Method for improving flavor of liquor-marinated fish by utilizing biological flavor increasing technique

A technology of drunk fish flavor, applied in the field of enhancing the flavor of drunk fish with biological aroma-enhancing technology, can solve the problems of insufficient flavor, difficult dehydration, spoilage and other problems of products, slow down fat oxidation, improve storage stability, prevent surface hardening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

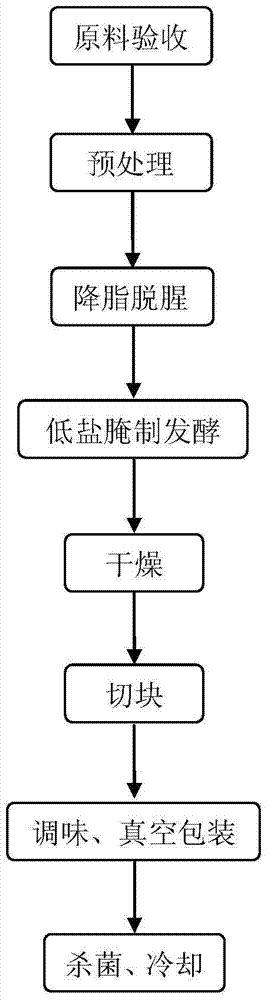

Method used

Image

Examples

Embodiment 1

[0021] Fresh or frozen catfish are thawed and then dissected. After removing the head, tail and viscera, cut them open from the back, divide them into two, and wash them with running water. Soak the treated fish fillets in a lipase solution with a pH of 9.0, a temperature of 30°C, and an enzyme activity of 45U / ml at a fish liquid ratio of 1:4 for 45 minutes, stirring regularly, and then remove the fish fillets and drain the surface Moisture: The fish fillets soaked in lipase solution were placed in a pickling solution containing fermenting bacteria at a ratio of 1:2 to fish solution and fermented at 10°C for 24 hours. The pickling solution is composed of bacteria with a concentration of 10 7 CFU / ml of Saccharomyces cerevisiae, Pediococcus pentosaceae and Staphylococcus xylosus were uniformly mixed in a volume ratio of 1:1:1 and then added with 4% salt and 1% glucose; then the fish fillets were placed at 40°C, Dry with hot air at a wind speed of 1m / s for 3 hours, then vacuum-d...

Embodiment 2

[0023] Fresh or frozen grass carp is thawed and slaughtered. After removing the head, tail and viscera, cut it from the back, divide it into two, and wash it with running water; add the processed fish fillets with a fish liquid ratio of 1:2 Soak in lipase solution with pH 9.5, temperature 40℃, enzyme activity 20U / ml for 65min, stir regularly, then fish out the fish fillets, drain the surface water; Place in the pickling solution containing fermenting bacteria and ferment for 3 hours at 25°C. The pickling solution is composed of bacteria with a concentration of 10 9 CFU / ml of Saccharomyces cerevisiae, Pediococcus pentosaceae and Staphylococcus xylosus are uniformly mixed in a volume ratio of 1:1:1 and then added with 7% salt and 3% glucose; then the fish fillets are heated at 55°C , dry with hot air at a wind speed of 1.5m / s for 1h, then vacuum-dry the fish fillets at a vacuum degree of 0.08MPa and 40°C to a moisture content of 40-45%, after natural cooling, cut and trim each ...

Embodiment 3

[0025] Fresh or frozen eels are thawed and dissected. After removing the head, tail and internal organs, cut them open from the back, divide them into two, and wash them with running water. Soak the treated fish fillets in a lipase solution with a pH of 9.2, a temperature of 35°C, and an enzyme activity of 40U / ml at a ratio of 1:3 for 60 minutes, stir regularly, then remove the fish fillets and drain the surface Moisture: The soaked fish fillets are placed in a pickling solution containing fermenting bacteria at a ratio of 1:2 fish liquid and fermented at 20°C for 12 hours. The pickling solution is composed of bacteria with a concentration of 10 8CFU / ml of Saccharomyces cerevisiae, Pediococcus pentosaceae and Staphylococcus xylosus were uniformly mixed in a volume ratio of 1:1:1 and then added with 5% salt and 2% glucose; other steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com