Method for rapidly producing sweet and sour garlic by ultra-high pressure

An ultra-high pressure, sweet and sour technology, applied in food science and other directions, can solve the problems of limited production scale, limited production season, green garlic cloves, etc., and achieve the effects of reduced production cost, hygienic production process, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

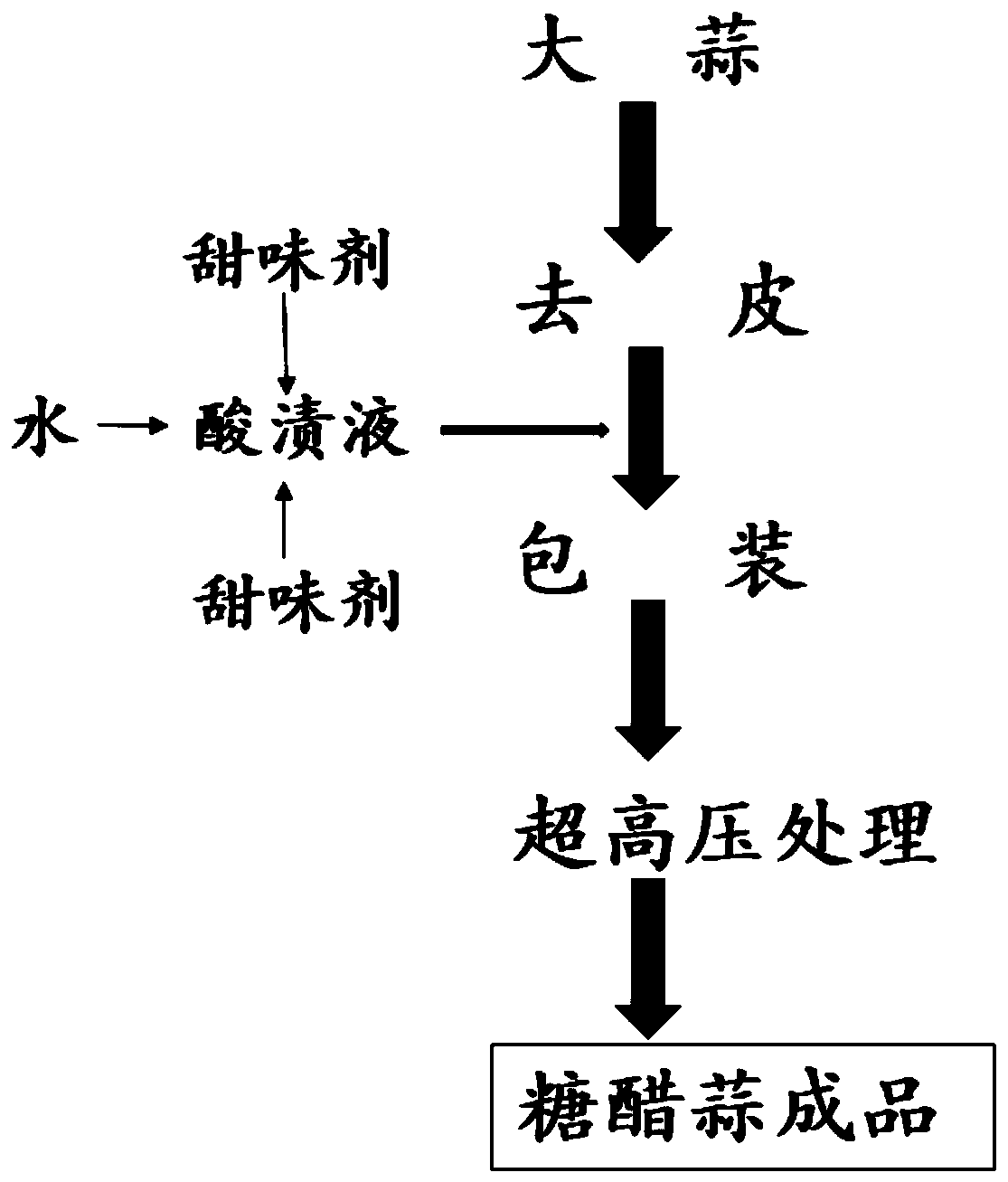

[0025] A kind of method for producing sweet and sour garlic with ultra-high pressure quickly, please refer to the brief process flow chart figure 1 , including the following steps:

[0026] Cut the dormant garlic raw materials, wash, soak, and peel to obtain clean, edible garlic, take 10kg, pack them in 0.5kg plastic bags, add 0.5kg of acid pickling solution, seal and put Put it into an ultra-high pressure machine, process it for 6 minutes under a high pressure of 600MPa, then take it out and pack it into a box to get the sweet and sour garlic.

[0027] The preparation of pickling liquid: take 4kg of sterile water, add 4kg of vinegar (with an acetic acid content of more than 5wt%), 5kg of sugar, and 150g of salt, dissolve and mix to obtain pickling liquid.

[0028] In the method of this embodiment, the ultra-high pressure treatment inactivates the discoloration enzyme that makes garlic green, and at the same time moderately inactivates alliin, which produces a strong pungent ...

Embodiment 2

[0030] A kind of method for producing sweet and sour garlic with ultra-high pressure quickly, please refer to the brief process flow chart figure 1 , including the following steps:

[0031] Get the edible garlic rice prepared in 10kg embodiment 1, pack in the plastic bag of 1kg, add the acid pickling liquid of 1.1kg respectively, put into ultra-high pressure machine after sealing, under 1000MPa high pressure, process 1 minute, Then take it out and pack it in a box to get the sweet and sour garlic.

[0032] Preparation of pickling liquid: take 10kg of sterile water, add 0.15kg of edible lactic acid, 30g of salt, and 3kg of sugar, dissolve and mix to obtain pickling liquid.

Embodiment 3

[0034] A method for rapidly producing sweet and sour garlic with ultra-high pressure, please refer to the brief process flow diagram figure 1 , including the following steps:

[0035] Get the edible garlic rice prepared in the method of 10kg embodiment 1, pack in the plastic bag of 0.75kg, add the pickling liquid of 0.9kg respectively, put into the ultra-high pressure machine after sealing, under 400MPa high pressure, process 20 minutes, then take it out and box it, you can get sweet and sour garlic.

[0036] Preparation of acid pickling solution: take 8kg of sterile water, add 300g citric acid, 1.8kg DE value 70% fructose syrup (more than 70% soluble solids), and 100g sodium cyclamate, dissolve and mix to obtain pickling solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com