Method for producing cereal milk

A milk and grain technology, applied in milk preservation, food science, milk preparations, etc., can solve problems such as low water content, affecting product quality, and damage to natural protective films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

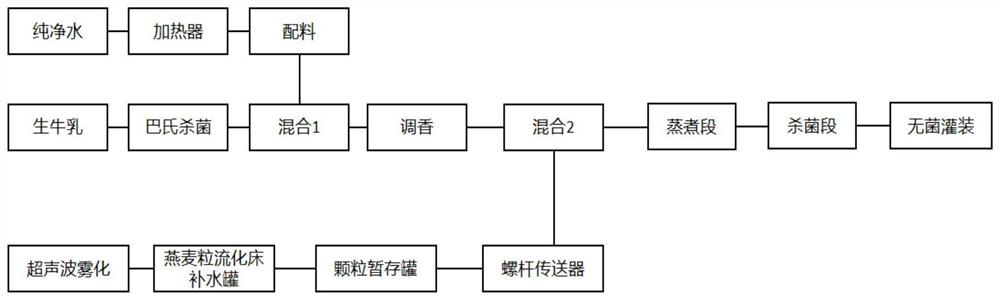

Method used

Image

Examples

Embodiment 1

[0096] This example provides a process combination of humidification for 20 minutes, cooking section at 90°C for 60s, and sterilization section at 133°C for 2s.

[0097] 1. Preparation process of cereal milk base material:

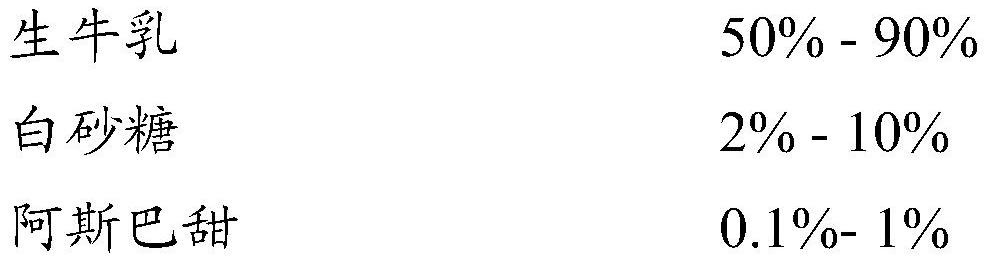

[0098]

[0099] Wherein the stabilizing agent is composed as follows:

[0100]

[0101] 1. Stir an appropriate amount of water, stabilizer, white sugar, etc. at a temperature of 25°C-60°C for 10-30 minutes;

[0102] 2. After the raw milk is pasteurized, it is stored in the batching tank for later use. The pasteurization temperature is 65°C-85°C and the time is 10-40s;

[0103] 3. Cool the chemical material solution and the pasteurized milk to 5°C respectively, then fully mix the two material solutions for 30 minutes, and the stirring speed is 45 rpm;

[0104] 4. According to the proportion, add the essence and mix it thoroughly for later use.

[0105] 2. Preparation process of oat grains:

[0106]

[0107] Selection of raw materials for oat gr...

Embodiment 2

[0114] This example provides a process combination of humidification for 20 minutes, cooking section at 105°C for 60s, and sterilization section at 133°C for 2s.

[0115] 1. Preparation process of cereal milk base material:

[0116]

[0117] Wherein the stabilizing agent is composed as follows:

[0118]

[0119] 1. Stir an appropriate amount of water, stabilizer, white sugar, etc. at a temperature of 25°C-60°C for 10-30 minutes;

[0120] 2. After the raw milk is pasteurized, it is stored in the batching tank for later use. The pasteurization temperature is 65°C-85°C and the time is 10-40s;

[0121] 3. Cool the chemical material solution and the pasteurized milk to 5°C respectively, then fully mix the two material solutions for 30 minutes, and the stirring speed is 45 rpm;

[0122] 4. Add essence according to the proportion and mix thoroughly before use.

[0123] 2. Preparation process of oat grains:

[0124]

[0125] Selection of raw materials for oat grains: choo...

Embodiment 3

[0132] This example provides a process combination of humidification for 20 minutes, cooking section at 115°C for 60s, and sterilization section at 133°C for 2s.

[0133] 1. Preparation process of cereal milk base material:

[0134]

[0135] Wherein the stabilizing agent is composed as follows:

[0136]

[0137] 1. Stir an appropriate amount of water, stabilizer, white sugar, etc. at a temperature of 25°C-60°C for 10-30 minutes;

[0138] 2. After the raw milk is pasteurized, it is stored in the batching tank for later use. The pasteurization temperature is 65°C-85°C and the time is 10-40s;

[0139] 3. Cool the chemical material solution and the pasteurized milk to 5°C respectively, then fully mix the two material solutions for 30 minutes, and the stirring speed is 45 rpm;

[0140] 4. Add essence according to the proportion and mix thoroughly before use.

[0141] 2. Preparation process of oat grains:

[0142]

[0143]

[0144] Selection of raw materials for oat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com