Workshop intelligent monitoring sterilization and dedusting system

A technology of dust removal system and intelligent monitoring, applied in sanitary equipment for toilets, electrostatic effect separation, solid separation and other directions, can solve the problems of unsuitable workshop, large space occupation, high cost, and achieve high intelligence, good effect and effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

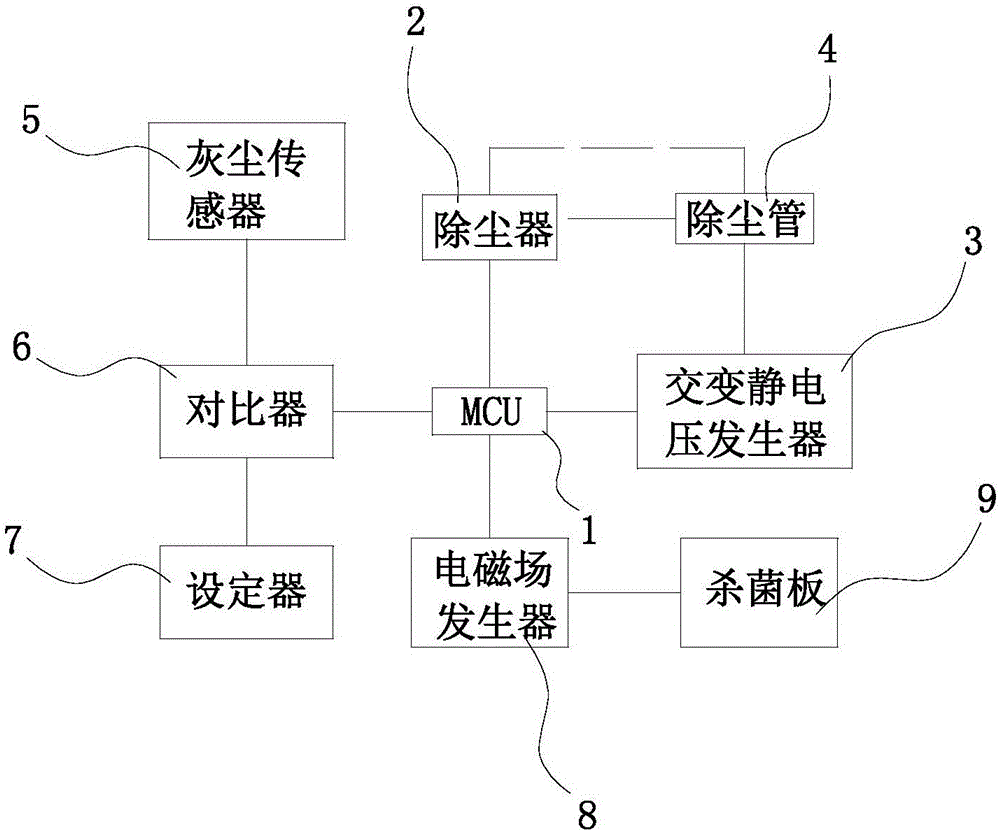

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the intelligent monitoring, sterilization and dust removal system of the workshop of this embodiment includes a dust collector 2 and a dust sensor 5 installed in the workshop, the dust sensor 5 is installed at the end of the air duct of the dust collector 2, and the dust sensor 5 is controlled by the MCU1 Dust collector 2, dust sensor 5 is connected to MCU1 through comparator 6, and the input terminal of comparator 6 is also connected to setter 7; Dust removal pipe 4 of dust collector 2 is connected to alternating static voltage generator 3, and the alternating static voltage generates The device 3 is controlled by the MCU1; the system also includes an electromagnetic field generator 8 connected to the MCU1, the electromagnetic field generator 8 is connected to the sterilizing plate 9, and the sterilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com