Patents

Literature

80 results about "Ground-bean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macrotyloma geocarpum is also known as the ground bean, geocarpa groundnut, Hausa groundnut, or Kersting's groundnut. In French, it is often called la lentille de terre. M. geocarpum is an herbaceous annual plant and a crop of minor economic importance in sub-Saharan Africa, tolerant of drought, with a growth habit similar to that of the peanut.

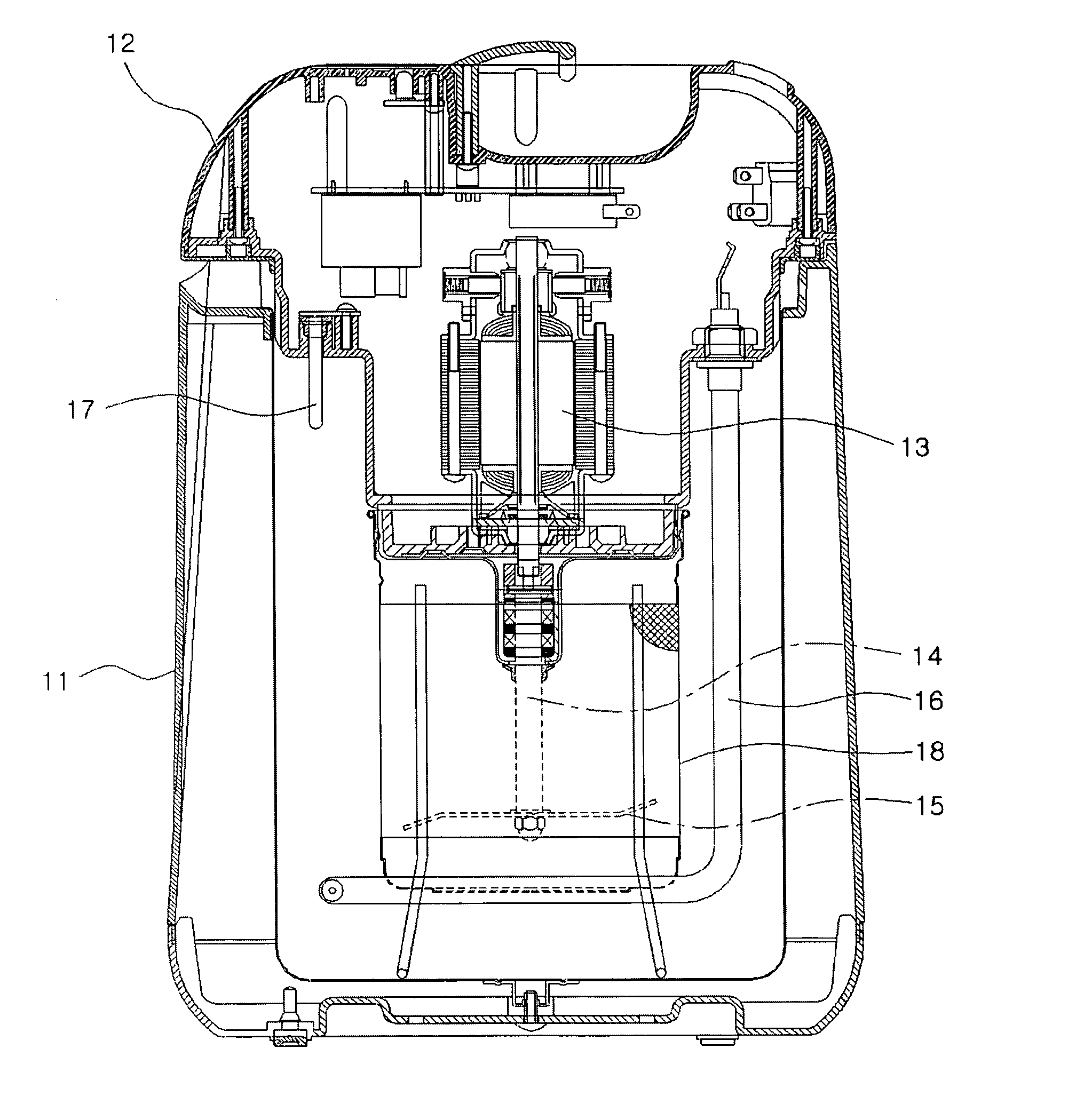

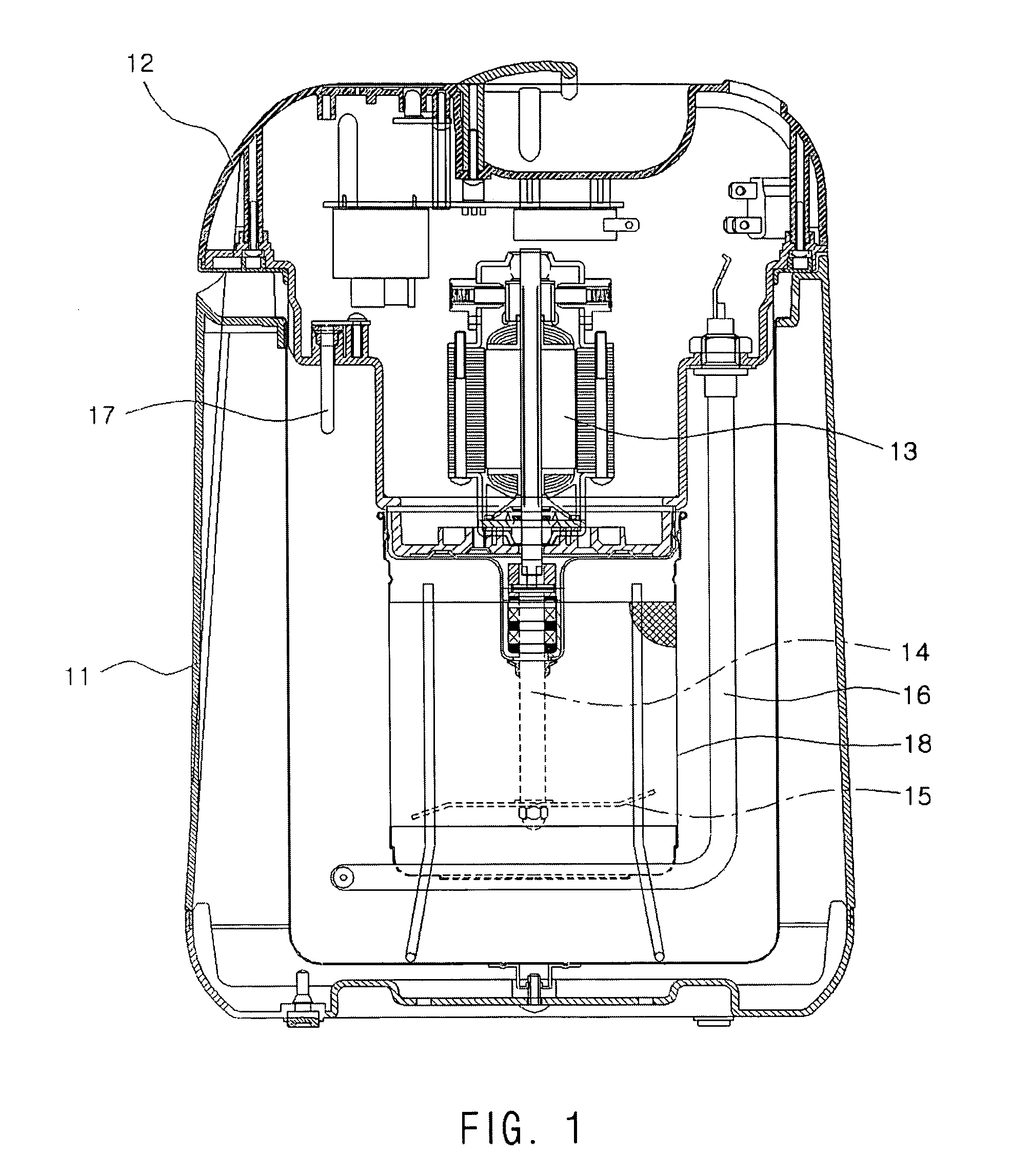

Heating control apparatus and method for controlling household bean milk and bean curd makers

InactiveUS20050051032A1Reduce power consumptionHigh heating temperatureBoiling over preventionBeverage vesselsAgricultural engineeringGround-bean

Heating control apparatus and method for controlling household bean milk and bean curd makers, which set a primary heating temperature to be relatively low, thus preventing beans from being excessively finely ground during a grinding process while reducing power consumption, in use. The control apparatus and method set a secondary heating temperature to be relatively high to heat the beans for a short period of time, in use, in a household bean milk and bean curd maker, thus sufficiently boiling the ground beans while reducing power consumption. A temperature sensor senses a temperature and a key input device allows a user to input commands. A control increases a primary heating temperature sufficiently to prevent beans from being excessively finely ground, and maintains a secondary heating temperature sufficiently long after the beans are ground, to cause the beans to be sufficiently boiled, while reducing power consumption.

Owner:KIM HONG BAE

Purified amylase inhibitor and novel process for obtaining the same

InactiveCN1665521AImprove postprandial glucose toleranceMetabolism disorderPeptidesDiabetes mellitusAmylase inhibitors

Owner:PHARMACHEM LAB INC

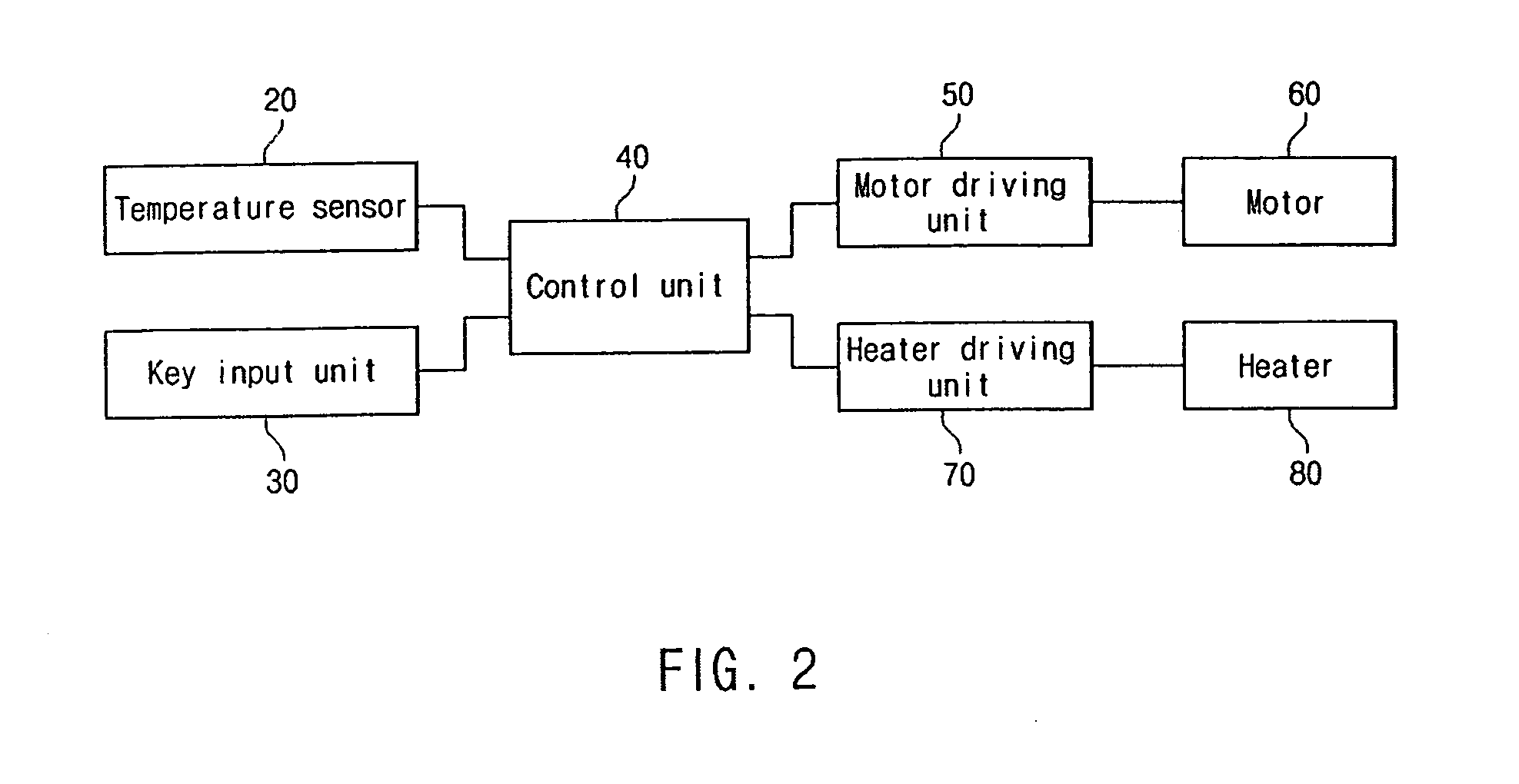

Nutraceutical method and additive for improving human physiology

ActiveUS7211279B1Improving energeticsReduced muscle responseOrganic active ingredientsBiocideGround-beanFat burning

A method for creating a coffee drink that having the addition of a nutraceutical additive composition of milk thistle; chromium picolinate, and carnitine. Milk thistle is present from about 50 to 99.7 parts by weight of the total composition, and preferably 50 to 60 parts by weight. Chromium picolinate is present from about 0.01 to 0.23 parts by weight of the composition and preferably from 0.01 to 0.1 parts by weight. Carnitine is present from about 0 to 50 parts by weight of the total composition, and preferably 40 to 50 parts by weight. The coffee drink can be created by an admixture of the composition with ground beans, sprayed and / or coated on the bean prior to grinding, or added to a brewed much the same as one would add sugar or other known flavor additives. The instant composition does not subtract from the flavor and improves human physiology by assisting in weight loss, body cleansing, weight loss, fat burning, and sugar regulation.

Owner:PEACHES & CREAM

Process for preparing bean dreg powder

The invention relates to a process for preparing bean dreg powder, which comprises the following steps of: putting fresh wet bean milk into a steam cabinet in a layered mode and steaming under normal pressure; cooling steamed bean dregs to room temperature, flatly spreading in the sun for airing or putting into an oven for baking until the moisture content is between 0.01 and 0.02 percent; and putting dried bean dregs into a grinding machine in batches for grinding, and stopping grinding until the average diameter of the ground bean dregs is between 100 and 300nm. The process is reasonable, and easy to operate, and has a short period; the nutritional ingredient loss of the bean dregs is low, and the water solubility of the bean dregs is improved; the bean dregs can be directly drunk with water after being ground into powder, have smooth mouthfeel, and also can be drunk when mixed with other electuaries; and cakes with rich nutrition can be made by mixing flour, corn meal and the like and the bean dregs.

Owner:常州市宣塘豆制品市场有限公司

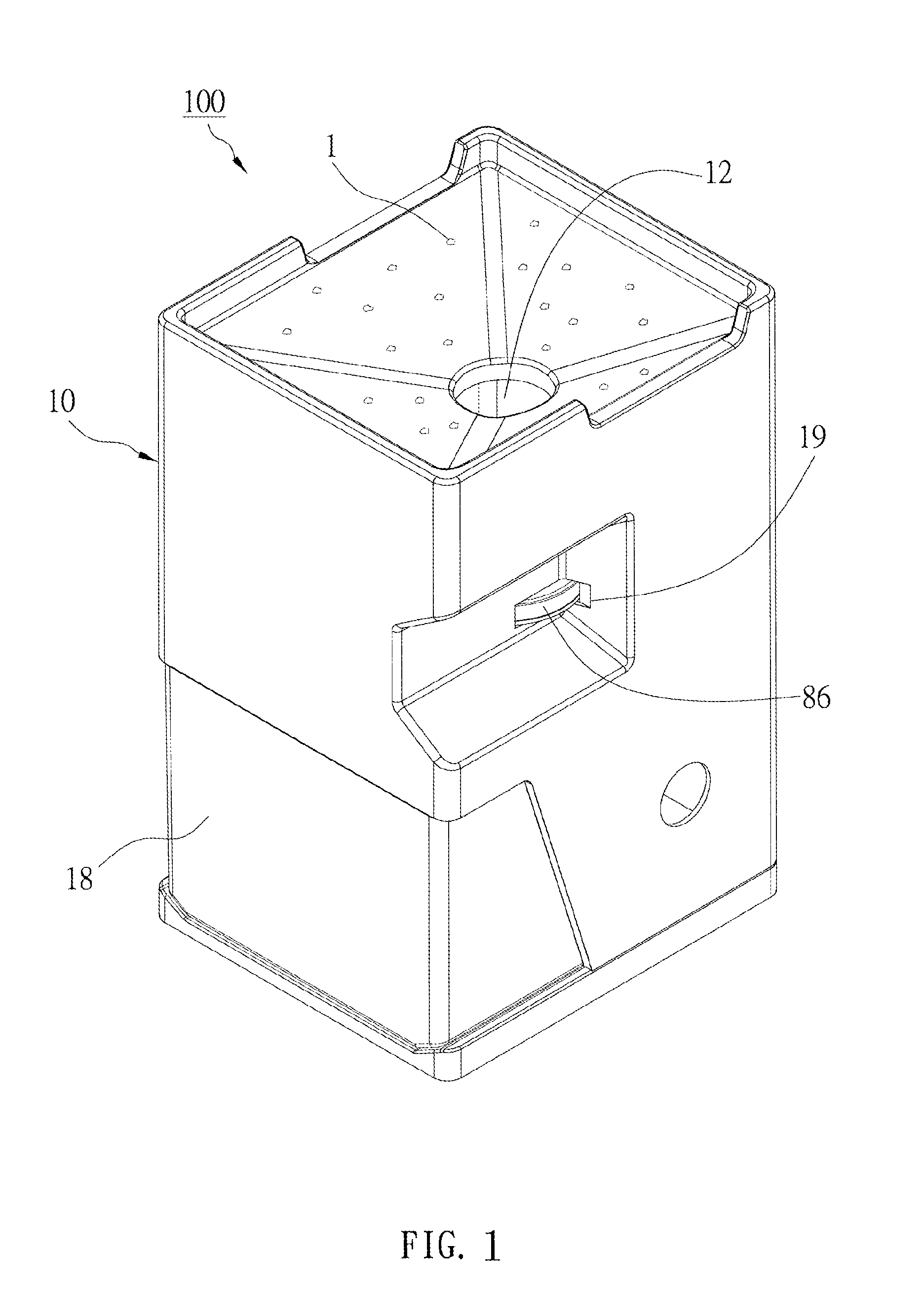

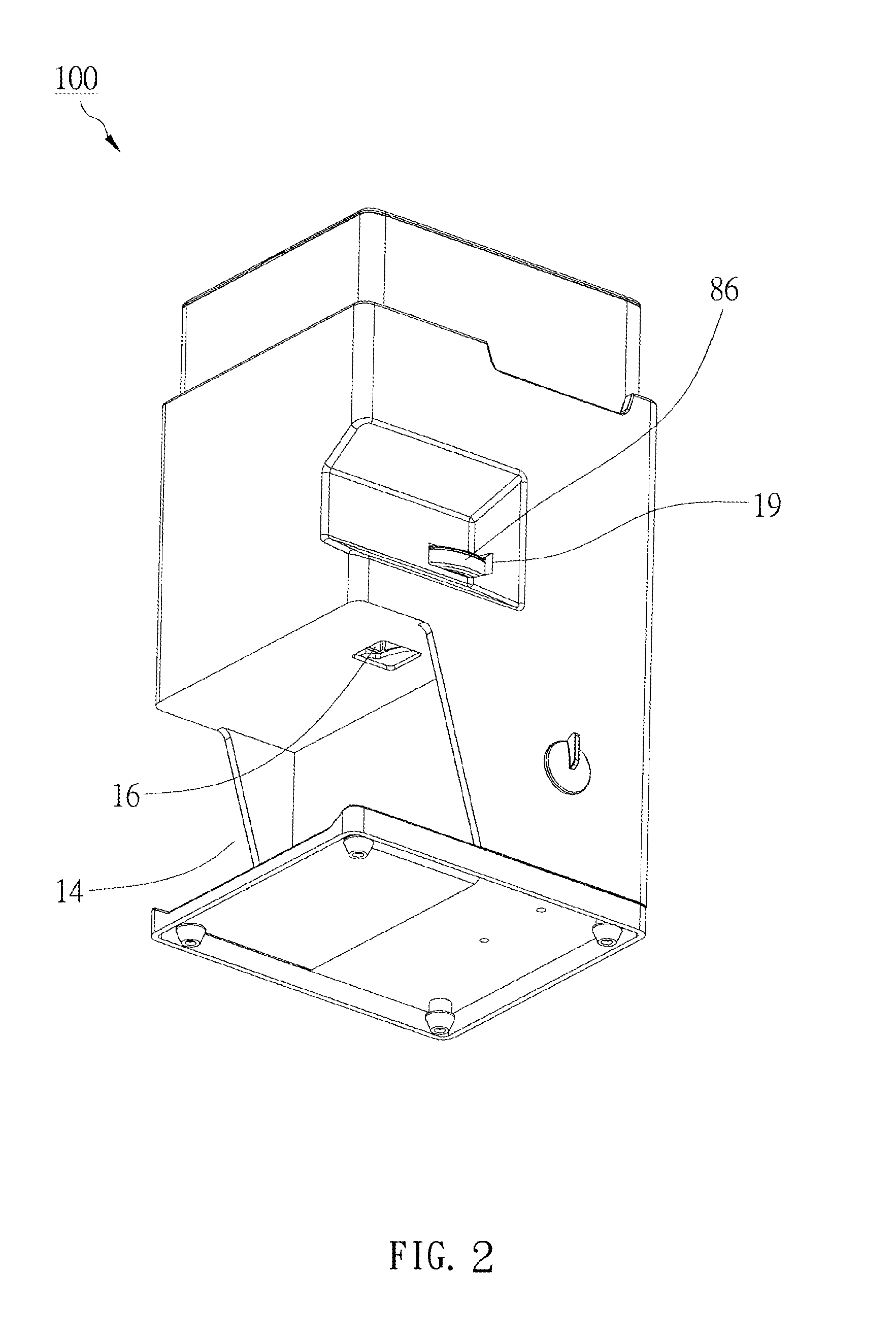

Coffee grinder capable of removing parchments of coffee beans and method of removing the parchments

InactiveUS20130056567A1Automatically and quickly remove the parchment from coffee beanCoffee millsSpice millsGround-beanWaste management

A coffee grinder includes a machine base, in which a crushing unit, a separating unit, and a grinding unit are provided. The machine base has an inlet and an outlet, and the crushing unit is under the inlet to crush coffee beans into parchments and beans. The separating unit has a rotary member and a collection container that the rotary member provides an air flow to send the parchments to the collection container. The grinding unit is between the crushing unit and the outlet to grind the beans from the separating unit and send the ground beans to the outlet. The present invention crush the coffee beans to separate the parchments and the beans, and the parchments are removed by the separating unit. Next, the beans will be ground.

Owner:LEE BING YANG

Method for processing boiling tofu

The invention discloses a method for processing boiling tofu, which comprises the steps of screening soy beans, soaking, cleaning, grinding the soy beans into milk, cooking the soybean milk, filtering, cooking, mixing and curdling, stirring, filling, heating and boiling, and cooling and forming. By using the method for processing the boiling tofu with the scheme, the produced boiling tofu not only maintains the original flavor and nutrition, but also has the greatly-improved tenacity, can maintain complete under high-temperature cooking, or even can be used as a new product which can maintain complete when the boiling tofu is processed into a noodle shape; the boiling tofu can be used for cooking soup, cold and dressed with sauce and sliced; and the boiling tofu has the characteristics of high tenacity and completeness maintenance under high-temperature cooking.

Owner:金兴仓

Coffee maker

The invention discloses a coffee maker. The coffee maker comprises a coffee maker main body, an upper abrasive disk, a lower abrasive disk and a powder channel; a bean containing cavity and a bean grinding cavity which is formed below the bean containing cavity and is communicated with the bean containing cavity are formed in the coffee maker main body, the powder channel is communicated with thebean grinding cavity, the upper abrasive disk and the lower abrasive disk are arranged in the bean grinding cavity, the coffer maker further comprises a heat source which is arranged on the coffee maker main body and an air tube which makes the heat source communicated with the bean containing cavity, and the heat source is used for heating the interior of the bean containing cavity through the air pipe; a plurality of blades are arranged on the circumference surface of the lower abrasive disk, and when the blades rotate along with the lower abrasive disk, negative pressure is formed in the bean grinding cavity so that hot airflow which passes through the bean containing cavity can dry the bean grinding cavity and the powder channel. According to the coffee maker, ground bean powder can bequickly conveyed to a brewing component through rotation of the blades, by matching with the heat source, the blades have the cleaning, high-temperature drying and disinfection and sterilization effects on the cavities and the powder channel where coffee beans and bean powder pass in the coffer maker, and the sanitation safety performance of the coffer maker is improved.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

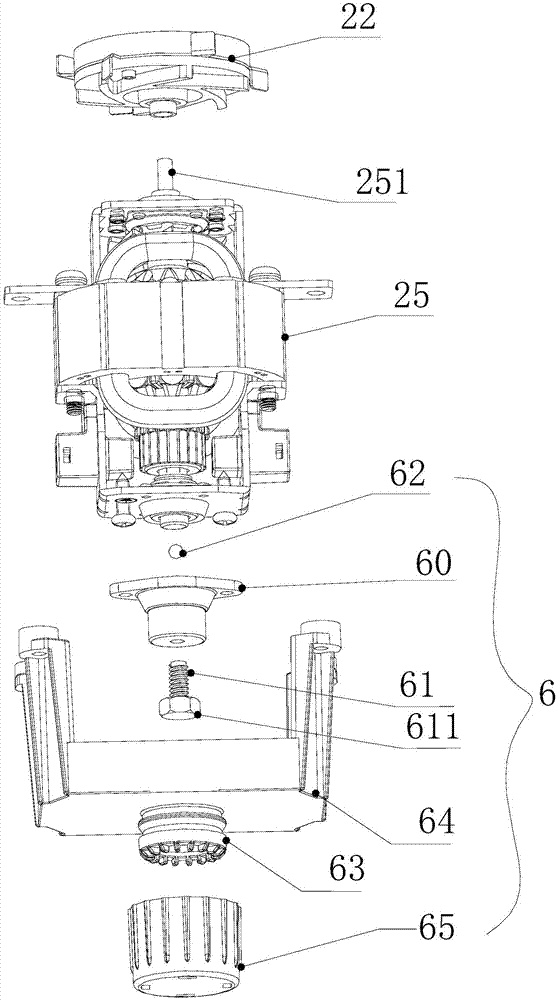

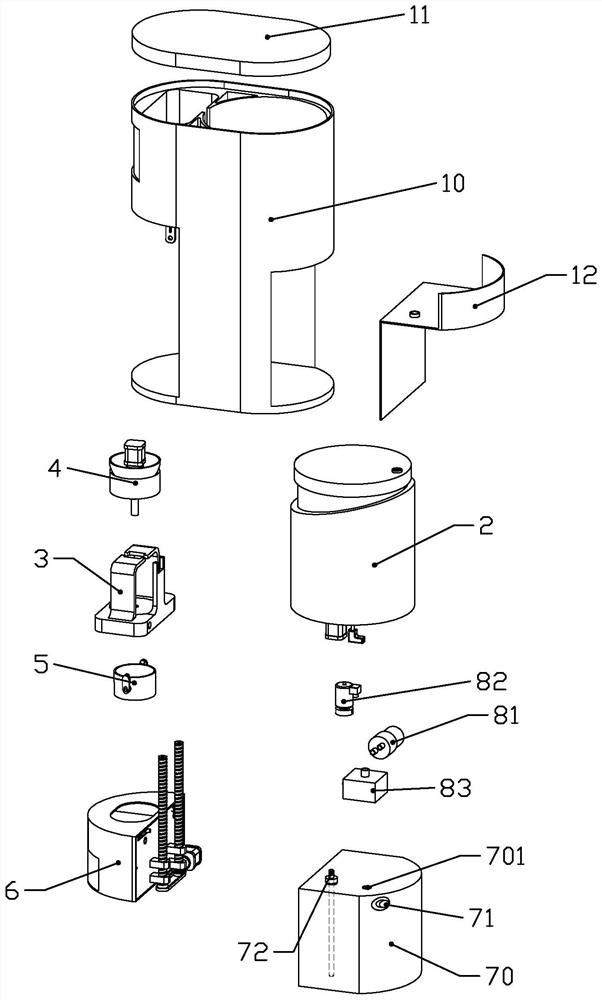

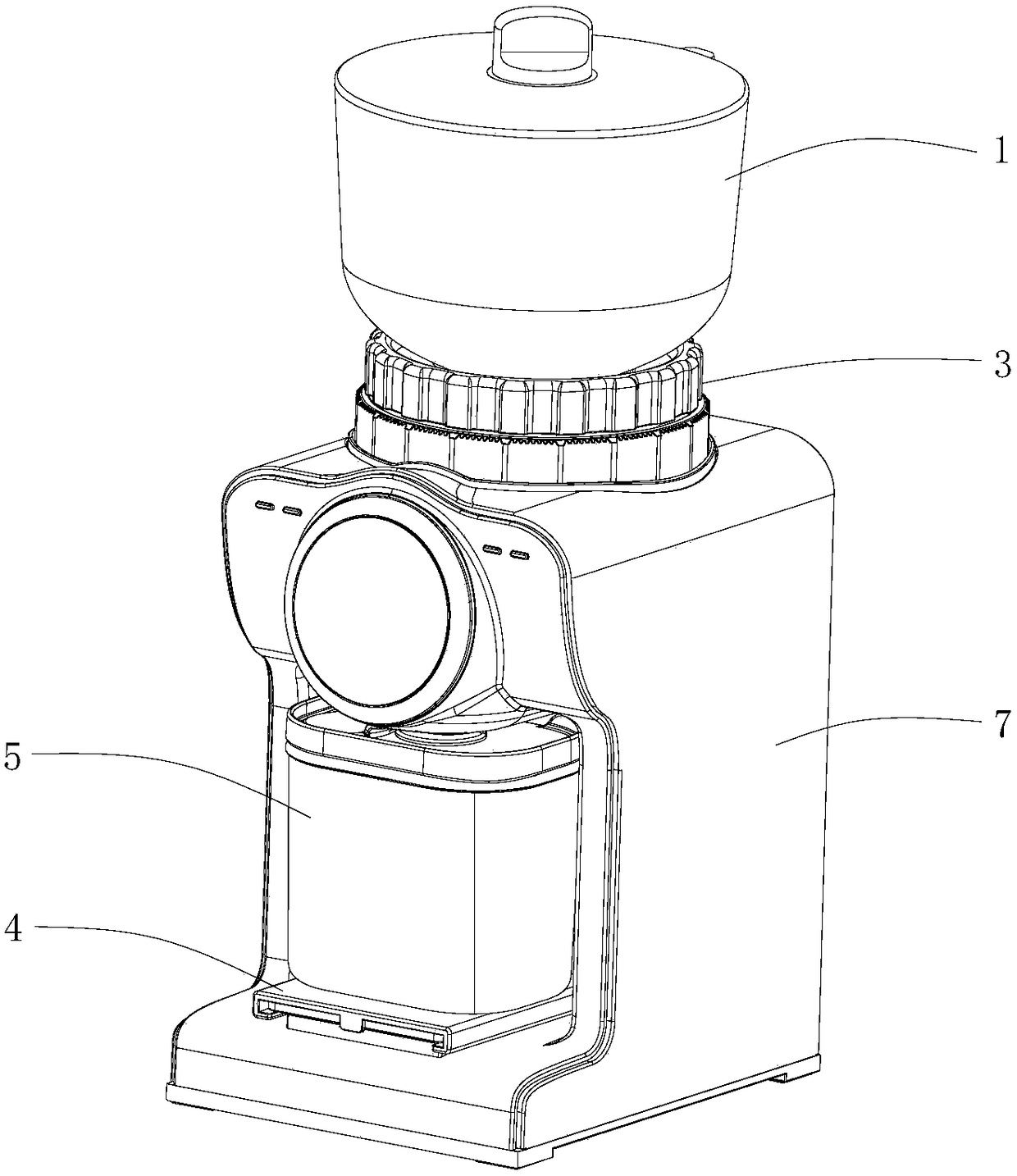

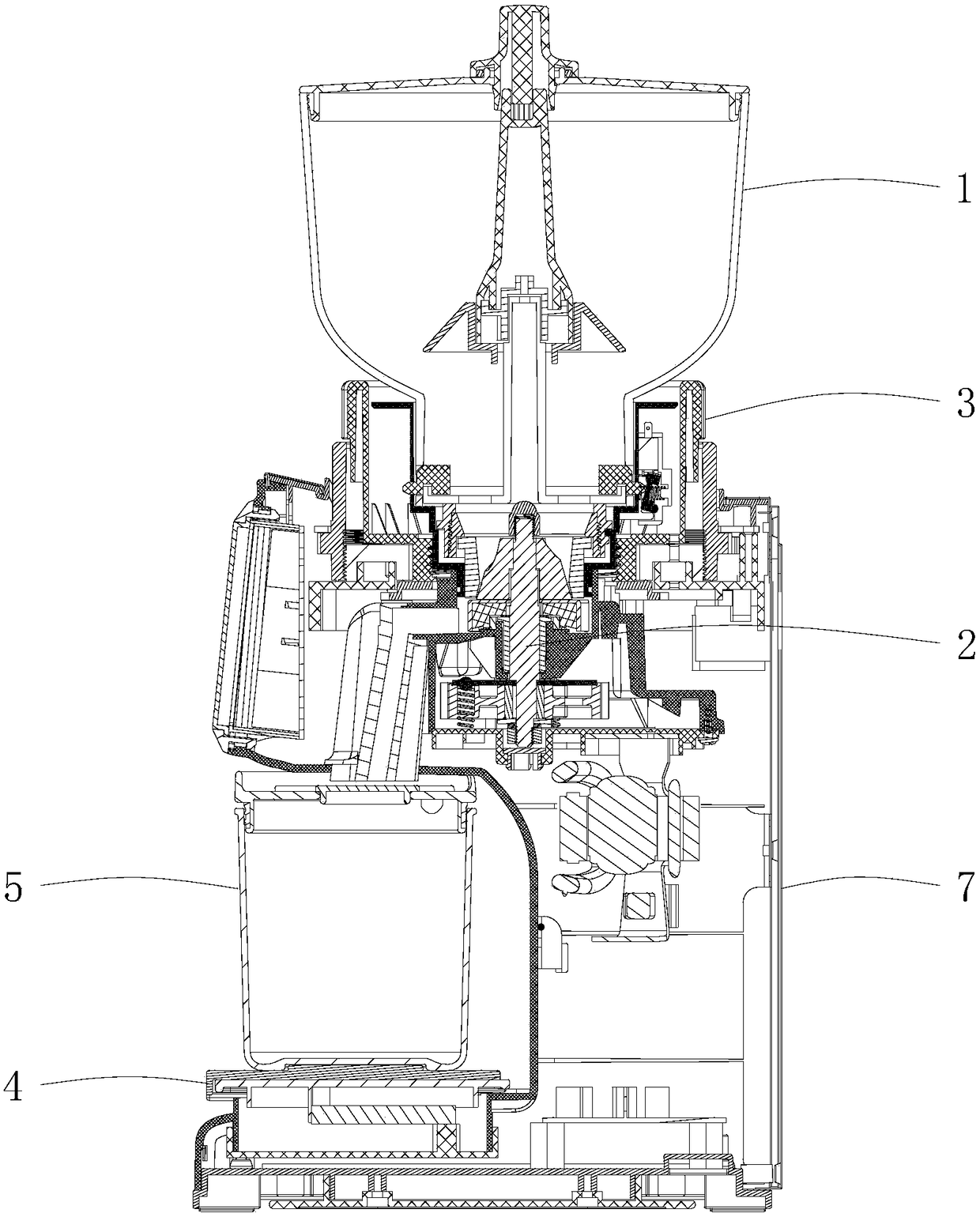

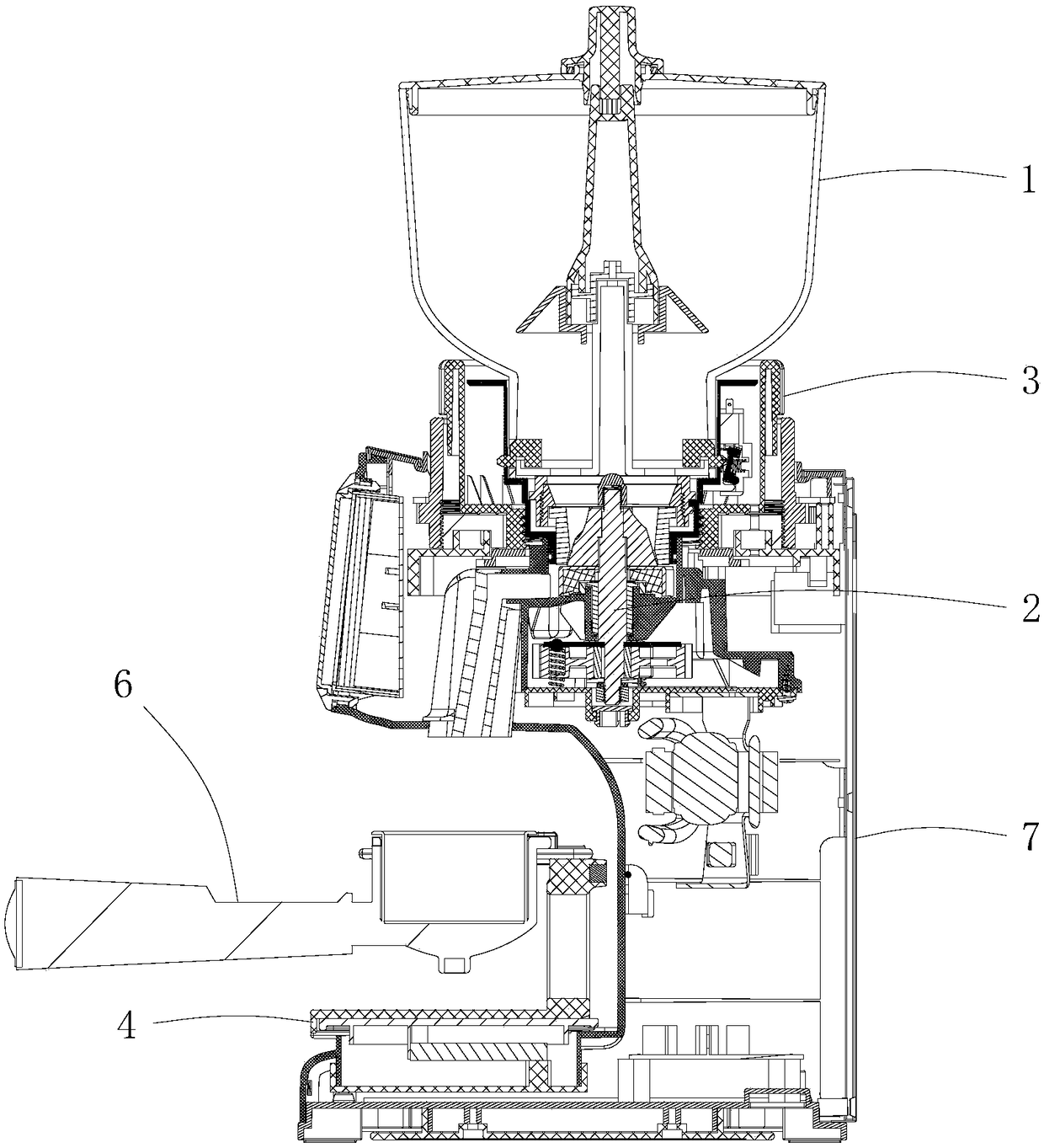

Coffee machine bean grinding device and coffee machine

InactiveCN111938435AGuaranteed tasteFeed speed controlCoffee millsSpice millsAgricultural scienceAgricultural engineering

The invention provides a coffee machine bean grinding device and a coffee machine. The coffee machine bean grinding device comprises a machine body, a material box arranged on the machine body, a discharging device arranged in the machine body and used for controlling the material box, and a weighing device, a grinding device, a conveying device and a brewing chamber which are sequentially arranged at the lower end of the discharging device, and the brewing chamber is connected with a liquid outlet nozzle. The rotating shaft rotates in the discharging cavity, coffee beans are released throughthe storage space between the fan plates, the feeding speed of the coffee beans is controlled, and the situation that a large number of coffee beans inrush, and consequently the grinding amount is toolarge is avoided. Coffee beans discharged from the discharging device enter the weighing cylinder, the discharging valve channel is closed, the pressure sensor monitors the weight of the coffee beansin the weighing cylinder in real time, after the specified weight is reached, the system closes the discharging device, and the discharging valve channel is opened to release the coffee beans to enter the grinding device; and the discharging device and the weighing device are matched with each other, so that quantitative feeding of coffee beans can be realized, the grinding amount of the coffee beans is packaged, and the taste of coffee drinking is guaranteed.

Owner:LUAN SOYEA ELECTRIC APPLIANCE MFG CO LTD

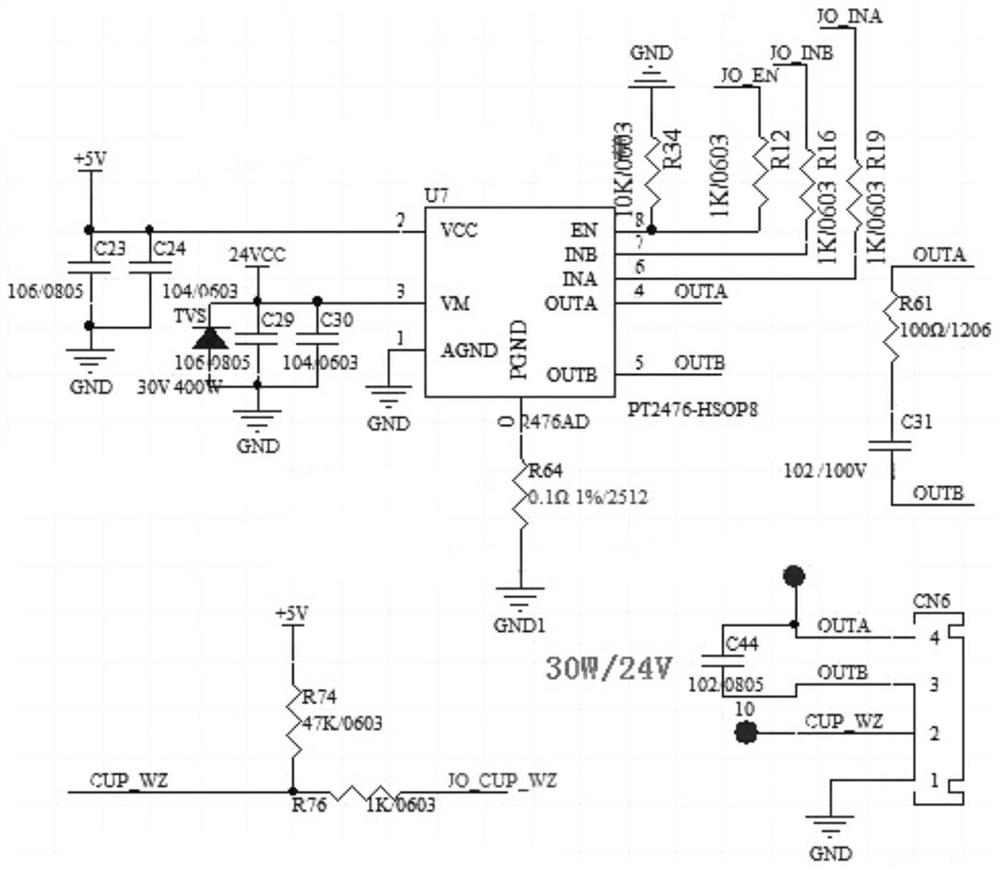

Rotational speed regulating system of bean grinding device

The invention relates to the technical field of bean grinding machines, in particular to a rotational speed regulating system of a bean grinding device. The bean grinding device comprises a grinding wheel group, a gear plate and a motor, the motor drives the grinding wheel group to rotate to grind beans, the gear plate is used for regulating the grinding wheel group to switch between a coarse gearand a fine gear of bean grinding, the regulating system comprises a regulating gear, a potentiometer and a controller, the regulating gear is meshed with the gear plate and is in transmission cooperation with the potentiometer, the potentiometer is connected to the output end of the controller, and the output end of the controller is connected to the control end of the motor. The rotational speedregulating system can automatically regulate the rotational speed of the motor according to grinding gears, the powder discharge amount during coarse powder grinding is relatively low, the powder discharge amount during fine powder grinding is relatively high, and meanwhile, the problems can be avoided that the motor is easily damaged due to too large load, and the grinding device is blocked during rotation.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

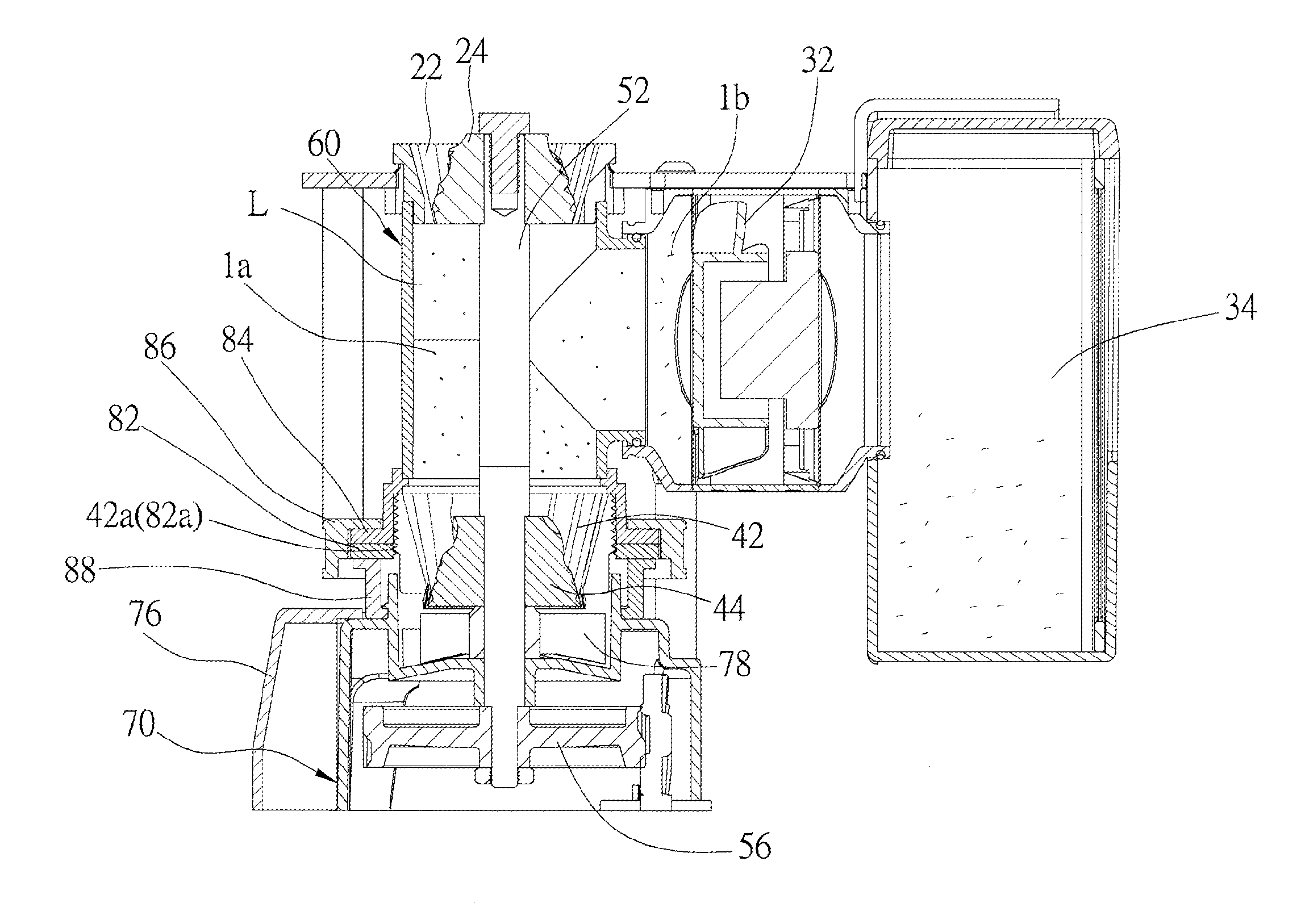

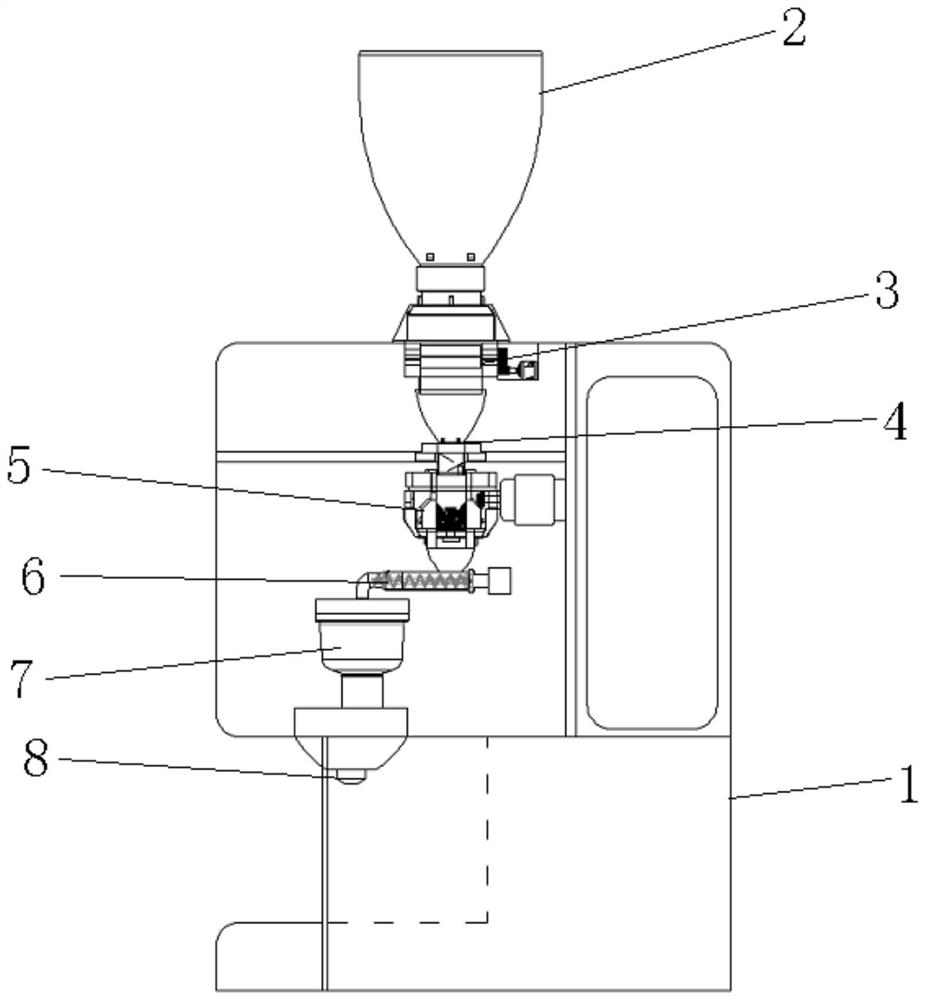

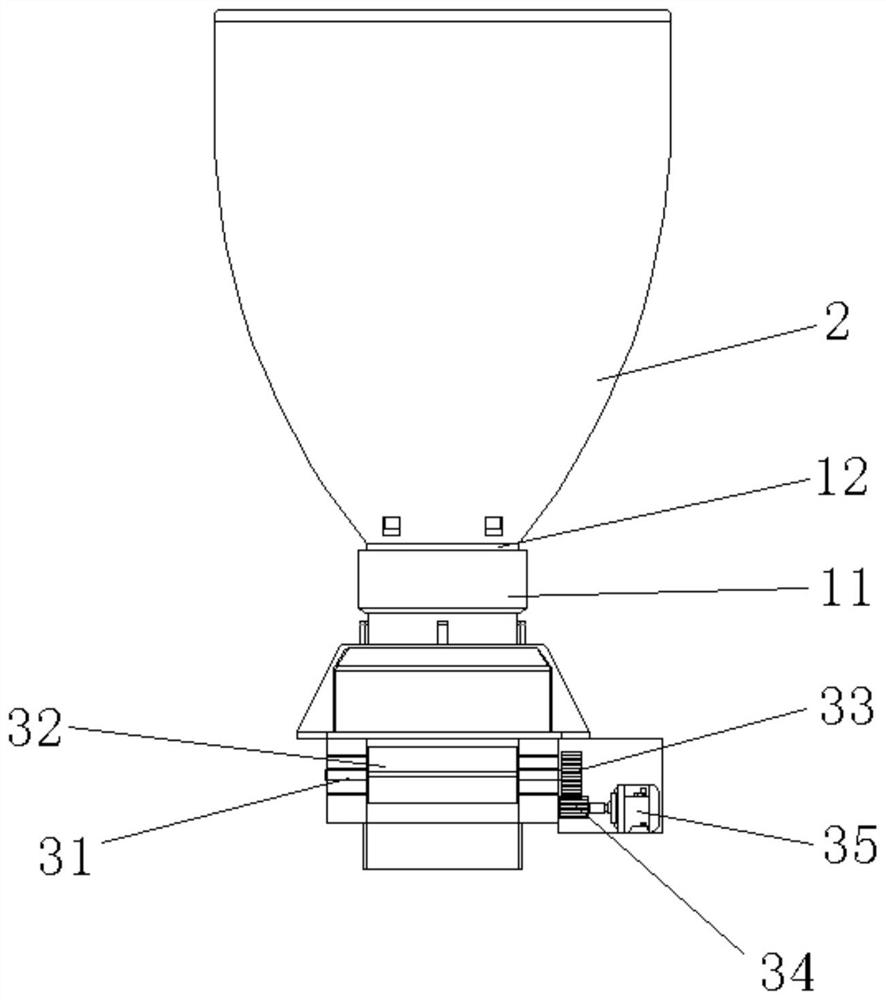

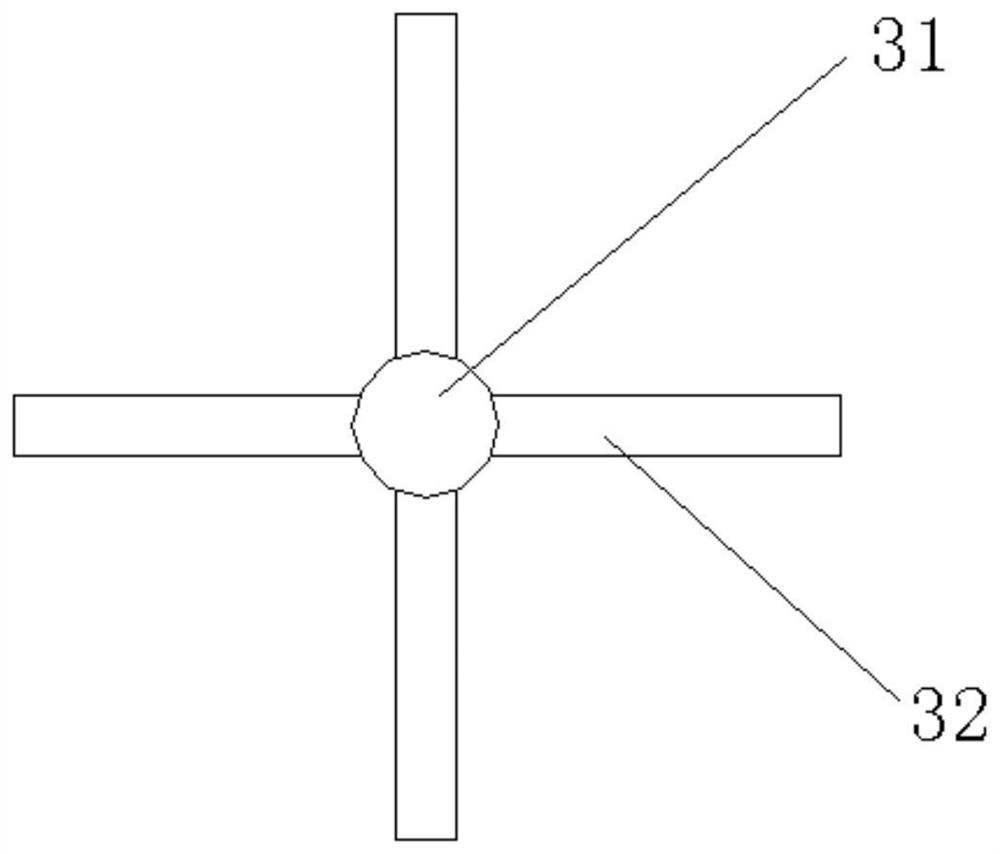

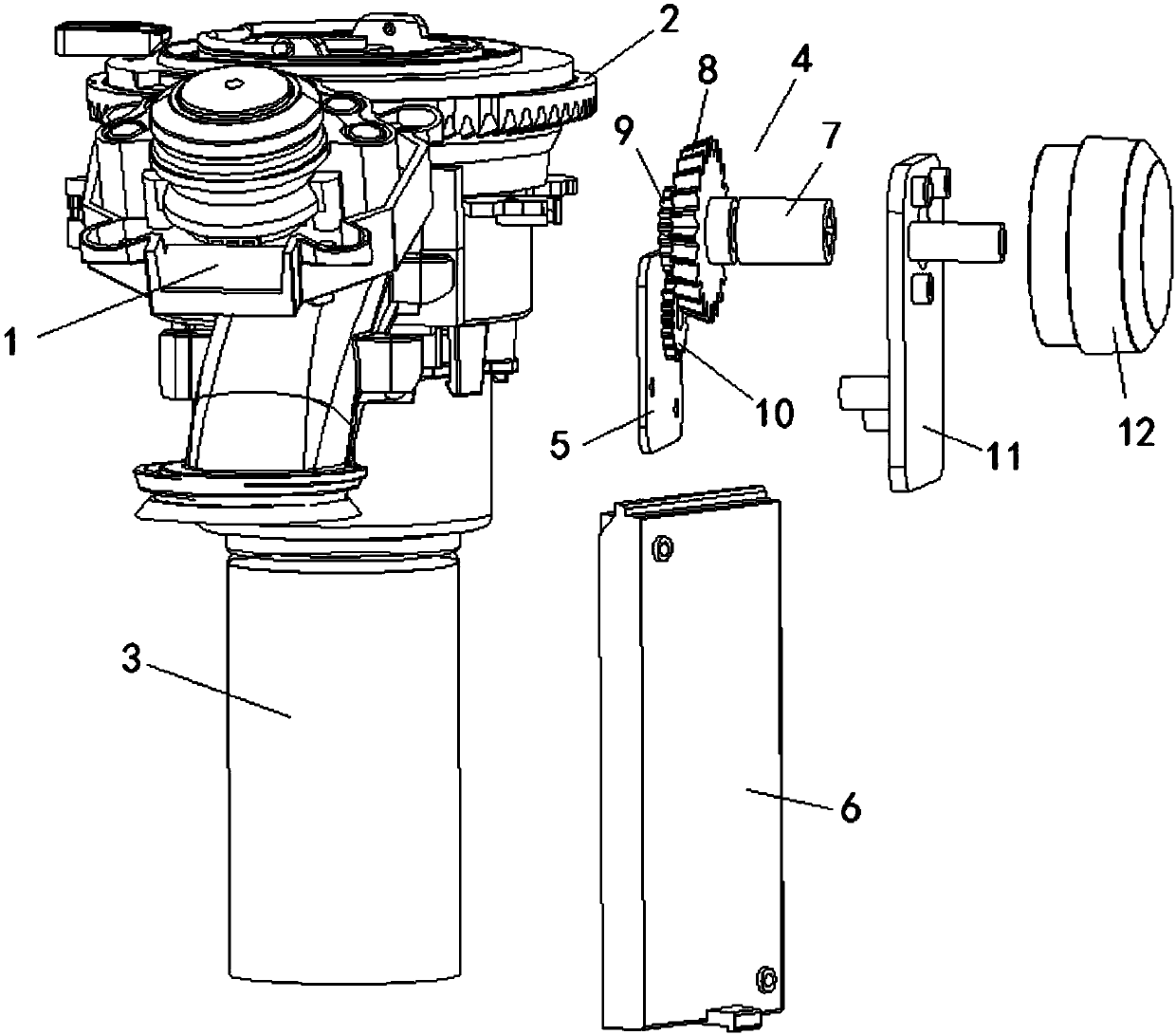

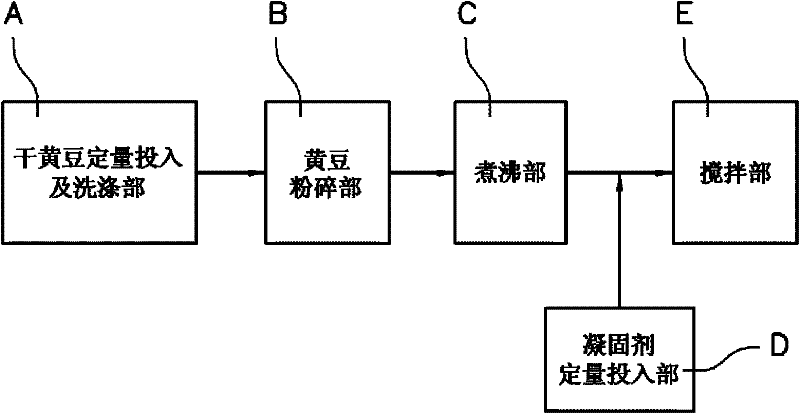

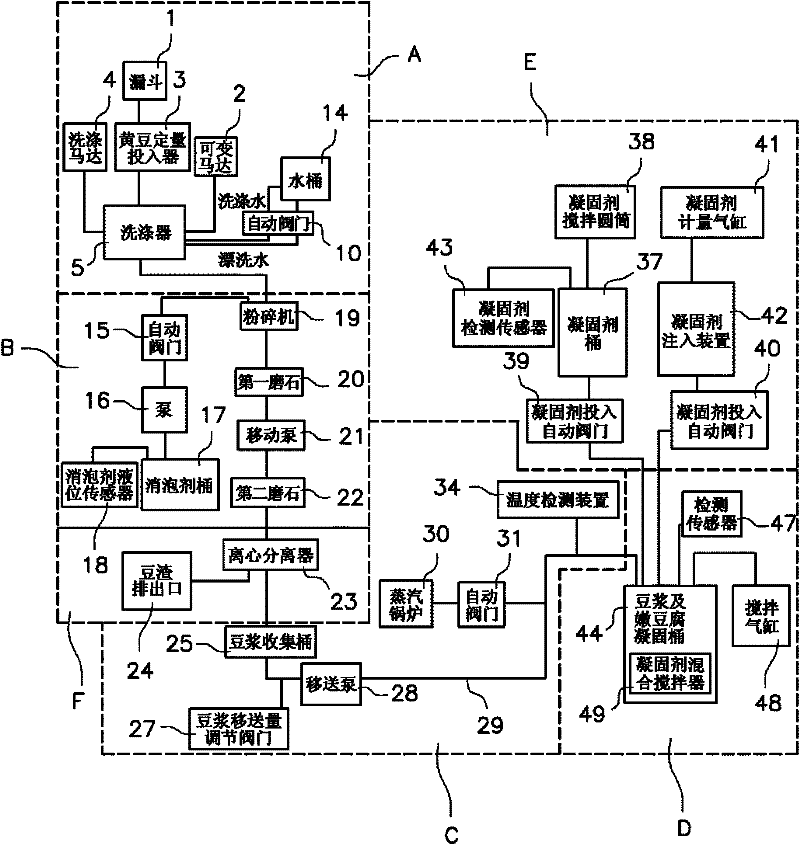

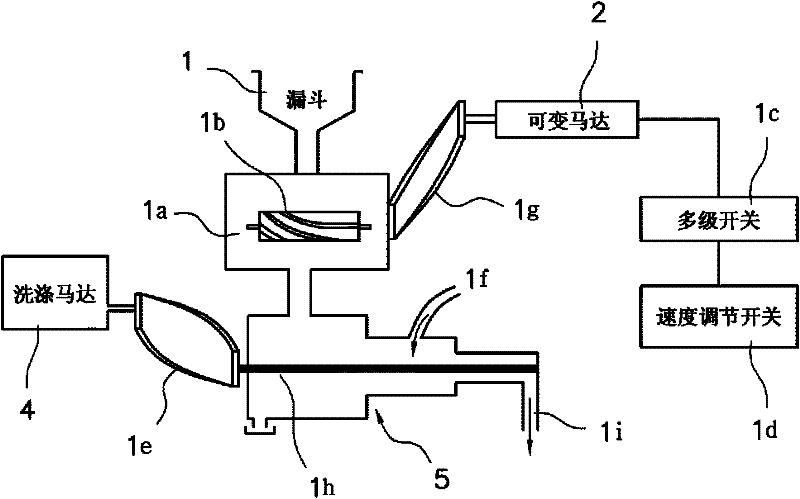

Apparatus for continuously producing tofu

The present invention relates to an apparatus for continuously producing tofu, and more particularly, to an apparatus which enables dry beans to be directly injected into the apparatus instead of being washed, stone-selected and soaked in water, and which automatically and continuously produces tofu. A machine for producing tofu starts operating when dry beans are supplied into a bean hopper (1) and a fixed amount of beans are injected into a washer (5) by a quantitative bean feeder (3) and by a predetermined frequency of rotation of a variable motor (2) such that the concentration of soymilk can be maintained at a predetermined level regardless of the type of beans. Subsequently, a washer motor (4) rotates, an automatic valve (10) opens, and washing water, rinsing water and water for producing tofu are supplied by a water tank (14).; Then, a screw rotates to collect stones into a stone-collecting container arranged below the washer (5), and beans are transferred along the screw, mixed with the water for producing tofu, and supplied into a crusher (19) and crushed. Subsequently, an automatic valve (15) opens, and a defoamer is fed into the crusher (19) from a defoamer container (17) and naturally dropped down together with the mixture of water and crushed beans. The dropped crushed beans are transferred to a first millstone (20) and second millstone (22) and ground into fine particles. The ground bean particles are divided into a soymilk and bean-curd dregs by a centrifugal separator (23).; Subsequently, the soymilk is boiled by means of the steam supplied by a steam boiler (30), and introduced into a soymilk and soft tofu coagulation container (44) together with a coagulant supplied from a coagulant container (37) to be instantaneously made into tofu.

Owner:WONDUWONFOOD

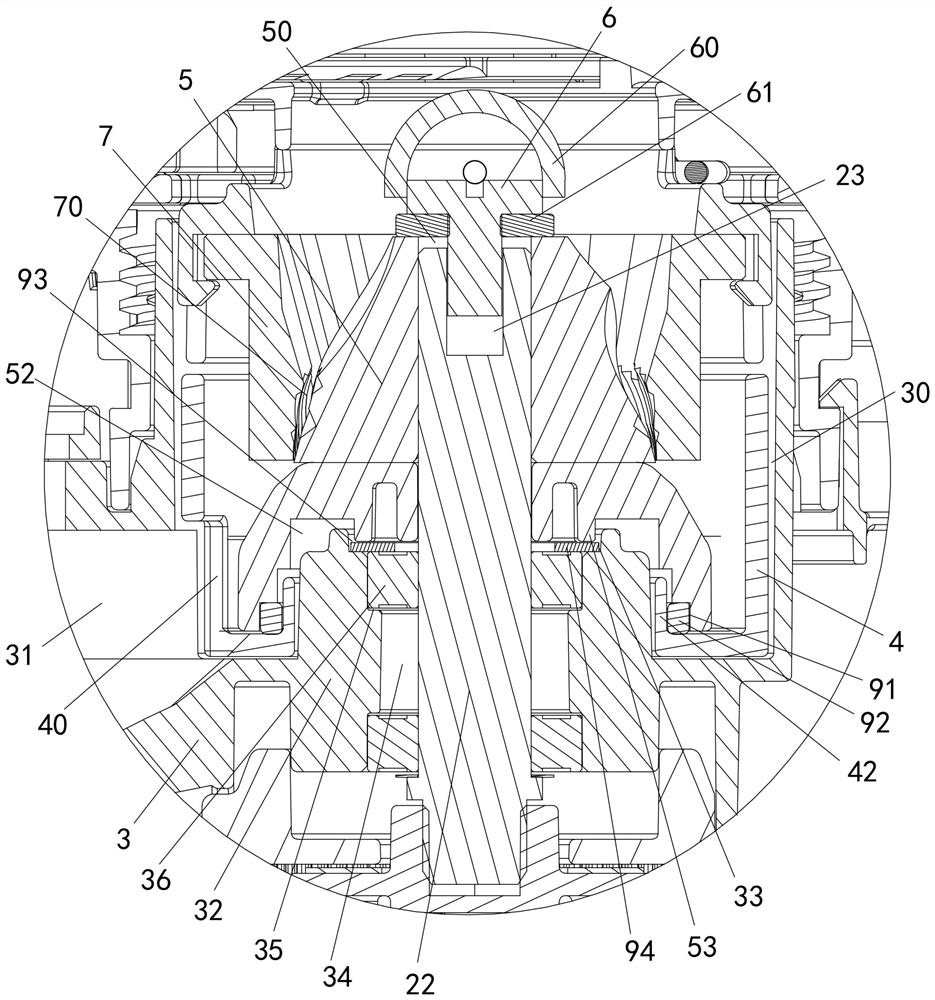

Regulating device for regulating fineness of ground coffee and coffee grinder

ActiveCN107411583AManufacturing precision requirements are lowReduce manufacturing difficultyCoffee millsSpice millsElectric machineGround-bean

The invention discloses a regulating device for regulating the fineness of ground coffee and a coffee grinder. The regulating device comprises a first bracket which is arranged under a motor and fixed at the lower end part of the motor, a regulating element and a limiting auxiliary regulating structure, wherein an axial screw hole is formed in the middle of the first bracket, and the upper tail end of the motor rotating shaft of the motor is fixedly connected with a lower millstone which is matched with an upper millstone so as to grind the coffee; the regulating element is screwed in the axial screw hole of the first bracket, and the lower tail end of the regulating element is provided with a polygonal regulating screw head; the limiting auxiliary regulating structure is used for preventing the regulating element from being loosened in the axial screw hole of the first bracket and providing the regulating element with rotation so as to regulate the axial position of the lower millstone; the limiting auxiliary regulating structure is connected with the regulating screw head. The regulating device can decrease the difficulty of manufacturing and improve the quality and efficiency of production, and is convenient to operate and high in reliability.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

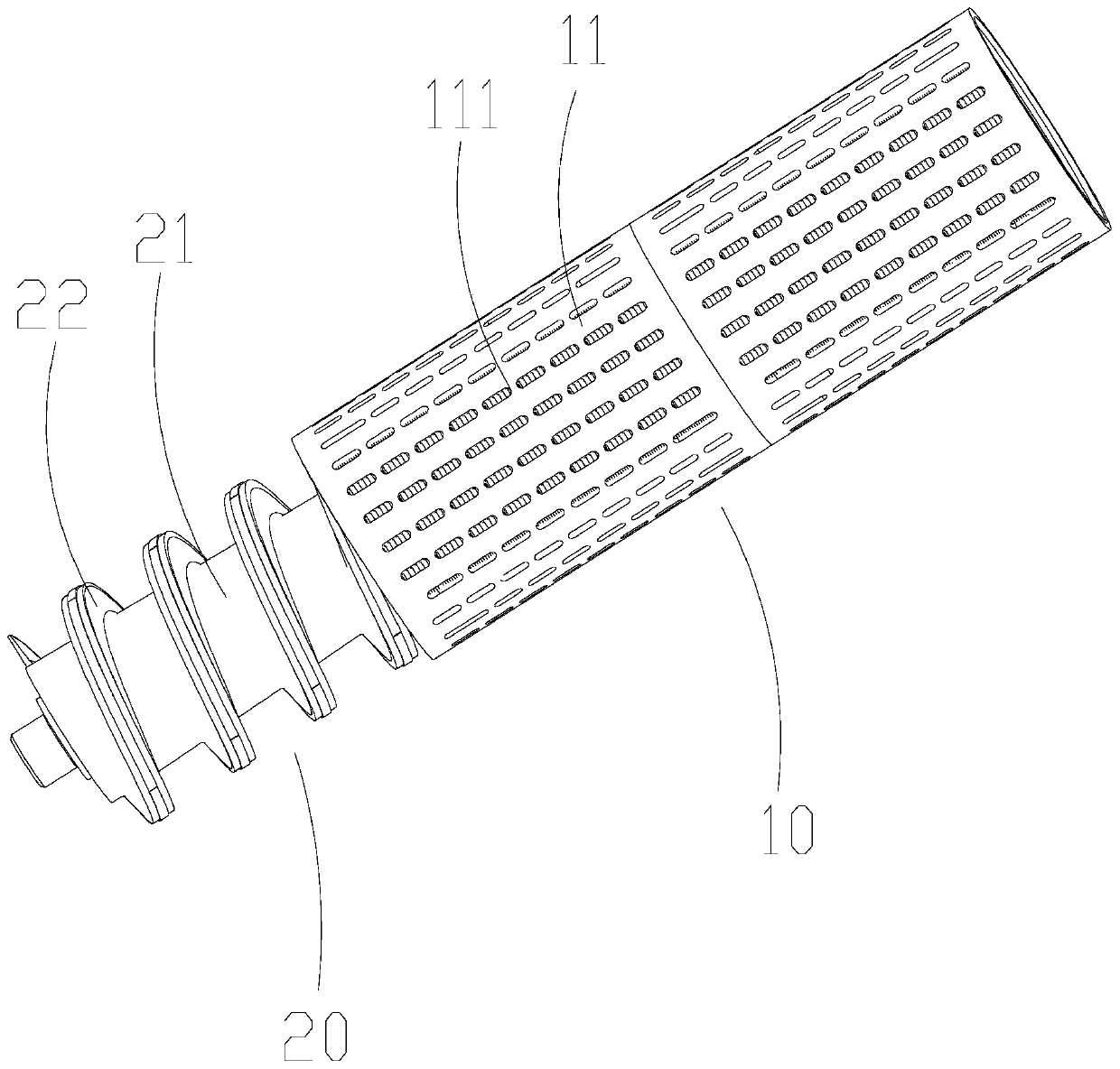

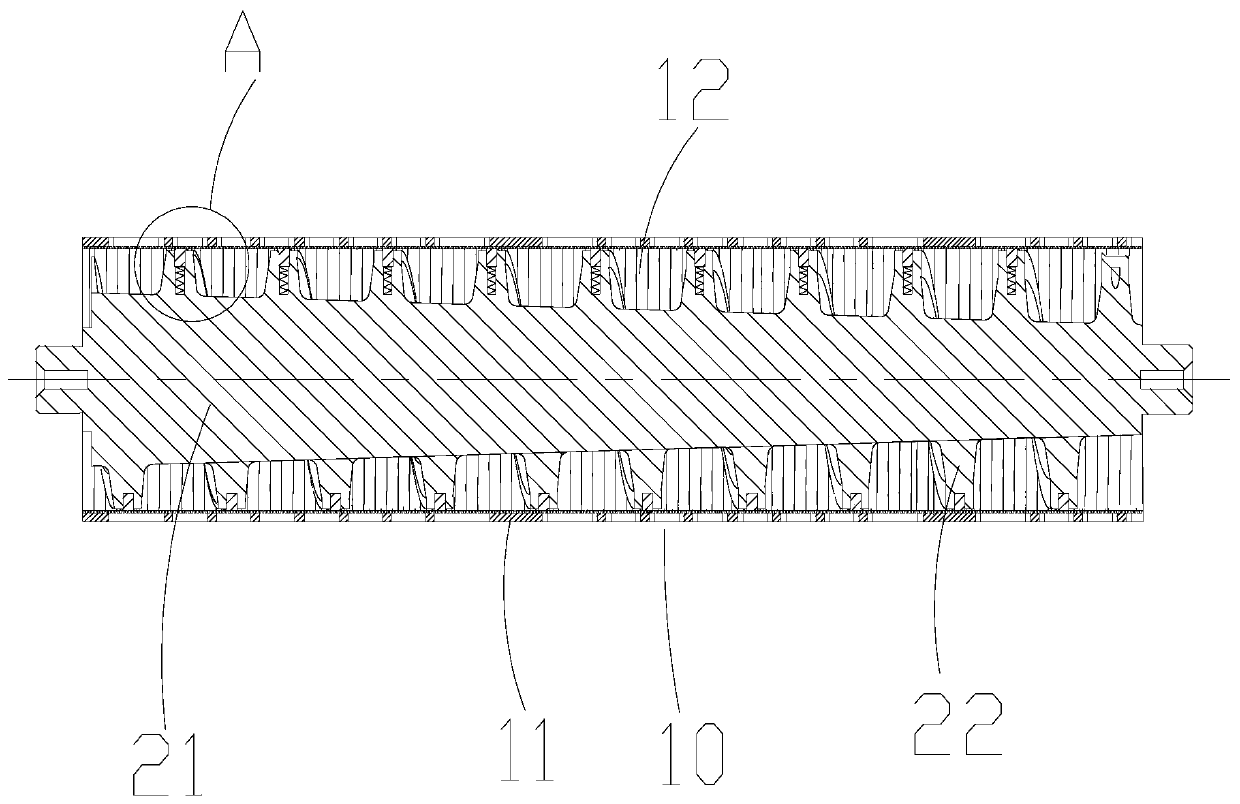

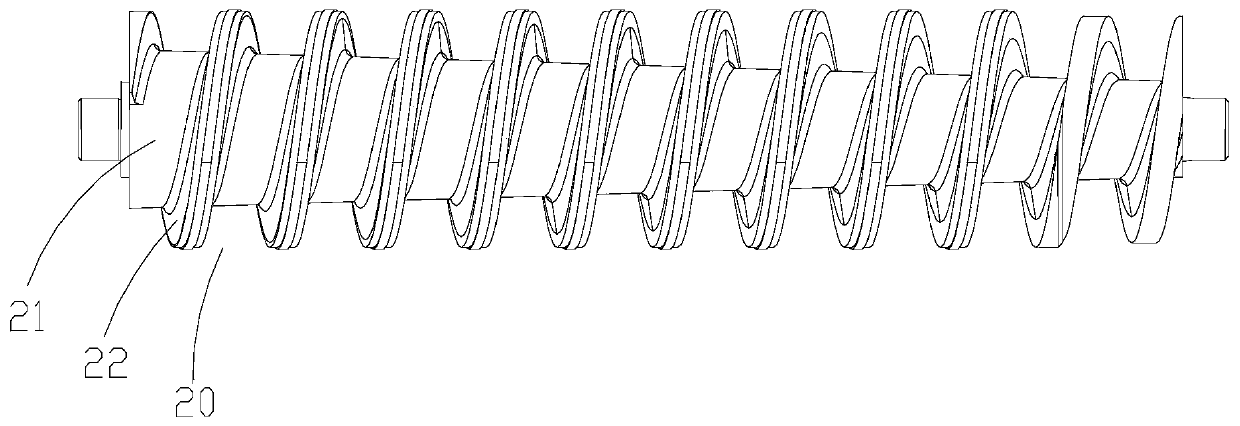

Dreg-milk separating device

PendingCN110252011AIncrease squeezeEasy to separateStationary filtering element filtersGround-beanEngineering

The invention provides a dreg-milk separating device. The dreg-milk separating device comprises a filtering device and a pressing device, wherein the filtering device comprises a filtering barrel and a filtering mesh inside the filtering barrel; the pressing device comprises a rotating shaft and a screw blade, and the rotating shaft drives the screw blade to rotate inside the filtering device; through rotation of the rotating shaft, the dreg and milk mixture of ground beans can be screwed into a sealed chamber, along with the diameter increase of the rotating shaft, the space of the sealed chamber between the screw blade and the filtering mesh can be gradually reduced to achieve pressing on the dreg and milk mixture, bean milk can be drained out via small holes in the filtering barrel and the residual dregs can be discharged from one end of the pressing device to automatically complete dreg-milk separation, so that the milk and the dregs can be separated more thoroughly and the production efficiency can be high; meanwhile, the rotating direction of the filtering mesh is identical to that of the pressing device, so that filtered materials can be better pushed forwards and pressed, and the dreg-milk separating device can achieve self-cleaning.

Owner:佛山市科屹五金电子有限公司

Purified amylase inhibitor and novel process for obtaining the same

InactiveUS20060147565A1Improving post-prandial glucose toleranceBiocideMetabolism disorderDiabetes mellitusAmylase inhibitors

The present invention provides a purified amylase inhibitor obtained by a superior process that includes extracting ground beans with supercritical carbon dioxide. The invention also provides a method for inducing weight loss in a mammal in need thereof comprising administering to the mammal, an effective amount of an amylase inhibitor obtained by the superior process. A method for improving post-prandial glucose tolerance in a diabetic mammal comprising administering to the mammal, an effective amount of an amylase inhibitor obtained by the superior process, is also provided.

Owner:PHARMACHEM LAB INC

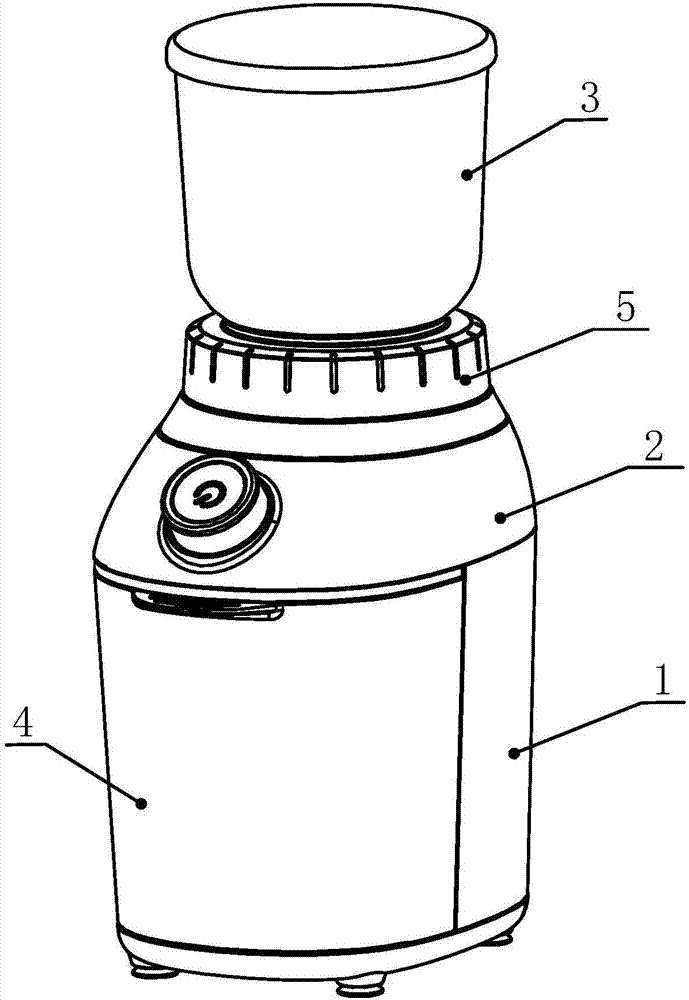

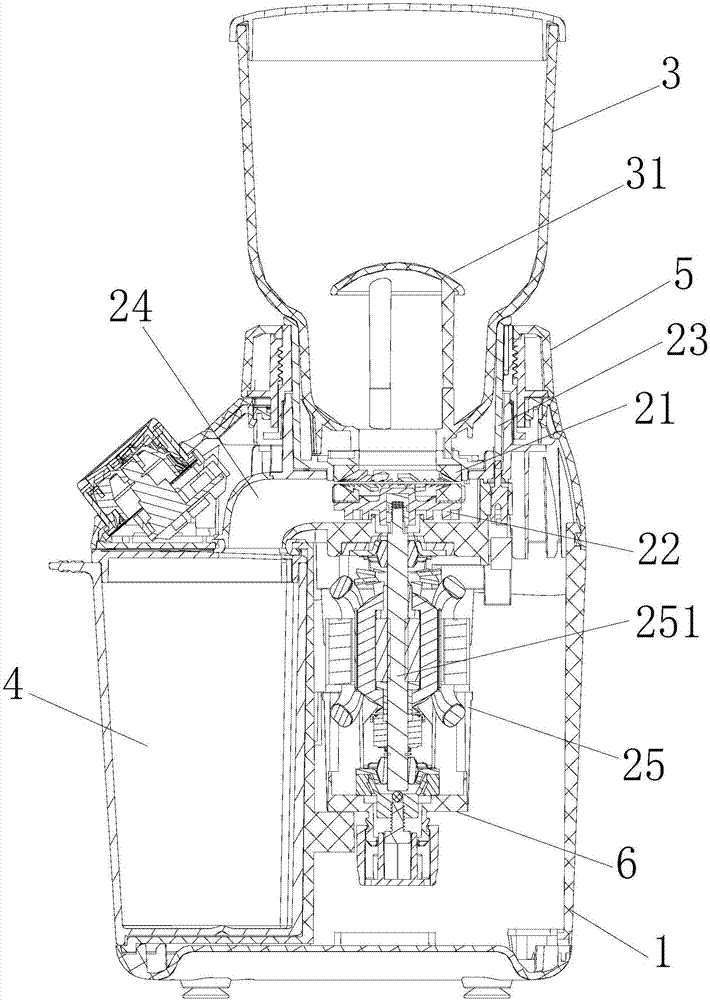

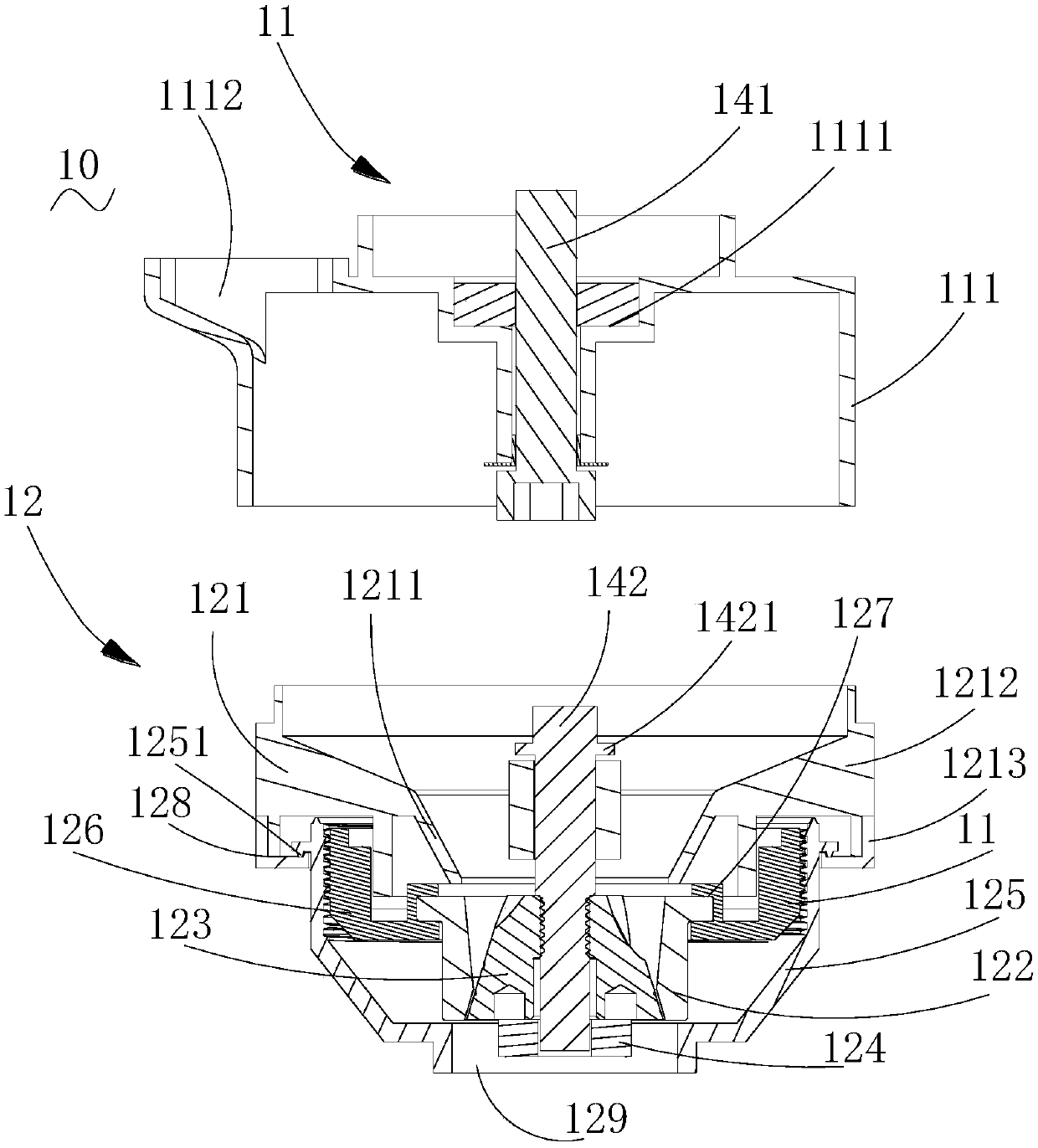

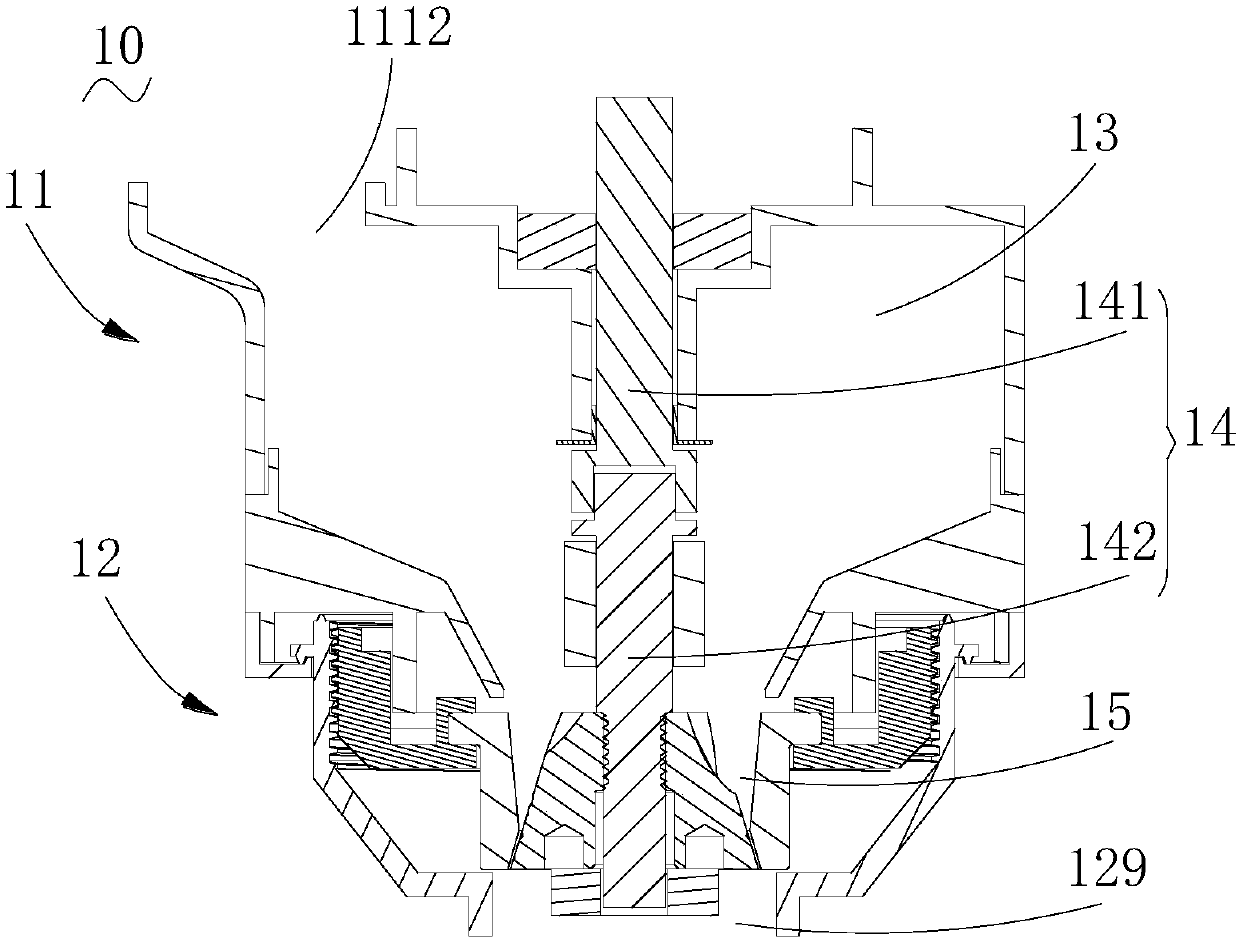

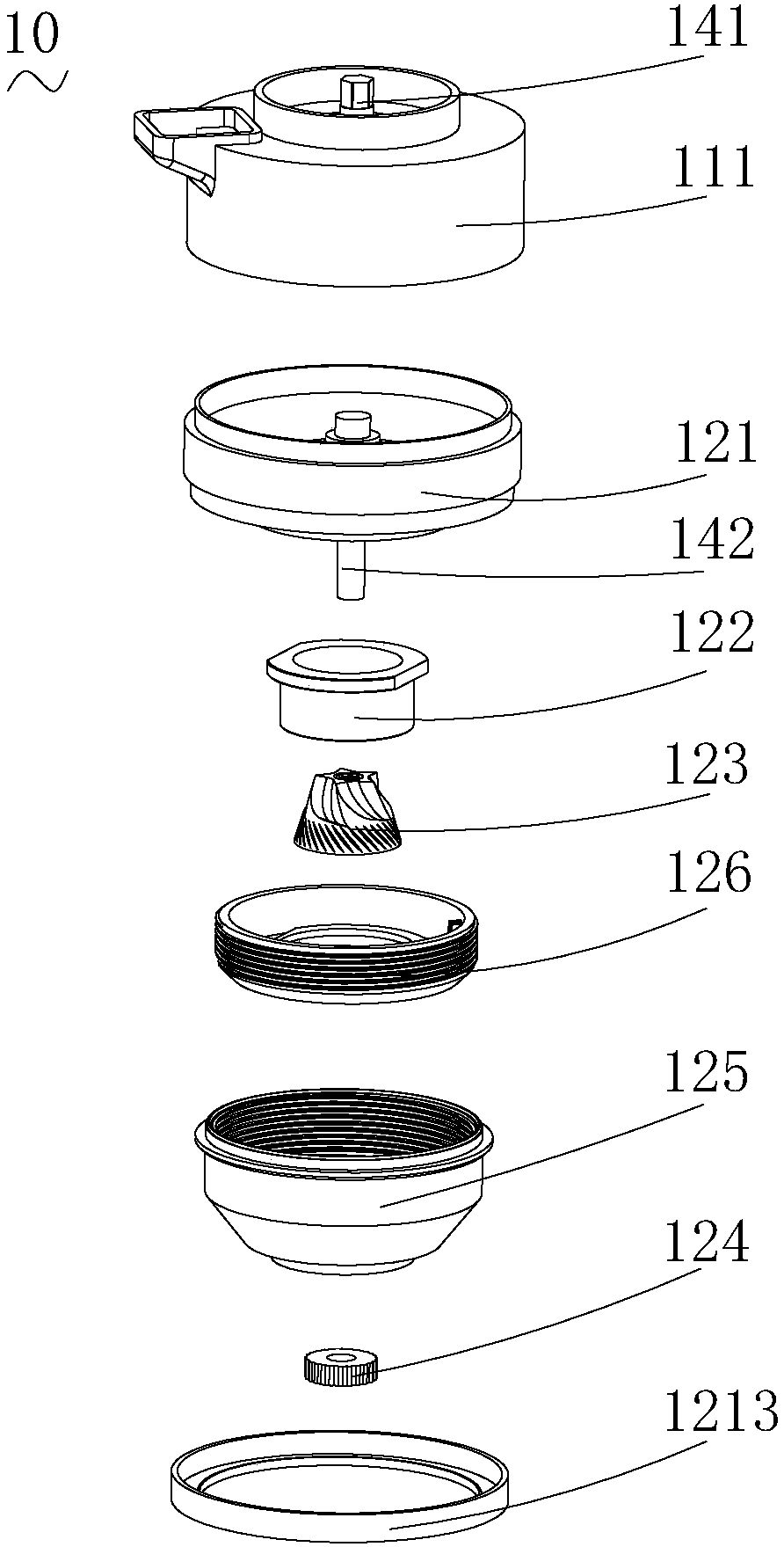

Bean grinding bin and bean grinding machine

The invention discloses a bean grinding bin which comprises an upper shell component, a lower shell component and a rotating shaft. The upper shell component comprises an upper shell, the lower shellcomponent comprises a lower shell, an outer knife head and a conical knife head, the outer knife head is arranged on the inner side of the lower shell, the lower shell can be detachably mounted with the upper shell, and when the lower shell is mounted to the upper shell, a bean grinding cavity is formed; the rotating shaft is rotatably arranged on the upper shell or the lower shell, the conical knife head is arranged on the rotating shaft and positioned on the inner side of the outer knife head, and a bean grinding gap is formed between the conical knife head and the outer knife head. The rotating shaft can drive the conical knife head to rotate when rotating while the outer knife head does not move, and beans positioned in the bean grinding cavity enter the bean grinding gap to be broken;the upper shell of the upper shell component and the lower shell of the lower shell component are in detachable connection, so that when the bean grinding bin needs to be cleaned, the upper shell andthe lower shell can be demounted for cleaning the inside of the bean grinding bin, and cleaning is convenient. The invention further discloses a bean grinding machine comprising the bean grinding bin.

Owner:GUANGDONG SHUNDE CHINNO IND DESIGN

Preparation method of kiwi-flavored bean dreg biscuit

InactiveCN106234537AFull of nutritionIncrease elasticityDough treatmentBakery productsCross-linkHydroxylamine

The invention discloses a preparation method of a kiwi-flavored bean dreg biscuit. The preparation method comprises the following steps of taking high gluten wheat flour, dispersing the high gluten wheat flour into distilled water, adding glutamine transaminase, and reacting for 2 hours; performing freeze drying to obtain modified wheat flour; taking bean dregs, drying the bean dregs, grinding the dried bean dregs, and sieving the ground bean dregs to obtain bean dreg powder; taking a kiwi, washing the kiwi clean, peeling the kiwi, and juicing the kiwi, filtering kiwi juice, and then diluting the kiwi juice with distilled water; mixing the modified wheat flour with the bean dreg powder; adding the diluted kiwi juice into the mixed powder, and preparing biscuits. Glutamine transaminase is a protease obtained by a cross-linking reaction between a gamma-hydroxylamine group of a glutamine residue and an epsilon-amidogen of lysine in a catalytic protein side chain; the glutamine transaminase is capable of catalyzing wheat protein crosslinking to generate a protein polymer with relatively high molecular weight; the modified wheat powder is taken as a raw material, and the kiwi juice and the bean dregs are added during a preparation process, so that the prepared biscuits are rich in nutrition and improved in elasticity, viscosity and hardness, and the taste and color of the prepared biscuits are improved to different extent.

Owner:淮南市农康食品有限公司

Processing method of rice noodle segments

The present invention discloses a processing method of rice noodle segments. The processing method of rice noodle segments comprises the following steps: (1) crushing: rice is ground into rice flour and beans are ground bean flour; (2) mixing and stirring: the bean flour and the rice flour are mixed and stirred evenly, and the addition mass percentage of the bean flour is 10%-30% of the rice flour; (3) water adding and stirring: the addition amount of the water is a sum of 30% of the mass of the rice flour and 25%-60% of the mass of the bean flour; (4) high-temperature extruding: a mixture of the rice flour and the bean flour is subjected to heating and extruding via a high-temperature pressure device to be extruded into the flat rice noodle segments; and (5) temperature lowering and outputting: the extruded rice noodle segments are subjected to temperature lowered plasticization and the rice noodle segments are output. The processing method solves the problems that the noodle skin of the rice noodle segments prepared by the conventional rice noodle segment preparation method is uneven in thickness, and the rice noodle segments are difficult to cook, have hard hearts, and are short in shelf period, easy to go bad, etc.

Owner:苏礼福

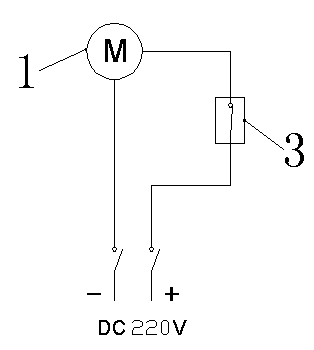

Bean grinding device with overheat protection function

InactiveCN103844923AAvoid burnsSimple structureCoffee millsSpice millsElectric machineAgricultural engineering

The invention discloses a bean grinding device with an overheat protection function. The bean grinding device comprises a bean grinding device body and a motor, wherein the bean grinding device body is connected to and arranged on the output end of the motor. The bean grinding device also comprises an overheat protection device which is arranged on the motor and electrically connected with the power end of the motor. The bean grinding device with the overheat protection function has the beneficial effect that motor burnout, caused by an overhigh temperature resulting from the rotor locking of the motor due to long-term working of the bean grinding device or due to that a blade is locked by a hard substance, is effectively avoided, and simultaneously, the bean grinding device is simple in structure, reliable in performance and low in production cost.

Owner:SUZHOU IND PARK KALERM ELECTRIC APPLIANCES CO LTD

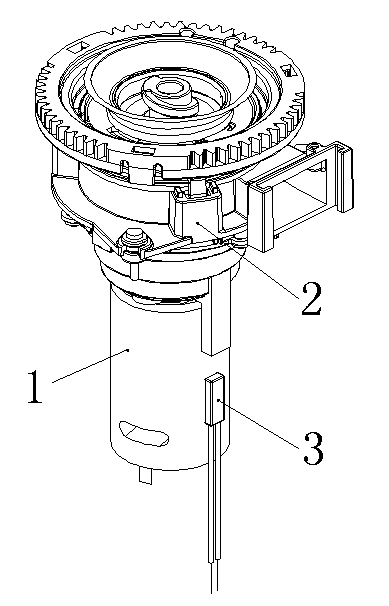

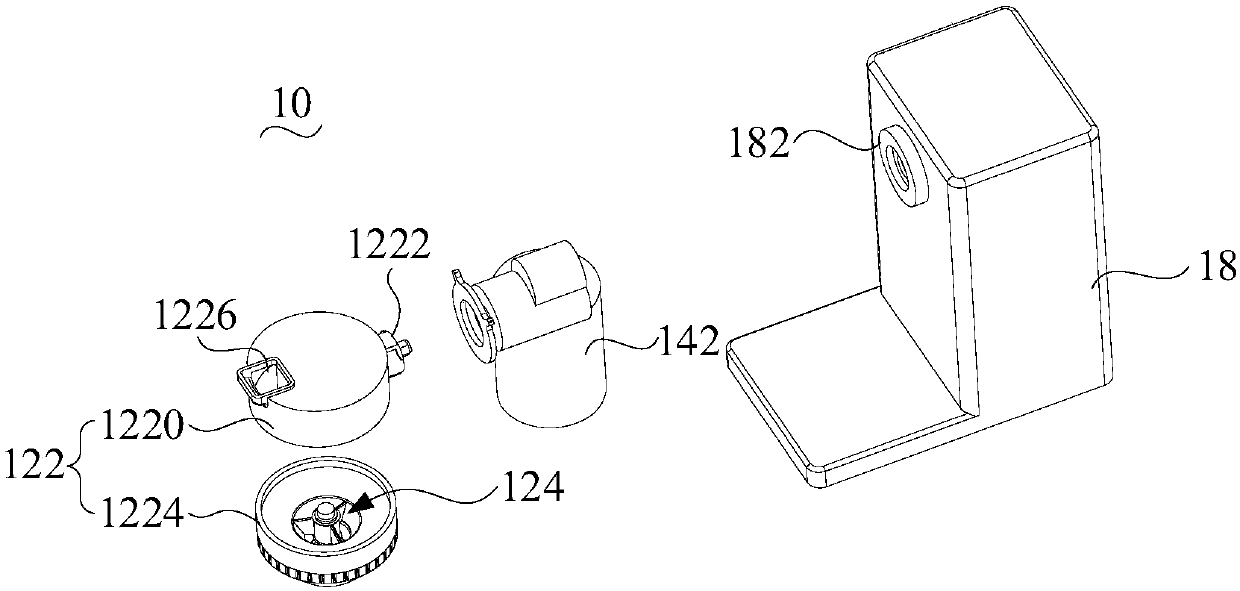

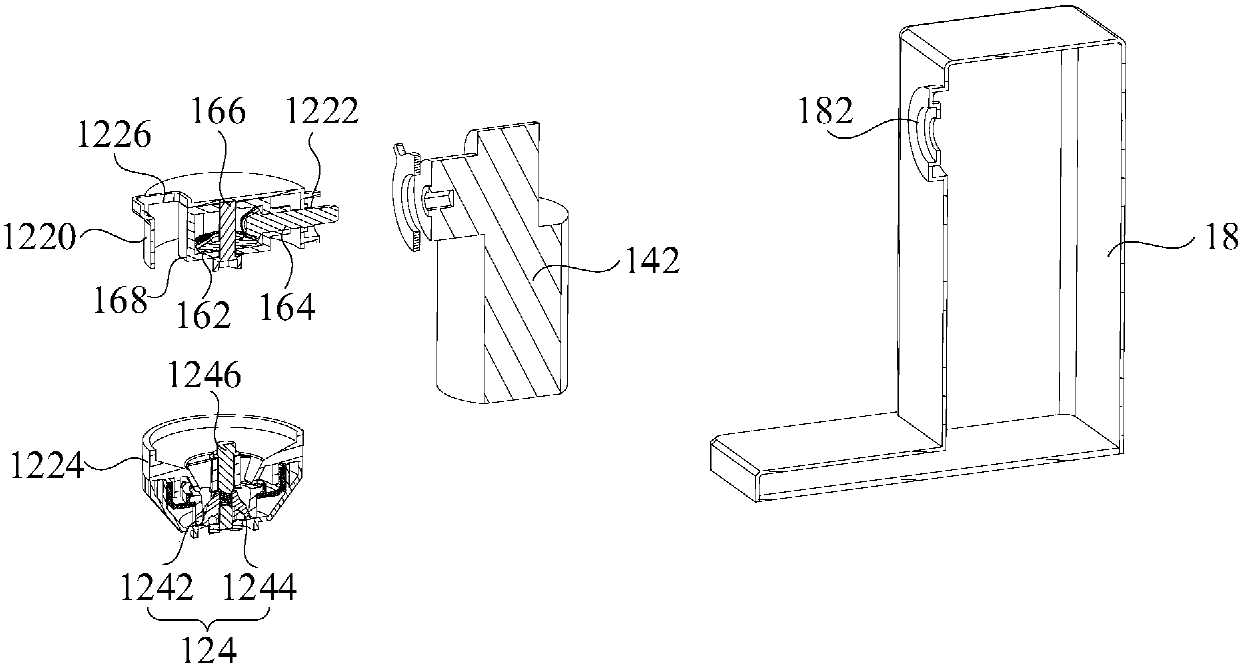

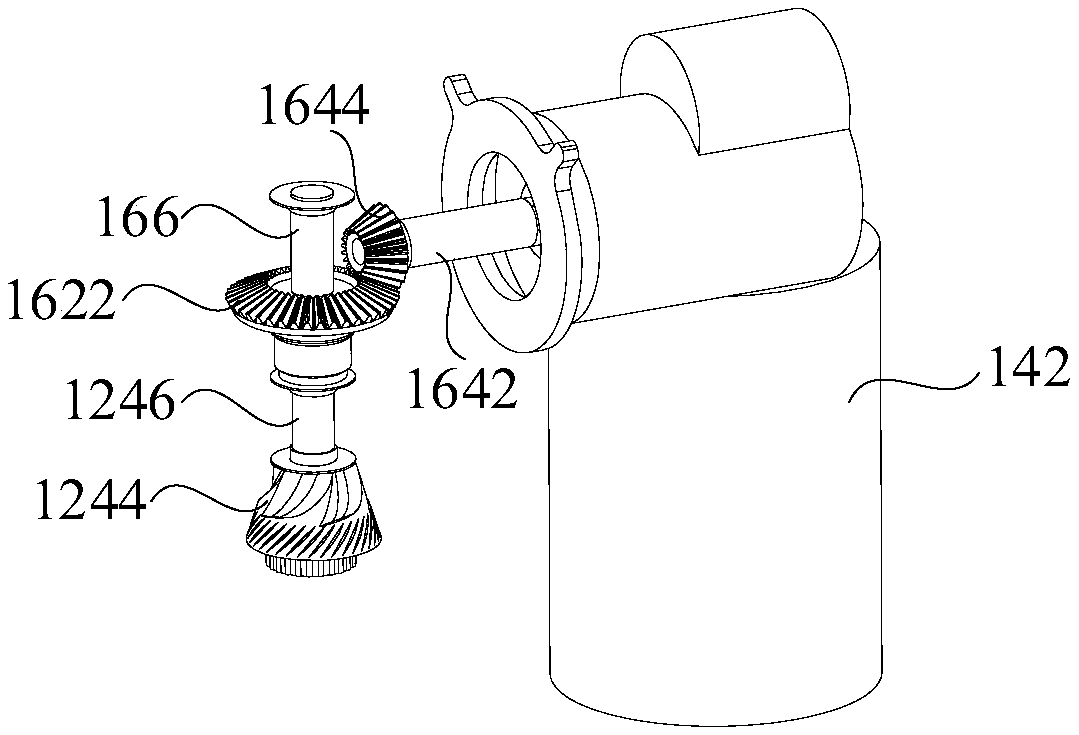

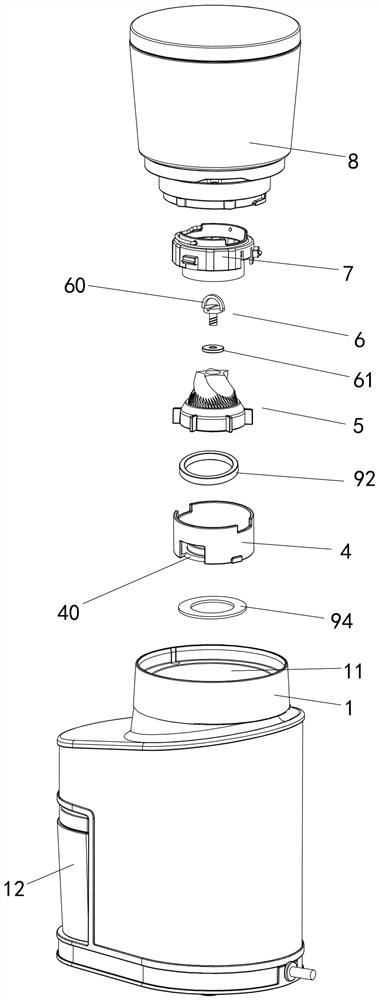

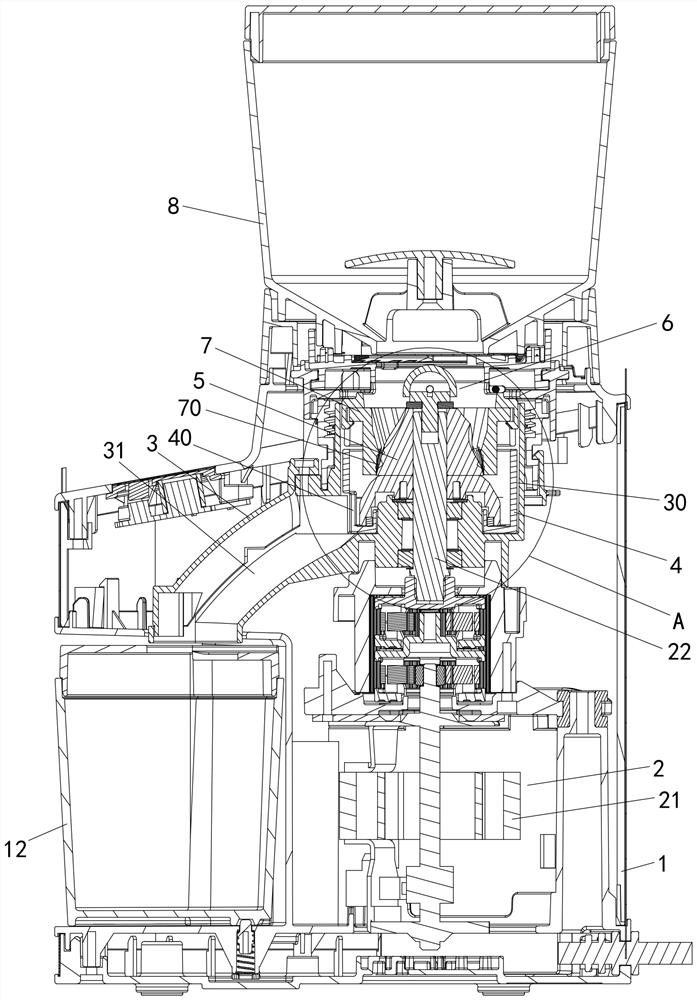

Bean grinding device and coffee maker

The invention relates to a bean grinding device which comprises a bean grinding mechanism, a driving mechanism, a transmission mechanism and a support. The bean grinding mechanism comprises a bean grinding bin body and a winching assembly. The driving mechanism is used for providing power. The transmission mechanism is arranged in the bean grinding bin body and used for transferring power of the driving mechanism to the winching assembly. The winching assembly comprises an outer tool bit arranged in the bean grinding bin body and an inner tool bit arranged in the bean grinding bin body in a pivoted mode, the driving mechanism is located on the outer peripherical side of the bean grinding bin body and can be separated from or be in matched connection with the transmission mechanism, and theinner tool bit can be driven by the driving mechanism to rotate when the driving mechanism is connected to the transmission mechanism. The bean grinding bin body and the driving mechanism of the beangrinding device are separately arranged, the bean grinding bin body and the driving mechanism are separated when cleaning is needed, dismounting is convenient, and cleaning is facilitated. The invention also provides a coffee maker.

Owner:GUANGDONG SHUNDE CHINNO IND DESIGN

Hydration process for a refried bean product

This application provides a process for producing a refried bean product. The refried bean product contains both homogenized cooked bean particles and larger sized cooked bean particles and provides a texture typical of refried beans. The present process includes hydrating dried beans in water a period of time sufficient to increase the moisture content of the beans, cooking the hydrated beans in water, coarse grinding the cooked beans to provide a bean slurry, dividing the bean slurry into first and second portions, milling the first bean portion to provide a milled bean portion, homogenizing the milled bean portion with water to provide an homogenized bean portion, combining the homogenized portion and the second coarse ground bean portion with water, spices and lard to provide a combined bean mixture, and mixing the combined bean mixture to provide a refried bean product.

Owner:FARIBAULT FOODS

Hydration process for a refried bean product

This application provides a process for producing a refried bean product. The refried bean product contains both homogenized cooked bean particles and larger sized cooked bean particles and provides a texture typical of refried beans. The present process includes hydrating dried beans in water a period of time sufficient to increase the moisture content of the beans, cooking the hydrated beans in water, coarse grinding the cooked beans to provide a bean slurry, dividing the bean slurry into first and second portions, milling the first bean portion to provide a milled bean portion, homogenizing the milled bean portion with water to provide an homogenized bean portion, combining the homogenized portion and the second coarse ground bean portion with water, spices and lard to provide a combined bean mixture, and mixing the combined bean mixture to provide a refried bean product.

Owner:FARIBAULT FOODS

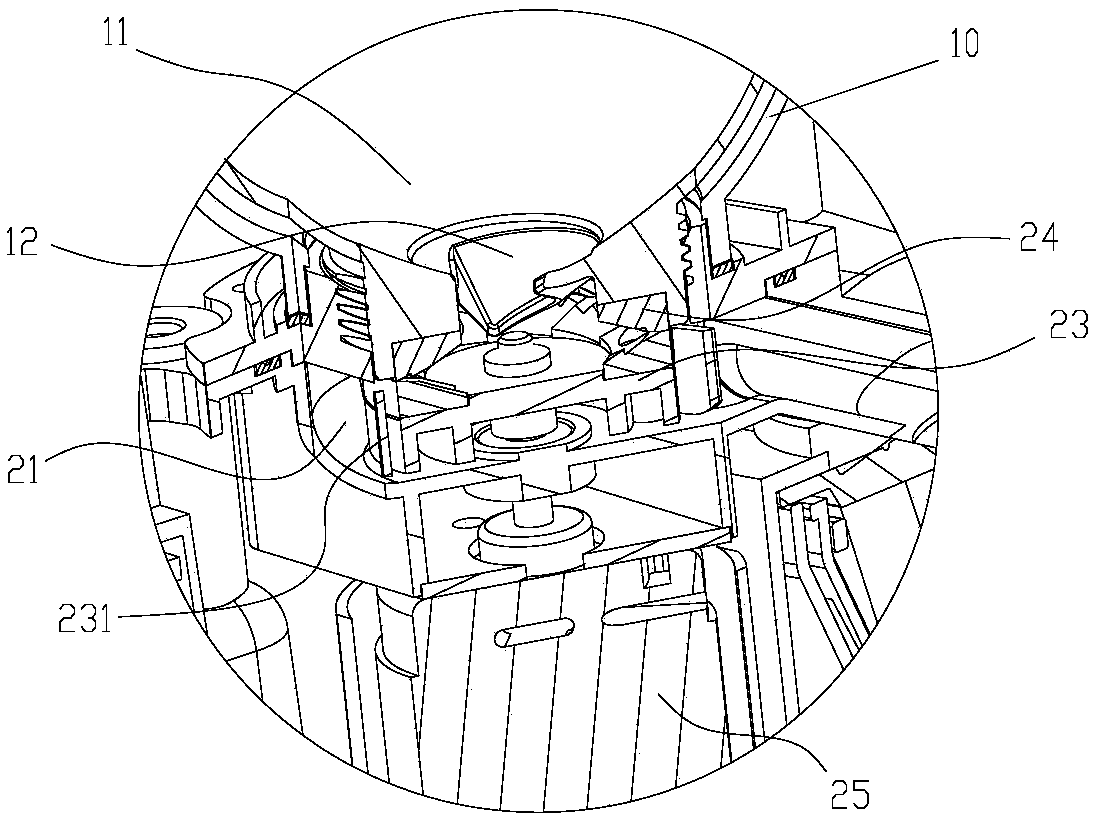

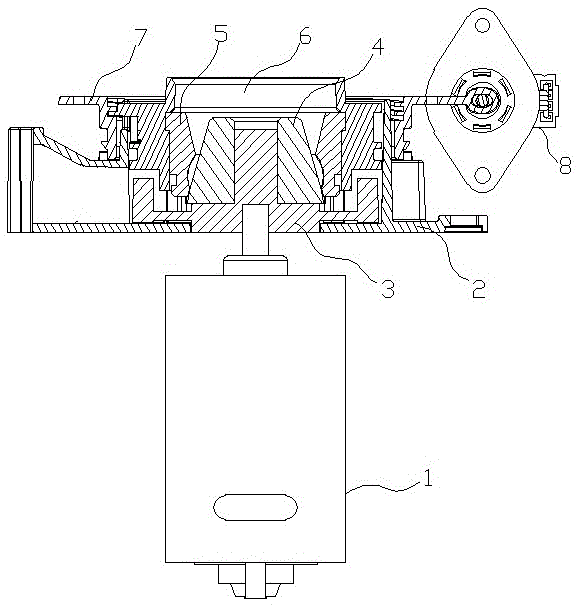

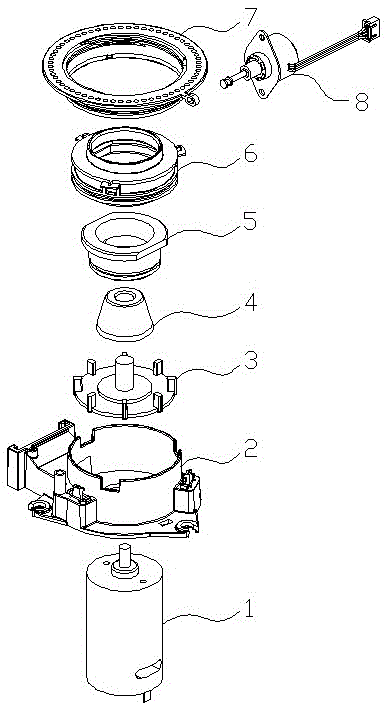

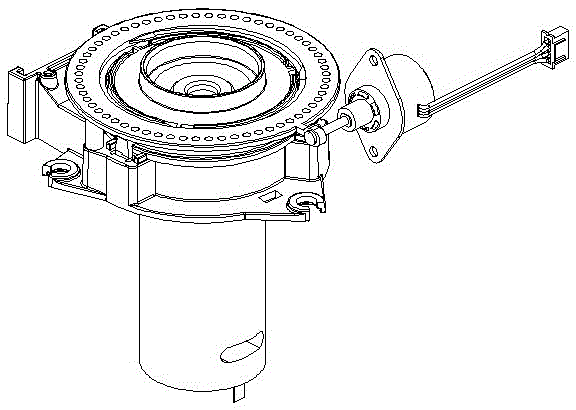

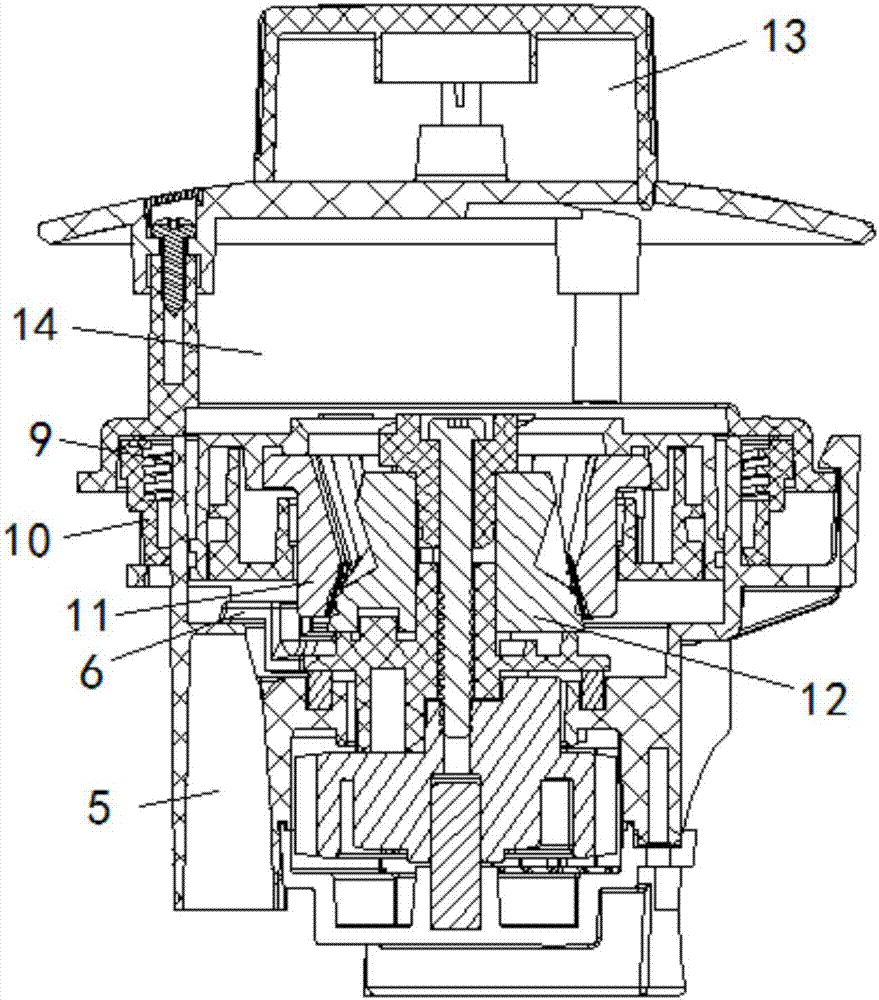

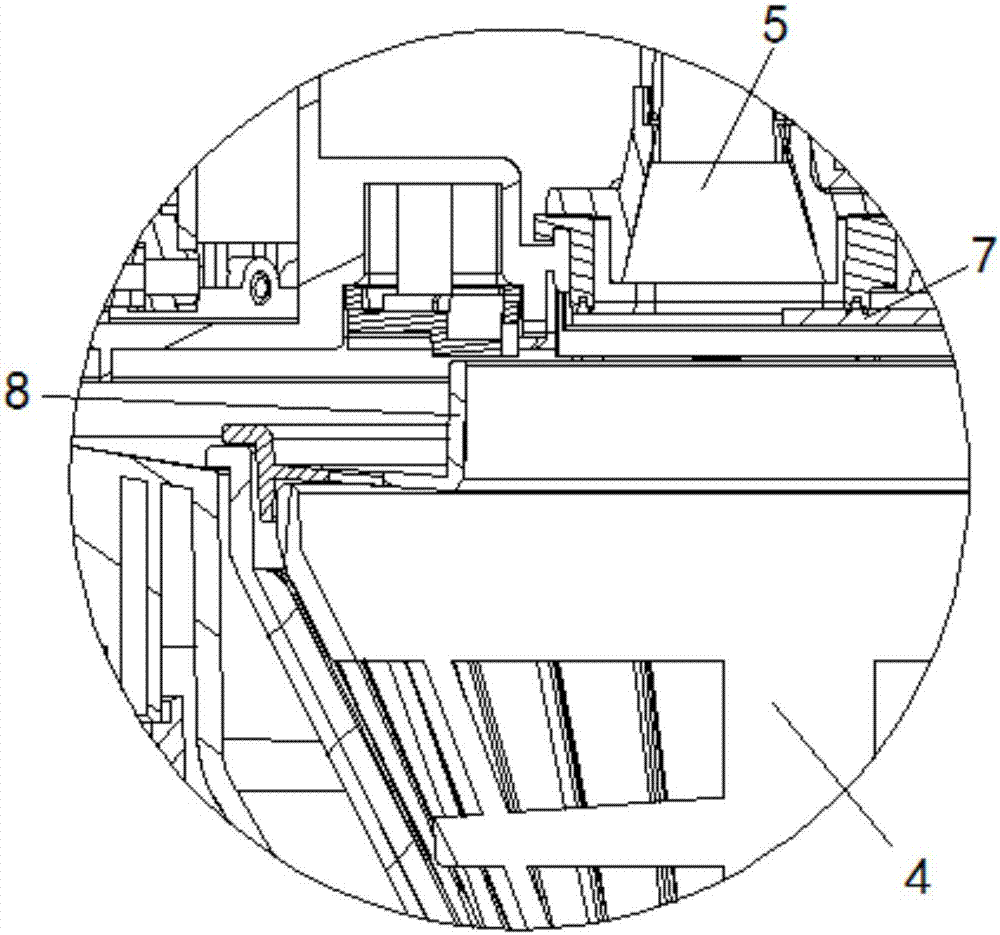

Grinding device for coffee machine

ActiveCN103799878BAccurate control of physical actual valuesControl Physical Actual ValuesBeverage vesselsElectric machineryGround-bean

The invention discloses a grinding device for a coffee machine, which comprises a driving motor, a coffee powder propeller, an inner grinder knife and an outer grinder knife assembly, and the coffee powder propeller is arranged on the output shaft of the drive motor , the inner grinder knife is set on the coffee powder pusher, the outer grinder knife assembly is set on the upper end of the inner grinder knife, and the outer grinder knife assembly and the inner grinder knife There is a gap between them; the bean grinder outer knife assembly includes a bean grinder outer knife, an outer knife fixing seat and an adjustment device for adjusting the gap between the bean grinder outer knife and the grinder inner knife, and the grinder outer knife is set In the outer knife fixing seat, the adjusting device is arranged at the upper end of the outer knife fixing seat. The beneficial effect of adopting this technical solution is: the physical actual value of the gap between the inner knife and the outer knife can be accurately controlled by the adjusting device, thereby controlling the size of the coffee powder particles, and the thickness of the powder used for each cup of coffee is consistent, thereby ensuring brewing coffee quality.

Owner:SUZHOU KALERM COFFEE MASCH TECH CO LTD

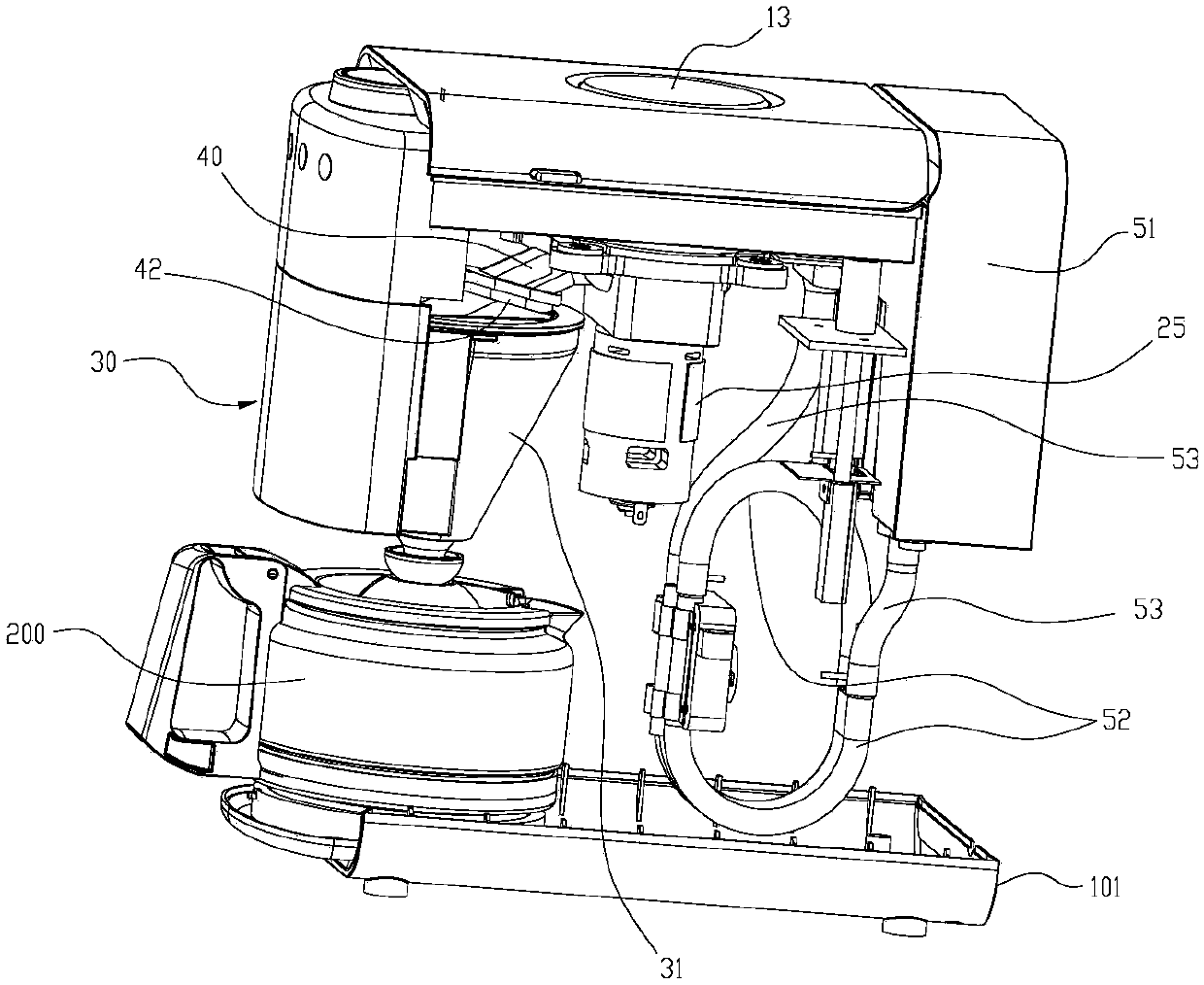

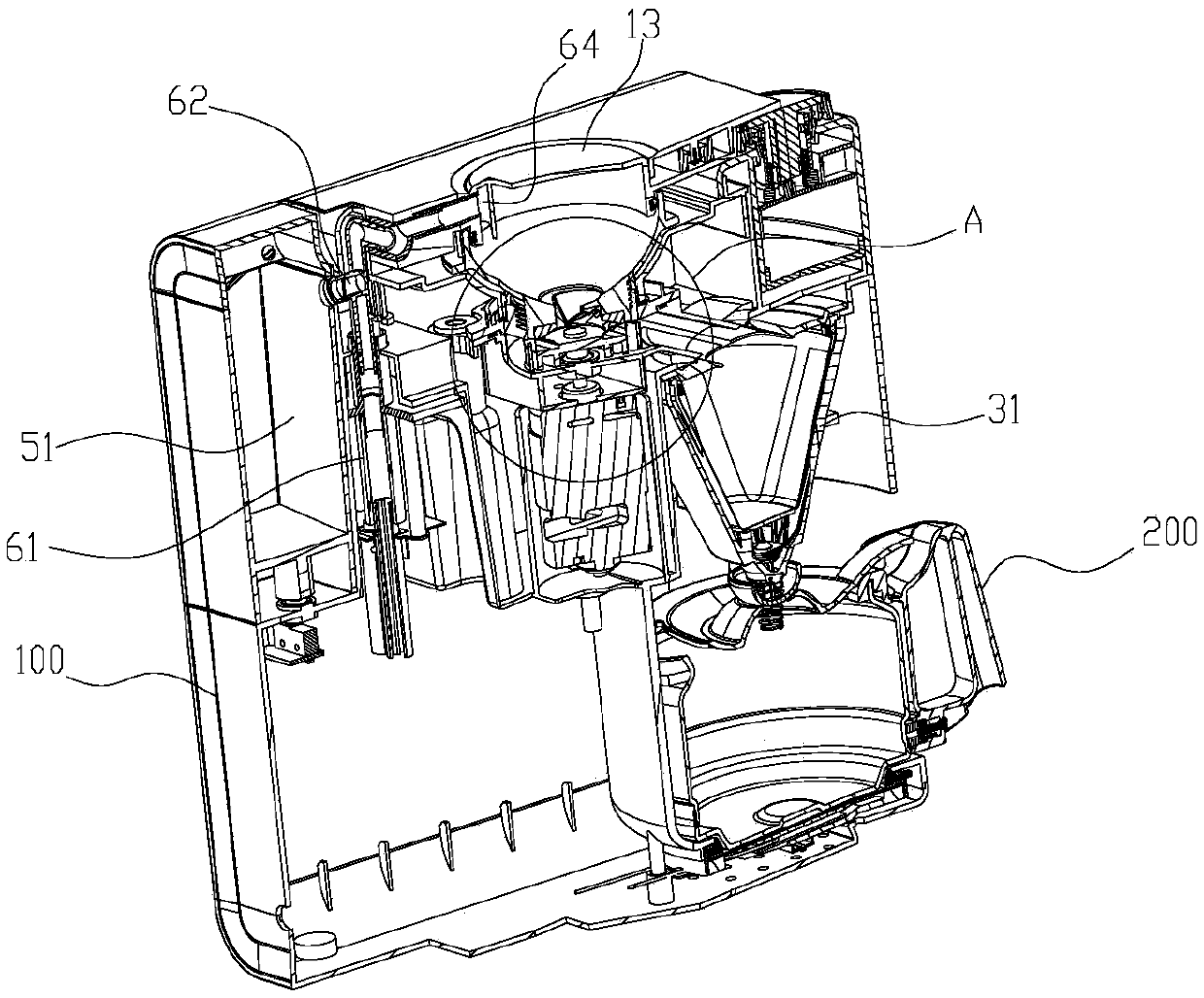

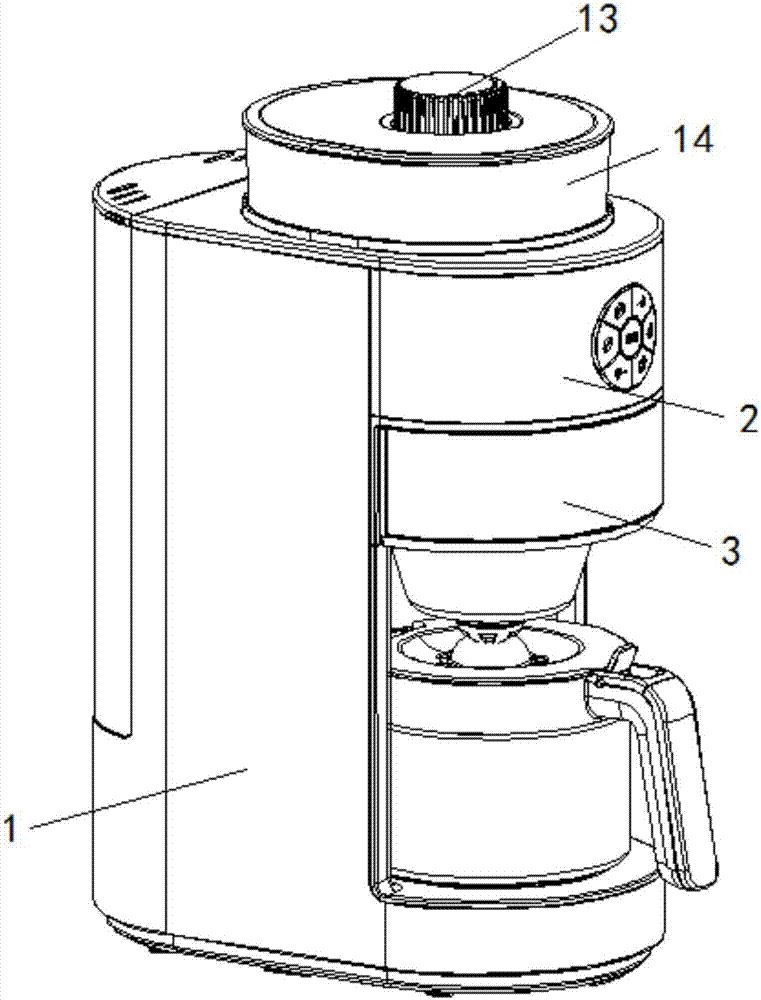

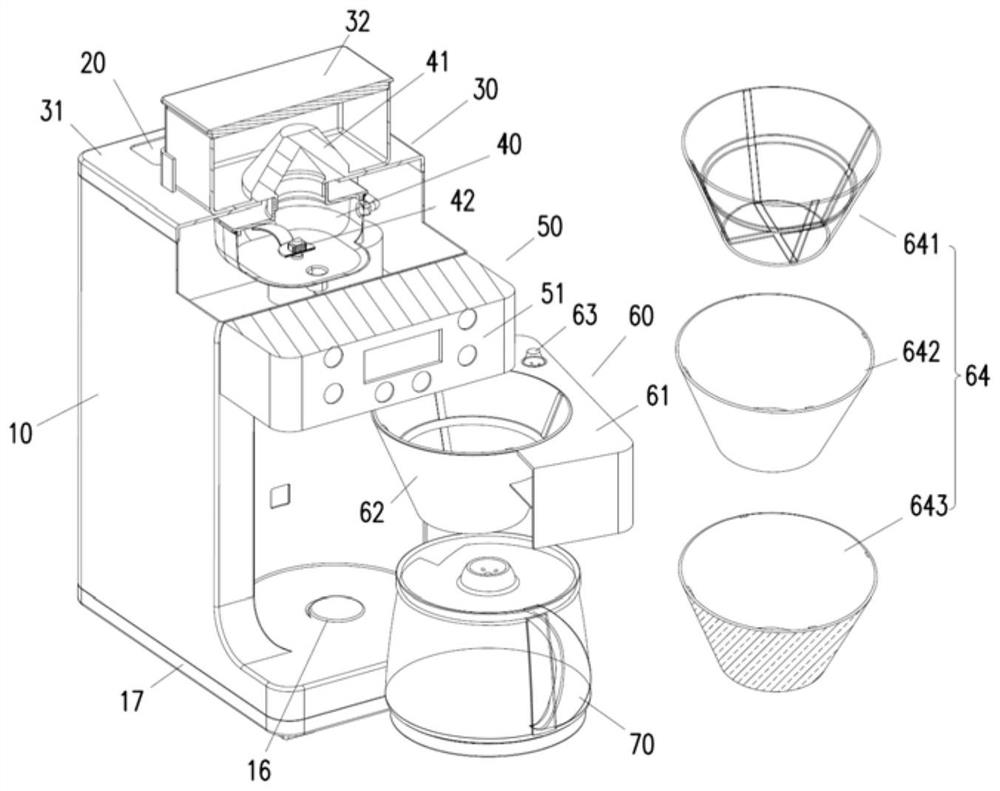

Ground bean dripping coffee maker

The invention relates to the technical field of coffee makers and in particular relates to a ground bean dripping coffee maker. The ground bean dripping coffee maker comprises a main machine, wherein a bean grinding device and a making device are arranged in the main machine; an upper opening of a funnel of the making device is positioned below a powder outlet of the bean grinding device; a powder dropping channel is formed in the powder outlet of the bean grinding device; the powder dropping channel is formed along a height direction of the main machine; the lower end of the powder dropping channel is connected to a position, which is close to the center, of the opening in the upper end of the funnel. According to the ground bean dripping coffee maker disclosed by the invention, residues of coffee powder in the powder outlet channel can be completely avoided, the powder outlet channel can be kept smooth and does not need to be periodically cleaned by a user, and the coffee maker is convenient to use.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

Preserved beancurd containing functional factor and preparation method thereof

The invention discloses preserved beancurd containing a functional factor, which comprises components of soybean and edible (medicinal) fungi. A preparation method for the preserved beancurd containing the functional factor comprises the following steps: soybean, edulcoration, soaking, soybean grinding, filtering separation, soybean milk, soybean milk cooking, soybean milk curdling, blanking, block division, pehtze preparation fermentation, salted pehtze, filling, ripening, and a finished product. During soybean milk curdling, a mixed solution of an aqueous solution of edible (medicinal) fungi ultra-fine powder and the soybean milk is added, and the soybean milk curdling is realized by the following steps: removing roots of the edible (functional) fungi and carrying out edulcoration on the edible (medicinal) fungi; carrying out ultrafine grinding on the edible (medicinal) fungi after drying or insolating; adding water to dissolve, wherein the ratio of the edible (medicinal) fungi ultra-fine powder to the water is 1:4; adding the soybean milk at 100 DEG C with the same quantity as the aqueous solution of the edible (medicinal) fungi ultra-fine powder into the mixture to dilute after the mixture is stirred fully and evenly; and during filling, the aqueous solution of the edible (medicinal) fungi ultra-fine powder is added. The preserved beancurd is rich in functional factor and multiple nutrients and has the advantages of health care function, tasty mouthfeel and simple processing.

Owner:JIANGSU ANHUI BIO TECH +1

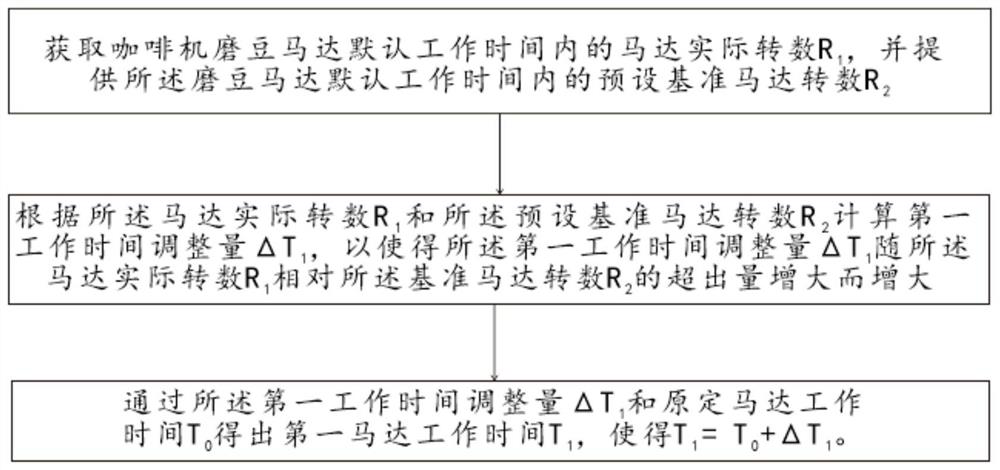

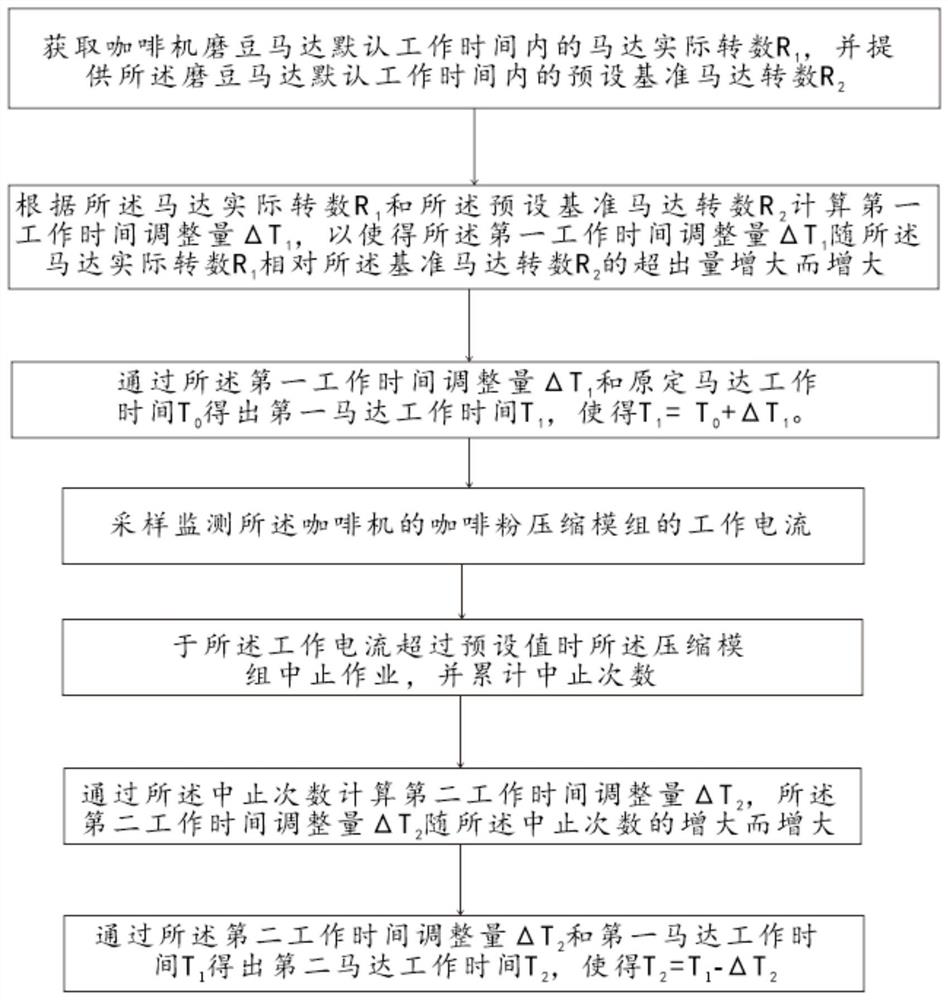

Self-calibration method for working time of bean grinding motor and coffee machine

ActiveCN114343428AAvoid affecting useThe amount of grinding powder is automatically increasedBeverage vesselsGround-beanProcess engineering

The invention relates to the technical field of coffee machine control, in particular to a bean grinding motor working time self-calibration method and a coffee machine.The bean grinding motor working time self-calibration method comprises the steps that the actual motor rotation number R1 within default working time of a bean grinding motor of a coffee machine is obtained and compared with the preset reference motor rotation number R2; calculating a first working time adjustment amount delta T1, so that the first working time adjustment amount delta T1 is increased along with the increase of the excess of the actual rotation number R1 of the motor relative to the rotation number R2 of the reference motor; and then the first motor working time T1 is obtained through the first working time adjustment amount delta T1 and the original motor working time T0, so that T1 is equal to T0 + delta T1. Compared with the prior art, the actual rotation number R1 of the bean grinding motor changing along with the abrasion condition of the bean grinding motor is monitored, so that when the bean grinding motor is abraded, namely the grinding capacity is reduced, in order to avoid the situation that the grinding amount is lower than the normal level and influences use, the grinding time can be automatically prolonged, and the proper grinding amount is kept.

Owner:厦门芯阳科技股份有限公司

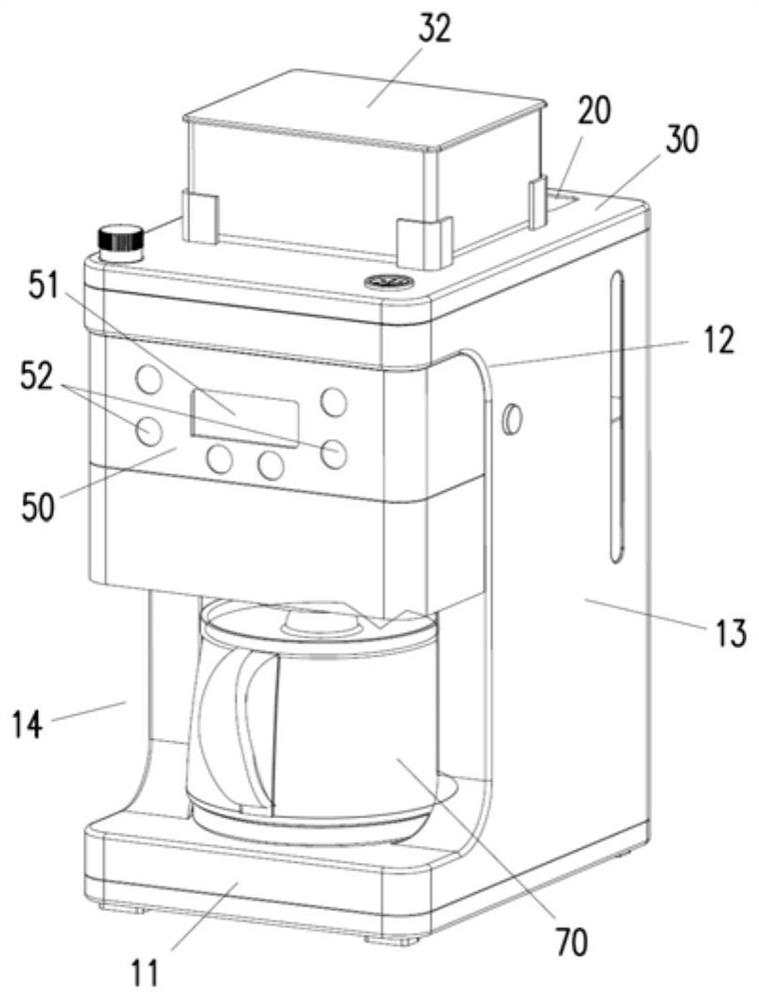

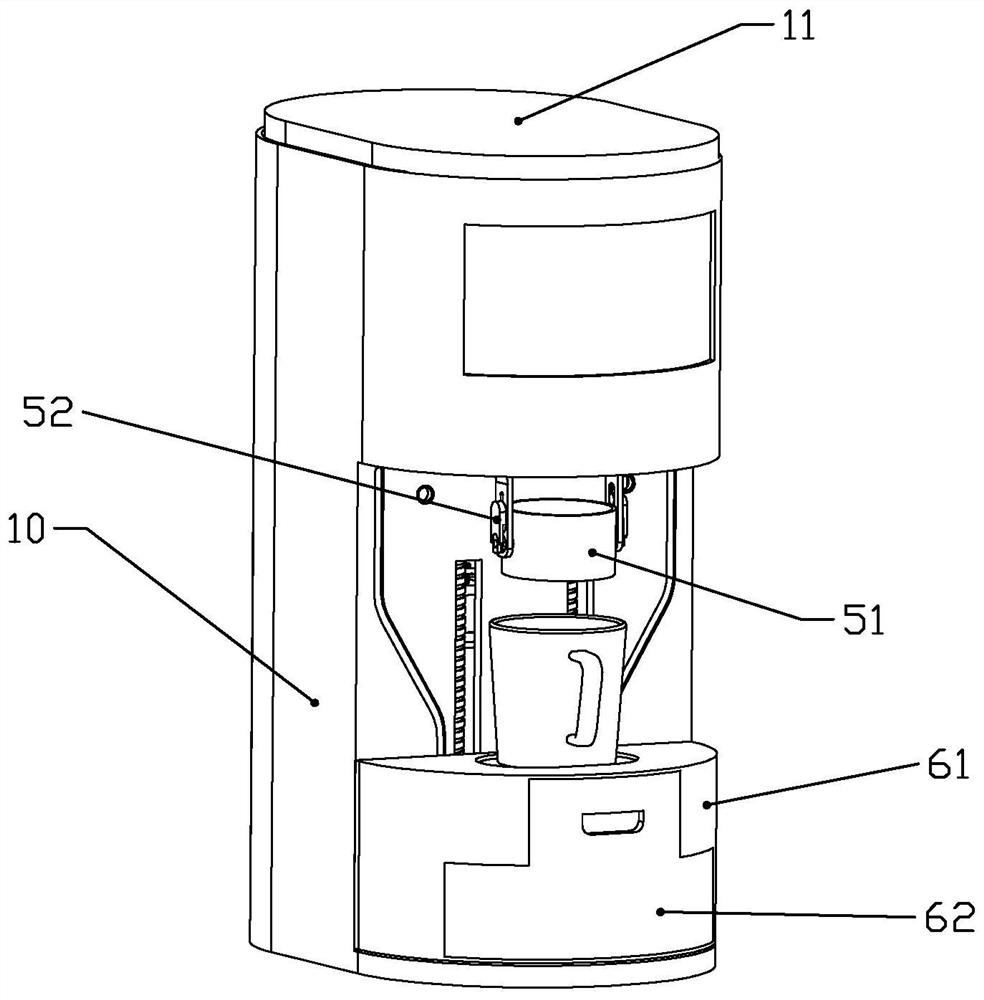

Automatic bean grinding and coffee brewing machine

The invention relates to the technical field of household appliances, and provides an automatic bean grinding and coffee brewing machine. The machine comprises a machine body, a water tank, a bean grinding machine, a control part and a brewing cup base; the machine body is provided with a machine base part, a machine head part and a main body part, and the main body part forms a containing space;a water tank opening penetrates through a cover part above the machine head part, the cover part is provided with a cover plane, and a bean bin protrudes out of the cover plane; the bean grinding machine comprises a bean grinding part; the bean grinding part penetrates through the cover part at the machine head part and is positioned between the bean bin and the control part; the control part comprises a circuit system and an operation panel; the circuit system comprises wireless communication equipment integrated on the back surface of the operation panel; and the brewing cup base abuts against the lower portion of the control part and is rotationally connected with the main body part. According to the invention, the technical problem of coffee brewing through bean grinding is solved through the structure, and the effects of being convenient to use, easy to manufacture and capable of improving the coffee taste are achieved.

Owner:李文庆

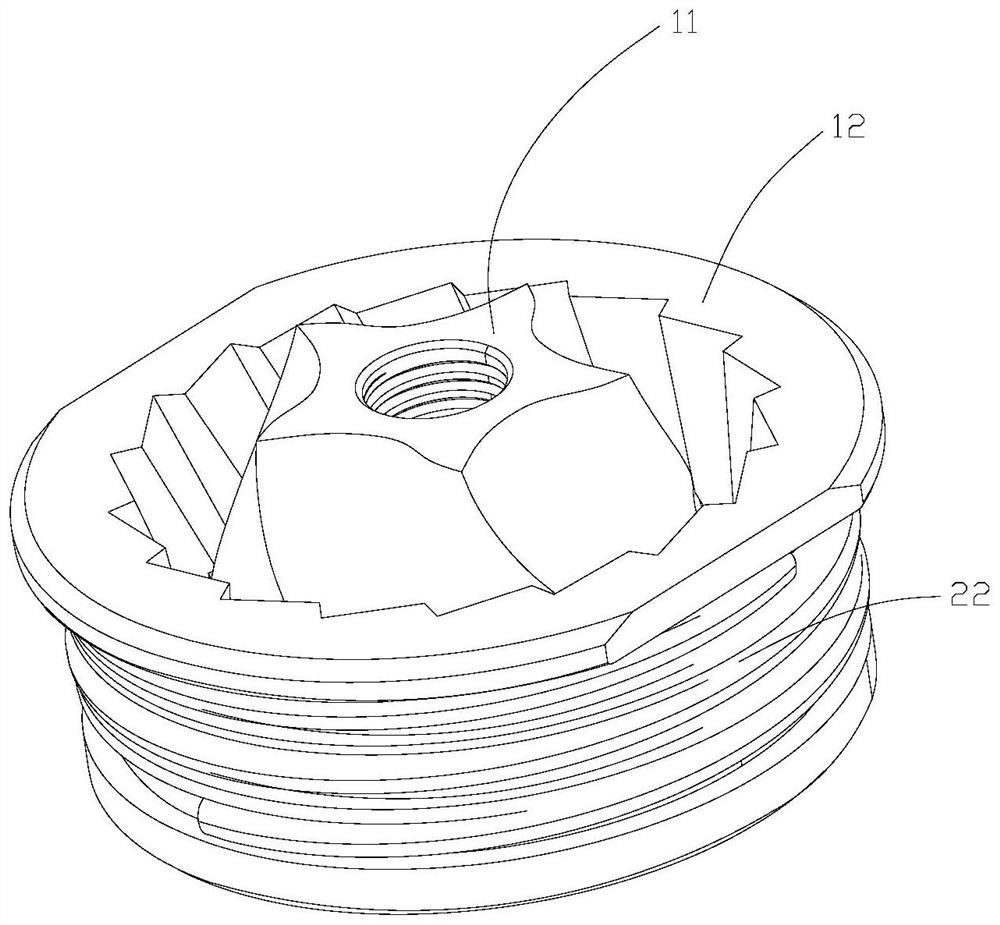

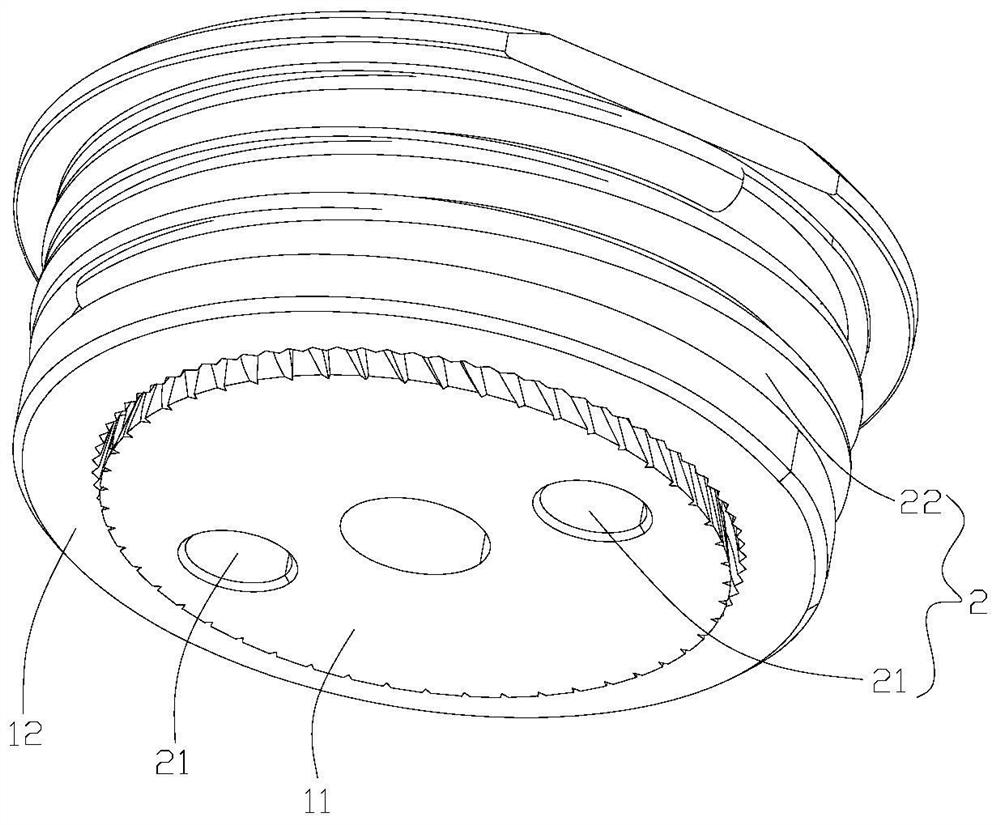

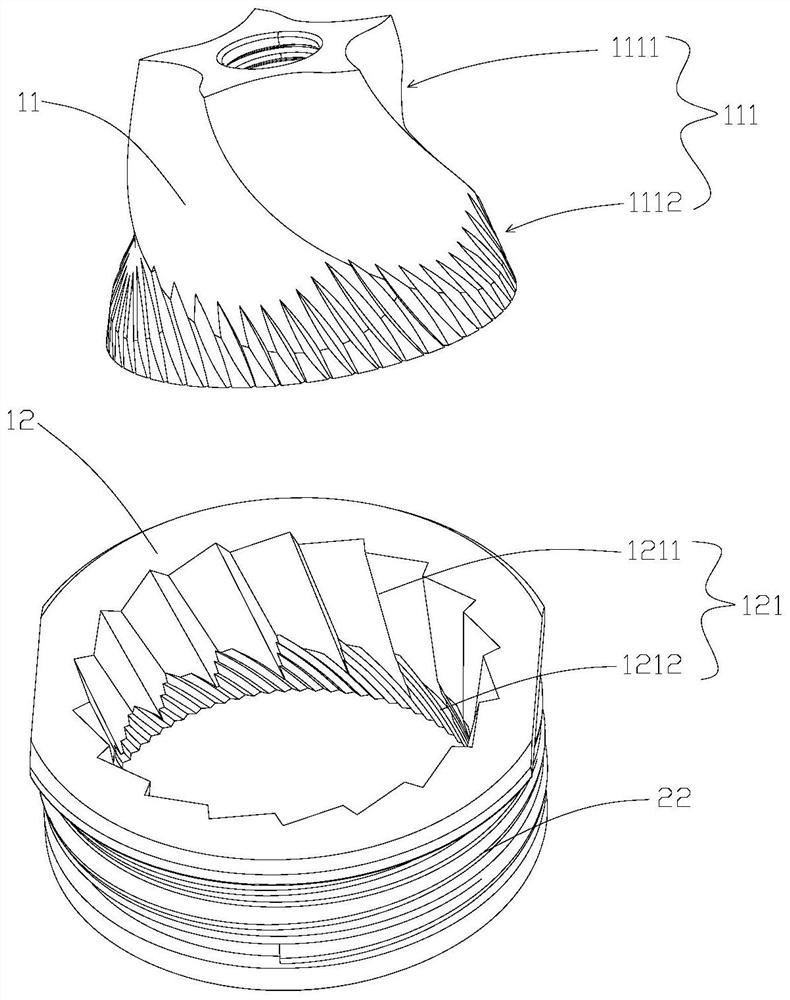

Cone grinding wheel and bean grinder with the same

PendingCN113786110AReduce the temperatureReduce wasteCoffee millsSpice millsGround-beanGrinding wheel

The invention discloses a cone grinding wheel and a bean grinder with the same. The cone grinding wheel comprises an inner grinding wheel and an outer grinding wheel, wherein the inner grinding wheel is cone-shaped, and a first meshing part is arranged on the outer surface of the inner grinding wheel; the inner grinding wheel is annular, and a second meshing part is arranged on the surface of the inner ring of the outer grinding wheel; and the first meshing part is meshed with the second meshing part, and a cooling device is arranged on the inner grinding wheel and / or the outer grinding wheel. The cone grinding wheel and the bean grinder with the same can effectively reduce the temperature of the cone grinding wheel in the working process, reduce waste of a coffee powder, clean the environment and prolong the service life of the whole coffee machine.

Owner:ZHONGSHAN JUNGUO ELECTRICAL APPLIANCES CO LTD

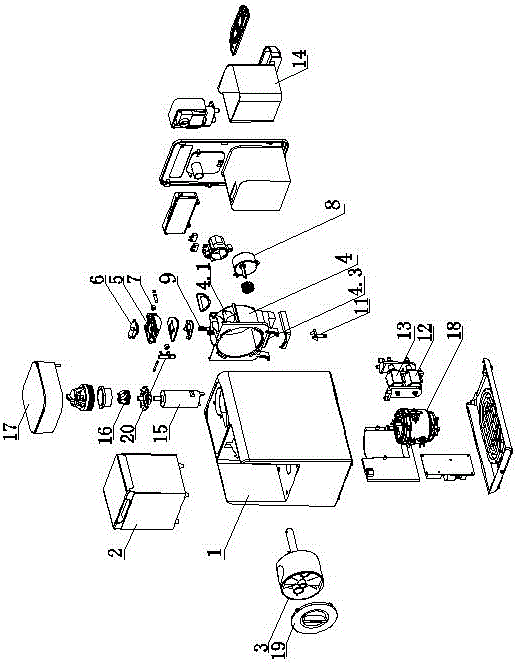

Bean-grinding coffee machine with movable brewing head

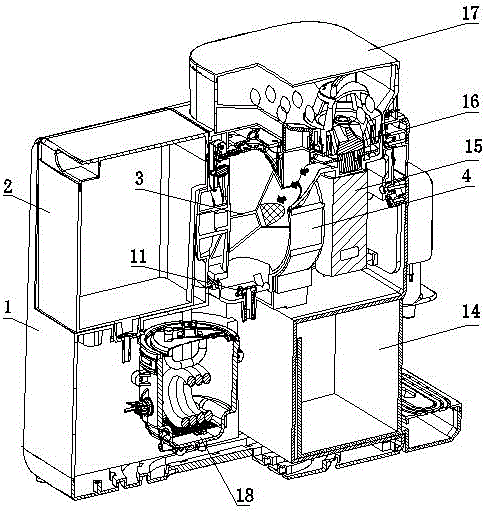

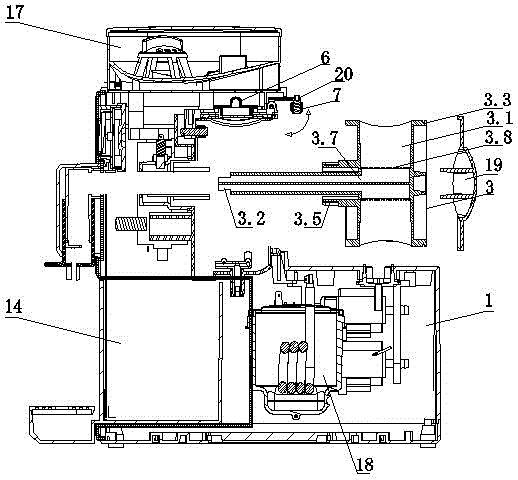

InactiveCN106580091AFully automatic requirementsImprove work efficiencyBeverage vesselsElectric driveEngineering

The invention provides a bean-grinding coffee machine with a movable brewing head. The bean-grinding coffee machine comprises a machine body (1), a water tank (2), a water supply assembly, an electric drive mechanism, a grinding assembly and a brewing assembly, wherein a brewing cavity (3.1) and a grinding chamber are at least arranged in the machine body (1); the bean-grinding coffee machine is characterized in that the brewing assembly comprises a rotation part (3) rotatably arranged, and the brewing cavity (3.1) is at least arranged on the rotation part (3); the brewing assembly is at least provided with the brewing head (5), and the opening of the brewing cavity (3.1) and the brewing head (5) move and extrude relative to each other and are in sealed connection under the acting force of an electric drive mechanism. According to the bean-grinding coffee machine, through the rotation part rotatably arranged, the feeding, brewing and discharging procedures of the coffee machine can be automatically, continuously and circularly carried out, and thus the requirement of full automation is realized.

Owner:周林斌

Full-automatic coffee bean grinder

InactiveCN112120534AEasy to storeTo achieve the purpose of automatic feedingBeverage vesselsAgricultural engineeringAir pump

The invention discloses a full-automatic coffee bean grinder, which belongs to the technical field of small household appliances, and comprises a shell, and a grinding assembly, a brewing assembly, afiltering part, a cleaning assembly, an air pump and a water tank are arranged in the shell; the water tank can supply water to the brewing assembly and the cleaning assembly; the filtering part comprises a filtering cup; the cleaning assembly comprises a cleaning shell, a water spraying plate, a dirt containing drawer and cleaning wheels. A rotating shaft of the cleaning wheel and a rotating shaft of the filtering cup are parallel and are positioned on a same longitudinal plane; the coffee bean grinder has a coffee bean storage function, and a low-pressure low-oxygen environment can be formedin a charging barrel; an automatic feeding function is achieved, and coffee beans can be automatically added into the grinding hopper according to the coffee demand; the filter cup cleaning functionis achieved, and the filter cup can be automatically cleaned. An automatic process is mostly adopted, and the functions of coffee grinding, coffee brewing, cleaning and the like are automatically completed through a touch panel selection function.

Owner:李昆娟

Bean grinder convenient to clean

PendingCN113796747APrevent looseningAvoid enteringCoffee millsSpice millsAgricultural engineeringGround-bean

The invention discloses a bean grinder convenient to clean. The bean grinder comprises a main machine, a driving device, a lower conical grinding wheel and an upper conical grinding wheel, wherein the main machine is provided with a grinding cavity, the driving device is arranged in the main machine, the grinding machine further comprises a powder container, the powder container is detachably connected and fixed in the grinding cavity, and an output end of the driving device penetrates through the grinding cavity and extends into the powder container; the lower conical grinding wheel is detachably connected and fixed to an output end of the driving device, the upper conical grinding wheel is detachably connected and fixed in the grinding cavity, a gap between the upper conical grinding wheel and the lower conical grinding wheel forms a bean grinding gap, and an output end of the driving device drives the lower conical grinding wheel to rotate so that powder ground in the bean grinding gap falls into the powder container. The bean grinder is advantaged in that the upper conical grinding wheel, the lower conical grinding wheel and the powder container are detachable, easy to take out and convenient to clean.

Owner:ZHONGSHAN CITY O BEKO ELECTRICAL APPLIANCES

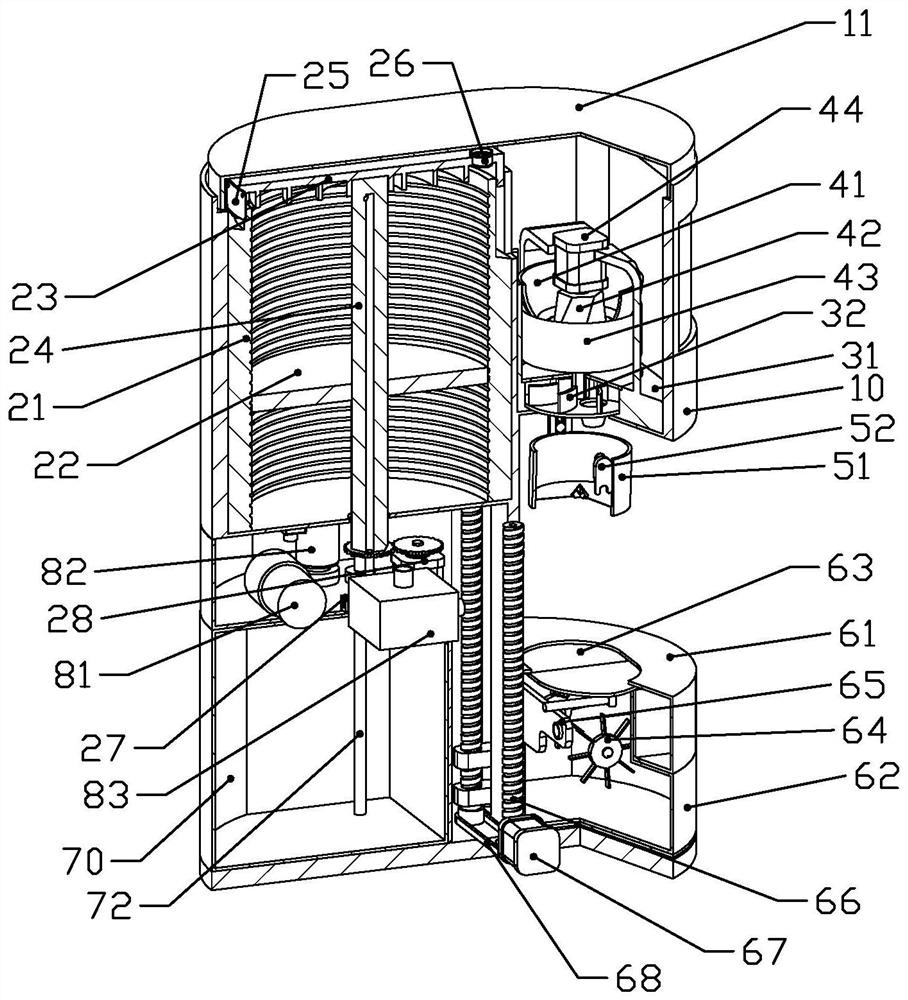

Bean grinder

PendingCN108478043AAccurate and convenient selectionEasy to replaceCoffee millsSpice millsGround-beanEngineering

The invention discloses a bean grinder, comprising a bean chamber component, a grinding component, a coarse and fine adjusting component, a weighing component and a powder receiving container; the bean chamber component is releasably mounted above the grinding component; the grinding component includes a spindle, a motor that drives the spindle to rotate, a conical tool and powder-stirring bladesmounted on the spindle, and a grinding disc sleeving the conical tool in vertically movable manner; a grinding gap is formed between the grinding disc and the conical tool; the powder-stirring bladesare positioned below the conical tool and are used for pushing ground bean powder to the powder receiving container; the coarse and fine adjusting component is used for driving the grinding disc to move up and down relative to the conical tool so as to change the size of the grinding gap; the weighing component is used for metering the bean powder falling into the powder receiving container. The bean grinder has the advantages that the coarse and fine adjusting component adjusts the fineness of bean powder, the weighing component controls the powder discharge quantity, and the different tasterequirements are met; the bean grinder is very convenient and practical to use, is simple to operate and is good in safety and reliability.

Owner:GUANGDONG MASTER ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com