Patents

Literature

37results about How to "Reduce the sterilizing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

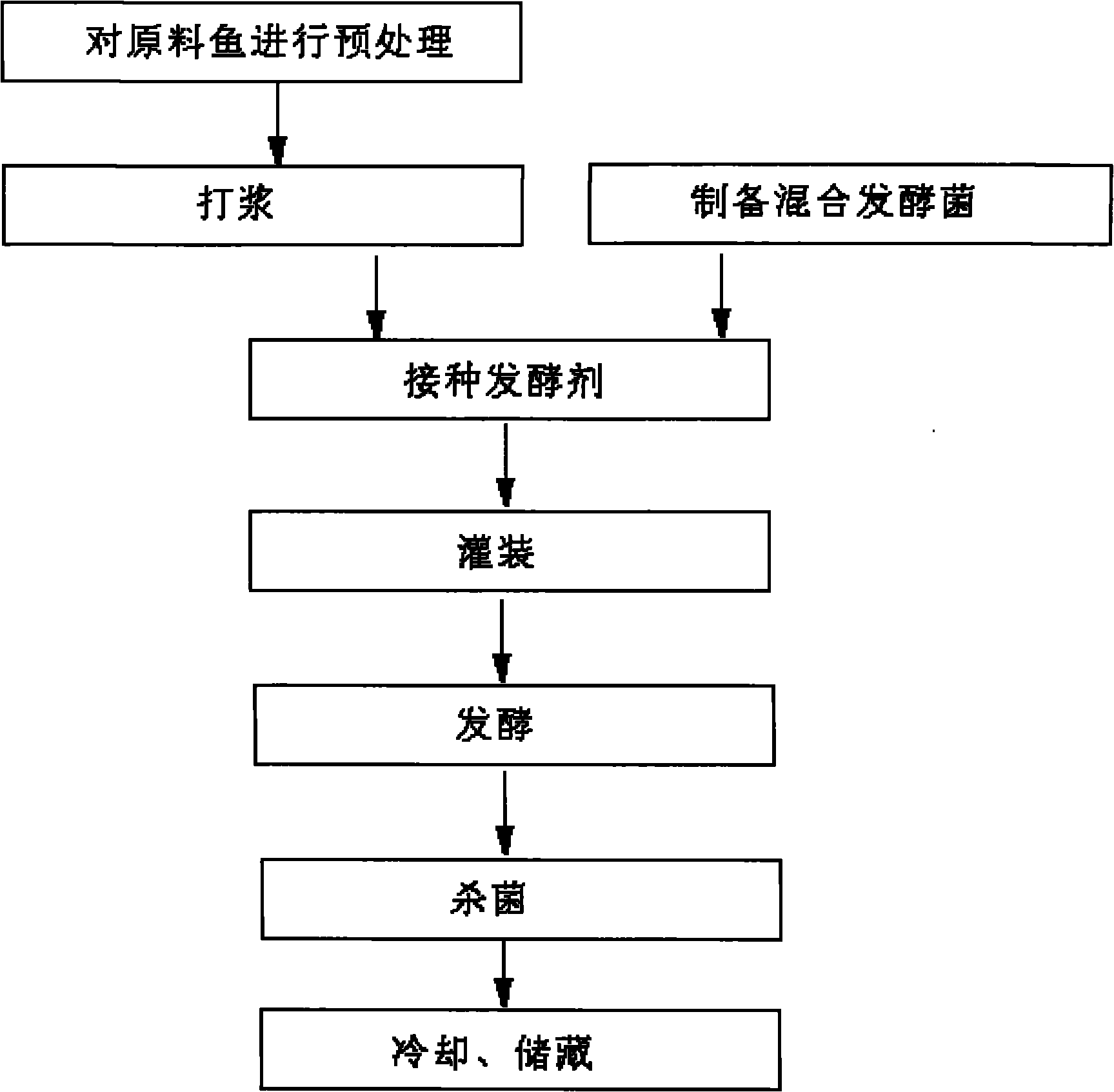

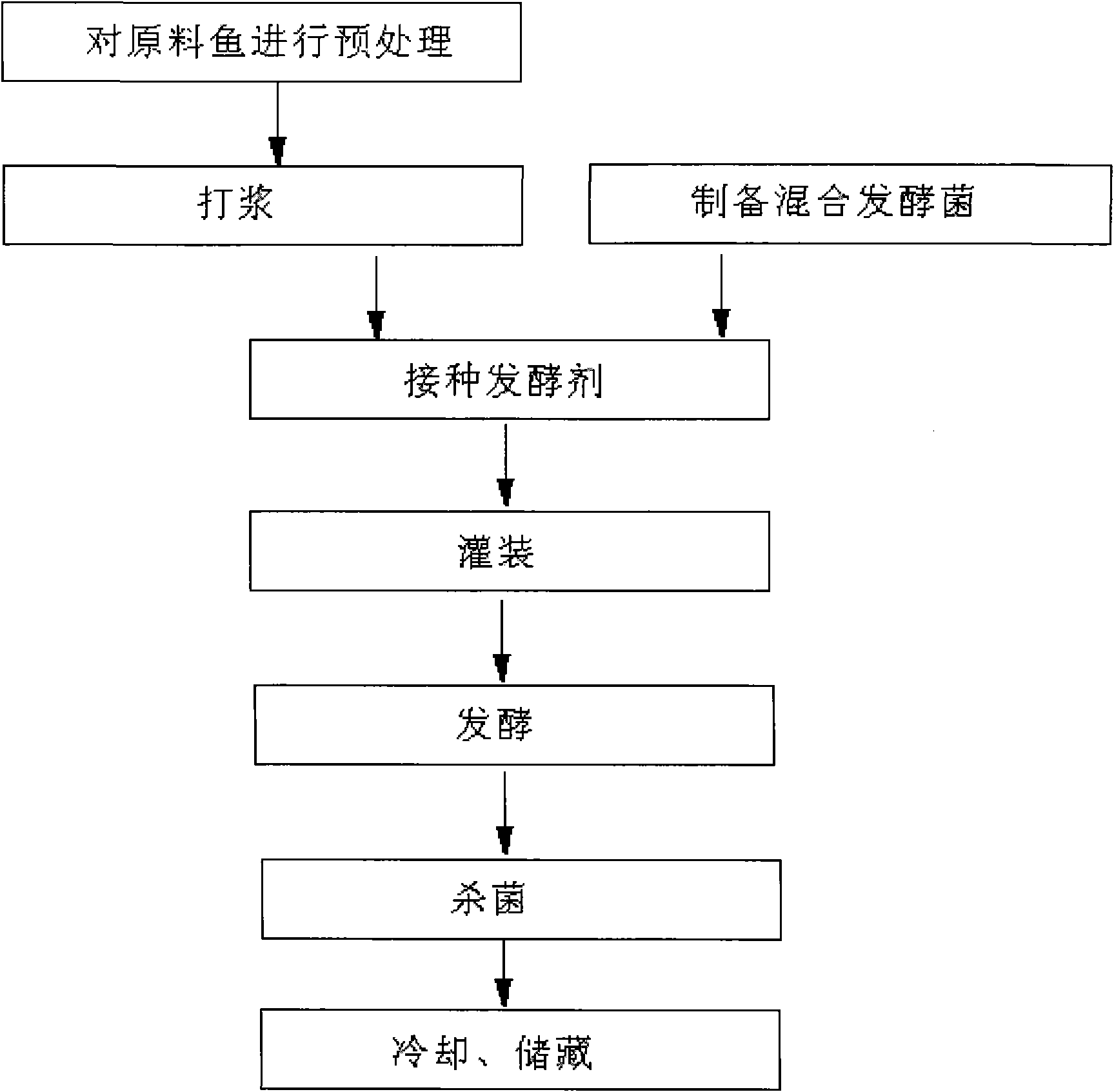

Method for preparing fish-and-rice mixed breaded fish sticks by using microorganism leavening agent

The invention discloses a method for preparing fish-and-rice mixed breaded fish sticks by using a microorganism leavening agent. The method is characterized in that fresh fish or frozen fish is taken as a raw material; and the fish-and-rice mixed breaded fish sticks are prepared by the following steps: pretreating and mashing the fresh fish or the frozen fish; inoculating the leavening agent; and filling, fermenting, sterilizing, cooling and storing. To sum up, the fish-and-rice mixed breaded fish sticks prepared by the method disclosed by the invention have unique fermentation flavors, are soft, fine and smooth in texture, and have the advantages of high resilience, high nutritive value, good safety and long storage period, thereby especially providing a brand new processing way for processing freshwater fish in China.

Owner:SUZHOU DUORUNDUO AGRI TECH +1

Natural fruit and vegetable enzyme product

InactiveCN105533544AImprove aftertasteIncrease nutritionBacteriaMicroorganism based processesAdditive ingredientNutrition

The invention discloses a natural fruit and vegetable enzyme product, and belongs to the technical field of fermentation. The natural fruit and vegetable enzyme product is prepared through a method comprising the steps that a lactobacillus agent with the mass being 0.2-1% that of fruit and vegetable raw materials and sugar with the mass being 0.3-1% that of fruit and vegetable raw materials are added into fruit and vegetable raw material pulp for fermentation for 6-10 h at the temperature of 20-25 DEG C, when the pH value is 4.7-5.3, lactobacillus plantarum CGMCC NO.11763 with the mass being 0.3-1% that of the fruit and vegetable raw materials and sugar with the mass being 0.1-0.5% that of the fruit and vegetable raw materials are added for fermentation for 20-40 h at the temperature of 25-30 DEG C, fermentation is finished when the pH value is 3.4-4.0, and sterilization or packaging storage and marketing are performed after filling is performed. The obtained natural fruit and vegetable enzyme product is sour, sweet, pure, good in taste and nutrition and high in functionality. The preparation method of the fruits and vegetables fermented through lactobacillus has the advantages that the fermentation method is adopted for processing, vitamins, dietary fiber and other nutritional ingredients in the fruit and vegetable raw materials are completely reserved, the sterilization strength is lowered, the food shelf life is prolonged, and rotting is avoided.

Owner:天津天绿健科技有限公司

Mycelium control and quality guaranteeing method for reducing heat sterilization intensity for conditioning fowl or fish product

InactiveCN101700051AReduce the sterilizing strengthHigh nutritional valueMeat/fish preservation using chemicalsMyceliumFish products

The invention relates to a mycelium control and quality guaranteeing method for reducing the heat sterilization intensity for conditioning fowl or fish product, belonging to the technical field of cooked meat product sterilization. The method mainly comprises the process: after being unfrozen, cut and washed, raw material is cooked according to the formulation; after being cooked for a certain period of time, nisin and other auxiliary materials are added into the raw material; after reaching a certain ripening degree, the mixture is cooled and packaged by vacuum; and the product is quick-frozen at ultralow temperature and then treated by flexible heat sterilization. The method has the advantages the fowl or fish product with high quality and long quality guarantee period can be obtained by the operation; (1) by compounding the nisin and potassium sorbate, antibacterial spectrum can be expanded; and (2) by combining freezing sterilization and the flexible heat sterilization, good sterilization effect can be achieved by large temperature difference change within a short time. Therefore, the method reduces the damage for the nutritional ingredients of the fowl or the fish under pure high temperature sterilization, ensures the quality of the products and finally the mycelium control and quality guaranteeing cooked meat product on the premise of guaranteeing the shelf life of the product.

Owner:JIANGNAN UNIV +1

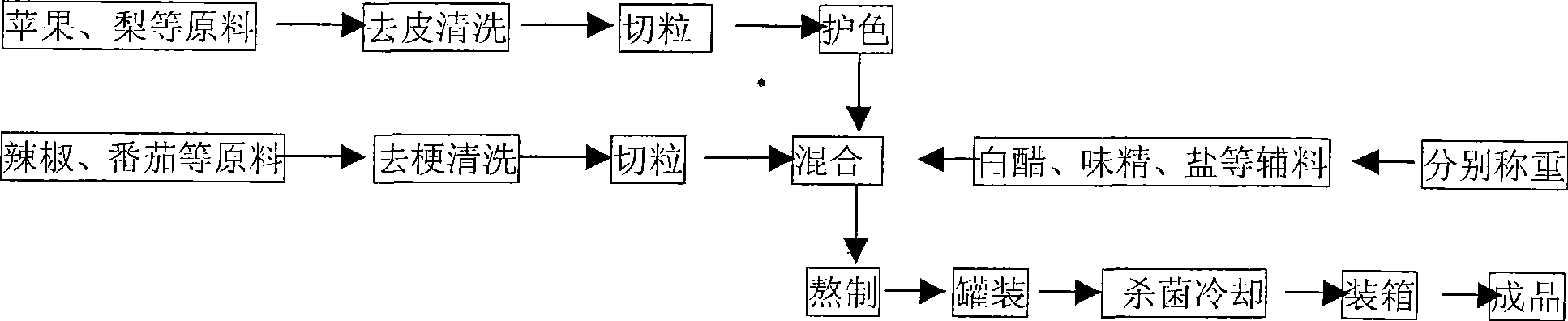

Fruit flavor chili paste and preparation method thereof

The invention discloses a safe fruity chili sauce having health care function and a preparation method thereof; the fruity chili sauce is prepared by processing a chili sauce added with ingredients including apples, pears, raisin, medlar, red date, tomatoes, and the like, and accessories including salt, white vinegar, sweet soybean paste, monosodium glutamate, garlic, sugar, and the like. The formula of the fruity chili sauce is as follows: 3Kg to 5Kg of chili is taken as the standard; according to weight mixture ratio, the formula of the fruity chili sauce consists of 100g to 500g of apples, 100g to 500g of pears, 10g to 100g of raisin, 10g to 100g of medlar, 50g to 200g of red date, 100g to 500g of garlic, 400g to 600g of white vinegar, 30g to 50g of monosodium glutamate, 60g to 120g of sweet soybean paste, 100g to 500g of tomatoes, 200g to 400g of salt and 250g to 500g of white sugar. The fruity chili sauce is directly broken after color protection, is added with various ingredients and accessories without an enzyme preparation and goes through boiling, thus shortening processing time, reducing processing cost and retaining mineral matters, vitamins and dietary fibers. The fruity chili sauce has the advantages of rich nutrition, health care and maintenance, and the like, and is easily accepted by people of all kinds.

Owner:黄海

Technique for producing fermented spareribs by using compound leavening agent

The invention belongs to the technical field of food processing and in particular relates to a technique for producing fermented spareribs by using a compound leavening agent. The technique comprises the following steps of: pretreatment of raw materials, pickling, predrying, frying, fermenting, baking, packaging, sterilizing and the like, wherein the compound leavening agent which takes microorganisms, such as lactobacillus plantarum, lactobacillus rhamnosus, Pediococcus pentosaceus and saccharomyces cerevisiae as strains is used for fermentation. The purpose of endowing spareribs with a basic fermentation flavor by using microbial fermentation is achieved; the nutritional value of the sparerib product is improved by fermentation; and the sparerib product do not need to be subjected to high-temperature and high-pressure sterilization by reducing the pH value of the sparerib product and combining the frying and baking processes, so that original taste and flavor of the sparerib product are ensured. The fermented sparerib product has the advantages of mellow flavor, high nutritional value, good safety, easiness in preservation, probiotic effect and the like; and due to development of the fermented spareribs, food which is unique in flavor, rich in nutritions and convenient to eat is provided for the society.

Owner:TENGQIAO FOOD CO LTD

Ultraviolet and nano zinc oxide combined sterilizing method for convenient vegetable dishes

InactiveCN102388956AReduce the sterilizing strengthHigh nutritional valueFruits/vegetable preservation by irradiation/electric treatmentNutrientBacteriostatic agent

The invention provides an ultraviolet and nano zinc oxide combined sterilizing method for convenient vegetable dishes, which belongs to the vegetable product treatment technical field. The method comprises the following steps: cleaning (hulling) vegetable raw materials, blanching and killing enzyme, frying according to the formula, then adding a bacteriostatic agent nano zinc oxide, vacuum packaging, carrying out ultraviolet irradiation and sterilization, finally storing at room temperature. Nano zinc is capable of inhibiting the growth of microbe, the frying process enables the effect of passivating enzyme and killing microbe; ultraviolet irradiation and sterilization enable further catalysis to increase the bacteriostasis performance of nano zinc, and perform synergism and ensure the long shelf-life of product. The ultraviolet and nano zinc combined cold sterilizing method used by the invention is capable of overcoming the inhomogeneity of ultraviolet sterilization, solving the disadvantage of poor bactericidal activity when nano zinc is individually acted under the safe dosage, eliminating the defect of loss of nutrients and local flavor caused by traditional high temperature sterilization, and ensuring the long shelf-life of products. The combined sterilizing method has the characteristics of simple process, easy operation, saved energy and the like.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

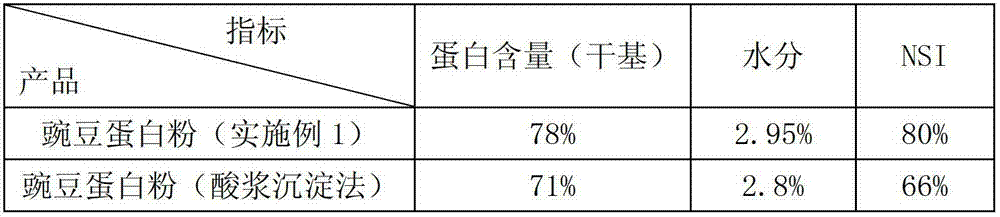

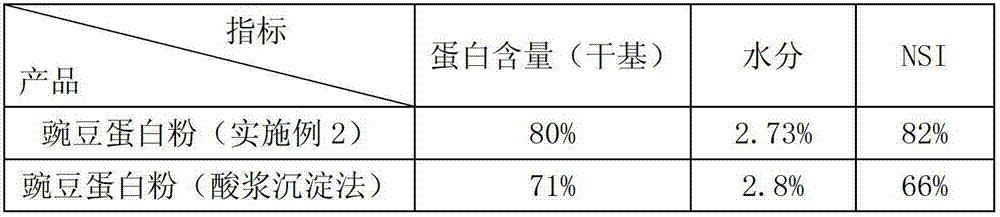

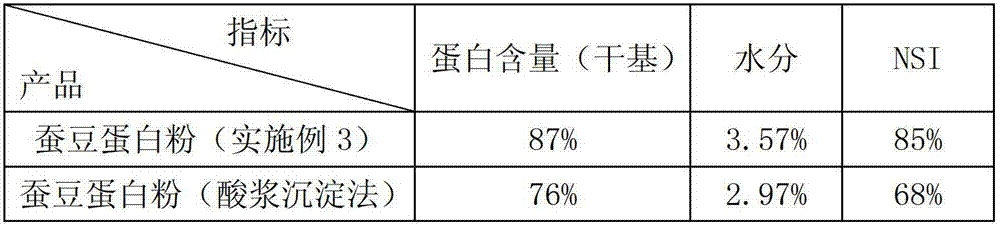

Production method of high-solubility bean type edible protein

InactiveCN102823713AAvoid environmental problemsAvoid mass breedingProtein composition from vegetable seedsSolubilityHigh pressure

The invention discloses a production method of high-solubility bean type edible protein. The method comprises the following steps of (1) screening and washing; (2) soaking; (3) milk milling; (4) placing and delamination; (5) protein acid precipitation; (6) centrifugal separation; (7) uniform mixing and neutralization; (8) high-pressure shearing; (9) sterilization; (10) spraying drying; and (11) screening and granulation: protein powder obtained through spraying drying is subjected to screening treatment in dry environment, and bean type edible protein powder with the uniform particles and with the moisture mass content lower than 5 percent can be obtained. The method provided by the invention has the advantages that the influence caused by the climate and environment of the traditional acid pulp precipitation method is avoided, the production period is short, the product added value can be effectively added, meanwhile, the mass propagation of microbes is avoided, the sterilization intensity is reduced, and the processing performance of products is more preferably maintained.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Preparation method of soup-stock-containing canned and smoked mackerel

The invention discloses a preparation method of soup-stock-containing canned and smoked mackerel. The preparation method mainly solves the problems that existing canned mackerel has a single taste and nutrition is poorly matched. According to the preparation method, heads, tails, fins and viscera of fresh mackerel raw materials are removed, and then the raw materials are washed clean, and mackerel blocks are prepared; the mackerel blocks are put into salt and sugar water and soaked, and histamine is reduced; salt and sugar on surfaces of the mackerel blocks are washed clean, then the mackerel blocks are put into clean water and subjected to superhigh-pressure treatment and smoked, and the smoked mackerel blocks are prepared; the smoked mackerel blocks are roasted until the smoked mackerel blocks are cooked totally, the smoked mackerel blocks are canned, soup stock is added, nisin is added for bacteriostasis, exhausting, sealing, can washing, sterilization and back pressure cooling are performed, then the canned mackerel is left to stand and cooled to the normal temperature, and the finished canned mackerel is prepared after being detected to be qualified. The preparation method is technologically reasonable, the operability is high, and the production efficiency is high. The canned and smoked mackerel prepared with the method taste delicious, mellow and unique, are rich in nutrition, safe and hygienic and have a long guarantee time.

Owner:荣成石岛广信食品有限公司

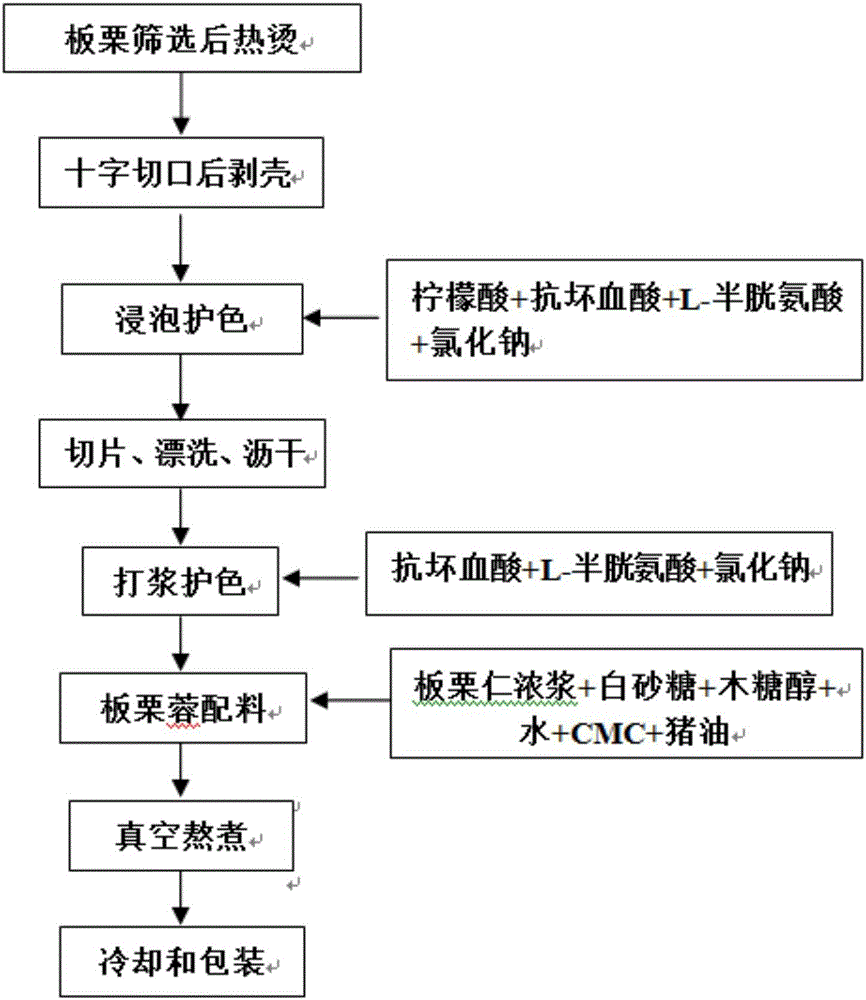

Method for preparing low-sugar primary-color chestnut paste through non-sulfur color protection technology

InactiveCN106213404AWon't change colorReduce pollutionFood ingredient as antioxidantSugar food ingredientsSucroseAdditive ingredient

The invention relates to a method for preparing low-sugar primary-color chestnut paste through a non-sulfur color protection technology. The method comprises the following steps that firstly, chestnuts are subjected to blanching treatment after being screened, shells are stripped, and skin is removed; then, the chestnuts are soaked in color protection liquid which contains 0.05 wt% of citric acid, 0.75 wt% of ascorbic acid, 0.17 wt% of L-cysteine and 1.00-3.00 wt% of sodium chloride, and the pH value of the color protection liquid is 3.8; the chestnuts are taken out, chopped, rinsed and drained off, and chestnut fragments are obtained; the chestnut fragments and pulping color protection liquid which contains 0.65 wt% of ascorbic acid, 0.05 wt% of L-cysteine and 1.5-2.3 wt% of sodium chloride are mixed to be uniform and prepared into thick chestnut pulp, auxiliary materials are added into the thick chestnut pulp for vacuum boiling, and lastly the low-sugar primary-color chestnut paste is obtained after cooling and packaging. According to the method, a two-step whole-process color protection process including soaking color protection and pulping color protection is adopted, color fixatives used are all non-sulfur ingredients harmless to the human body, safety and reliability are achieved, and pollution to the environment is small. According to the formula, the sucrose content is lowered, the functional sweetening agent xylitol is added, decayed teeth can be effectively prevented, and the chestnut paste can be used as a raw material of low-fat low-sugar snack food for old people and children.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Rhizoma dioscoreae cloudy beverage and preparation method thereof

InactiveCN106962700AInhibits enzymatic browningInhibitory reactivityFood ingredient as antioxidantFood thermal treatmentCarboxymethyl celluloseFlavor

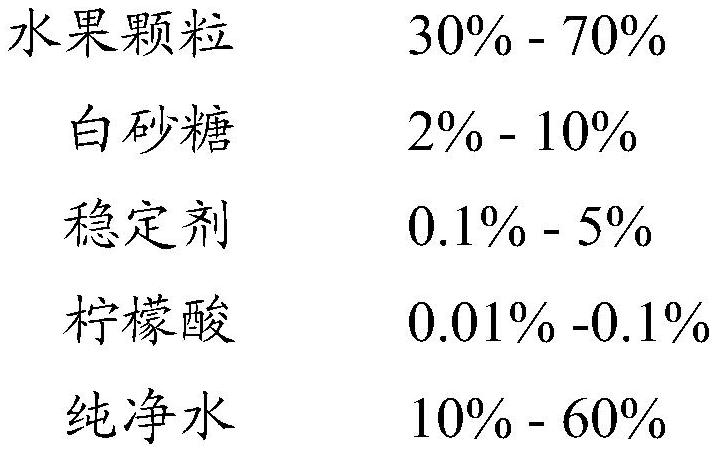

The invention provides a rhizoma dioscoreae cloudy beverage and a preparation method thereof. The beverage is prepared from, by mass, 88-94 parts of rhizoma dioscoreae pulp, 3-6 parts of purified water for drinking, 1-3 parts of white granulated sugar, 1-3 parts of trehalose, 0.1-0.25 part of D-erythorbic acid, 0.05-0.1 part of citric acid, 0.1-0.2 part of sodium carboxymethyl cellulose and 0.05-0.15 part of xanthan gum. The rhizoma dioscoreae pulp is prepared by peeling, slicing, color protecting, ageing and pulping of fresh rhizoma dioscoreae. The preparation method includes steps of mixing, homogenizing, filling, sterilizing and cooling. By the preparation method, a production process of the rhizoma dioscoreae cloudy beverage can be simplified, production cost is reduced, nutrients and flavor of rhizoma dioscoreae can be retained to the greatest extent, and white color, tender taste and high stability of products are realized.

Owner:SICHUAN UNIV

Method for performing flexible sterilization on cooked dishes at room temperature

InactiveCN102057980AEnsure safetyNisinFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingPotassiumPasteurization

The invention relates to a method for performing flexible sterilization on cooked dishes at room temperature, belonging to the technical field of vegetable product processing. The method mainly comprises the following steps: performing cleaning, shredding and nano silver coating on vegetable raw material, frying according to a formula, then adding preservatives of potassium sorbite, nisin and the like, performing vacuum packaging, and performing flexible thermal sterilization. The method in the invention has the advantages that cooked vegetable products with high quality and long quality guarantee period can be obtained by the following operations: 1) nano silver, nisin and potassium sorbate are compounded, so that the antibacterial spectrum is expanded and sterilization strength is weakened; and 2) the flexible sterilization way of pasteurization is adopted, and damages of high temperature to nutrient components and tissue structure of vegetable can be greatly reduced, so that the vegetable products with bacterium resistance and quality guarantee can be obtained while the shelf life of the products is ensured.

Owner:杭州思味王食品有限公司 +1

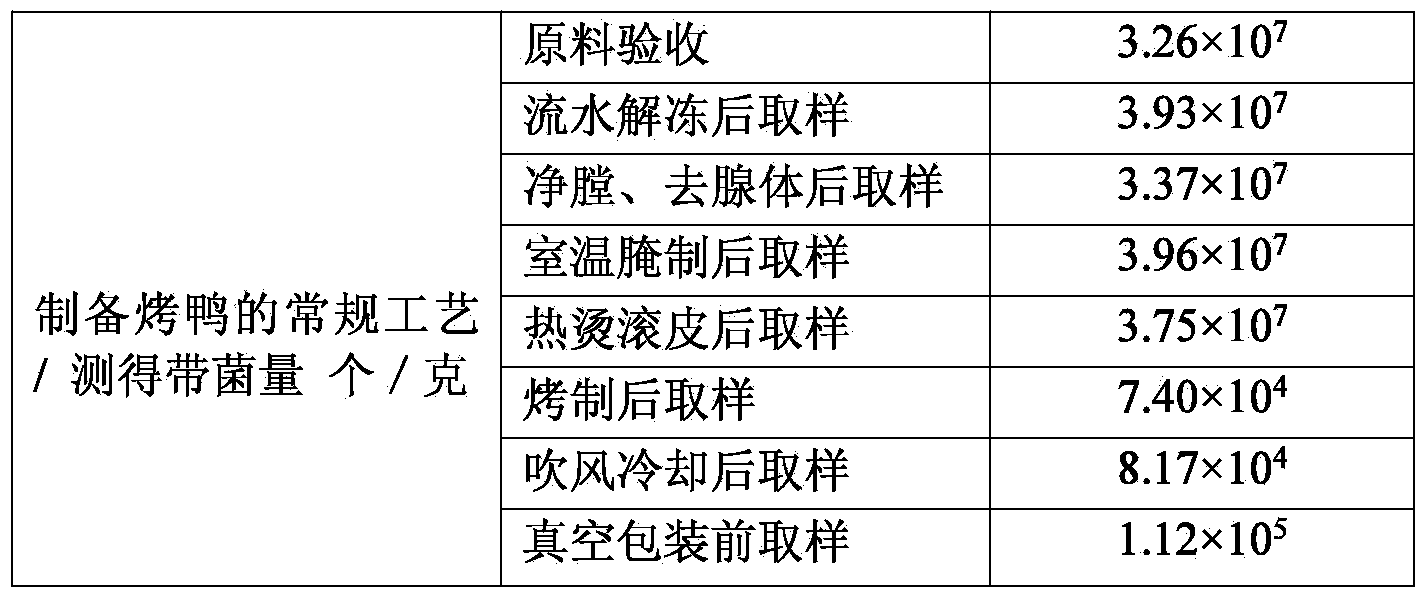

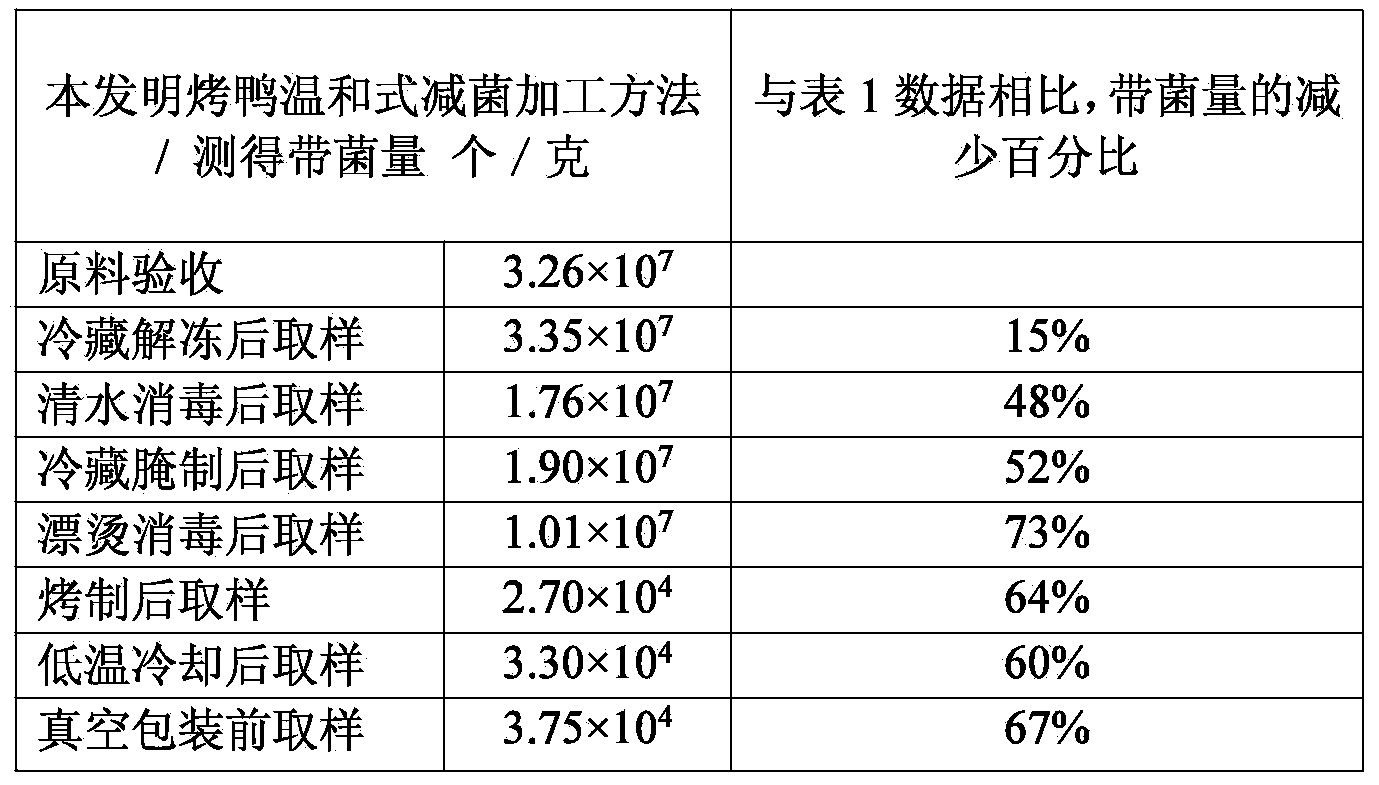

Gentle type decontamination processing method for meat product

ActiveCN103719231AGuaranteed textureGuaranteed tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsCooking & bakingAdditive ingredient

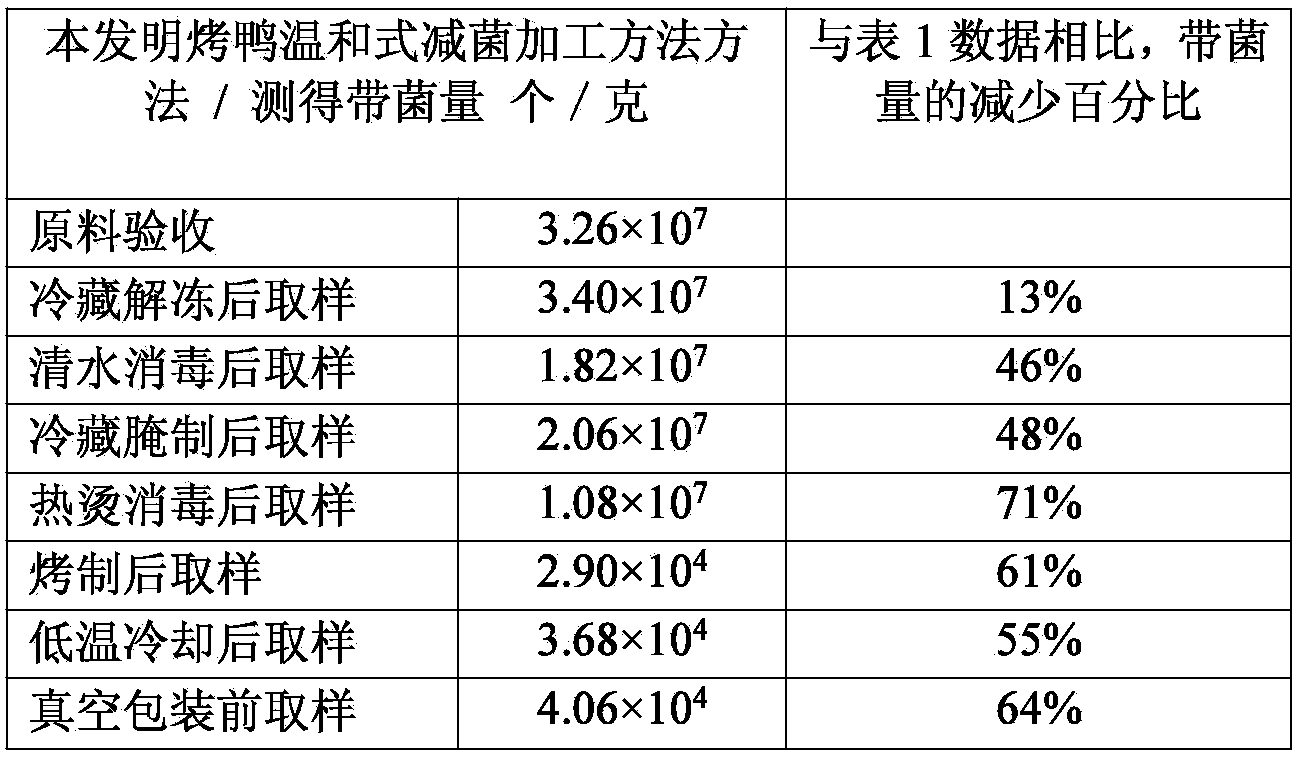

The invention provides a gentle type decontamination processing method for a meat product. The gentle type decontamination processing method comprises the following flow: checking and accepting raw materials; putting into a storage and refrigerating and storing; delivering and checking; refrigerating and thawing; washing and disinfecting; refrigerating and pickling; blanching, disinfecting and baking or marinating; cooling at low temperature; metering and dividing; packaging in vacuum; sterilizing; cooling by cold flow water; airing outer water; and checking and storing. According to the gentle type decontamination processing method for the meat product, a series of decontamination measures are added in a raw material meat processing process; the bacteria carrying amount of the meat product packaged in vacuum is reduced and the sterilization strength in a terminal high-temperature sterilization process is reduced; the color, the aroma, the taste and the shape, and the nutritional ingredients of the meat product are kept unchanged to the greatest extent. Correspondingly, the gentle type decontamination processing method for the meat product provided by the invention is also applicable to processing vegetables with long shelf lives.

Owner:北京中农探味科技有限公司

Composite method for quality-preserving shelf life of conditioning eight-treasure sauce

ActiveCN109730234AGrowth inhibitionReduce lossesFood preservationEpsilon-PolylysineVegetable processing

The invention relates to a composite method for prolonging quality-preserving shelf life of conditioning eight-treasure sauce, and belongs to the technical field of food processing. The eight-treasuresauce processing process comprises vegetable processing, meat processing, hot processing and addition of epsilon-polylysine, then the conditioning eight-treasure sauce is prepared; a kelp carbon quantum dot solution is added into the conditioning eight-treasure sauce after the conditioning eight-treasure sauce is cooled, low-frequency ultrasonic wave synergistic treatment is adopted at the same time, packaging, low-intensity radio frequency and hot air combined sterilization, cooling are carried out, and storing is carried out at room temperature. The method adopts the following steps: combination of epsilon-polylysine, the kelp carbon quantum dot solution and low-frequency ultrasonic wave synergistic treatment with low-intensity radio frequency and hot air combined sterilization can effectively prolong the shelf life of the product to 12 months, and ensure that the conservation rate of sensory quality such as color, fragrance, taste and the like of the conditioning eight-treasure sauce is over 90 percent to the utmost extent.

Owner:JIANGNAN UNIV +1

Preparation method of can containing Urechis unicinctus with tomato juice

InactiveCN105639508AImprove sensory qualityPrevent agingMeat/fish preservation using chemicalsMeat/fish preservation by irradiation/electric treatmentTomato ketchupNutrition

The invention discloses a preparation method of a can containing Urechis unicinctus with tomato juice. The method mainly solves the problems of eating inconvenience and short storage life, because only fresh Urechis unicinctus can be eaten and Urechis unicinctus powder is agglomerate easily. Soft hair parts, internal organs and blood of fresh Urechis unicinctus are removed, after cleaning, water is drained, Urechis unicinctus is cut into segments, and after salting, blanching and dehydrating, Urechis unicinctus segments are prepared; plant oil, chopped green onion, catsup, granulated sugar, salt, chilli oil, yellow rice wine, edible vinegar and water are used for preparing a tomato juice ingredient; Urechis unicinctus segments and the tomato juice ingredient are packed into cans, nisin is added, after exhausting, vacuum closing, washing of cans, cold sterilization with electron beam radiation, and cooling, the can product containing Urechis unicinctus with tomato juice is prepared. The preparation method has the advantages of reasonable process, scientific steps, and feasible operation; and the can containing Urechis unicinctus with tomato juice has the advantages of abundant nutrition, elastic and tender mouthfeel, delicious taste, eating convenience, and long storage life.

Owner:SHANDONG HOMEY AQUATIC DEV

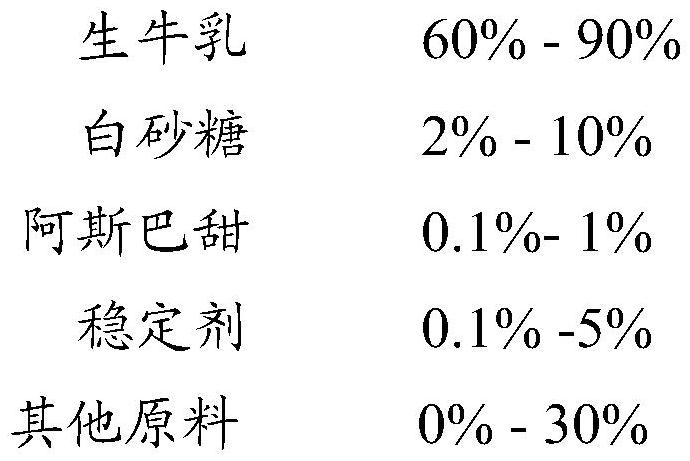

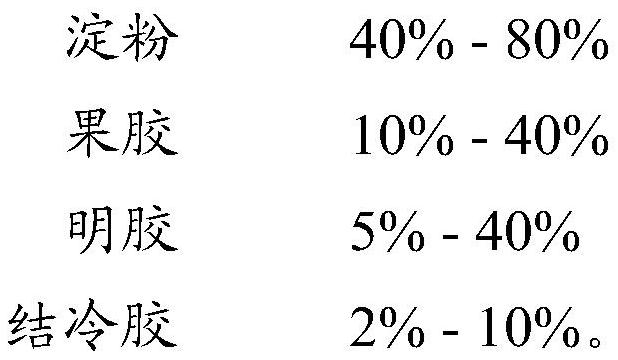

Normal-temperature yoghourt and preparation method thereof

PendingCN113133484AGuaranteed qualityTo achieve the effect of heating at the same timeMilk preparationFood thermal treatmentBiotechnologyNutrition

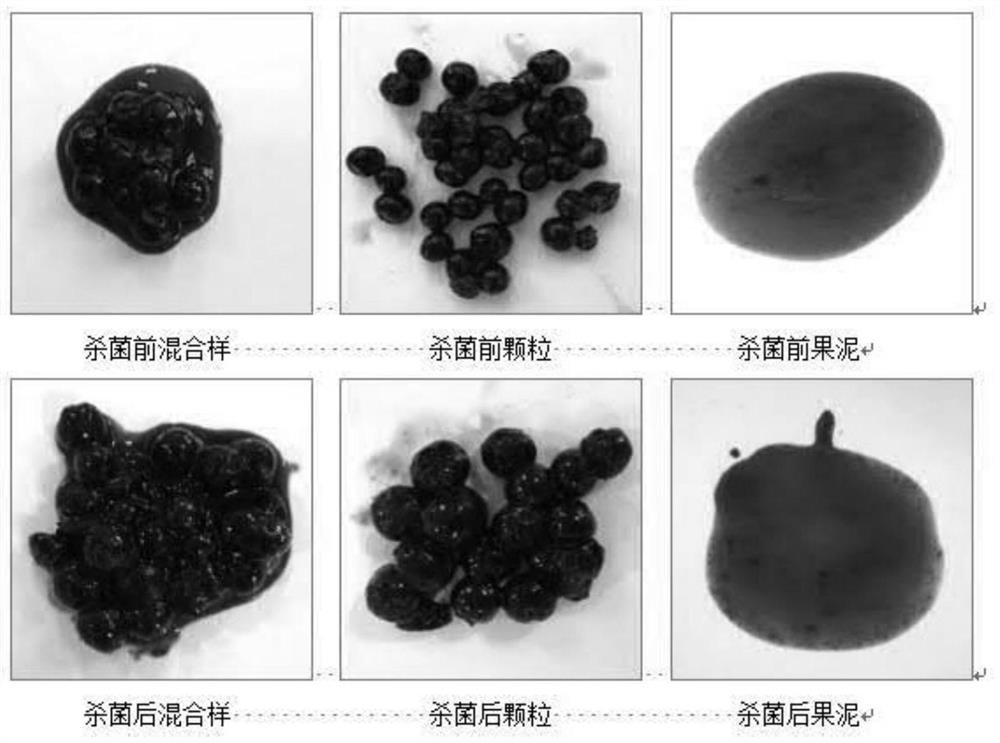

The invention relates to normal-temperature yoghurt and a preparation method thereof, in particular to normal-temperature yoghurt and a method for producing the normal-temperature yoghurt by an ohmic sterilization process. The normal-temperature yoghourt containing large fruit particles is prepared mainly by adjusting the treatment and sterilization process of the fruit particles (including adjusting the pretreatment step of the fruit particles and replacing a traditional fruit particle sterilization method with an ohmic sterilization method), and the preparation method effectively solves the problem of damage of the large fruit particles in the product. The stability of a product system is ensured, and fruit grains are complete and full. The yoghurt also has the advantages of rich nutrition, excellent flavor and taste, good stability and capability of being stored at normal temperature.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method for decontaminating dehydrated garlic products

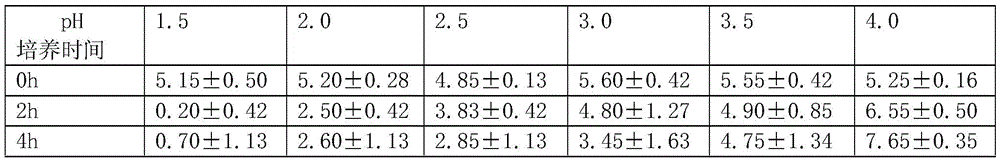

InactiveCN108567098AReduce the amount of bacteriaSolve slow salesMagnetic separationFood dryingElectrolysisColony count

The invention discloses a method for decontaminating dehydrated garlic products. The method for manufacturing the dehydrated garlic products includes steps of soaking and disinfecting selected garlicin acidic electrolytic water with the pH (potential of hydrogen) value of 2-4 for 5-15 min and then cleaning the garlic by the aid of pure water; placing the garlic in ozone water, carrying out cooling treatment on the garlic for 5-10 minutes and splitting the garlic; secondarily treating split raw materials by the aid of ozone water for 20-40 minutes; draining raw materials treated by the aid ofthe ozone water, then carrying out stepped temperature control drying on the raw materials, in other words, drying the raw materials at the temperatures of 110-120 DEG C for 1-2 hours, gradually reducing the temperatures until the temperatures reach 60-80 DEG C, and continuing to dry the raw materials until the moisture contents of the raw materials are reduced and reach 5-8%. The method has the advantages that the quantity of germs carried by the garlic can be reduced by 60%-67%, late sterilization can be omitted, the sterilization intensity of the method is far lower than the sterilization intensity of conventional processing technologies, dehydrated garlic which is subjected to contamination treatment by the aid of the method is little in color and nutritional component change, but thetotal colony count of the dehydrated garlic can be obviously reduced and reaches high standards, and the problem of dull sale due to the fact that the total colony count of existing garlic products exceeds standards can be effectively solved by the aid of the method.

Owner:徐州农丰生物化工有限公司

Method for preparing fish-and-rice mixed breaded fish sticks by using microorganism leavening agent

The invention discloses a method for preparing fish-and-rice mixed breaded fish sticks by using a microorganism leavening agent. The method is characterized in that fresh fish or frozen fish is taken as a raw material; and the fish-and-rice mixed breaded fish sticks are prepared by the following steps: pretreating and mashing the fresh fish or the frozen fish; inoculating the leavening agent; and filling, fermenting, sterilizing, cooling and storing. To sum up, the fish-and-rice mixed breaded fish sticks prepared by the method disclosed by the invention have unique fermentation flavors, are soft, fine and smooth in texture, and have the advantages of high resilience, high nutritive value, good safety and long storage period, thereby especially providing a brand new processing way for processing freshwater fish in China.

Owner:SUZHOU DUORUNDUO AGRI TECH +1

Processing method capable of applying antimicrobial polypeptide and spices to poultry products in vacuum package

InactiveCN103202490AReduced Flavor VariationReduce texture deteriorationMeat/fish preservation using chemicalsFood preparationFlavorPoultry product

The invention provides a processing method capable of applying antimicrobial polypeptide and spices to poultry products in vacuum package; and the processing method takes fresh and alive poultry as raw material, and the poultry product can be prepared by the steps of slaughtering, cutting, cleaning, precooking, marinating, vacuum packaging, sterilizing and cooling. The processing method is characterized in that the marinating liquid containing the spices and seasonings is adopted during marinating; before the marinated product leaves a pot, mixed material formed by lysozyme, protamine, lactic acid streptococci and corn antioxidant peptide is added to the marinating liquid; and then, the product is cooled and packaged in a vacuum way. Based on the traditional poultry processing technology, the processing method comprehensively utilizes the modern sterilization technology with low sterilization intensity, the antioxidation technology and the flavor control technology, so that the traditional characteristic flavor of the poultry product with vacuum package can be maintained, and the poultry product in vacuum package is more nutrient and healthy; and the whole processing process is in accordance with the requirements on the food quality and safety, and industrial production is easily realized.

Owner:YANGZHOU XINGYUE FARM PROD

Method for producing yoghurt by Ohm sterilization process

ActiveCN113133483ASensitive to system stabilityGuaranteed qualityMilk preparationMilk preservationFood safetyNutrition

The invention relates to a method for producing yoghourt through an ohmic sterilization process, in particular to a method for producing normal-temperature yoghourt through the ohmic sterilization process. The method provided by the invention solves the problems of high sterilization strength, long heating time, poor stability, high stabilizer addition amount and the like caused by a traditional sterilization mode after fermentation. Specifically, the yogurt production process is improved, and the ohmic sterilization process is adopted to replace a traditional tubular or plate type sterilization machine heat exchange sterilization process, so that the heat treatment strength and the heating time are reduced on the premise of ensuring food safety, the stability of a product system is ensured to the greatest extent, meanwhile, the mechanical loss caused by a traditional sterilization mode is reduced, the damage of a sterilization process to a yoghourt tissue structure system is reduced, and the taste and the nutritional quality of the product are ensured.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

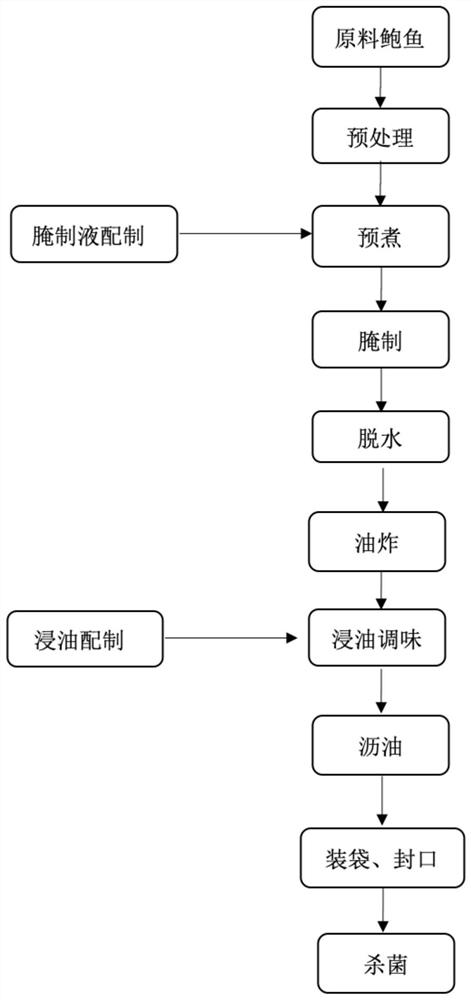

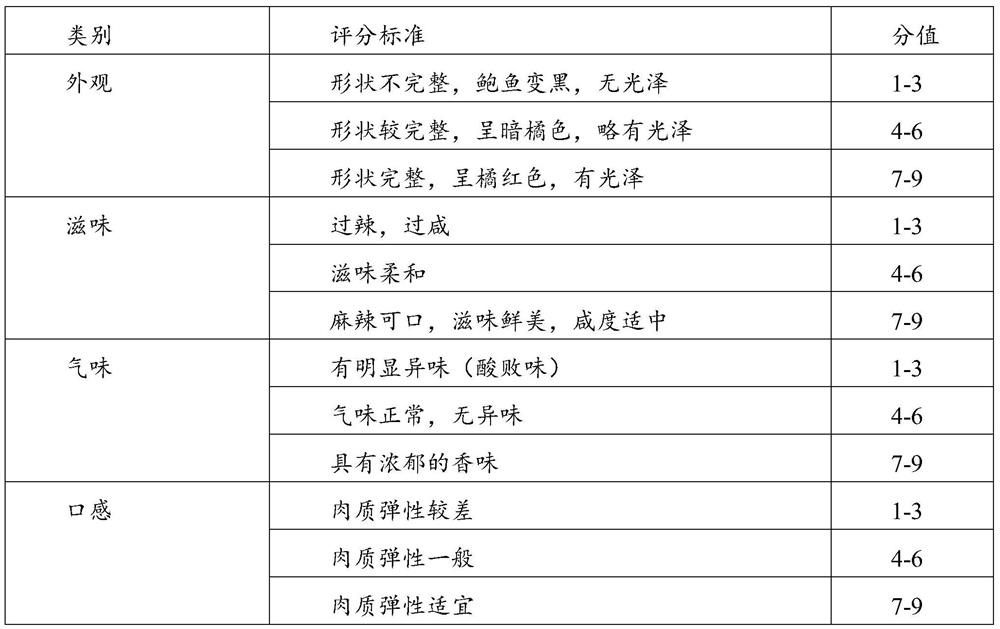

Processing method of instant abalones

The invention discloses a processing method of instant abalones, and belongs to the technical field of foods. According to the method, the abalones are better tasty through pre-cooking and pickling, and then seasoning oil containing a biological bacteriostatic agent is rapidly infiltrated through pulse impregnation, so that an abalone product has rich fragrance, the biological bacteriostatic agentin the seasoning oil can effectively inhibit germination of heat-resistant spores, the heat sterilization intensity is greatly reduced on the basis of realizing normal-temperature storage of the instant abalones, the damage of heat sterilization to the texture and flavor of the abalones is remarkably reduced, and better texture, flavor and color are kept under the condition of higher moisture content (the moisture content is more than 65%).

Owner:江苏欣悦海食品科技有限公司

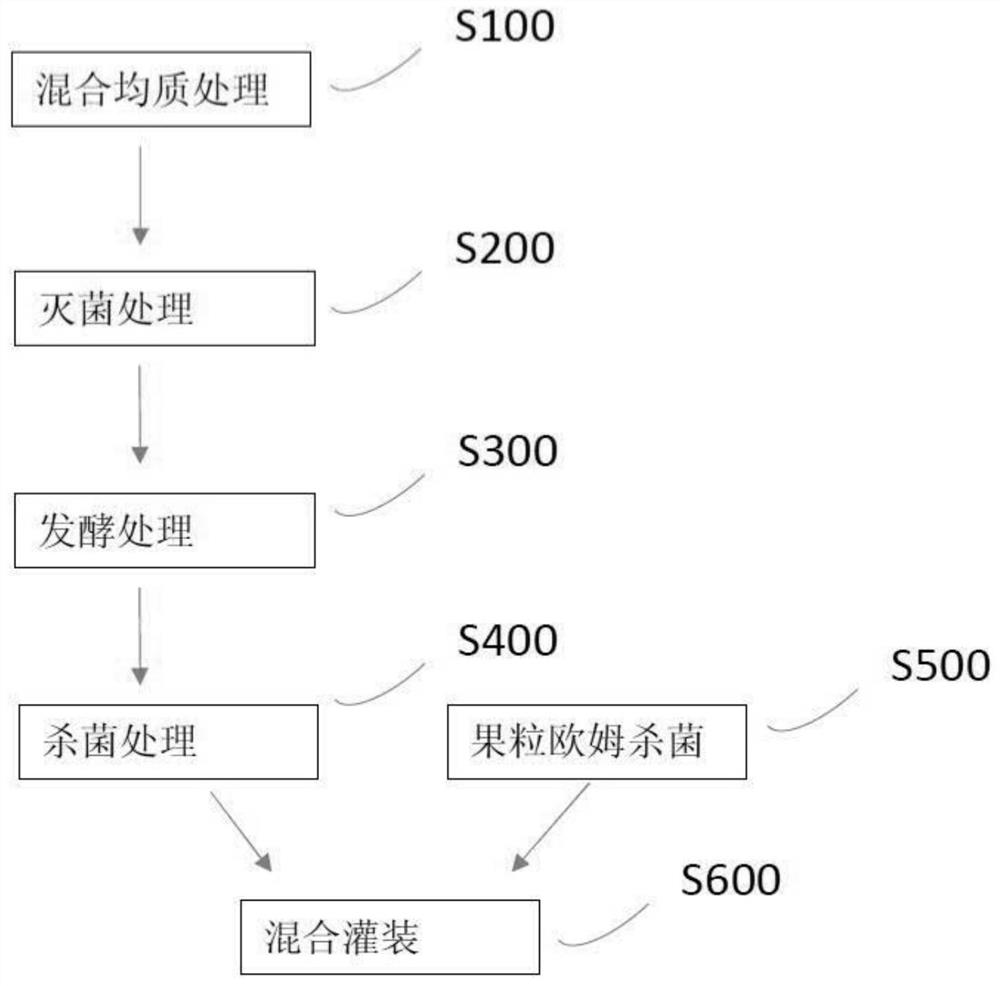

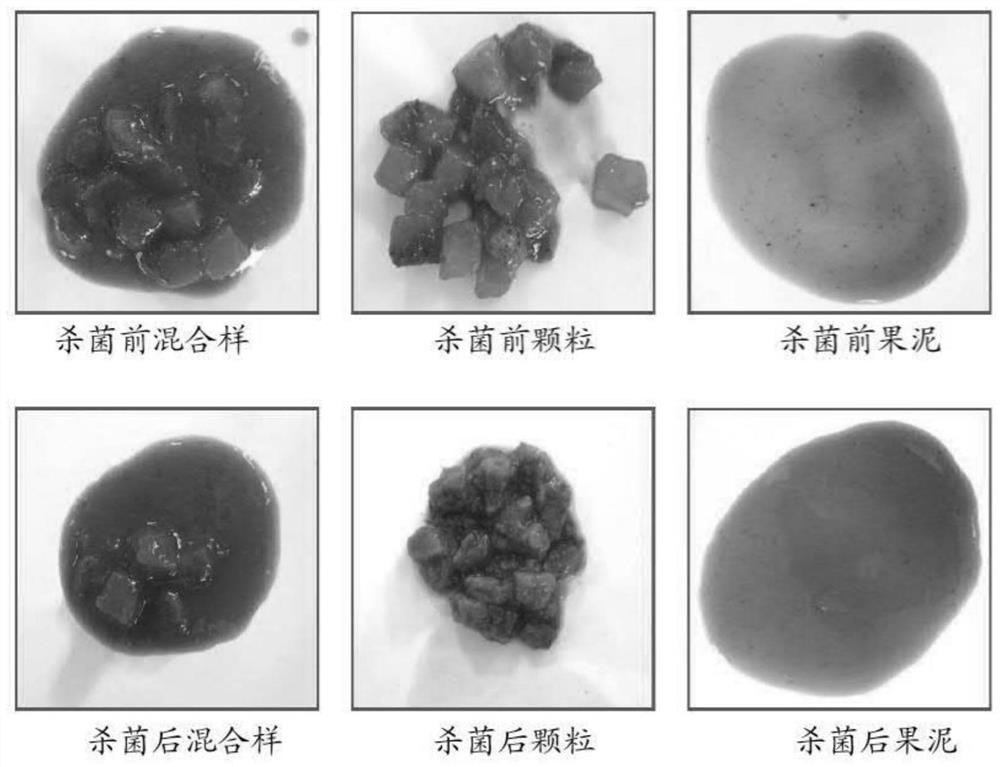

Method for producing dairy product containing fruit grains by ohmic sterilization process

PendingCN113133486AHeating evenlyTo overcome the heat transfer rate depends on the temperature gradient in the direction of heat transfer and other deficienciesMilk preparationFood thermal treatmentBiotechnologyFood safety

The invention relates to a method for producing a dairy product containing fruit grains by adopting an ohmic sterilization process. According to the present invention, a fruit particle sterilization process method is mainly adjusted, such that a traditional fruit particle sterilization process is replaced with the Ohmic sterilization method, such that the heat treatment strength is reduced on the premise of food safety ensuring, the fruit particle freshness is ensured to the maximum extent, the mechanical loss caused by the traditional sterilization mode is reduced, the fruit particle damage degree is reduced, and the taste is ensured. The product adopting the ohmic sterilization process is generally superior to a traditional tube type fruit granule sterilization process and a scraper type ultra-high temperature sterilization process in terms of overall flavor, fruit taste and product color.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Modern method for processing special poultry

InactiveCN101637274AShorten the fermentation cycleOptimizing Fermentation ConditionsMeat/fish preservation by heatingMeat/fish preservation using chemicalsFlavorChinese traditional

The invention relates to a modern method for processing special poultry, belonging to the field of food processing. The method researches processing theories and modern key technologies of Chinese traditional poultry meat products, breaks through the modern key processing technologies of poultry meat products, such as a modern sterilization technology, a rapid fermentation technology, a modern pickling technology, an oxidative stability control technology, a flavor control technology, a large-scale industrialized engineering technology, and the like and develops a series of safe, health and novel poultry meat products with traditional flavor specialties.

Owner:沛县凯润食品有限公司

Flexible sterilization method for promoting storage of flavor of fish tablet sauce

ActiveCN102487987BPromote resource utilizationReduce the sterilizing strengthMeat/fish preservation by heatingNutritive valuesWater activity

The invention relates to a flexible sterilization method for promoting the storage of flavor of fish tablet sauce, which belongs to the field of the processing and the storage of sauce food and fish by-products. According to the flexible sterilization method for promoting the storage of the flavor of the fish tablet sauce, flexible sterilization is carried out to fish tablet sauce for 10min at 90DEG C; nano-silver and nano-zinc oxide are added as a preservative when fish tablet sauce is prepared; the grain size of the nano-silver is 80nm to 100nm, and the addition of the nano-silver is 0.10mg / kg sauce to 0.13 mg / kg sauce; the grain size of the nano-zinc oxide is 55nm to 80nm, and the addition of the nano-zinc oxide is 0.10mg / kg sauce to 0.15 mg / kg sauce; and due to the prescription of the sauce, the water activity aw is controlled to be 0.8 to 0.9, the pH value is controlled to be 4.0 to 4.1, and the shelf life of the finished product reaches 12 months. The flexible sterilization method for promoting the storage of the flavor of the tablet sauce fully applies the hurdle effect, so that a longer shelf life can be realized at the low-sterilization intensity under 90DEG C for 10min. The invention not only fully utilizes fish offal mince to prepare the fish tablet sauce with mushroom flavor, rich sauce flavor, high nutritional value and unique flavor, but also provides a method for safely storing the sauce under the condition of short-time sauceurization.

Owner:JIANGNAN UNIV

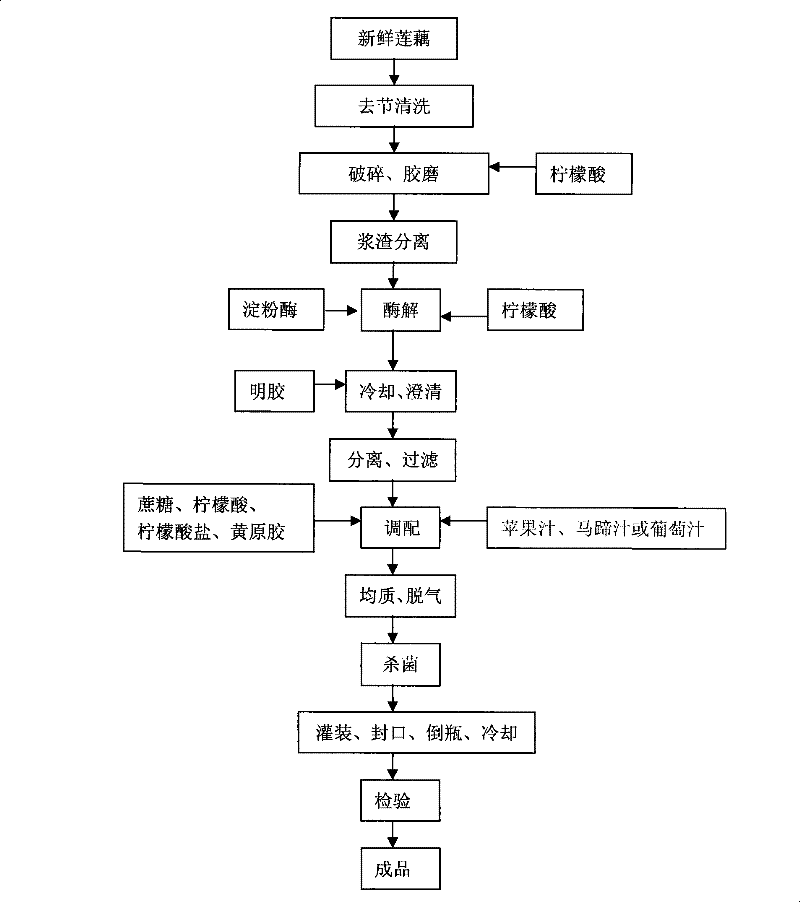

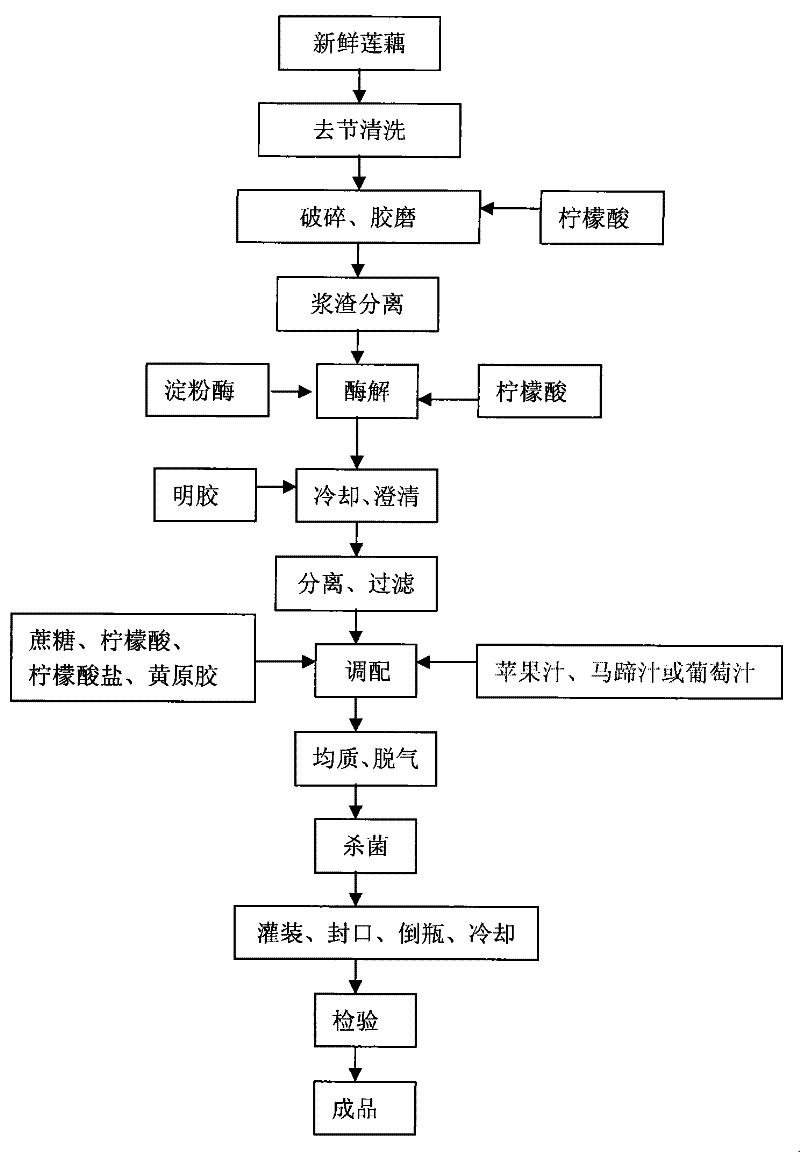

Method for processing clear type lotus rhizome juice series drink in PET bottles

InactiveCN101297709BSolve precipitationIncrease the juice yieldFood preparationFiltrationAdditive ingredient

The invention relates to a processing method for a PET bottling clarifying lotus root juice series drink, belonging to the technical field of food processing. The method takes fresh lotus root as raw material and produces the novel PET bottling clarifying lotus root juice series drink by carrying out the steps of nodus removal and washing, crushing, glue-grinding, slurry and dreg separation, zymohydrolysis, clarification, separation, filtration, preparation, homogenization, degasification, sterilization, hot filling, sealing, bottle falling, cooling and inspection, and utilizing modern biotechnology, color protecting technology and conserving technology. The lotus root juice drink produced by the method of the invention has full-bodied lotus root flavor due to clarification, can be conserved at normal temperature, is convenient to be drunk and adopts one-time sterilizing hot filling with low sterilization strength, thus having less damages to the nutrient content of the products.

Owner:JIANGNAN UNIV

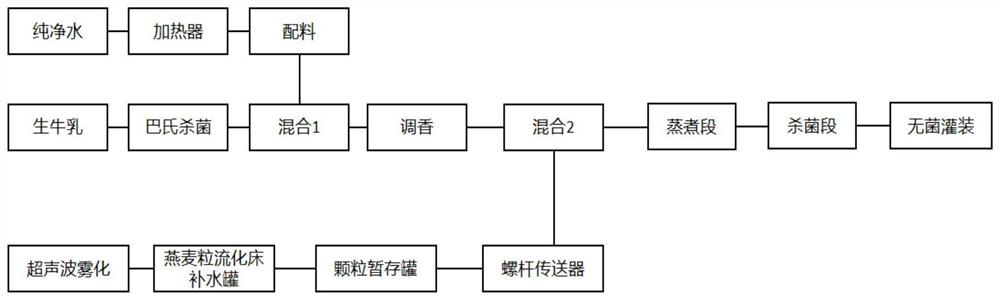

Method for producing cereal milk

ActiveCN114190439AGuaranteed qualityEnsure safetyMilk preparationMilk preservationBiotechnologyAnimal science

The invention relates to cereal milk and a preparation method thereof, in particular to a method for producing cereal milk by adopting an ultrasonic fluidization water replenishing and / or ohm sterilization process. According to the invention, through combination of ohmic sterilization and ultrasonic fluidization water replenishing, the problems of brown stain of milk base materials, serious heat loss of particle surfaces and the like caused by the fact that solid and liquid of cereal milk products cannot be heated at the same time and the heat intensity of the whole sterilization process is at a relatively high level at present are solved; as the water content is low, cereal grains are generally not suitable for ohmic sterilization; according to the present invention, the rapid cold water supplementing of the grain particles is achieved through the ultrasonic wave fluidization water supplementing technology, and the natural characteristics of the grains are not damaged while the water content of the particles is increased, such that the ohmic sterilization of the grain particles is achieved so as to obtain the grain milk with characteristics of complete particles and good taste.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Clarified purple yam drink and preparation method thereof

ActiveCN105851734BPreserve the flavorRetain nutritionFood ingredient functionsAdditive ingredientTrehalose

The invention provides a natural clear purple yam beverage and a sweet clear purple yam beverage, and production methods thereof. The production method of the natural clear purple yam beverage comprises the following steps: blanching color protection, beating refinement, enzymatic hydrolysis clarification, pH adjustment, filling, and sterilizing. Ingredients of the sweet clear purple yam beverage comprise, by mass, 92-98 parts of a purple yam enzymatic hydrolysis liquid, 1-4 parts of edible sugar, 1-3 parts of trehalose, 0.03-0.08 parts of edible salt, 0.1-0.9 parts of a concentrated snow pear juice and 0.02-0.04 parts of citric acid. The production method of the sweet beverage mainly comprises blending, filling and sterilizing steps. The two clear purple yam beverages have the advantages of pretty color, high transparency, refreshing mouthfeel, strong thirst quenching effect, richness in anthocyanidins, and no artificial pigments, essences or antiseptics.

Owner:SICHUAN UNIV

The preparation method of clarified yam drink

ActiveCN105724995BPreserve the flavorRetain nutritionFood ingredient as flavour affecting agentForest yamHydrolysate

The invention discloses a plain and sweet clear Chinese yam beverage and a making method thereof.The plain clear Chinese yam beverage is made through blanching, color protecting, pulping, refining, enzymolysis to be clear, pH adjusting, filling, sterilizing and other procedures with fresh Chinese yam as the raw material.The sweet clear Chinese yam beverage is made from, by mass, 90-98 parts of Chinese yam enzymatic hydrolysate, 1-6 parts of edible sugar, 0.5-3.5 parts of trehalose, 0.05-0.15 part of edible salt, 0.1-0.5 part of concentrated pear juice and 0.01-0.03 part of citric acid.The making steps mainly include blending, filling and sterilizing.The plain and sweet clear Chinese yam beverage is fresh and cool in taste, strong in thirsty relieving property, high in transparency, and free of any artificial pigment, essence and preservatives.

Owner:SICHUAN UNIV

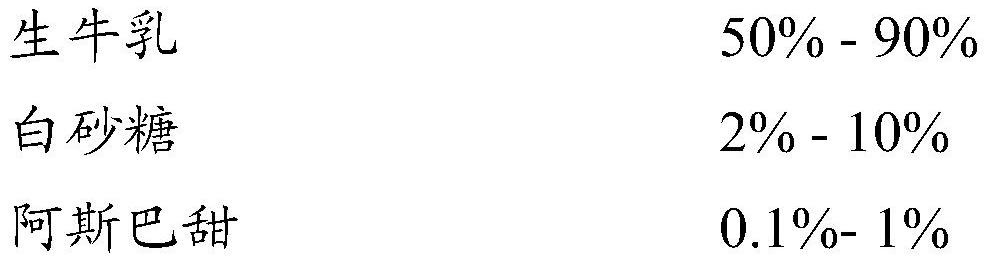

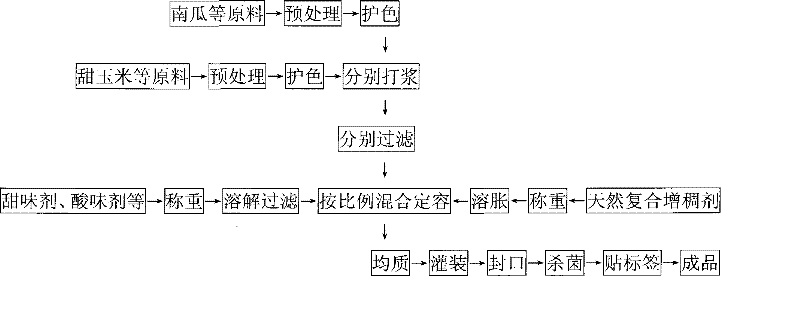

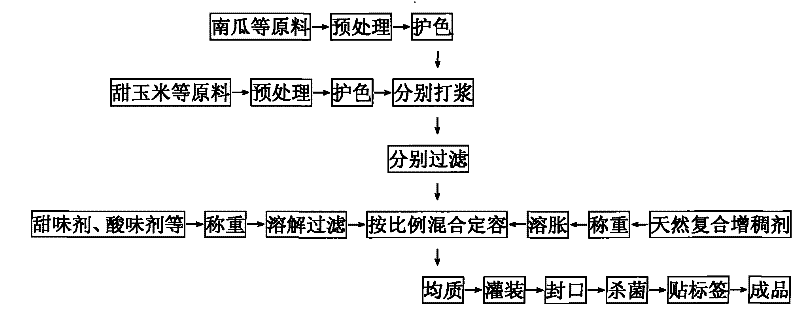

Pumpkin sweet-corn beverage and preparation method thereof

InactiveCN101103830BStrong production practicabilityEasy to keepFood preparationPumpkin seedAdditive ingredient

The invention discloses a safe low-sugar beverage which takes pumpkin and sweet corn as the main raw materials, and is added with the auxiliary materials of sweetener, sour agent and thickener, and the production method. The pumpkin, sweet corn beverage ingredients is based on the weight of the beverage of 100Kg according to the percentage by weight; the ingredients comprises pumpkin pulp of 1Kg to 5Kg, shelled corn of 5Kg to 10Kg, composite sweetener of 0.02Kg to 0.05Kg, composite acetic acid of 0.15Kg to 0.3Kg, natural composite stabilizer of 0.1Kg to 0.25Kg, the remainder are water. After the protective coloration is implemented, the raw materials are crushed and pulped for making the jatex; the dissolution rate of the soluble solid of the raw materials can be increased without enzyme preparation by regulating the ratio of the raw materials and the water. The invention has the advantages that: the processing time is shortened; the processing costs are lowered; the mineral composition, vitamins and dietary fiber are reserved. The product also has the advantage of low sugar, low energy and rich nutrition, thereby which is easy to be accepted by the people.

Owner:XINJIANG UNIVERSITY

Mycelium control and quality guaranteeing method for reducing heat sterilization intensity for conditioning fowl or fish product

InactiveCN101700051BEnsure safetyReduce the sterilizing strengthMeat/fish preservation using chemicalsQuick FreezeAdditive ingredient

The invention relates to a mycelium control and quality guaranteeing method for reducing the heat sterilization intensity for conditioning fowl or fish product, belonging to the technical field of cooked meat product sterilization. The method mainly comprises the process: after being unfrozen, cut and washed, raw material is cooked according to the formulation; after being cooked for a certain period of time, nisin and other auxiliary materials are added into the raw material; after reaching a certain ripening degree, the mixture is cooled and packaged by vacuum; and the product is quick-frozen at ultralow temperature and then treated by flexible heat sterilization. The method has the advantages the fowl or fish product with high quality and long quality guarantee period can be obtained by the operation; (1) by compounding the nisin and potassium sorbate, antibacterial spectrum can be expanded; and (2) by combining freezing sterilization and the flexible heat sterilization, good sterilization effect can be achieved by large temperature difference change within a short time. Therefore, the method reduces the damage for the nutritional ingredients of the fowl or the fish under pure high temperature sterilization, ensures the quality of the products and finally the mycelium control and quality guaranteeing cooked meat product on the premise of guaranteeing the shelf life of the product.

Owner:JIANGNAN UNIV +1

Technique for producing fermented spareribs by using compound leavening agent

ActiveCN103230022BHigh nutritional valueDelicious and uniqueFood preparationCooking & bakingMicroorganism

The invention belongs to the technical field of food processing and in particular relates to a technique for producing fermented spareribs by using a compound leavening agent. The technique comprises the following steps of: pretreatment of raw materials, pickling, predrying, frying, fermenting, baking, packaging, sterilizing and the like, wherein the compound leavening agent which takes microorganisms, such as lactobacillus plantarum, lactobacillus rhamnosus, Pediococcus pentosaceus and saccharomyces cerevisiae as strains is used for fermentation. The purpose of endowing spareribs with a basic fermentation flavor by using microbial fermentation is achieved; the nutritional value of the sparerib product is improved by fermentation; and the sparerib product do not need to be subjected to high-temperature and high-pressure sterilization by reducing the pH value of the sparerib product and combining the frying and baking processes, so that original taste and flavor of the sparerib product are ensured. The fermented sparerib product has the advantages of mellow flavor, high nutritional value, good safety, easiness in preservation, probiotic effect and the like; and due to development of the fermented spareribs, food which is unique in flavor, rich in nutritions and convenient to eat is provided for the society.

Owner:TENGQIAO FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com