Method for producing dairy product containing fruit grains by ohmic sterilization process

A technology for ohmic sterilization and dairy products, applied in dairy products, milk preparations, applications, etc., can solve the problems that the volume heating method of ohmic sterilization cannot give full play to its advantages, pure liquid products cannot reflect the technical advantages, and there is little difference in ohmic sterilization , to achieve the effects of small mechanical damage, reduced heat loss, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This embodiment provides a method for producing a milk beverage with real taste of yellow peach particles.

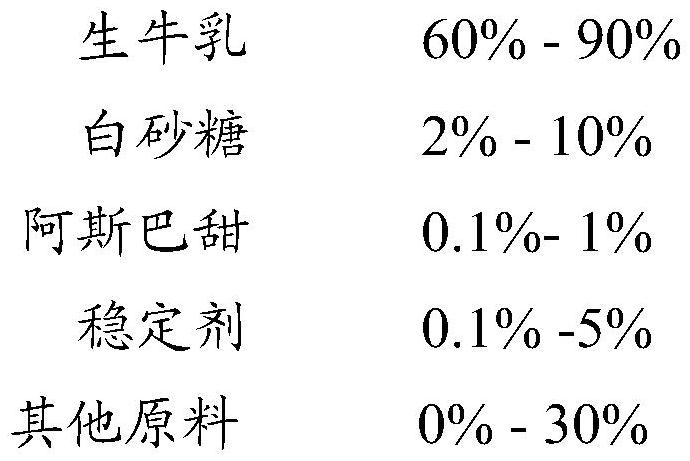

[0094] 1. Milk beverage base material preparation process:

[0095]

[0096] Wherein the stabilizing agent is composed as follows:

[0097]

[0098] 1. Disperse the starch, pectin, gelatin and gellan gum into the aqueous solution at room temperature with a high-speed shearing machine, and prepare a 5% stabilizer solution;

[0099] 2. Add white sugar and sweetener to raw milk, stir at 30°C for 20 minutes, mix well, and then add stabilizer solution;

[0100] 3. Stirring speed is 400-700 rpm;

[0101] 4. Homogenize after preheating to 50-65°C, and the homogenization pressure is 240bar;

[0102] 5. Ultra-high temperature sterilization treatment, the sterilization parameters are 121°C, 60s;

[0103] 6. Cool to the filling temperature of 30°C;

[0104] 7. Send it to the mixing aseptic tank and mix it with the fruit solution at a ratio of 10:1 by weight.

[...

Embodiment 2

[0118] This embodiment provides a method for producing a milk beverage with a taste of real pineapple particles.

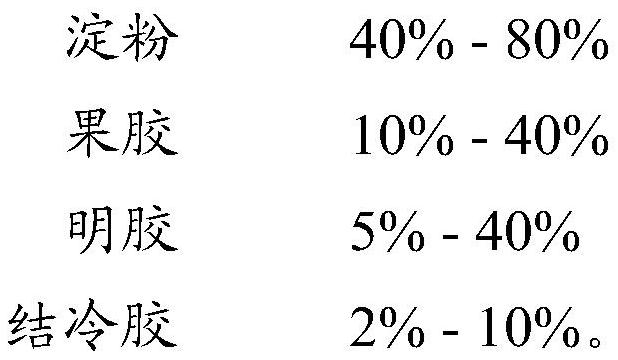

[0119] 1. Milk beverage base material preparation process:

[0120]

[0121]

[0122] Wherein the stabilizing agent is composed as follows:

[0123]

[0124] 1. Disperse the starch, pectin, gelatin and gellan gum into the aqueous solution at room temperature with a high-speed shearing machine, and prepare a 5% stabilizer solution;

[0125] 2. Add white sugar and sweetener to raw milk, stir at 30°C for 20 minutes, mix well, and then add stabilizer solution;

[0126] 3. Stirring speed is 400-700 rpm;

[0127] 4. Homogenize after preheating to 50-65°C, and the homogenization pressure is 240bar;

[0128] 5. Ultra-high temperature sterilization treatment, the sterilization parameters are 121°C, 60s;

[0129] 6. Cool to the filling temperature of 30°C;

[0130] 7. Send it to the mixing aseptic tank and mix it with the fruit solution at a ratio of 10:1 by w...

Embodiment 3

[0144] This embodiment provides a method for producing a milk beverage with a taste of real blueberry particles.

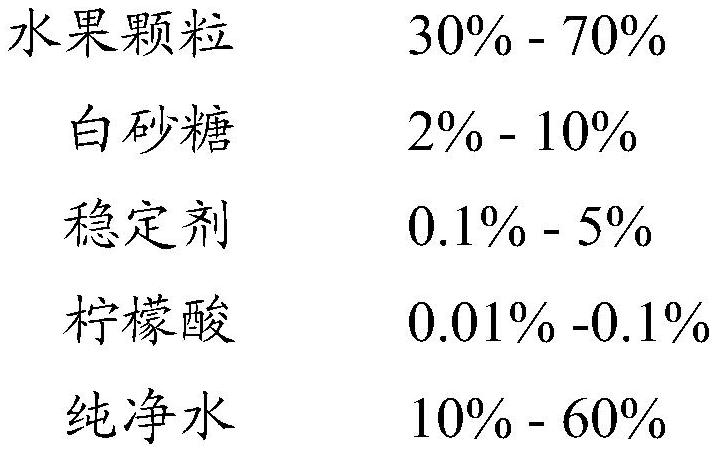

[0145] 1. Milk beverage base material preparation process:

[0146]

[0147] Wherein the stabilizing agent is composed as follows:

[0148]

[0149] 1. Disperse the starch, pectin, gelatin and gellan gum into the aqueous solution at room temperature with a high-speed shearing machine, and prepare a 5% stabilizer solution;

[0150] 2. Add white sugar and sweetener to raw milk, stir at 30°C for 20 minutes, mix well, and then add stabilizer solution;

[0151] 3. Stirring speed is 400-700 rpm;

[0152]4. Homogenize after preheating to 50-65°C, and the homogenization pressure is 240bar;

[0153] 5. Ultra-high temperature sterilization treatment, the sterilization parameters are 121°C, 60s;

[0154] 6. Cool to the filling temperature of 30°C;

[0155] 7. Send it to the mixing aseptic tank and mix it with the fruit solution at a ratio of 10:1 by weight.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com