Method for preserving meat products

A fresh-keeping method and technology for meat products, which are applied in the direction of preserving meat/fish with a coating protective layer, can solve the problems of not mentioning preservatives, etc., and achieve the effect of good fresh-keeping effect, improving commercial value, and delaying fat oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

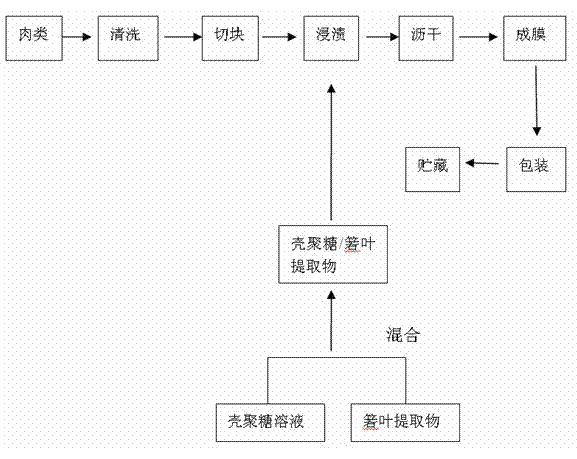

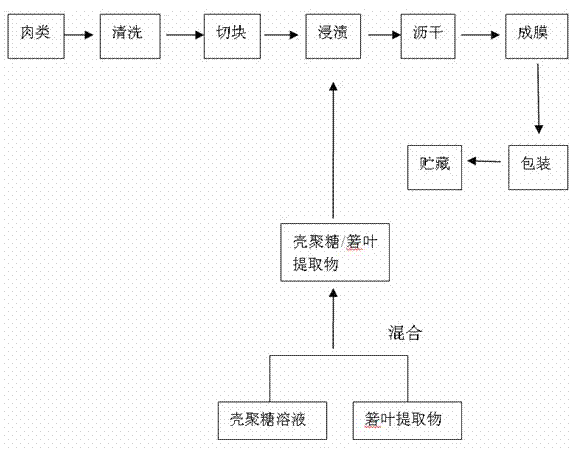

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the fresh-keeping method of this meat product, concrete operations are as follows:

[0019] (1) dissolving chitosan with 1% acetic acid with a concentration of 1% by mass, the degree of deacetylation of chitosan is 85%, to obtain a chitosan solution with a concentration of 1% by mass;

[0020] (2) Use ultrasonic-hot water to extract Ruoye leaves, the ratio of solid to liquid is 1:20, ultrasonic frequency is 20kHz, ultrasonic is 20 minutes, and then extracted at 80°C for 2 hours to obtain Ruoye extract thing;

[0021] (3) Mix 900ml of chitosan solution with 100ml of Ruoye leaf extract, stir well, and make a chitosan composite solution containing 10% of Ruoye leaf extract;

[0022] (4) Soak 1 kg of meat products in the mixed solution of chitosan and Ruoye leaf extract, soak for 2 minutes, drain, and repeat the dipping 3 times to form a composite layer of chitosan and Ruoye leaf extract on the surface film, then packed with polyethylene film, and stored in ...

Embodiment 2

[0023] Embodiment 2: the fresh-keeping method of this meat product, concrete operations are as follows:

[0024] (1) dissolving chitosan with 1.5% acetic acid with a mass percentage concentration, the deacetylation degree of chitosan is 96%, and a chitosan solution with a mass percentage concentration of 2% is obtained;

[0025] (2) Use ultrasonic-hot water to extract Ruoye, the ratio of solid to liquid is 1:25, ultrasonic frequency is 20kHz, ultrasonic is 30 minutes, and then extracted at 60°C for 3 hours to obtain Ruoye Extract thing;

[0026] (3) Take 850ml of chitosan solution and 150ml of Ruoye leaf extract, mix them, and stir evenly to make a chitosan composite solution containing 15% of Ruoye leaf extract;

[0027] (4) Soak 1 kg of meat products in the mixed solution of chitosan and Ruoye leaf extract. After soaking for 5 minutes, drain and repeat the dipping twice to form a composite layer of chitosan and Ruoye leaf extract on the surface. film, then packed with poly...

Embodiment 3

[0028] Embodiment 3: the fresh-keeping method of this meat product, concrete operation is as follows:

[0029] (1) dissolving chitosan with acetic acid with a mass percentage concentration of 2%, the degree of deacetylation of chitosan is 90%, and a chitosan solution with a mass percentage concentration of 1.5% is obtained;

[0030] (2) Use ultrasonic-hot water to extract Ruoye leaves, the ratio of solid to liquid is 1:23, ultrasonic frequency is 20kHz, ultrasonic is 25 minutes, and then extracted at a temperature of 70°C for 2.5 hours to obtain Ruoye extract thing;

[0031] (3) Mix 880ml of chitosan solution with 120ml of Ruoye leaf extract, stir well, and make a chitosan composite solution containing 12% of Ruoye leaf extract;

[0032] (4) Soak 1 kg of meat products in the mixed solution of chitosan and Ruoye leaf extract, soak for 4 minutes, drain, and repeat the dipping once to form a composite layer of chitosan and Ruoye leaf extract on the surface film, then packed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com