Method for detecting oxidative deterioration of cured meat product

A detection method and oxidative deterioration technology, which is applied in the field of detection of oxidative deterioration of cured meat products, can solve the problems of not knowing the detection method and the explanation of the detection method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Detection method for oxidative deterioration of cured meat products

[0029] 1. Pretreatment of cured bacon

[0030] Weigh 10 g of evenly cured bacon products, put it into a 20 mL sample bottle, seal it, and keep the temperature at 60 ° C for 1 h. Insert the aged 50 / 30μm divinylbenzene / Carboxen / polydimethylsiloxane (DVB / CAR / PDMS) solid-phase microextraction tip into the sample bottle, push out the fiber head, and be careful not to let the extraction head touch to the meat sample. Adsorb at 60°C for 30 minutes, then withdraw the fiber head, pull out the extraction head from the sample bottle, insert the extraction head into the gas chromatography-mass spectrometer, push out the fiber head, desorb at 250°C for 10 minutes, pull back the fiber head and pull out the extraction head, and start the instrument to collect data at the same time.

[0031] 2. Gas chromatography conditions

[0032] DB-1701 (30m×0.32mm×0.25μm) quartz capillary column; helium: purity ≥ ...

Embodiment 2

[0038] Embodiment 2: Supplementary explanation as confirming experiment and data

[0039] 1. Detection method:

[0040] Zhongshan sausage and bacon were respectively selected as test objects, stored at 37°C, sensory evaluation was performed every 5-10 days, and the odor substances were detected according to Example 1.

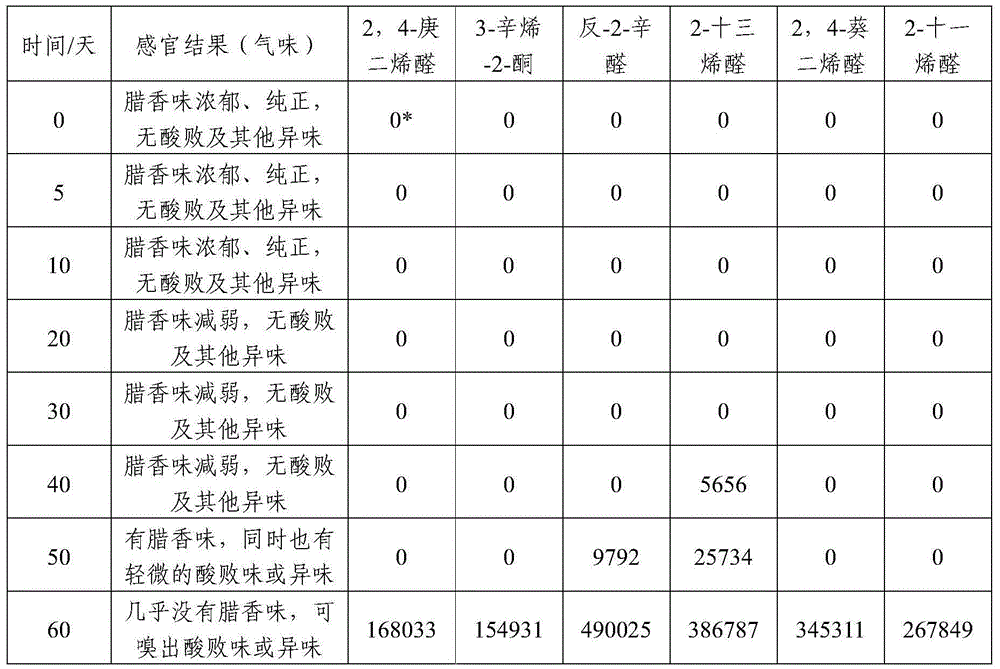

[0041] 2. Results: See Table 1 and Table 2

[0042] Table 1: Smell change table of Zhongshan sausage (under storage at 37°C)

[0043]

[0044] *:Peak area.

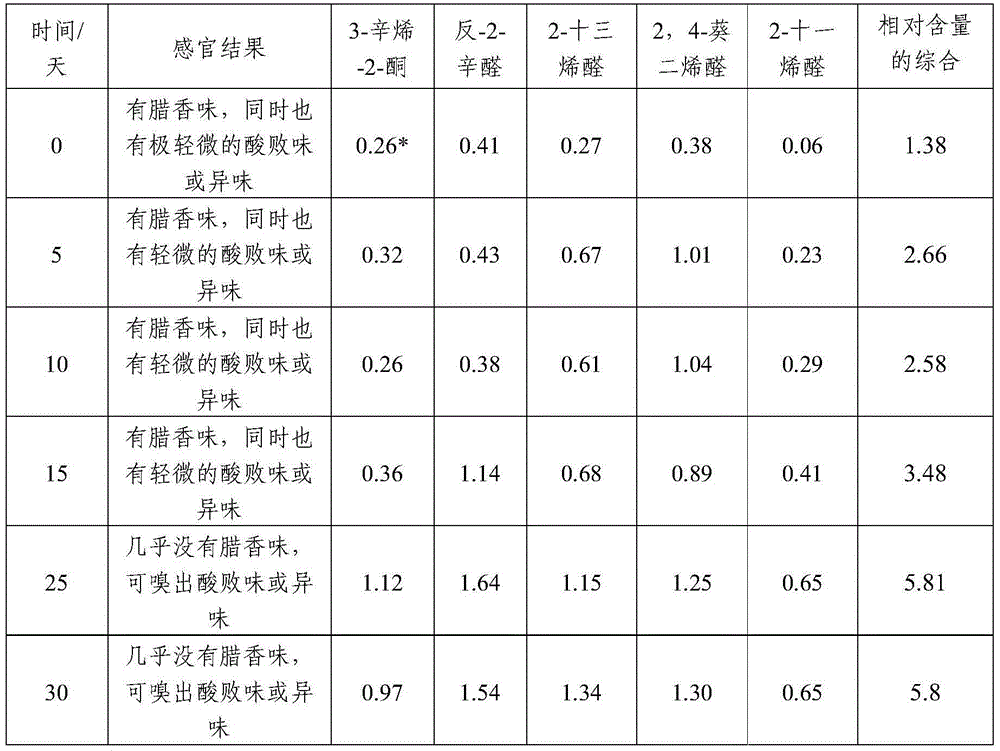

[0045] Table 2: Smell change table of bacon (under storage at 37°C)

[0046]

[0047] *: percentage content.

[0048] The results of Table 1 and 2 show that:

[0049] The first five batches of Zhongshan sausage did not produce the six odorous substances that caused the odor. Although no odorous substances were detected in the six batches, 2-tridecenal had been detected, and the seven batches produced 2-10 Trienal and trans-2-octanal, as time goes on, finally produce six kinds of odor substances...

experiment example 3

[0053] Choose a kind of cured meat products for destruction experiments, that is, to create a storage environment that is conducive to product oxidation, at a high temperature of 50 ° C, in bulk, that is, exposed to air and light, to speed up the oxidation speed of the product. After being stored for 20 days, the sample already had an obvious harsh smell, and the sample was analyzed and tested by the headspace solid-phase microextraction-mass spectrometry technique provided in Example 1, and the odor substances produced were qualitatively analyzed.

[0054] It was found that 2,4-heptadienal, 3-octen-2-one, trans-2-octanal, 2-tridecenal, 2,4-decadienal, 2-undecene All the substances were detected, and the content of the six components had reached 23.5%, which indicated that the product had a deep degree of fat oxidation and deterioration, which was consistent with the sensory results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com