Inline Folding Machine

A film machine, in-line technology, applied in the field of in-line folding film machines, can solve the problems of low production efficiency, long labor cycle, wasted labor, etc., and achieve the effects of improving production efficiency, saving labor, and hygienic production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

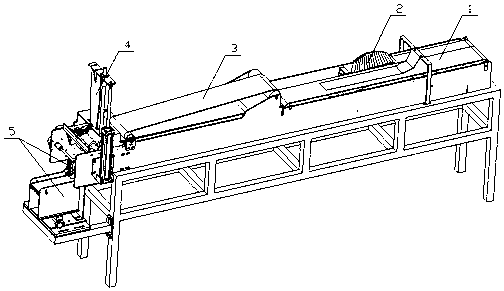

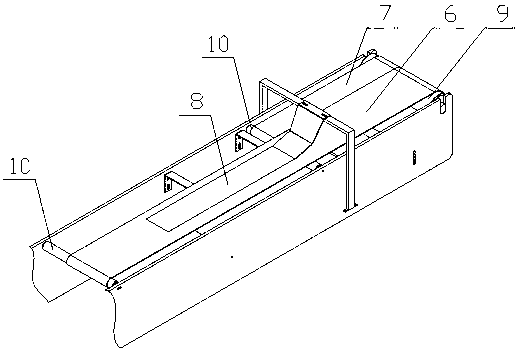

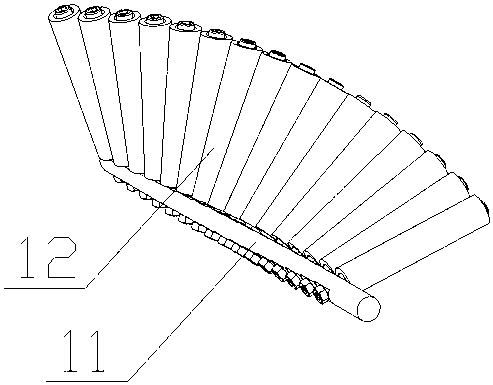

[0016] refer to Figure 1-Figure 6 , the in-line film folding machine of the present embodiment, it comprises frame, film conveyor belt 1, overturning roller table 2, opposite conveying pressure film belt 3, pneumatic film punching device 4, bag-up and bag-opening mechanism 5, frame from The film conveyor belt 1, the film conveyor belt 3 for opposite conveying, the pneumatic film punching device 4, the bag loading and bag opening mechanism 5 are arranged sequentially from the back to the front, the turning roller table 2 is arranged on the film conveyor belt 1, the film conveyor belt 1 and the opposite Coplanar with the conveying lamination belt 3, the bag-up and bag-opening mechanism 5 is located below the pneumatic film punching device 4 . The film conveyor belt 1 comprises a long belt 6, a short belt 7, a film pressing plate 8, a large electric drum 9, a driven roller 10, the long belt 6 and the short belt 7 are arranged side by side, and the large electric drum 9 is a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com