Method for producing crystal decorative paper

A production method and decorative paper technology, applied in the field of veneer paper printing, can solve the problems of low production efficiency, poor product quality, high processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: a kind of production method of diamond decorative paper, the method comprises the following steps:

[0016] (a) Take 100 parts by weight of butyl acrylate, dissolve it in 65 parts by weight of butyl ester, add 10 parts by weight of laser powder with a particle diameter of 0.1-1 mm in the above mixed solution, stir it evenly, and prepare The laser powder coating is ready for use. Butyl acrylate is easily soluble in butyl ester, and butyl ester will not dissolve the resin layer printed with graphics on the laser powder;

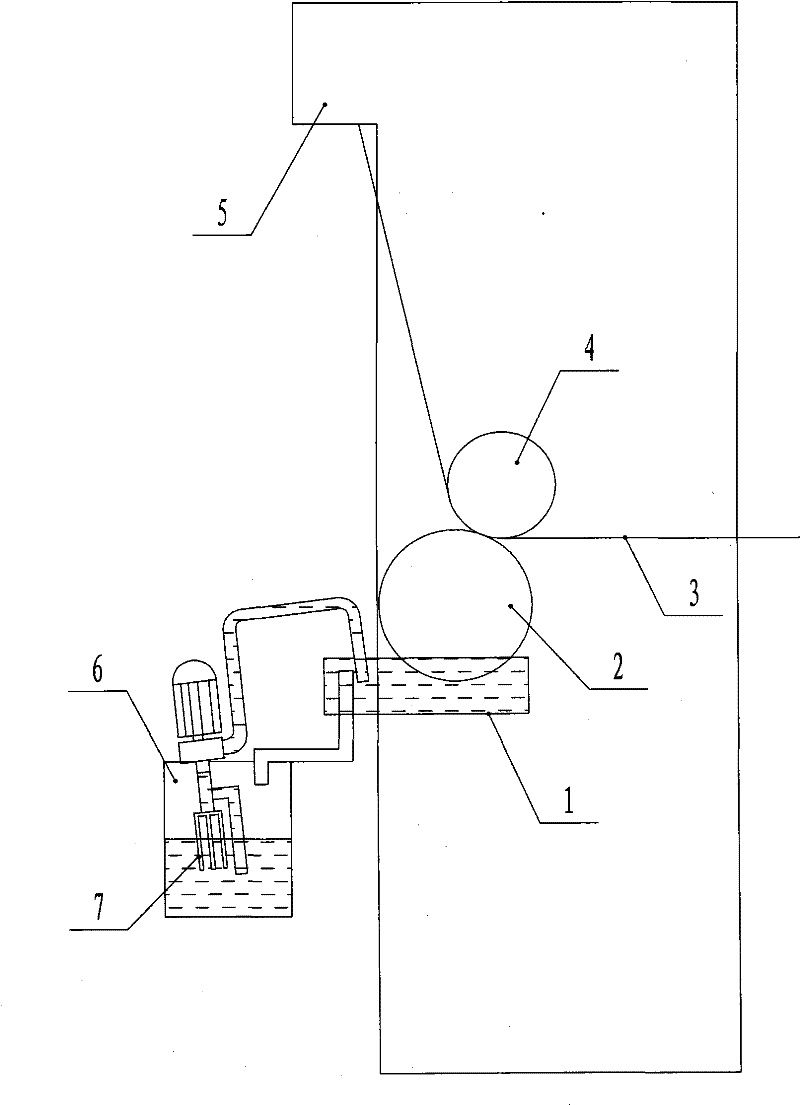

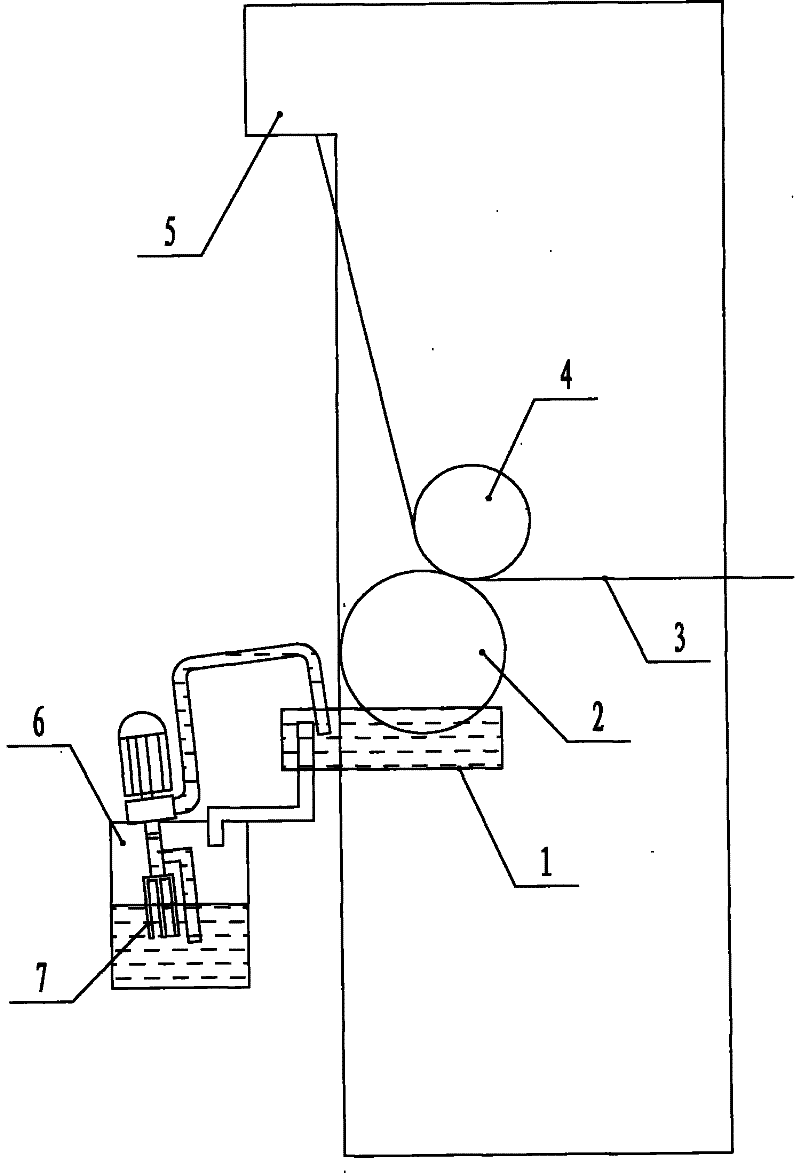

[0017] (b) In the printing unit of the printing press, a base layer of ink is printed on paper 3 and applied as figure 1 Drying in the oven 5 of the printing machine shown, the average longitudinal elongation of the paper is 3.6%, and the tensile strength is 2.7kn / m;

[0018] (c) Put the laser powder coating prepared in the step (a) into the feed barrel 6, and stir the laser powder coating with the motor-driven stirrer 7, so that the las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com