A kind of preparation method of non-soaked soybean milk suitable for industrialized tofu production

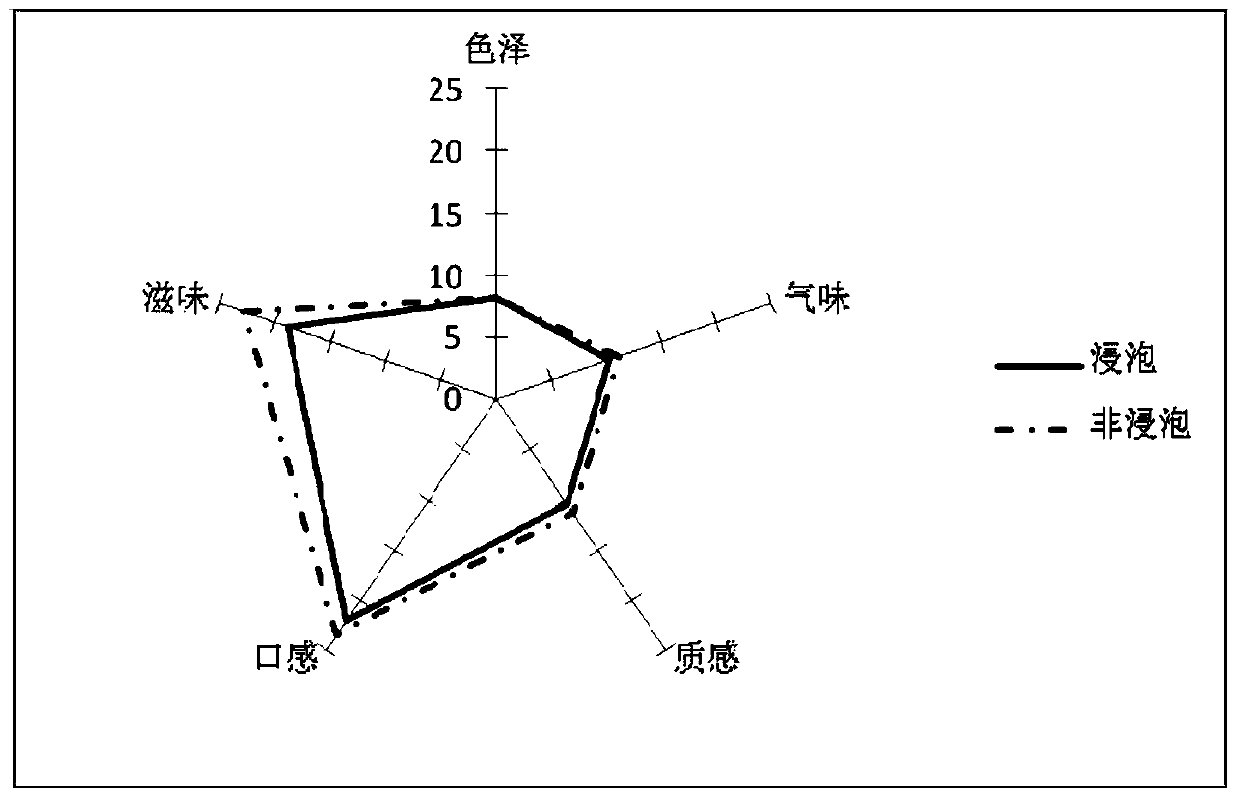

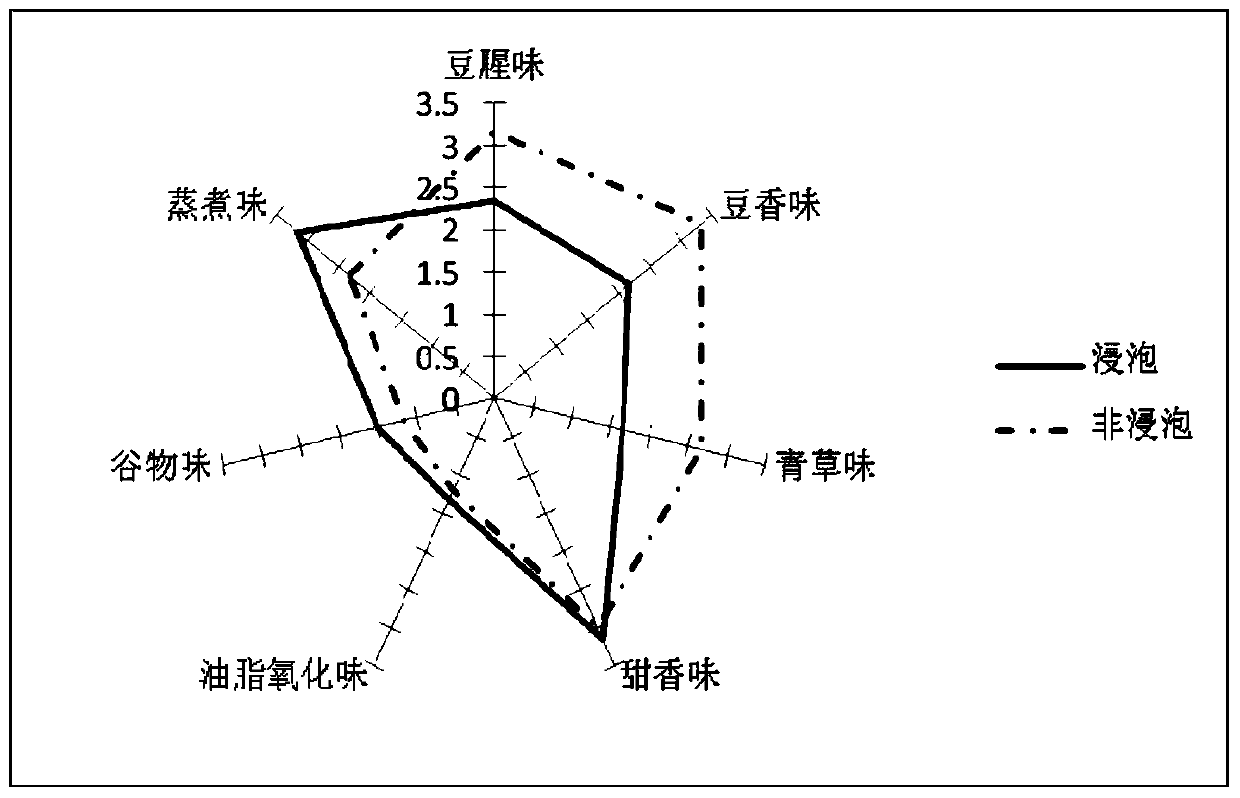

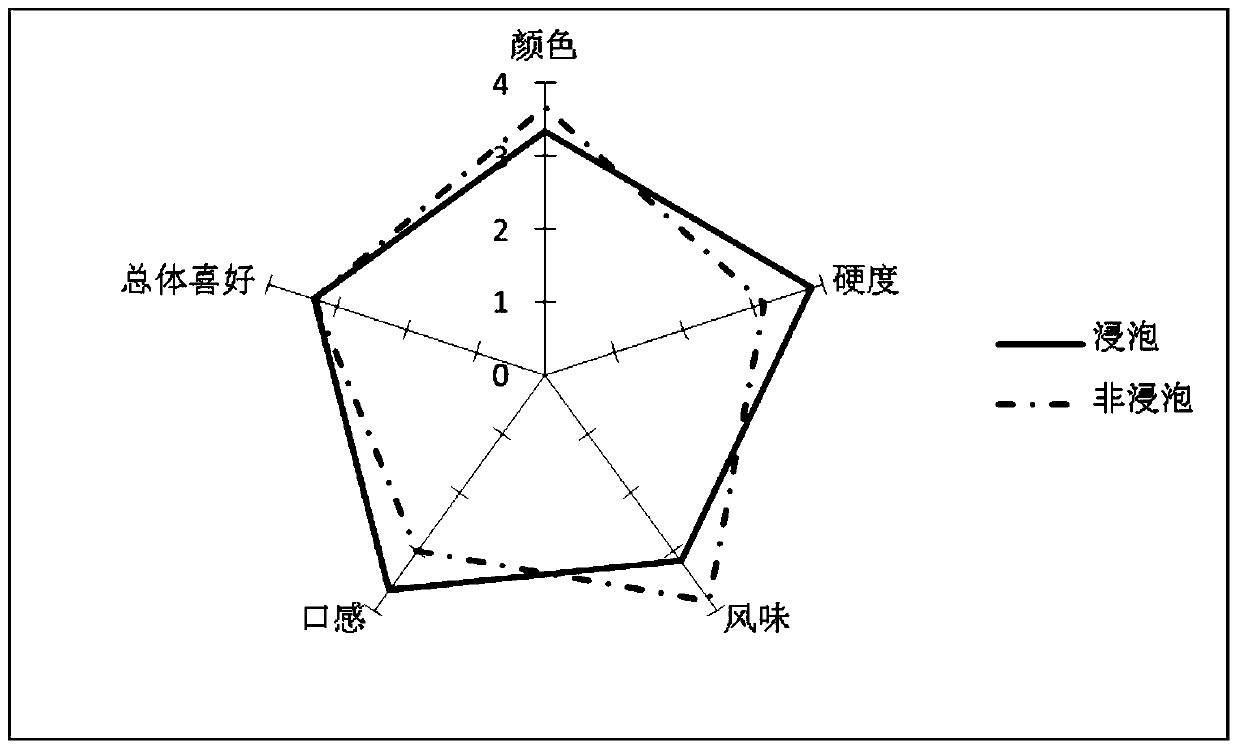

A soymilk and tofu technology, which is applied in the field of food processing, can solve the problems of poor toughness of tofu and affect the sensory quality of tofu, and achieve the effects of saving water, removing bad flavor, and improving protein dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, a kind of non-soaked soya-bean milk preparation technology (raw pulp method) that can be used for industrialized bean curd production

[0040] The raw soybeans are mechanically crushed to reduce the particle size of the crushed soybeans to less than 6 mesh. Prepare a mixed aqueous solution of sodium tartrate and glyceryl monostearate with a concentration of 0.3%. In the mixed aqueous solution, broken soybeans (6 mesh) and the solution enter the refining system at a mass ratio of 1:7. Refining once at room temperature. The ground bean paste is mixed and extracted for 5 minutes during material transportation at room temperature, and then re-enters the refining system for secondary refining at room temperature. Use a sieve of not less than 60 mesh to remove the bean dregs by centrifugation or extrusion to obtain raw soybean milk. The raw soybean milk enters the cooking tank, and the slurry is heated to 95° C. with steam, and kept for 5 minutes to obtain the...

Embodiment 2

[0047] Embodiment 2, a kind of non-soaked soybean milk preparation technology (cooked pulp method) that can be used for industrialization tofu production

[0048] The raw soybeans are mechanically crushed to reduce the particle size of the crushed soybeans to less than 6 mesh. A mixed aqueous solution of sodium tartrate and glyceryl monostearate with a concentration of 0.3% was prepared, and the mass ratio of crushed soybeans and the solution was 1:7 and then entered into the refining system, and a refining was performed at room temperature. The ground bean paste is mixed and extracted for 5 minutes during material transportation (the extraction temperature is room temperature), and then re-enters the refining system for secondary refining at room temperature. Heat the bean paste with steam to 95°C and keep it for 5 minutes, then use a sieve no less than 60 mesh to remove the bean dregs by centrifugation or extrusion to obtain finished soybean milk (non-soaked soybean milk tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com