Processing method for high quality vacuum packaged poultry products

A vacuum packaging and processing method technology, applied in the field of food processing and preservation, can solve the problems of narrow antibacterial spectrum, loss of interest, long sterilization time, etc., and achieve the effect of easy industrial production, reducing flavor changes and texture deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

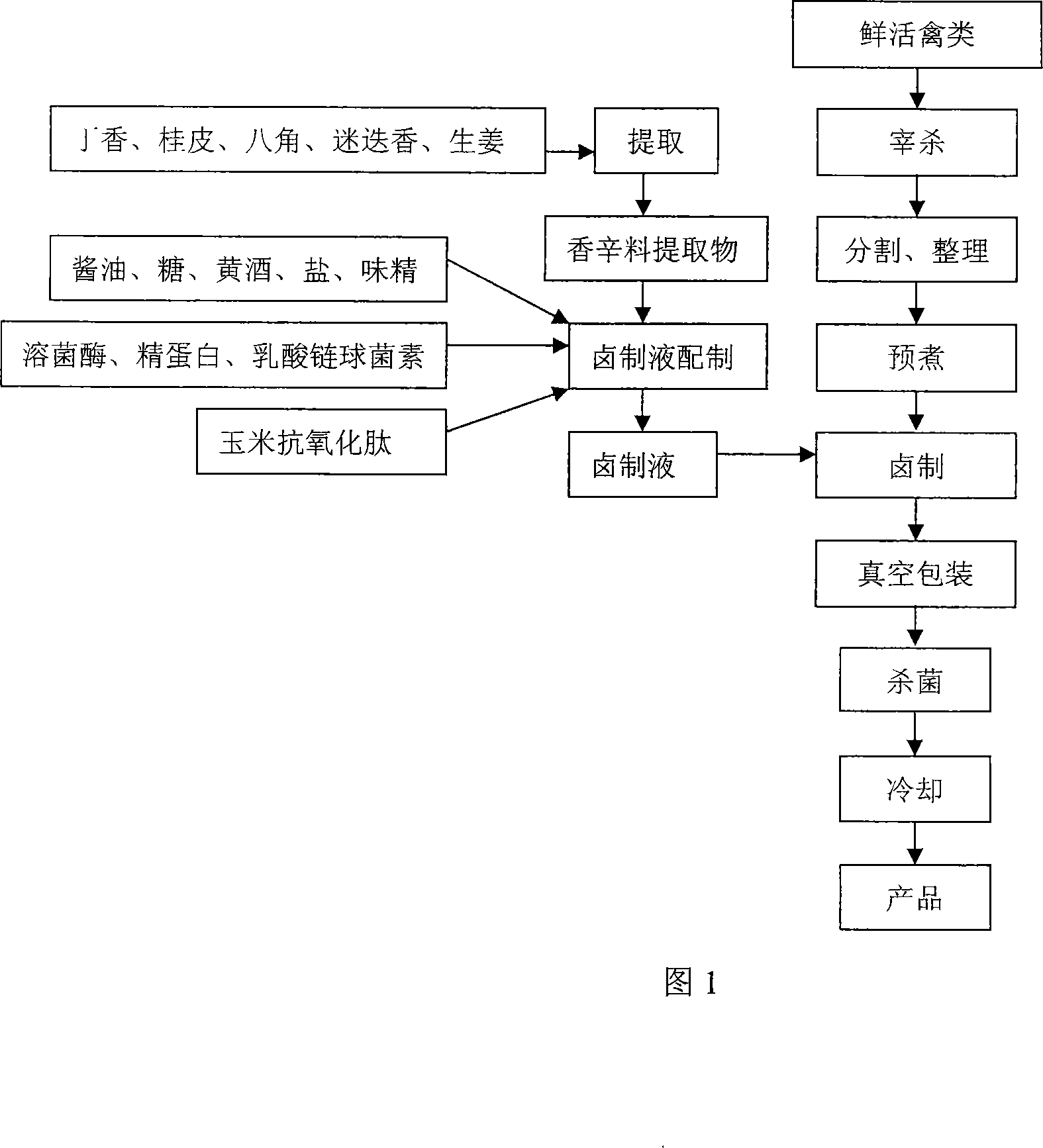

Method used

Image

Examples

Embodiment 1

[0021] Fresh chickens that have passed the quarantine inspection are used as raw materials. The necks are slaughtered and bloodletted after 20 hours of non-feeding and watering, and then they are scalded in hot water at 70°C for 60 seconds and then plucked. The chicken carcass after plucking is divided according to the requirements, and cuts, bleeding spots, broken bones, cartilage, blood stains, lymph nodes, etc. are repaired, washed with clean water, and then placed in a jacketed pot for pre-cooking. The pre-cooking time is about 10- For 20 minutes, the center of the meat is just bloodless. After the pre-cooked chicken is drained and drained, it is marinated immediately. The mass ratio of chicken to marinating liquid is 1:1, the marinating temperature is 80-100°C, and the time is 40-120 minutes. The marinated meat pieces are taken out and drained, and then bagged as required, each bag weighs 500g, and then vacuum sealed. The vacuum-sealed product is sent to a sterilization pot f...

Embodiment 2

[0024] Using fresh ducks that have passed the quarantine inspection as raw materials, the neck is slaughtered and blood-letted after 20 hours of non-feeding and watering, and then blanched in hot water at 60°C for 100 seconds before plucking the hair. The duck carcass after plucking is divided according to the requirements, and cuts, bleeding spots, broken bones, cartilage, blood stains, lymph nodes, etc. are repaired, washed with clean water, and then placed in a sandwich pot for pre-cooking. The pre-cooking time is about 10- For 20 minutes, the center of the meat is just bloodless. After the pre-cooked duck meat is drained and drained, it is marinated immediately. The mass ratio of duck meat / marinating liquid is 1:1, the marinating temperature is 80-100°C, and the time is 40-120 minutes. The marinated meat pieces are taken out and drained, and then bagged as required, each bag weighs 500g, and then vacuum sealed. The vacuum-sealed product is sent to a sterilization pot for high-...

Embodiment 3

[0027] Using fresh geese that have passed the quarantine inspection as raw materials, the neck is slaughtered and blood-letted after 20 hours of non-feeding and watering, and then scalded in hot water at 65°C for 80 seconds before plucking the hair. Divide the plucked goose carcass according to the requirements, repair cut spots, bleeding spots, broken bones, cartilage, blood stains, lymph nodes, etc., wash it with clean water, and place it in a jacketed pot for pre-cooking. The pre-cooking time is about 10- For 20 minutes, the center of the meat is just bloodless. After the pre-cooked goose meat is removed and drained, it is marinated immediately. The mass ratio of goose meat / brine liquid is 1:1, the marinating temperature is 80-100°C, and the time is 40-120 minutes. The marinated meat pieces are taken out and drained, and then bagged as required, each bag weighs 500g, and then vacuum sealed. The vacuum-sealed product is sent to a sterilization pot for high-temperature sterilizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com