Method for preparing low-sugar primary-color chestnut paste through non-sulfur color protection technology

A technology of sulfur color protection and chestnut puree, which is applied in the field of preparing low-sugar and primary color chestnut puree, can solve the problems of misuse of sulfur-containing color protection agent, browning of chestnut puree products, high thermal processing intensity, etc. The effect of less pollution and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

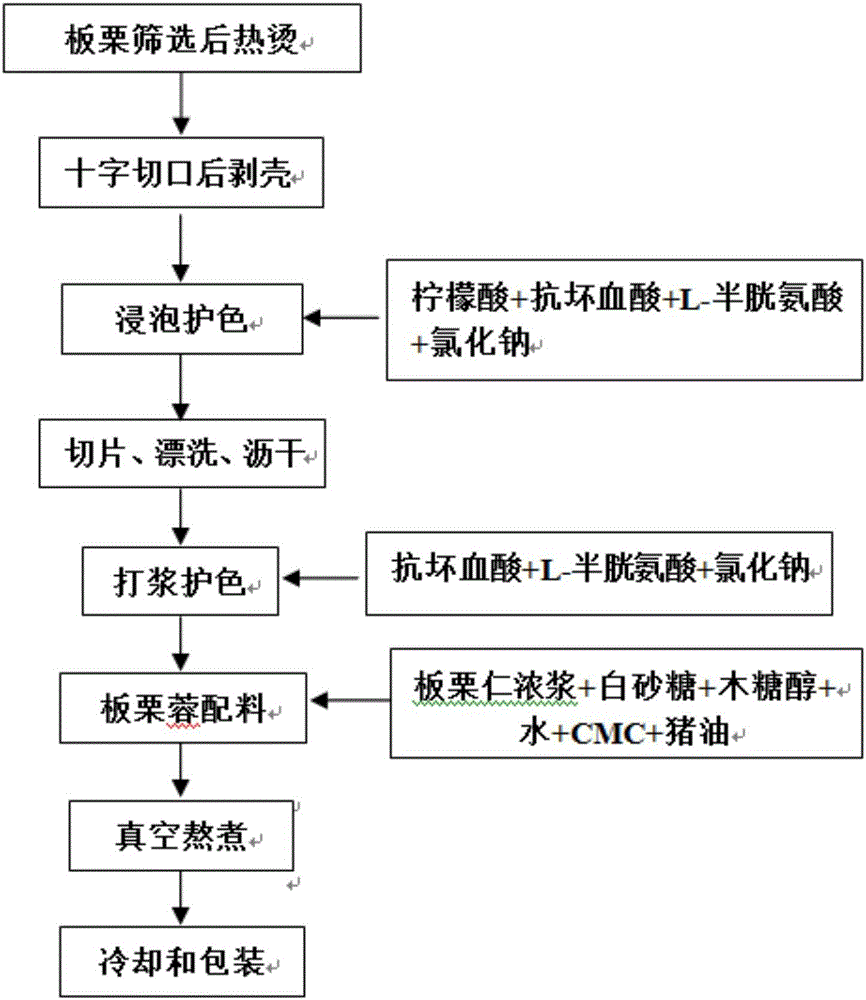

Image

Examples

Embodiment 1

[0026] A method for preparing low-sugar, primary-color pureed chestnuts using non-sulfur color protection technology, comprising the following steps:

[0027] (1) Pretreatment of chestnut

[0028] Put the chestnuts in 100°C water for 60 seconds after screening, take them out, draw a cross cut with a knife, peel off the shells one by one, and then put the chestnut kernels in 25°C soaking color protection solution (the formula is: citric acid 0.05wt% , 0.75wt% ascorbic acid, 0.17wt% L-cysteine, 2.00wt% sodium chloride, and the balance is water, soaked in the color-protecting solution (pH value 3.8) for 20min, took it out and cut it into about 0.5cm pieces, Rinse with distilled water, drain, and set aside.

[0029] (2) beating color protection

[0030]The chestnut kernel fragments of step (1) gained and beating color protection solution (prescription is: ascorbic acid 0.65wt%, L-cysteine 0.05wt%, sodium chloride 1.9wt%, surplus is water) according to 70 milliliters / The rati...

Embodiment 2

[0036] (1) Pretreatment of chestnut

[0037] Put the chestnuts in 100°C water for 30 seconds after screening, take them out, draw a cross cut with a knife, peel off the shells one by one, and then put the chestnut kernels in 10°C soaking color protection solution (the formula is: citric acid 0.05wt% , 0.75wt% ascorbic acid, 0.17wt% L-cysteine, 1.00wt% sodium chloride, and the balance is water, soaked in the color-protecting solution (pH value 3.8) for 30min, took it out and cut it into pieces of about 0.5 cm, Rinse with distilled water, drain, and set aside.

[0038] (2) beating color protection

[0039] The chestnut kernel fragments of step (1) gained and beating color protection solution (prescription is: ascorbic acid 0.65wt%, L-cysteine 0.05wt%, sodium chloride 1.5wt%, surplus is water) according to 50 milliliters / The ratio of 100 grams of chestnut kernel samples is poured into a blender for beating.

[0040] (3) Chestnut puree ingredients

[0041] Thoroughly mix th...

Embodiment 3

[0045] (1) Pretreatment of chestnut

[0046] Put the chestnuts in 100°C water for 30 seconds after screening, take them out, draw a cross cut with a knife, peel off the shells one by one, and then put the chestnut kernels in 40°C soaking color protection solution (the formula is: citric acid 0.05wt% , 0.75wt% ascorbic acid, 0.17wt% L-cysteine, 2.00wt% sodium chloride, and the balance is water, soaked in the color-protecting solution (pH value 3.8) for 10min, took it out and cut it into pieces about 0.5 cm, Rinse with distilled water, drain, and set aside.

[0047] (2) beating color protection

[0048] The chestnut kernel fragments of step (1) gained and beating color protection solution (prescription is: ascorbic acid 0.65wt%, L-cysteine 0.05wt%, sodium chloride 1.9wt%, surplus is water) according to 70 milliliters / The ratio of 100 grams of chestnut kernel samples is poured into a blender for beating.

[0049] (3) Chestnut puree ingredients

[0050] Thoroughly mix the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com