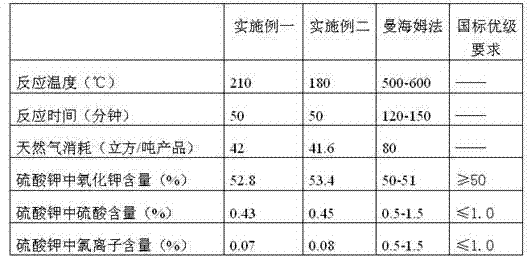

[0027] Potassium chloride with a content of 95% and industrial sulfuric acid with a concentration of 98% are put into the reaction kettle 1 under continuous stirring at a ratio of 1:1 according to the amount of substances, and the reaction temperature is controlled at 210°C, and the reaction is carried out for 50 minutes. After completion, the generated potassium hydrogen sulfate is atomized and sprayed into the aqueous solution in the reactor kettle 2, and ethanol is added to the solution until the ethanol concentration reaches 70% or more, and the solid and mother liquor are obtained by filtration. The solid was washed with an aqueous solution, dried at 110°C, and crushed to obtain the finished potassium sulfate. The above mother liquor is distilled and separated at a temperature of 110°C to obtain ethanol, water and sulfuric acid. The sulfur...

Embodiment 2

[0028] Embodiment 2: A new method for producing potassium sulfate (sodium) at low temperature.

[0029] Potassium chloride with a content of 95% and industrial sulfuric acid with a concentration of 93% are put into the reactor 1 under continuous stirring at a ratio of 0.8:1 according to the amount of substances, and the reaction temperature is controlled at 180°C, and the reaction is carried out for 50 minutes. After completion, the generated potassium hydrogen sulfate is atomized and sprayed into the aqueous solution in the reactor 2, methanol is added to the solution until the concentration of methanol reaches 70%, and the solid and mother liquor are obtained by filtration. The solid was washed with an aqueous solution, dried by heating at 120°C, and pulverized to obtain potassium sulfate. The above mother liquor is separated by vacuum distillation at 80°C to obtain alcohol, aqueous solution and sulfuric acid. Both sulfuric acid and alcohol are recycled, and water is used to...

Embodiment 3

[0030] Embodiment 3: A kind of new method of producing potassium sulfate (sodium) at low temperature.

[0031] The sodium chloride with a content of 99% and the industrial sulfuric acid with a concentration of 98% are put into the reaction kettle 1 under continuous stirring at a ratio of 0.85:1 according to the ratio of substances, and the reaction temperature is controlled at 180°C, and the reaction is carried out for 40 minutes. After completion, the generated sodium bisulfate is atomized and sprayed into the aqueous solution in the reaction kettle 2, ethanol is added to the solution until the ethanol concentration reaches 80%, and the solid and mother liquor are obtained by filtration. The solid was washed with aqueous solution and heated to obtain anhydrous sodium sulfate. The above mother liquor is separated by vacuum distillation at 80°C to obtain alcohol, aqueous solution and sulfuric acid. Both sulfuric acid and alcohol are recycled, and water is used to wash solid sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com