Preparation method of cooled meat plastic film mat

A technology for fresh-keeping film and cooling meat, which is applied in the field of preparation of fresh-keeping film pads for cooled meat, can solve the problems of affecting the appearance and senses of cooled meat products, affecting the commercial value of the cooled meat, and the outflow of juice, so as to improve the sensory quality of products and achieve good fresh-keeping effect. , Control the effect of fat oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

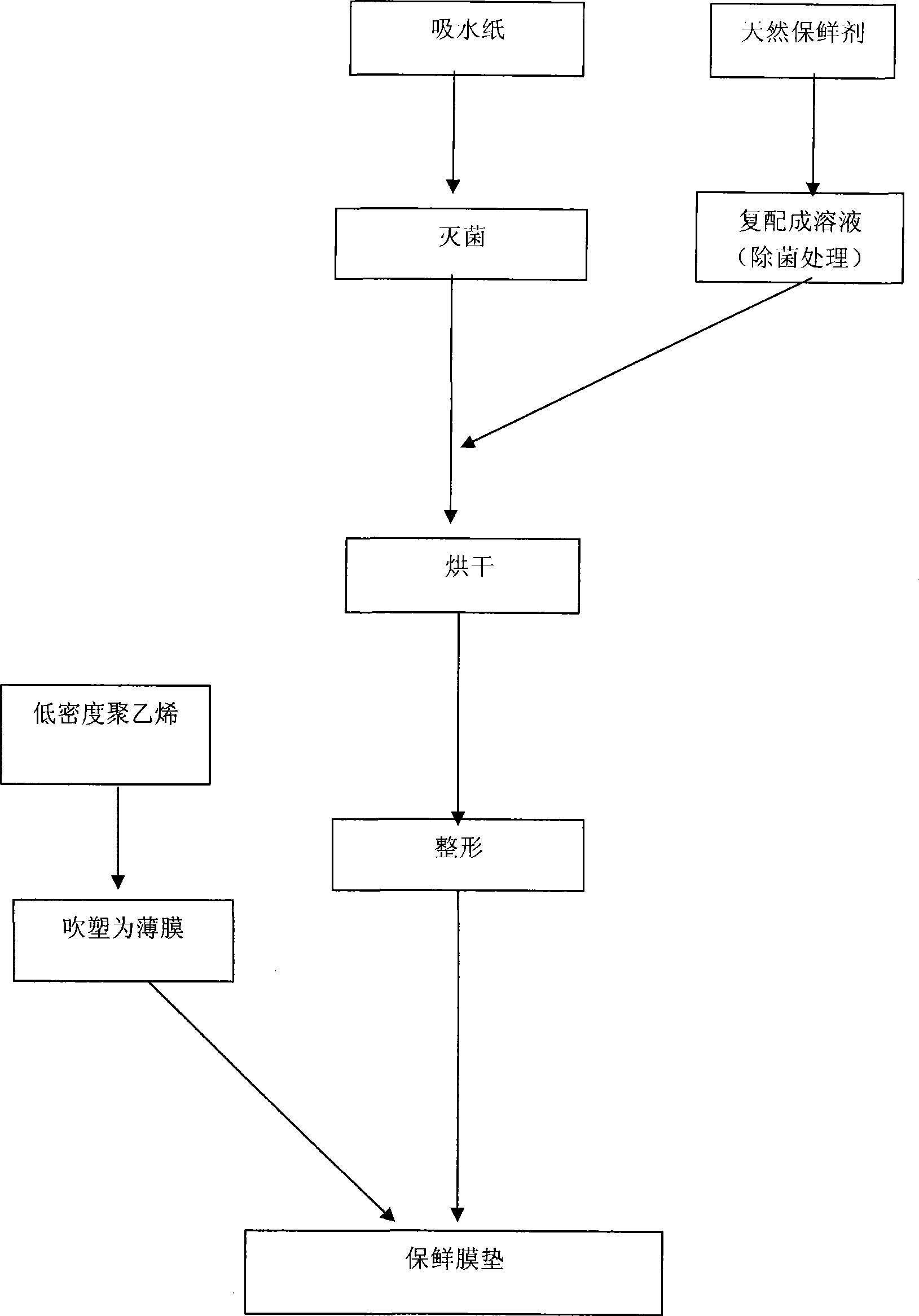

Image

Examples

Embodiment Construction

[0007] Give an example below:

[0008] (1) Preparation of film:

[0009] Low-density polyethylene (LDPE) is blow-molded with a blow molding machine to make a film product, and then a small hole with a diameter of 0.5mm is pierced on the film with a punching machine, 6 holes / cm 2 .

[0010] (2) Preparation of sterile absorbent paper:

[0011] Autoclave plain absorbent paper.

[0012] (3) Preparation of antistaling agent: 9.7kg of nisin, 6.7kg of rosemary extract, 19.0kg of tea polyphenols, 18.0kg of carnosine, 16.6kg of natamycin, and 30.0kg of water-soluble propolis were compounded into 100kg Preservative, dissolved in 10000L sterile distilled water to become a preservative solution.

[0013] (4) Membrane pad preparation:

[0014] Spray the preservative solution evenly into the absorbent paper in the form of spray, the spray ratio is 6L preservative solution / m 3 Water-absorbing paper, then dry and reshape the water-absorbing paper and pack it into the film, and make a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com