Method for preparing fish-and-rice mixed breaded fish sticks by using microorganism leavening agent

A microbial fermentation agent and fish cake technology, applied in the fields of application, food preparation, food science, etc., can solve the problems affecting the healthy development of freshwater fish farming industry, the lack of freshwater fish deep processing technology, and the destruction of fish meat nutrients, etc., and achieve the purpose of inhibiting spoilage bacteria and pathogenic microorganism growth, unique fermentation flavor, and the effect of promoting peristalsis and secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

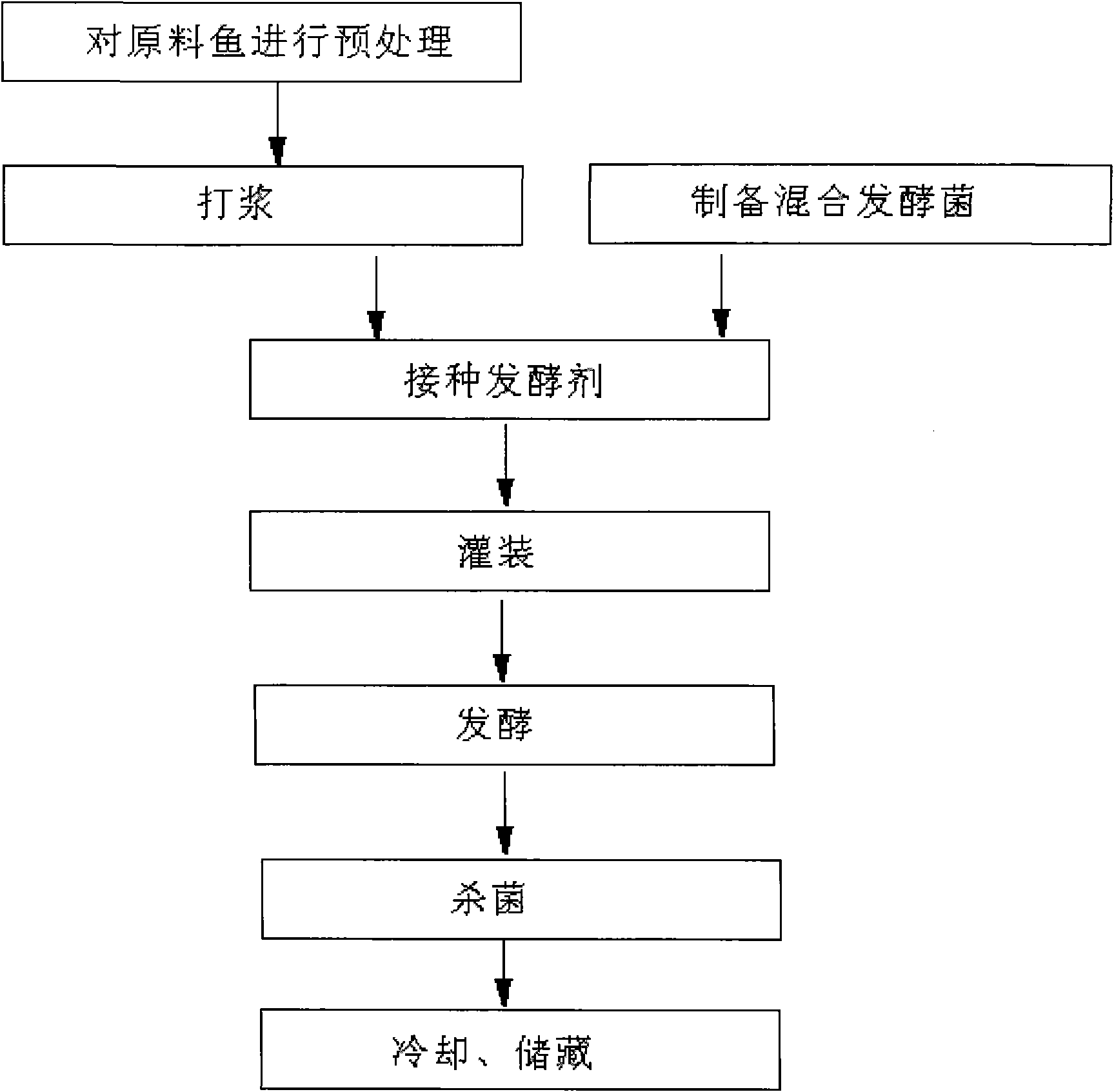

[0027] Fig. 1 is a process flow diagram of an embodiment of the present invention.

[0028] As shown in Figure 1: the method utilizing microbial starter to make fish rice mixed fish cake is characterized in that, comprises the following steps:

[0029] (1) Pretreatment of the raw fish: remove the scales, viscera, head and bones of the raw fish, rinse them with clean water, and cut them into fish meat cubes;

[0030] (2) Beating: Add steamed glutinous rice or glutinous rice flour, water, salt and auxiliary materials to the fish meat granules prepared in step (1), place them in a cooling room at a temperature of 0-5°C and chop for 5-8 minutes to make Fish paste, in which the amount of steamed glutinous rice or glutinous rice flour added is 5% to 20% of the mass of fish flesh, the amount of salt added is 0.5% to 2% of the mass of fish flesh, and the amount of auxiliary materials added is 2.03% to 5.0% of the mass of fish flesh %, while the mass ratio of water to fish meat grains...

Embodiment 1

[0041] Use fresh silver carp as raw material, remove scales, viscera, head and bones, rinse with clean water, cut into fish meat pieces, add 5% steamed glutinous rice and 100% drinking water according to the mass percentage of fish meat pieces , 1% salt, 1% glucose, 1% cooking wine, 0.03% sodium erythorbate, 0.2% polyphosphate, a little green onion, ginger, monosodium glutamate, chopped and stirred in a cooling room at 4°C for 5 minutes Fish pulp, then access is calculated as 2% mixed starter by fish pulp mass percentage, contains 10 in every gram of fish pulp after the inoculation 5 ~10 7 CFU fermentation bacteria, chopped and mixed evenly below 10°C, poured into the retort bag, vacuum sealed, fermented the filled fish paste at 30°C for 20 hours, sterilized at 115°C for 60 minutes, cooled, and stored at room temperature .

[0042] Preparation of the mixed starter described in this example: Lactobacillus plantarum L.plantarum, Pediococcus pentosaceus P.pentosaceus and Saccha...

Embodiment 2

[0044] Use fresh bighead carp as raw material, remove scales, viscera, head and bones, rinse with clean water, cut into fish meat pieces, add 15% steamed glutinous rice and 150% drinking water according to the mass percentage of fish meat pieces, 1.5% table salt, 1.5% glucose, 1% cooking wine, 0.05% sodium erythorbate, 0.3% polyphosphate, a little green onion, ginger, and monosodium glutamate, chop and mix in a cooling room at 4°C for 5 minutes to make fish meat pulp, and then insert the mixed starter that is 1.5% by the mass percentage of fish pulp, and after inoculation, every gram of fish pulp contains 10 5 ~10 7 CFU fermentation bacteria, chopped and mixed evenly below 10°C, poured into a plastic box, vacuum-sealed, fermented the canned fish paste at 37°C for 12 hours, sterilized at 95°C for 35 minutes, cooled and placed in 0 Store at ~10°C.

[0045] Preparation of the mixed starter described in this example: Lactobacillus plantarum L.plantarum, Lactobacillus casei L.cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com