Production method of high-solubility bean type edible protein

A technology with high solubility and production method, which is applied in the protein composition of vegetable seeds, protein food ingredients, applications, etc., can solve the problems of chemical residues, protein structure changes, bitterness, etc., achieve short reaction time, improve diet Structure, the effect of reducing the bactericidal intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

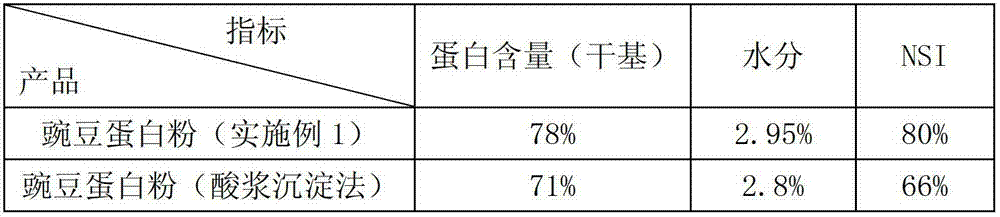

Embodiment 1

[0025] A method for producing high-soluble soybean edible protein, comprising the steps of:

[0026] (1) Sieve and wash: sieve and wash the dried peas with water to remove sediment impurities.

[0027] (2) Soaking: Soak the sifted and washed dry peas in water for 16 hours;

[0028] (3) Refining: take water according to the mass ratio of dry peas and water as 1:12, add some water to the soaked peas first, beat for 3 minutes with a beater, filter the slurry with an 80-mesh filter cloth, and then Add the remaining water to the filter residue, beat for 3 minutes, filter with 80 mesh filter cloth, and collect the filtrate;

[0029] (4) Place and stratify: put the filtrate obtained in step (3) to stand for 90 minutes, and the filtrate is stratified, and the light yellow protein layer crude liquid on the upper part is extracted, and the white starch layer precipitated at the bottom is used for vermicelli production;

[0030] (5) Protein acid precipitation: add lactic acid aqueous s...

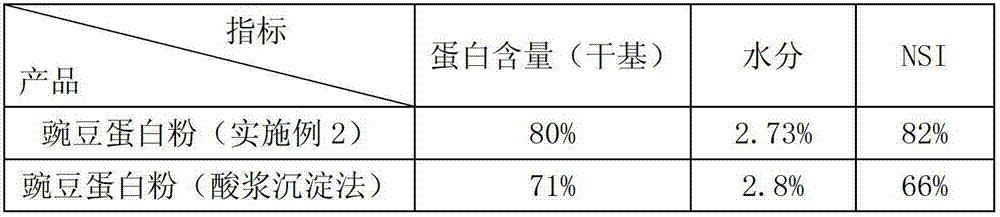

Embodiment 2

[0042] A method for producing high-soluble soybean edible protein, comprising the steps of:

[0043] (1) Sieving: sieve and wash the dried peas with water to remove sediment impurities;

[0044] (2) Soaking: Soak the sifted and washed dry peas in water for 32 hours;

[0045] (3) Refining: Take water according to the mass ratio of dry peas and water as 1:8, add some water to the soaked beans first, beat with a beater for 1min, filter the slurry with an 80-mesh filter cloth, and then put Add the remaining water to the filter residue, beat for 1 min, filter with 80 mesh filter cloth, and collect the filtrate;

[0046] (4) Place and stratify: put the filtrate obtained in step (3) to stand for 20 minutes, and the filtrate is stratified, and the crude liquid of the light yellow protein layer on the upper part is extracted, and the white starch layer precipitated at the bottom is used for vermicelli production;

[0047] (5) Protein acid precipitation: add lactic acid aqueous soluti...

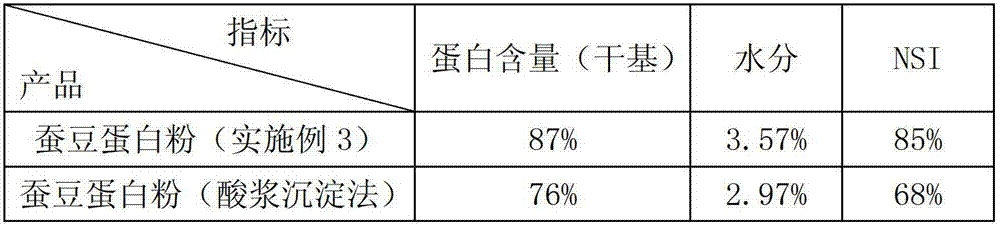

Embodiment 3

[0059] A method for producing high-soluble soybean edible protein, comprising the steps of:

[0060] (1) Screening and washing: sieve and wash the dried broad beans with water to remove sediment impurities;

[0061] (2) Soaking: Soak the sifted and washed dried broad beans in water for 24 hours, and peel them;

[0062] (3) Refining: Take water according to the mass ratio of dry broad beans and water as 1:12, add some water to the soaked broad beans first, beat for 3 minutes with a beater, filter the slurry with 80 mesh filter cloth, and then put Add the remaining water to the filter residue, beat for 3 minutes, filter with 80 mesh filter cloth, and collect the filtrate;

[0063] (4) Place and stratify: put the filtrate obtained in step (3) to stand for 90 minutes, and the filtrate is stratified, and the light yellow protein layer crude liquid on the upper part is extracted, and the white starch layer precipitated at the bottom is used for vermicelli production;

[0064] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com