Seedling culture medium bagged splitting machine

A technology for cultivating substrates and slitting machines, which is applied in packaging and other directions, and can solve problems such as poor sanitary conditions, low work efficiency, and many scattered substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

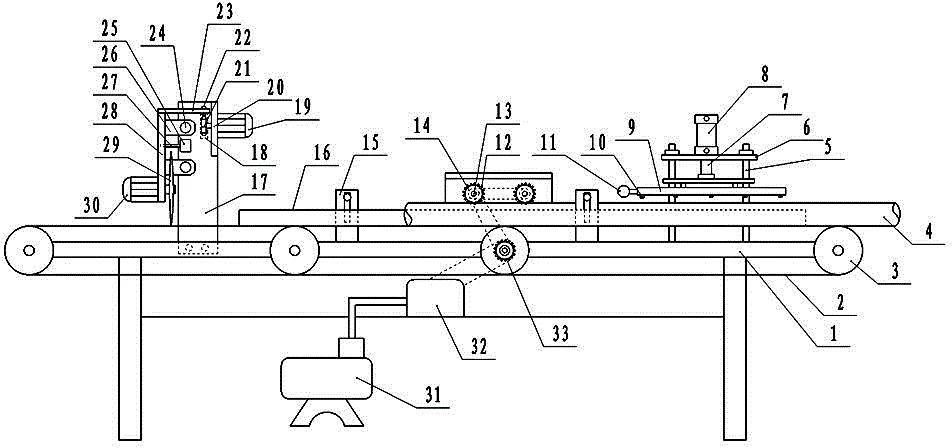

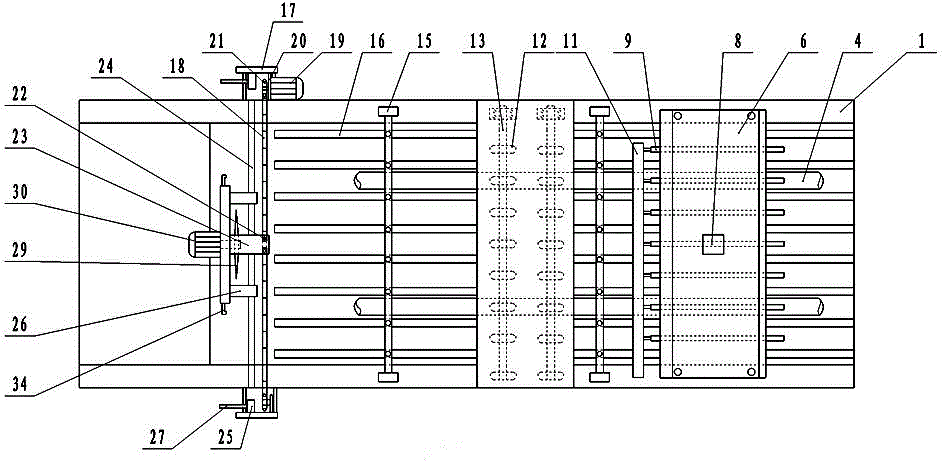

[0007] Example: such as figure 1 and figure 2 As shown in the figure, a seedling culture substrate filling bag cutting machine is equipped with a conveying roller 3 on the frame 1, a conveying belt 2 is set on the conveying roller 3, and a pressing device for a matrix strip 4 is installed at the front end of the conveying belt 2. The stepping device of the matrix strip 4 is installed in the middle, and the cutting device of the matrix strip 4 is installed at the rear end; A cylinder 8 is installed, and a plurality of pressure tubes 9 are installed on the movable shaft 7 of the cylinder, and a nozzle 10 is arranged on the pressure tubes, and one end of the pressure tubes 9 is connected with a high-pressure water pipe 11; the driving gear 33 of the stepping device is installed on the frame 1 , the driving gear 33 is connected with the transmission box 32 below the frame 1 and the driven gear 14 above with a chain, the transmission box 32 is connected with the air pump 31, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com