An isolation method for vacuum diffusion welding

A technology of vacuum diffusion and welded parts, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc. It can solve the problems of complex process, easy breaking of ceramic sheets, and easy raising of graphite powder, etc., and achieves simple welding operation and coating The effect of controllable thickness and good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

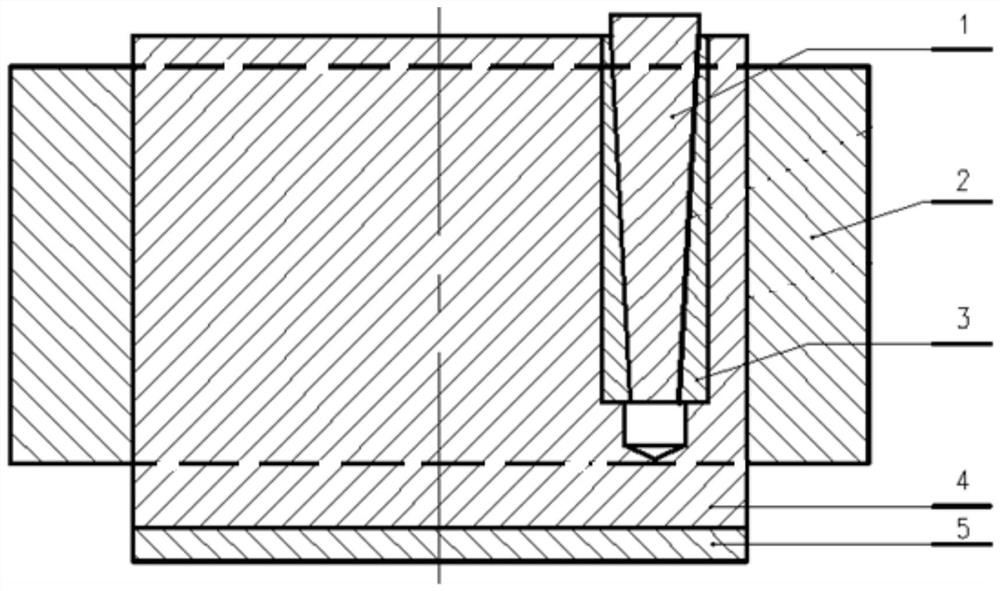

[0022] Example 1. It is used for the isolation layer used in the welding and forming of the existing bimetallic copper-steel rotor with special-shaped structure (such as YZBXXX-4001 (H) rotor), such as figure 1 As shown, the existing bimetallic copper-steel rotor tooling includes a tapered pressure column 1 and an outer circular clamp 2, and a group of welded parts constituting the bimetallic copper-steel rotor are respectively welded copper sleeves 3 with tapered inner holes. , welded steel matrix 4 and welded copper plate 5; when the special-shaped structure bimetallic copper-steel rotor is welded and formed, the welding equipment applies pressure downward through the pressure column 1, so that the welded steel matrix 4 and the welded copper plate 5 are in close contact, and the pressure column 1 is pressed down. At the same time, the welded copper sleeve 3 is in close contact with the welded steel substrate 4 , and the outer circular clamp 2 is used to limit the position of...

Embodiment 2

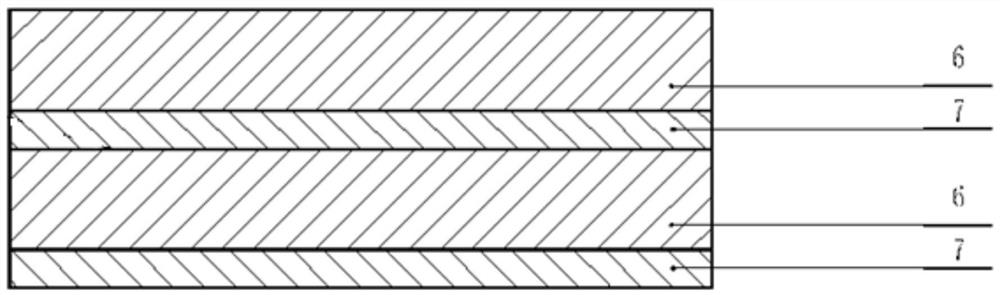

[0029] Example 2. It is used for the isolation layer used in the welding and forming of the existing flat structure copper-steel pressing plate (YZBXX-3212 (H) pressing plate). figure 2 As shown, the two sets of weldments are stacked and welded at the same time, and the welding equipment is used to apply pressure downward to the stacked two sets of weldments, so that the weldments are in close contact. The existing process requirement is that an isolation layer needs to be formed between the two sets of weldments.

[0030] An isolation method for vacuum diffusion welding, comprising the following steps,

[0031] a. In parts by weight, pour 1000 parts of hot water not lower than 60°C into the container to obtain product A,

[0032] b. Pour 60, 70, 85, 100 or 110 parts (optimally 85 parts) of water glass into product A, and stir while pouring until the water glass dissolves to obtain product B.

[0033] c. Pour 50, 60, 70, 80 or 90 parts (optimally 70 parts) of zinc oxide po...

Embodiment 3

[0036] Example 3. Carry out with reference to embodiment 1, the difference is that the object of action is changed, the bimetallic copper-steel rotor is changed into a bimetallic titanium steel rotor, that is, the materials of the welded copper sleeve 3 and the welded copper plate 5 are all changed into titanium.

[0037] In step f of the isolation method, the spray thickness was changed to 0.1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com