Patents

Literature

175 results about "Flavor Additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Common flavor additives such as sweeteners, fruit flavors, and butter or cheese flavors are found in both natural and artificial forms. The difference between the two depends on the source of the flavor and way it was derived.

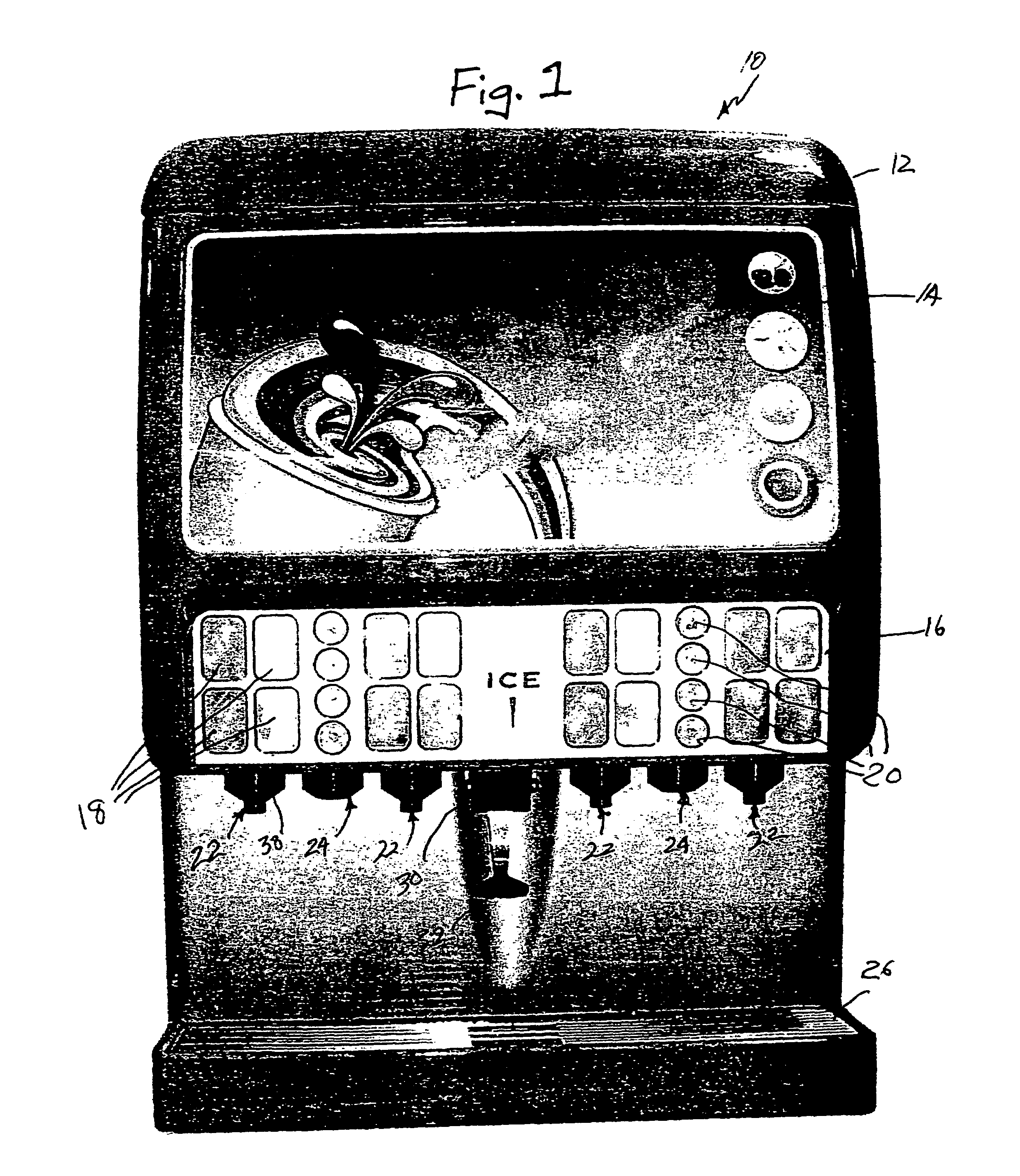

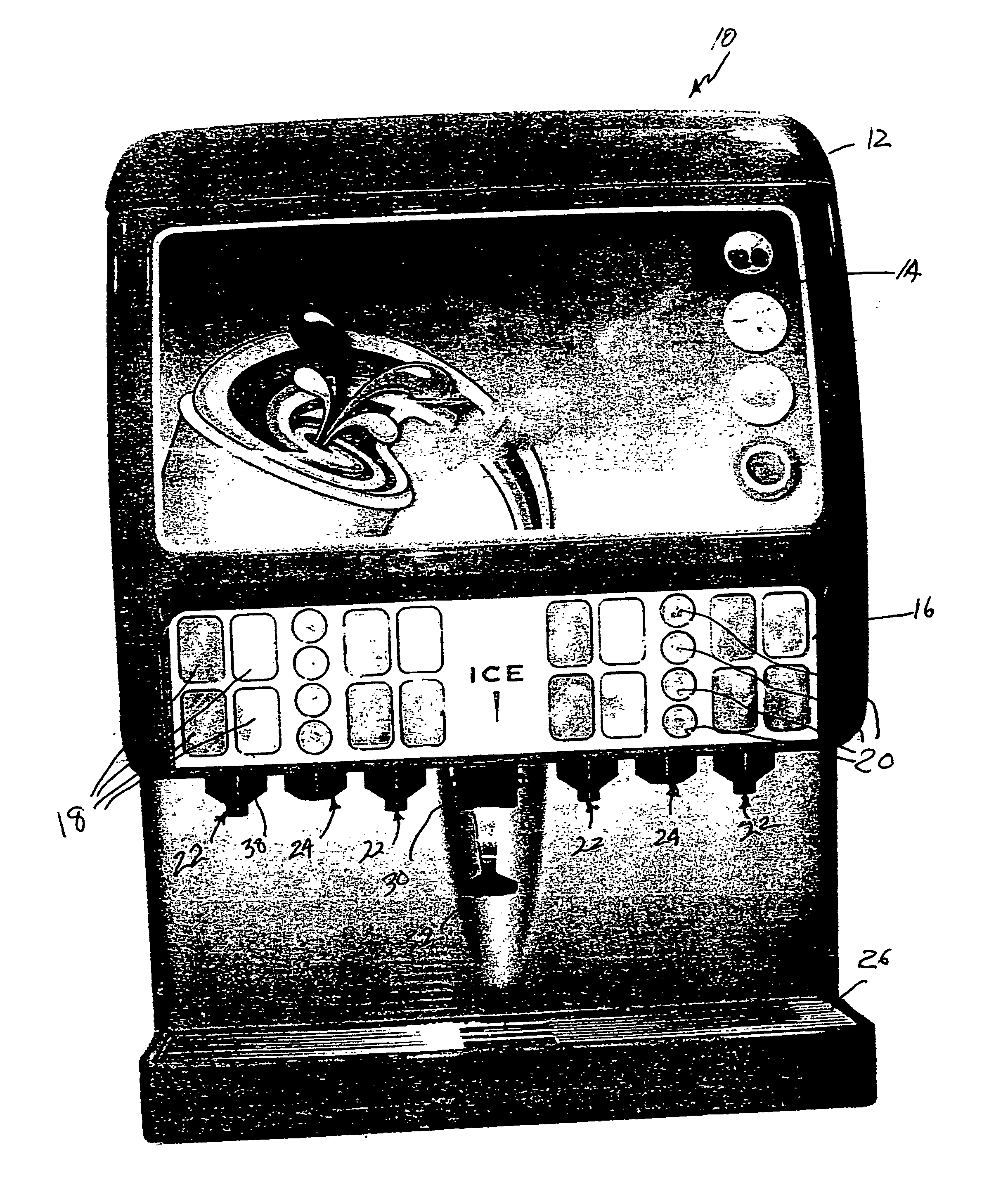

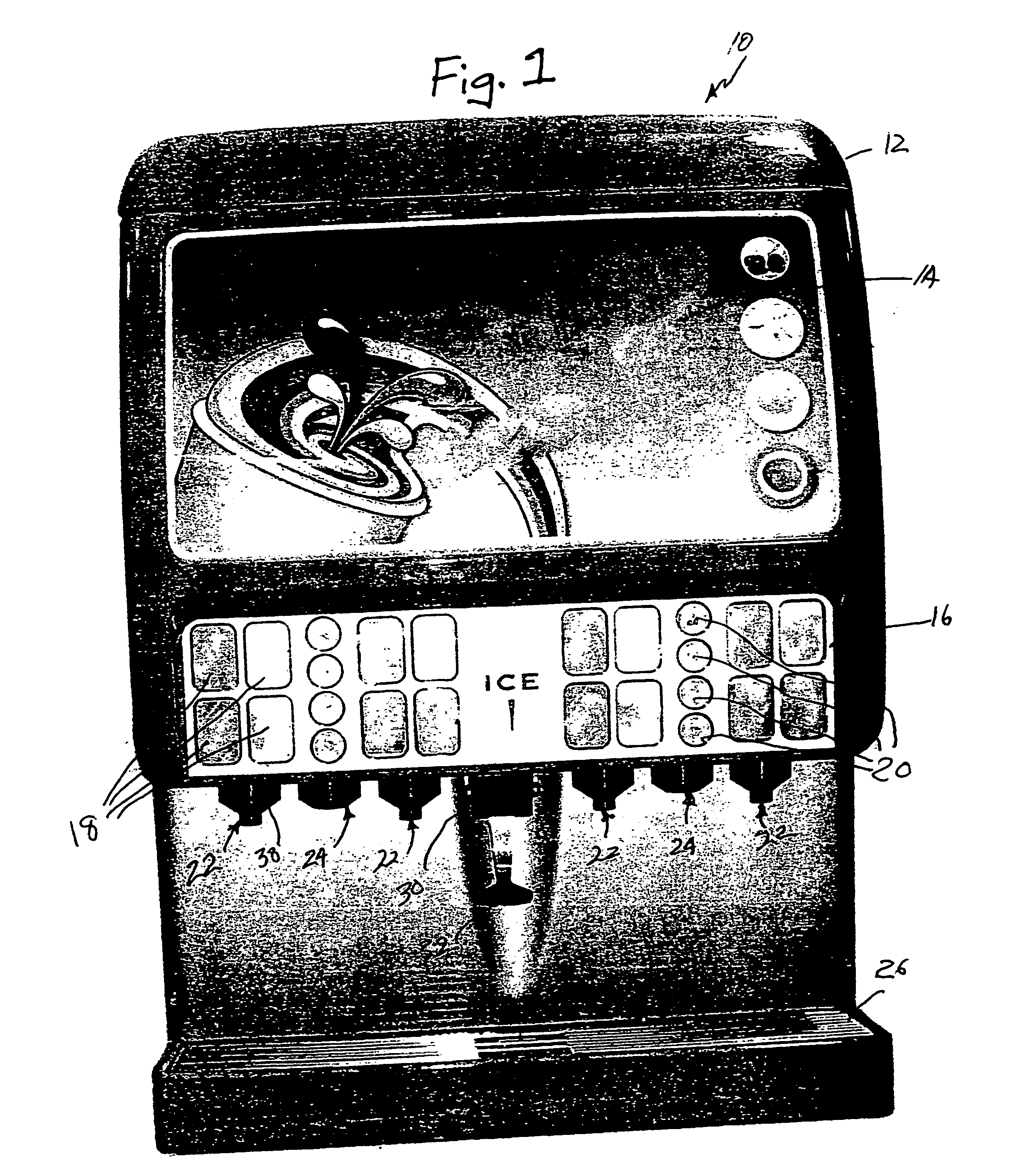

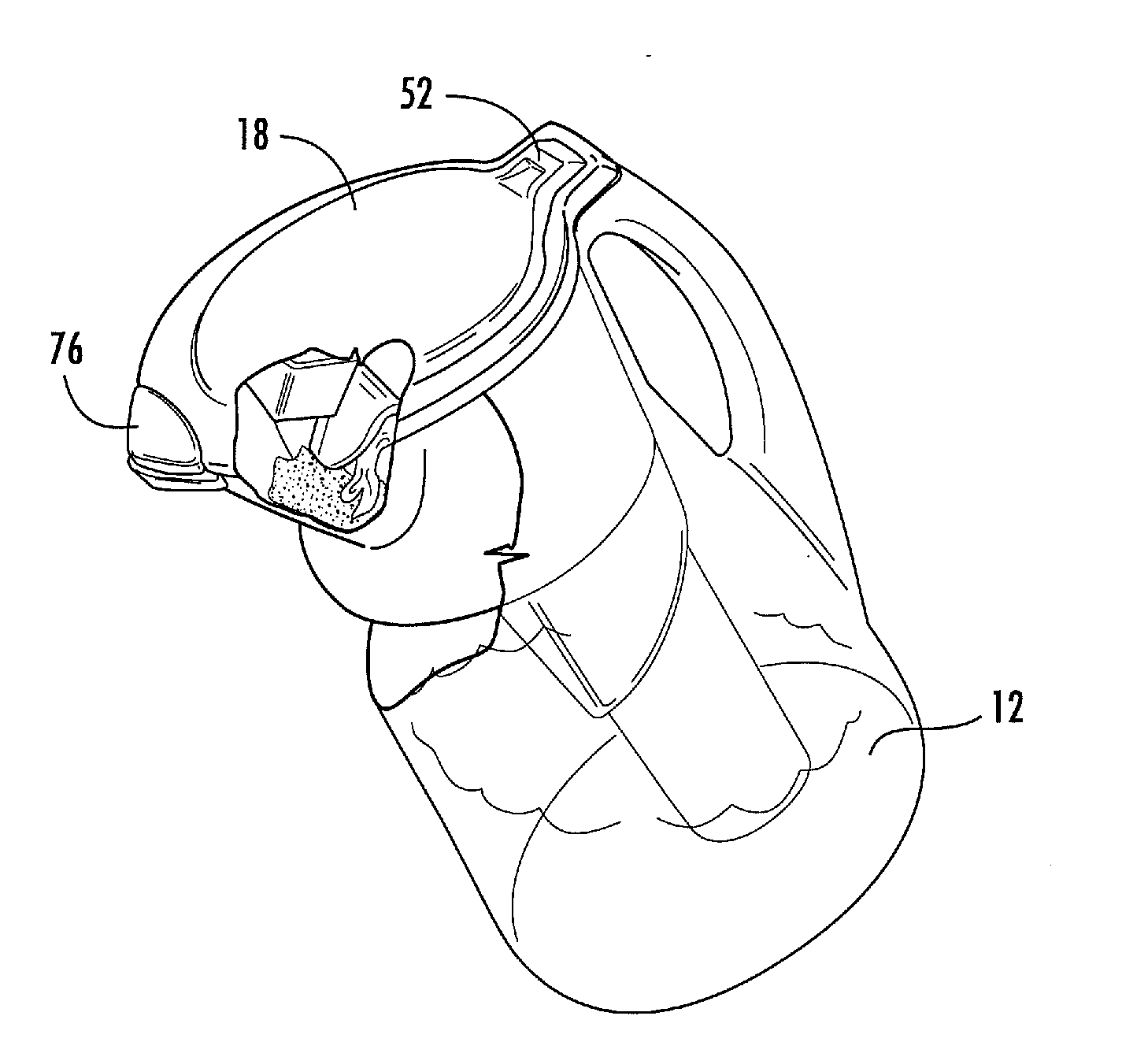

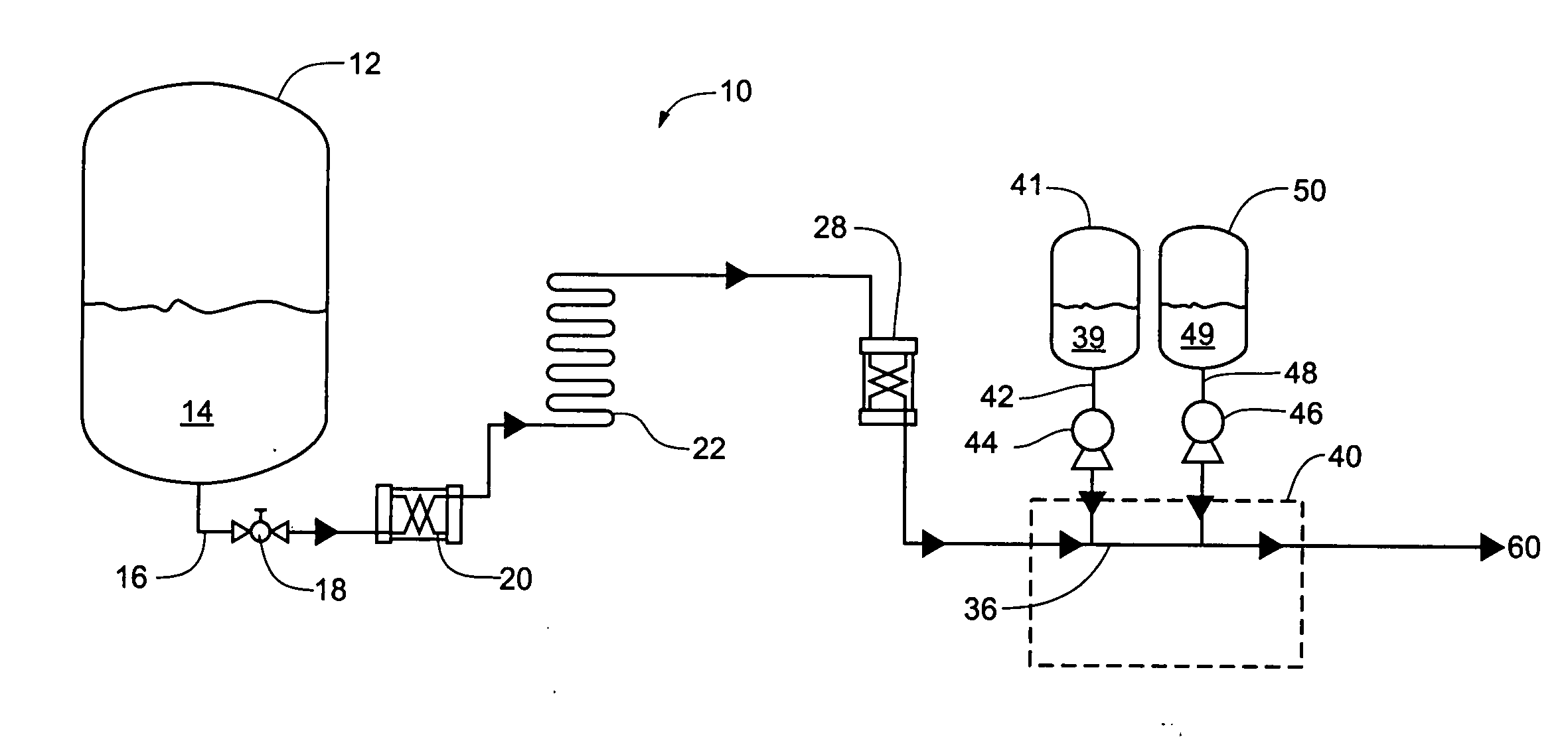

Multiple beverage and flavor additive beverage dispenser

ActiveUS7445133B2Well mixedEasy maintenanceLiquid transferring devicesLiquid dispensingSpray nozzleDiluent

Owner:MARMON FOODSERVICE TECH INC

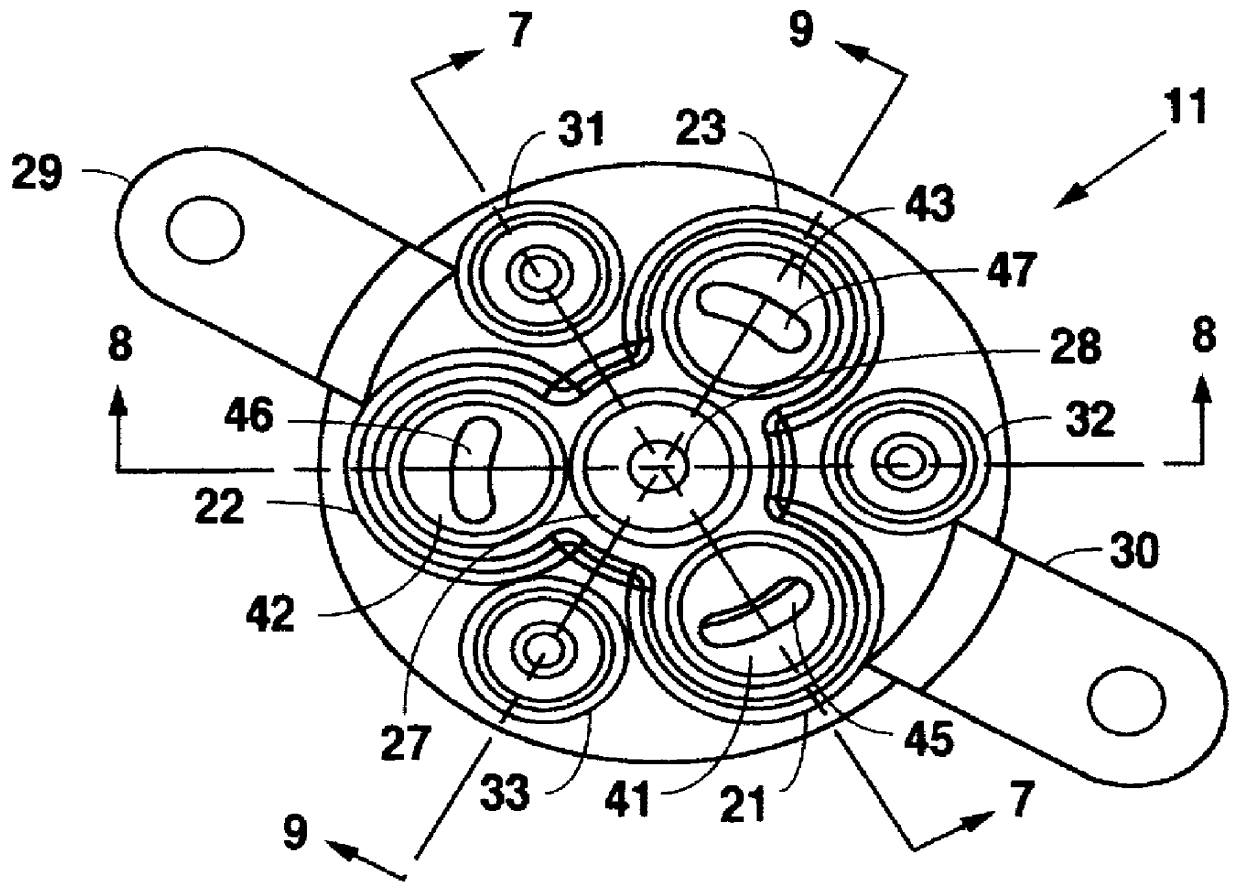

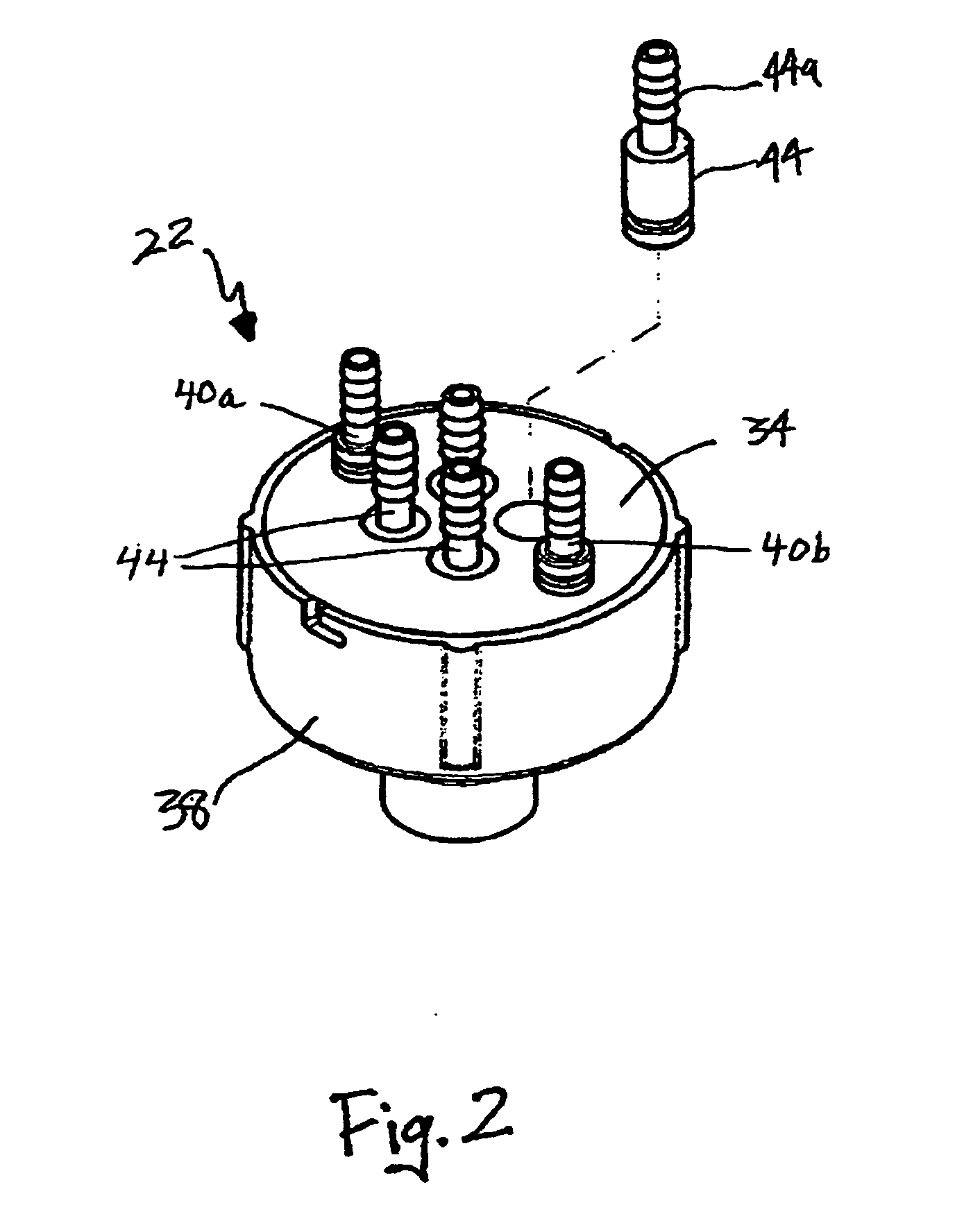

Multiple flavor beverage dispensing air-mix nozzle

InactiveUS6047859AAvoiding carbon dioxideIncrease surface areaOpening closed containersBottle/container closureEngineeringFood flavor

In a beverage dispensing nozzle, a cap member includes a first beverage syrup inlet port coupled to a first beverage syrup source and a mixing fluid inlet port coupled to a mixing fluid source. The cap member further includes a flavor additive port coupled to a flavor additive source. An inner housing including a chamber is coupled to the cap member. A first annulus disposed within the chamber of the inner housing defines a first annular beverage syrup channel with the inner housing, wherein the first beverage syrup inlet port communicates beverage syrup to the first annular beverage syrup channel for discharge from the beverage dispensing nozzle. The first annulus further includes a flavor additive passageway, wherein the flavor additive inlet port communicates flavor additive to the flavor additive passageway for discharge from the beverage dispensing nozzle. An outer housing coupled to the cap member defines a mixing fluid channel with the inner housing, wherein the mixing fluid inlet port communicates mixing fluid to the annular mixing fluid channel for discharge from the beverage dispensing nozzle in an annular flow pattern that contacts exiting beverage syrup and flavor additive to mix therewith outside the beverage dispensing nozzle.

Owner:LANCER PARTNERSHIP

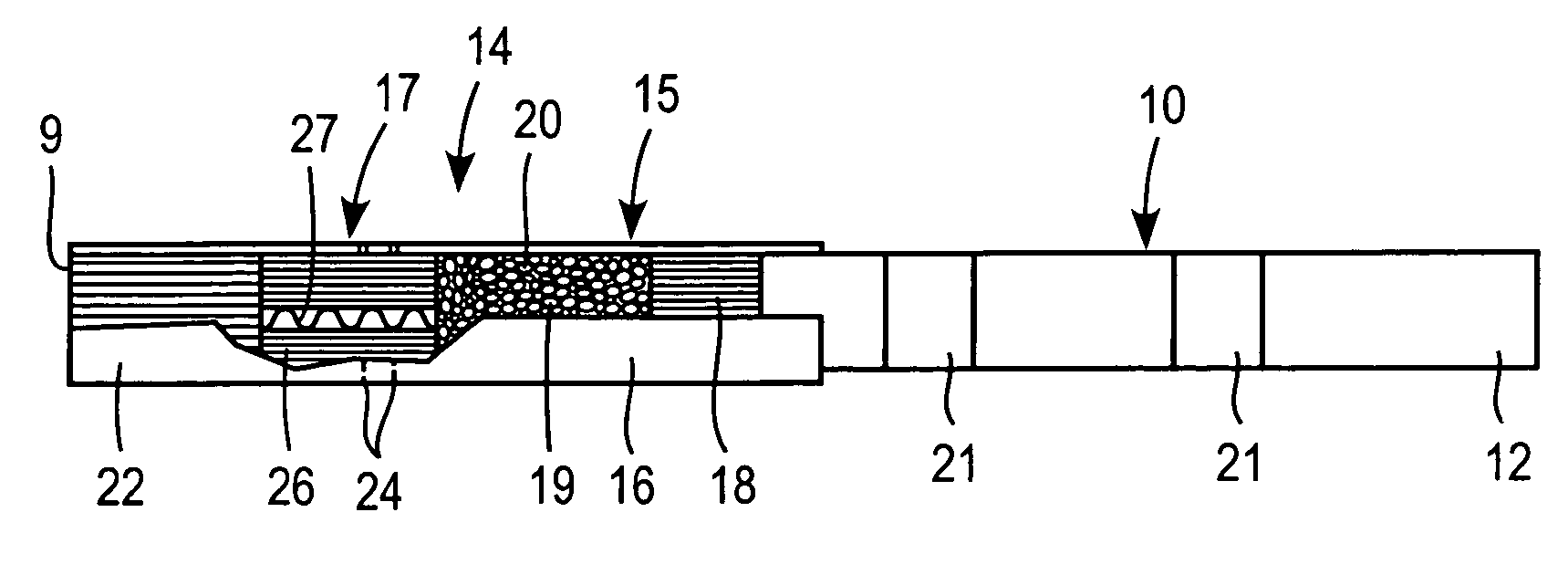

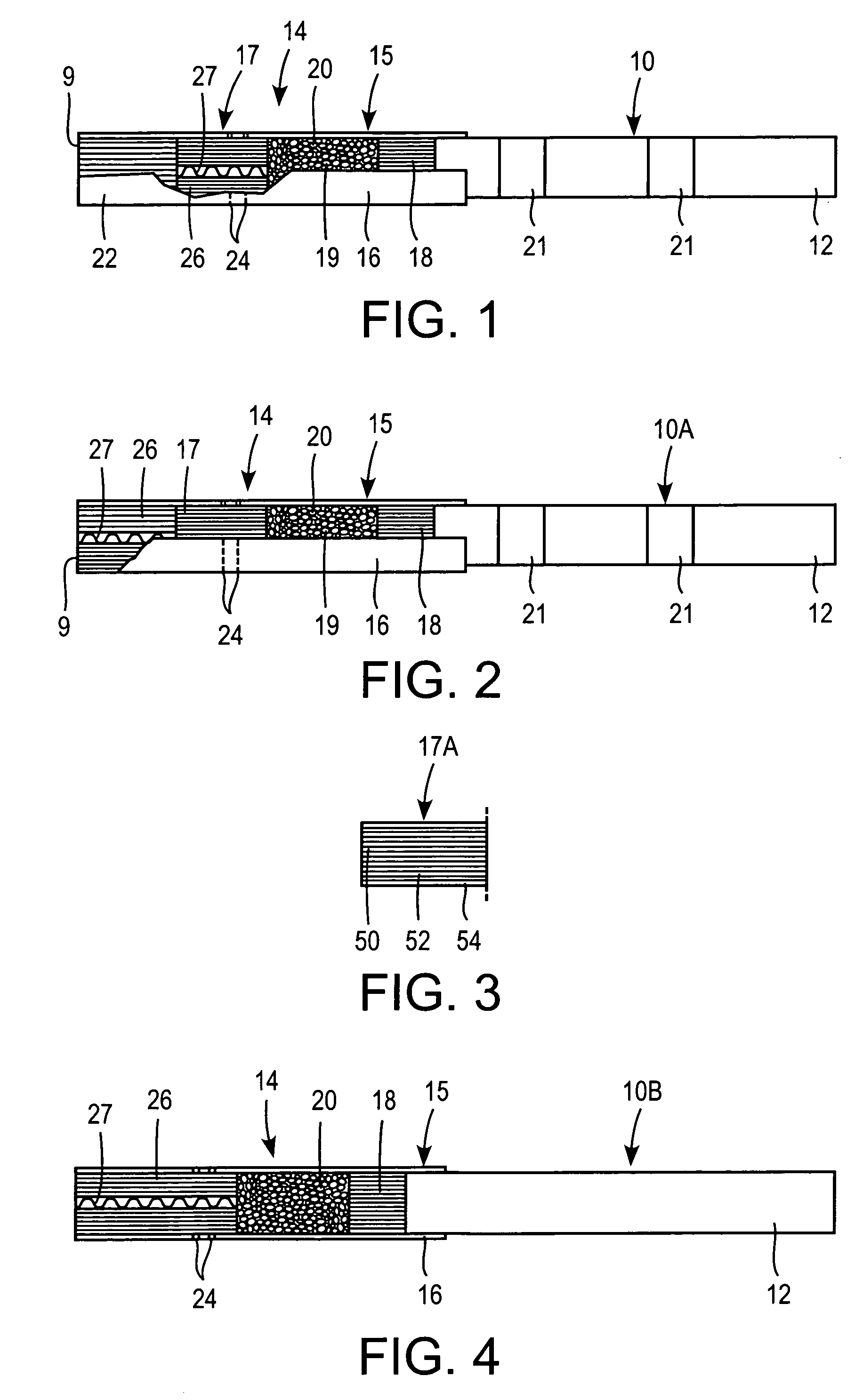

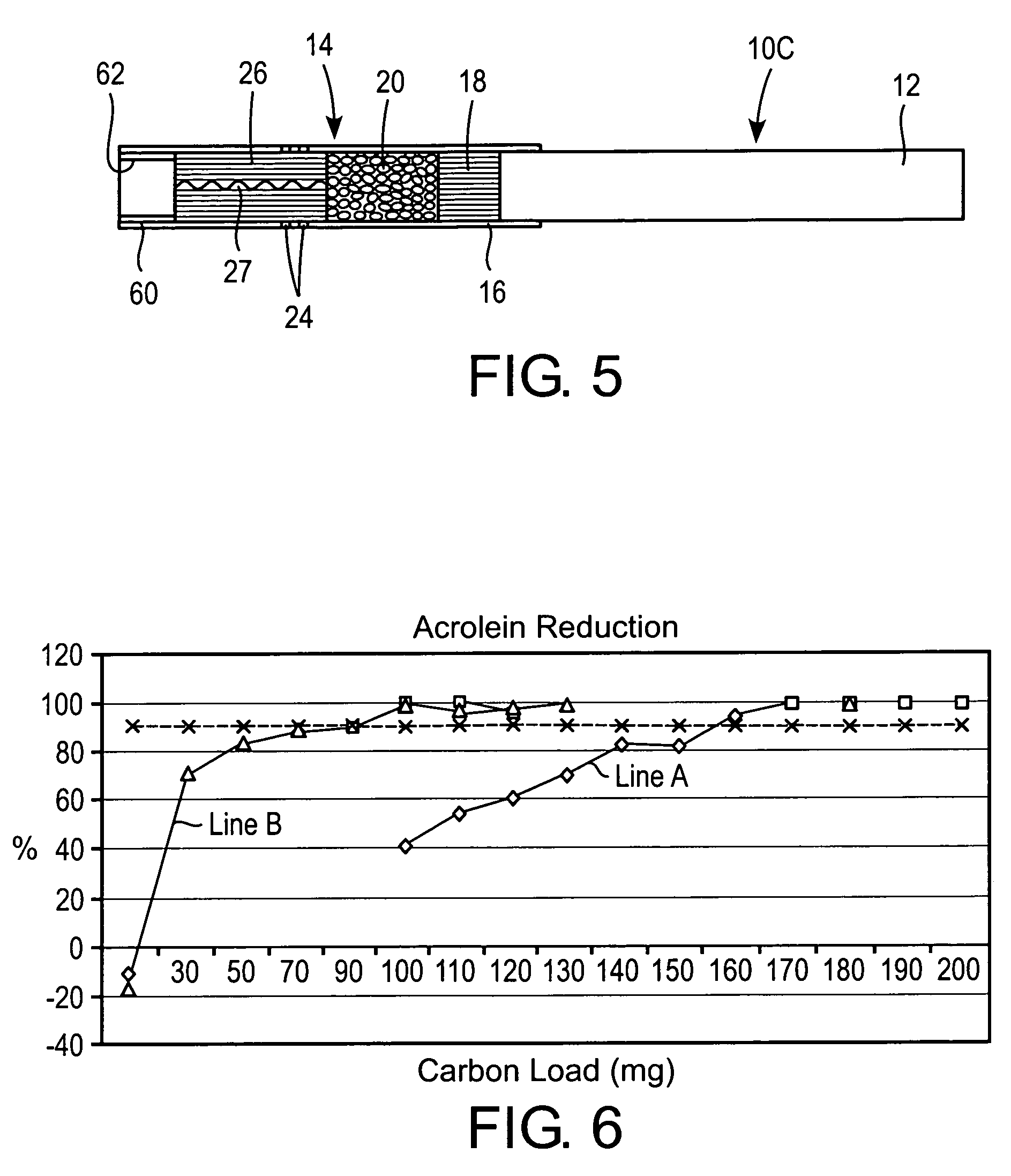

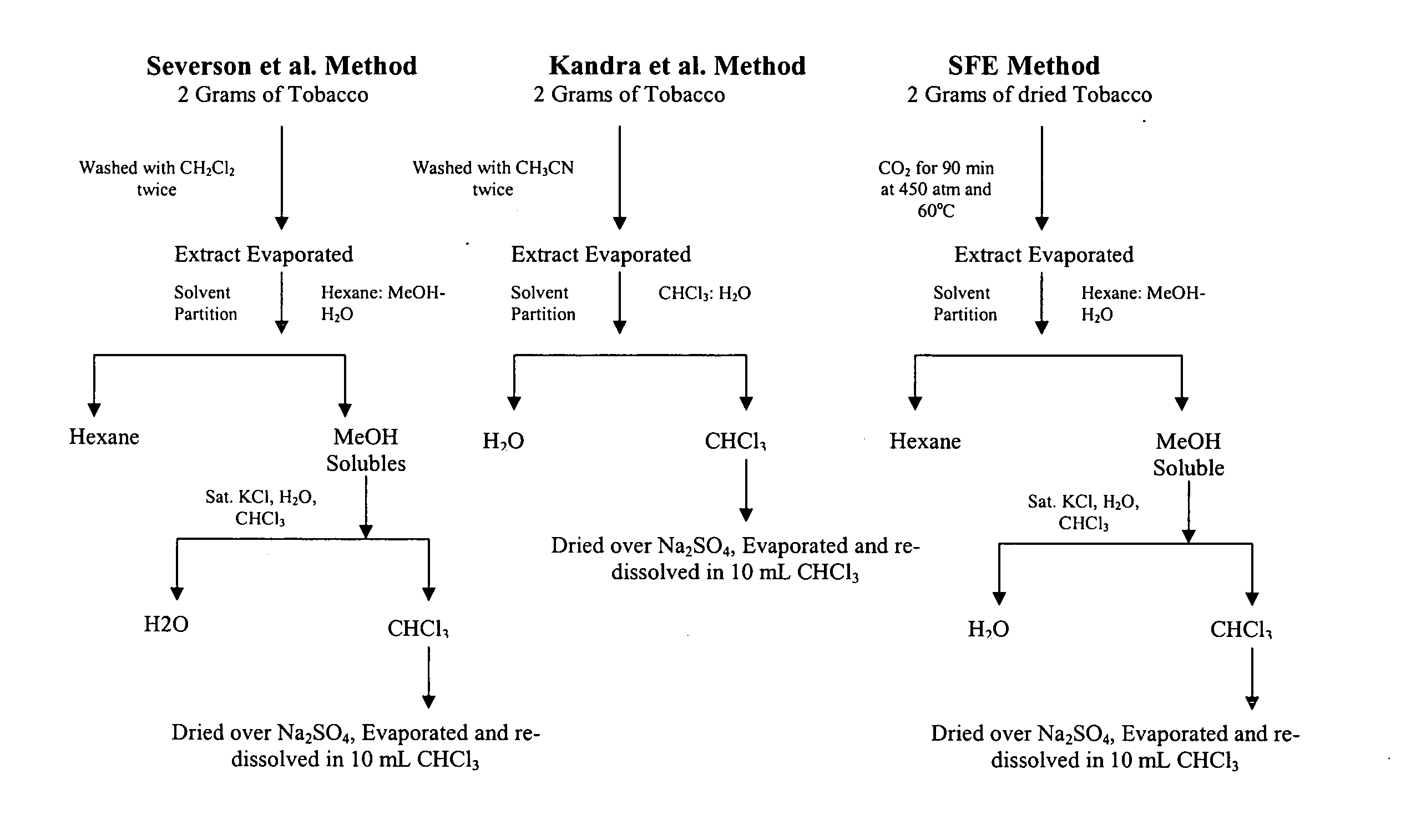

Cigarette and filter with cellulosic flavor addition

ActiveUS20060272662A1Large specific surface areaMainstream smoke velocityTobacco smoke filtersVolatile flavorTobacco smoke

A cigarette having a multi-component filter wherein an upstream sorbent removes at least one constituent from mainstream tobacco smoke passing through the filter and a downstream flavor segment compensates for taste lost to the sorbent. The flavor component includes cellulosic flavor bearing granules which release volatile flavor constituents into the mainstream smoke under ambient conditions. The cellulosic granules include microcrystalline cellulose or other cellulosic material which can be formed into a paste with the flavor additive, extruded and spheronized to form the flavor granules.

Owner:PHILIP MORRIS USA INC

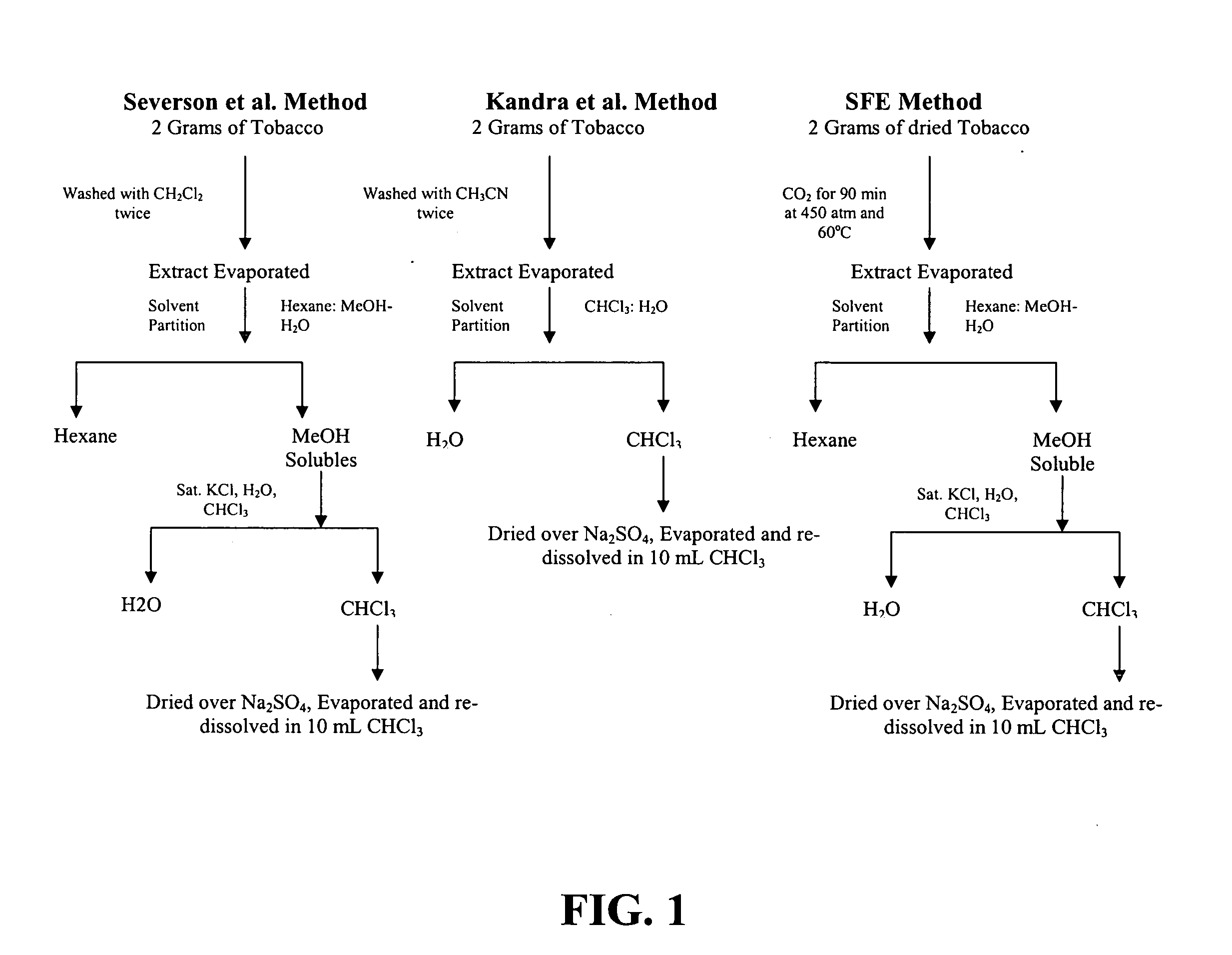

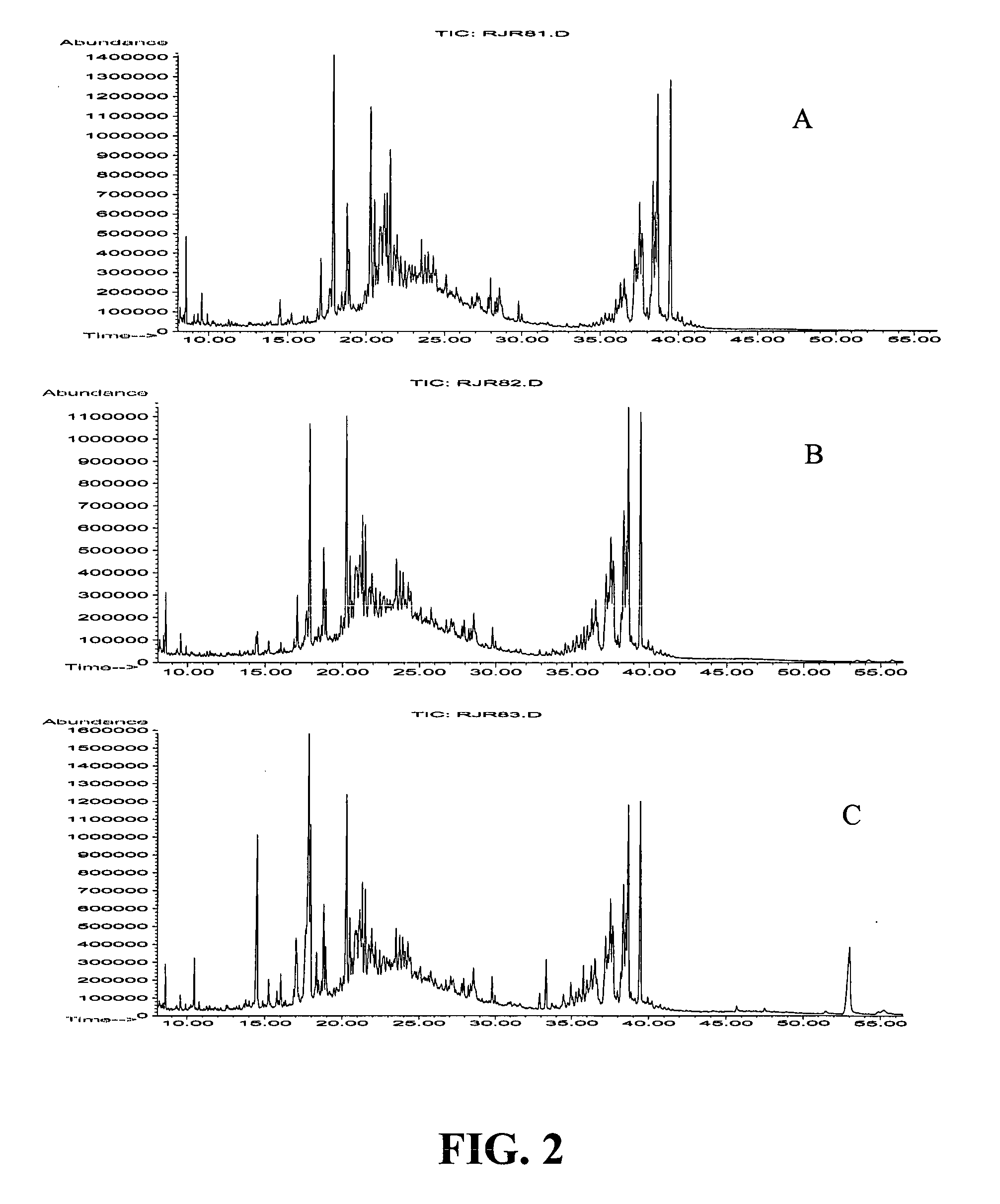

Method of extracting sucrose esters from oriental tobacco

InactiveUS20070137663A1High selectivityIncrease fluid pressureTobacco treatmentCigar manufactureSucroseNicotiana tabacum

The invention provides a method of extracting sucrose esters from Oriental tobacco, the method comprising: providing a Oriental tobacco material; contacting the solid Oriental tobacco material with a supercritical fluid, such as supercritical carbon dioxide, for a time and under conditions sufficient to extract sucrose esters from the Oriental tobacco into the supercritical fluid; and separating the supercritical fluid comprising extracted sucrose esters from the Oriental tobacco. The resulting extract can comprise more than 90% by weight of tetra-acyl sucrose esters, and can be used as a flavor additive for tobacco materials used in smoking articles.

Owner:R J REYNOLDS TOBACCO COMPANY +1

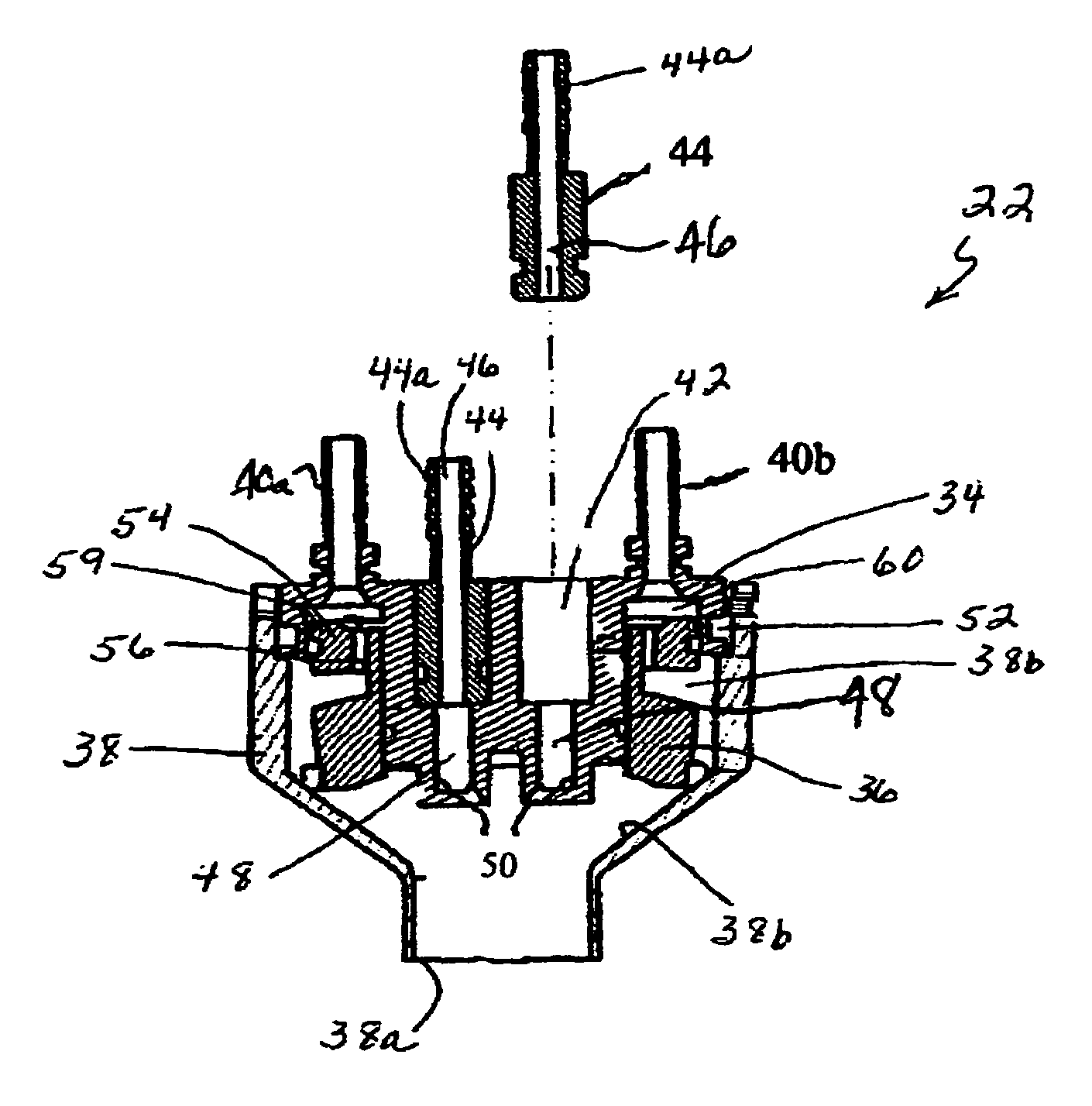

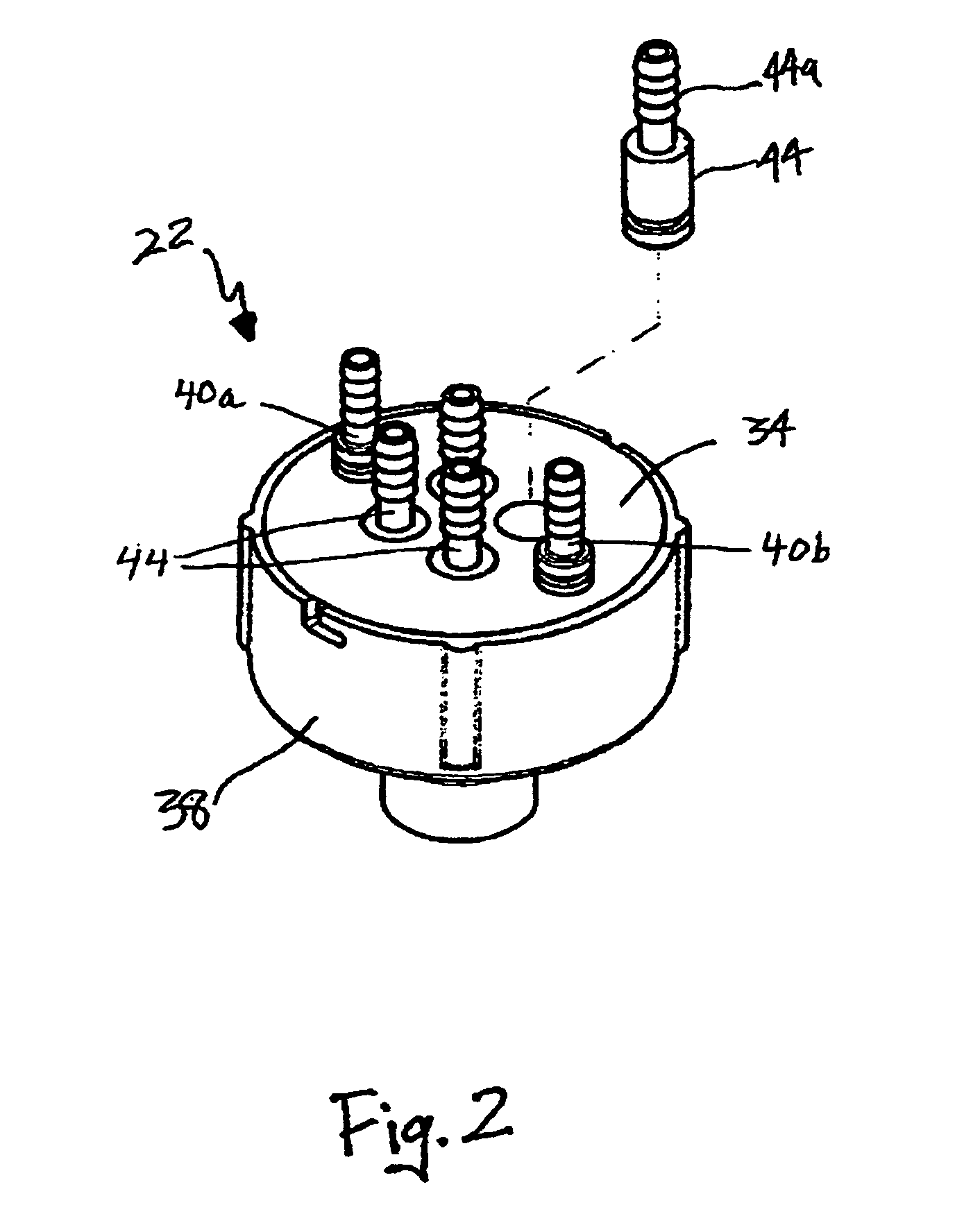

Multiple beverage and flavor additive beverage dispenser and method

ActiveUS20050115989A1Well mixedEasy maintenanceLiquid transferring devicesLiquid dispensingDiluentSpray nozzle

A beverage dispensing head for a beverage dispenser admixes diluent and syrup for dispensing into a cup. The dispensing head has a nozzle with a diluent receiving surface that leads downward to a juncture of the surface with an outlet from the nozzle. Diluent delivered to the dispensing head is introduced onto the diluent receiving surface for flow along the surface to and past the juncture. Syrup delivered to the dispensing head is emitted in the nozzle as a plurality of discrete streams directed toward and against diluent at the juncture for admixture with the diluent. The admixture of diluent and syrup then exits the dispensing head nozzle through the nozzle outlet for being dispensed into the cup.

Owner:MARMON FOODSERVICE TECH INC

Instant noodle seasoning packet and manufacturing method thereof

The invention provides an instant noodle seasoning packet and a manufacturing method thereof, which mainly takes fresh beef, pork, entire chicken, fresh shrimp, seasonal fresh vegetables, shrimpbran, kelp, mushroom, shallot, ginger, and the like as the main materials, takes spice powder, salt, sugar, monosodium glutamate, and the like as flavoring additives and accessories, adopts the brand-new technical conception which combines stewing with frying as well as combines enzymolysis with fining to convert the nutrition components of poultry with fresh vegetables into amino acids which are easily absorbed by human bodies, and implements seasoning based on the steps to manufacture the flavoring additives with more familization as well as excellent color, fragrance and taste, changes the fixed modes of the original instant noodles including powder packet, sauce packet and vegetable packet, and recommends the brand-new three-packet seasoning combination of brand-new soup packet, oil packet and vegetable packet, thus effectively improving the defects of less vegetables and high fats of the instant noodle seasoning packet, and being more beneficial to the body health of people. The seasoning adopts scientific and precise mixture ratio, which has the advantages of simple manufacturing technique and high production efficiency, thus greatly simplifying the traditional production technique of the instant noodle seasoning packet.

Owner:ANHUI XIN JINFENG ENTERPRISE INVESTMENT GROUP

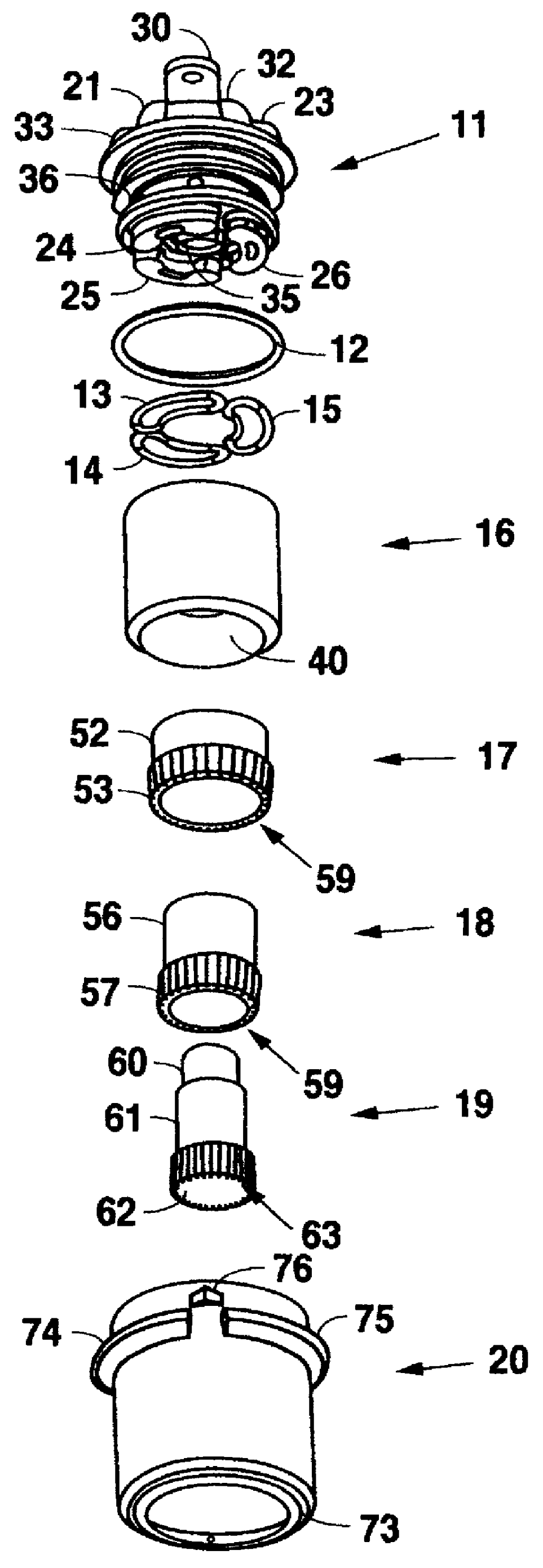

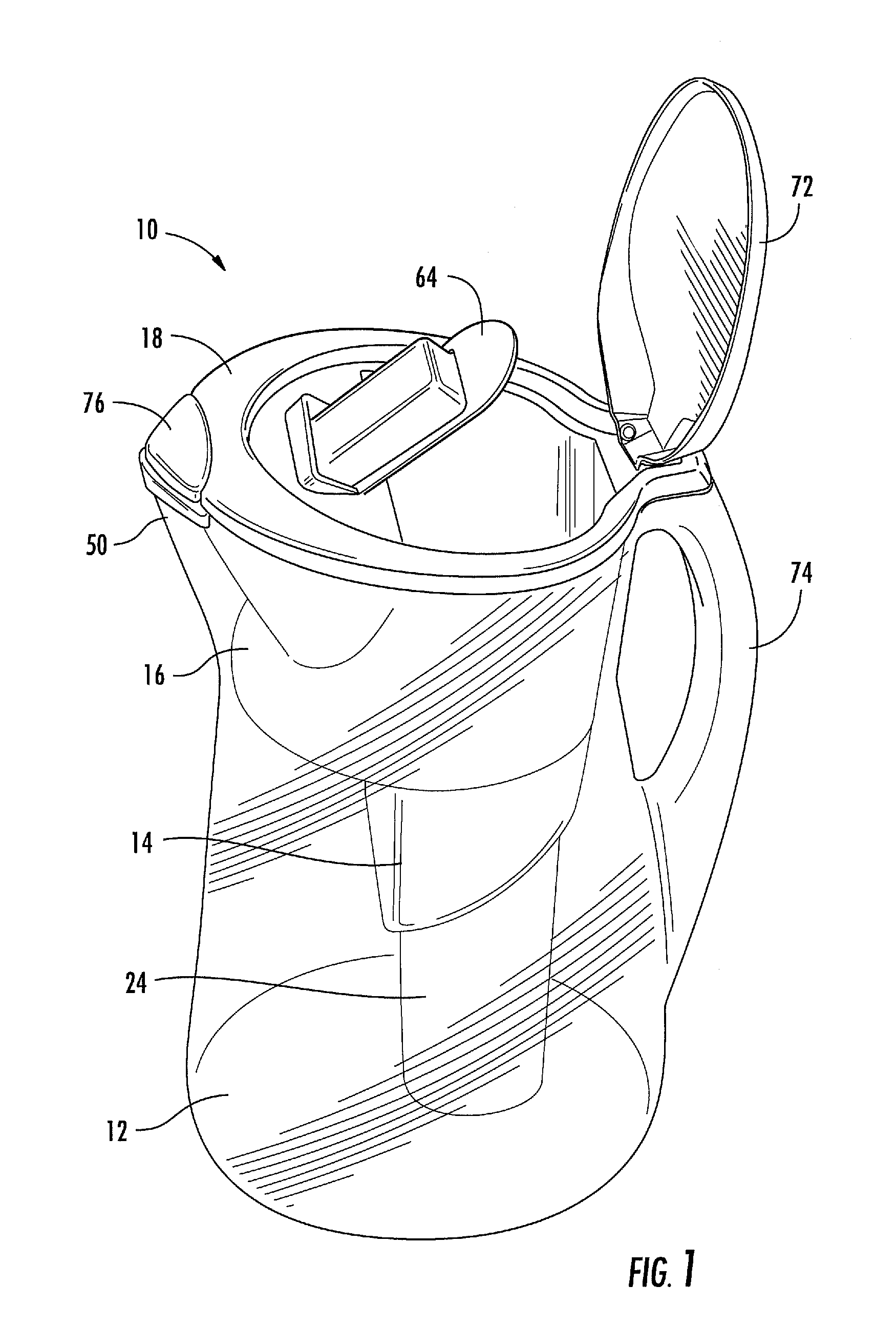

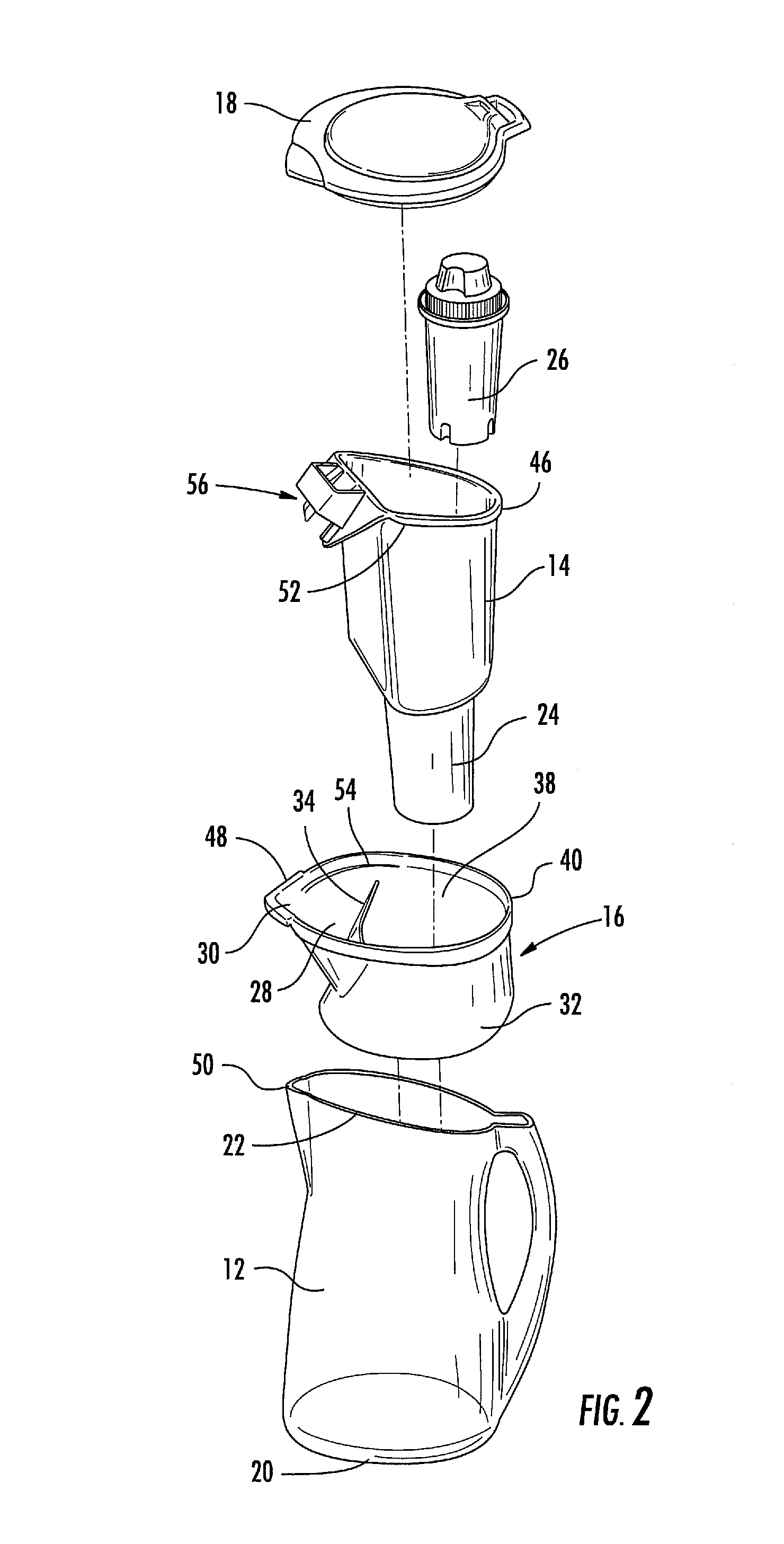

Water filtration and flavor additive device

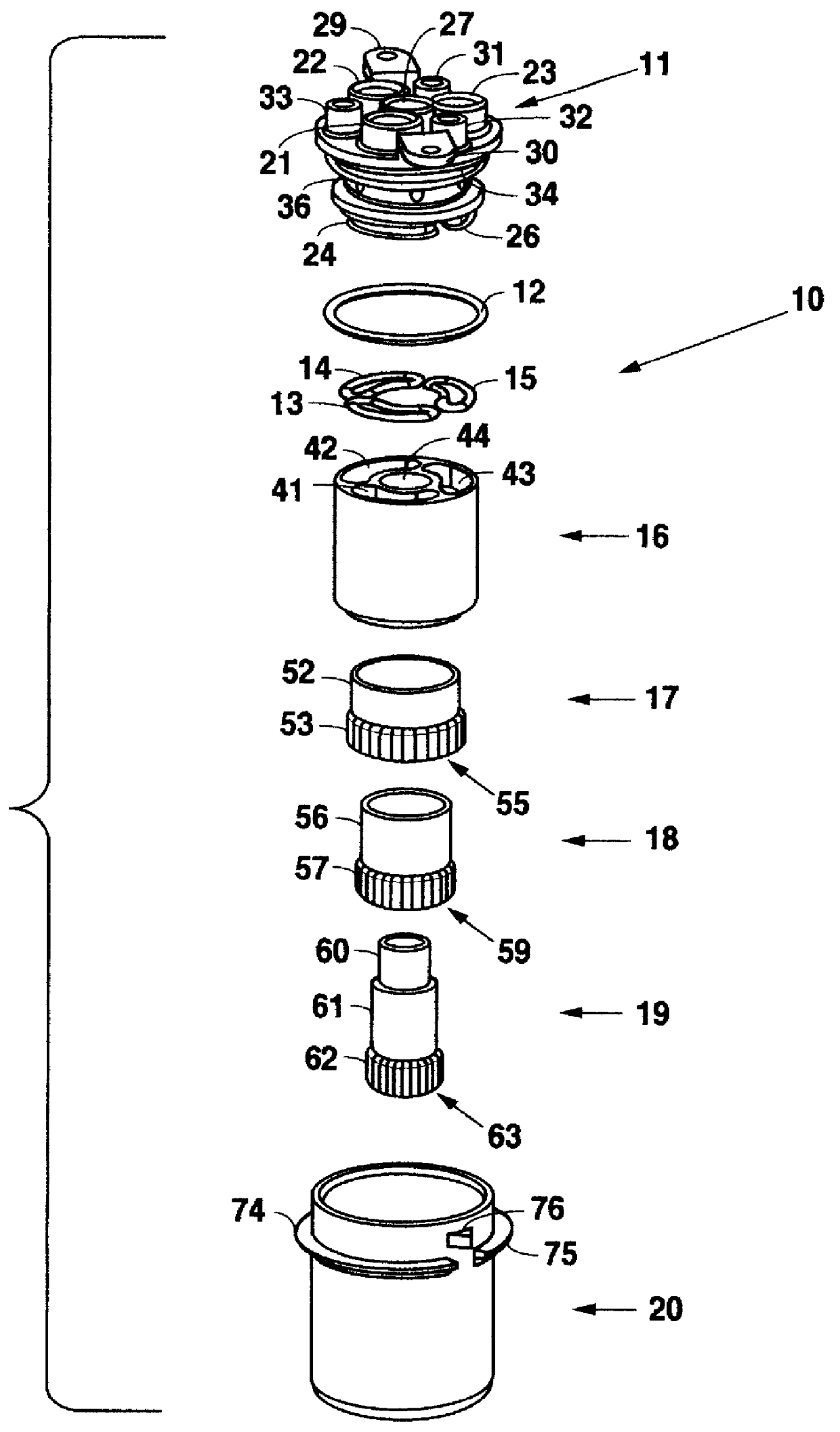

InactiveUS20120148707A1Add flavorTreatment involving filtrationBeverage vesselsFiltrationFlavor Additives

The present invention provides methods and systems for a water filtration and flavor additive device that includes a lower reservoir for storing filtered water having a base and a top portion, an upper reservoir, a filter housing affixed to and extending below the upper reservoir. The filter housing is adapted to contain a filter cartridge wherein the upper reservoir and the filter housing are in liquid communication. The device further includes a mixing chamber for receiving a flavor additive and allowing for the mixture of the flavor additive and filtered water.

Owner:PROTECT PLUS

Technology for production of peanut coated food by variable-temperature pressure-difference puffing technology

ActiveCN101889699AExtended shelf lifePromote digestion and absorptionFood preparationAdditive ingredientHardness

The invention relates to a technology for the production of peanut coated food by variable-temperature pressure-difference puffing technology, which comprises the following steps of: acceptance check, pick-out, baking, cooling, peel-off, coating, oven drying, puffing drying, cooling, pick-out of edible material, metal detection, weighing and packaging, box sealing and warehousing of the finished product, wherein the ingredients in the process of coating and the weight parts thereof are as below: 20-50% of peanut kerbel, 10-30% of flour, 10-30% of modified starch, 0-10% of rice flour, 0-15 of white crystal sugar and flavoring additives as the balance; the puffing drying process is as below: the coated and dried peanuts are put in an puffing tank which is heated up to the puffing temperature of 60 to 120 DEG C, evacuation is performed at the temperature of 70 to 100 DEG C for 120 to 210 minutes after standstill for 5 to 20 minutes; and the puffing pressure difference is 0.2 to 0.5MPa. The peanut coated food produced according to the technology of the invention is rich in nutrition, convenient for digestion and absorption by human body, long in storage period, less in nutrient loss, good in crispness, low in hardness and excellent in taste, thus the peanut coated food meets the demand of massive consumers and includes wide market prospect.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

Preparation method for oil cooked chili

ActiveCN101791103AFor long-term storageRefined completelyFood preparationFlavouring agentOil temperature

The invention discloses a preparation method for oil cooked chili, which comprises the following steps that: (1) primary oil refining: oil is poured into a frying pan and is heated for refining, the heating is stopped after oil temperature reaches 190-210 DEG C, and the oil is cooled to 34-36 DEG C; (2) secondary oil refining: oil obtained after the primary oil refining is heated to 165-175 DEG C; (3) chili refining: chili is poured into the oil obtained after the secondary oil refining and is continuously stirred and fried, and the heating is stopped after the chili is refined for 24-26 minutes; and (4) flavoring: 100kg of chili obtained after refining is taken out and flavoring additives are added for flavoring, wherein the flavoring additives are formed by gourmet powder, salt, beef, chicken, black salted turnip and peanuts. The prepared oil chili has the advantages of delicious taste and bright color.

Owner:遵义椒源食品有限公司

Piglet milk powder capable of completely replacing sow milk

InactiveCN101926415AEliminate early weaning stressMeet rapid growthFood processingAnimal feeding stuffVitamin CAdditive ingredient

The invention provides a piglet milk powder capable of completely replacing sow milk, comprising the following components: 25-98wt% of dried whole milk, 0-70wt% of defatted milk powder, 0-13wt% of dried egg powder, 0-30wt% of mixed powder of emulsified plant fat and lactose, 0-5wt% of whey powder, 0.5-2.0wt% of lactocin powder, 0.3wt% of probiotics preparation, 0.2-1.0wt% of acidulant, 0.15-0.3wt% of trace elements pre-mix material, 0.25-1.0g / kg of piglet vitamin pre-mix material, 50-300mg / kg of vitamin C, 800-2000mg / kg of choline chloride, 10-50mg / kg of colistine sulfate, and 30-80mg / kg of oxycycline; and the rest is flavoring additive and preservative.

Owner:高俊松

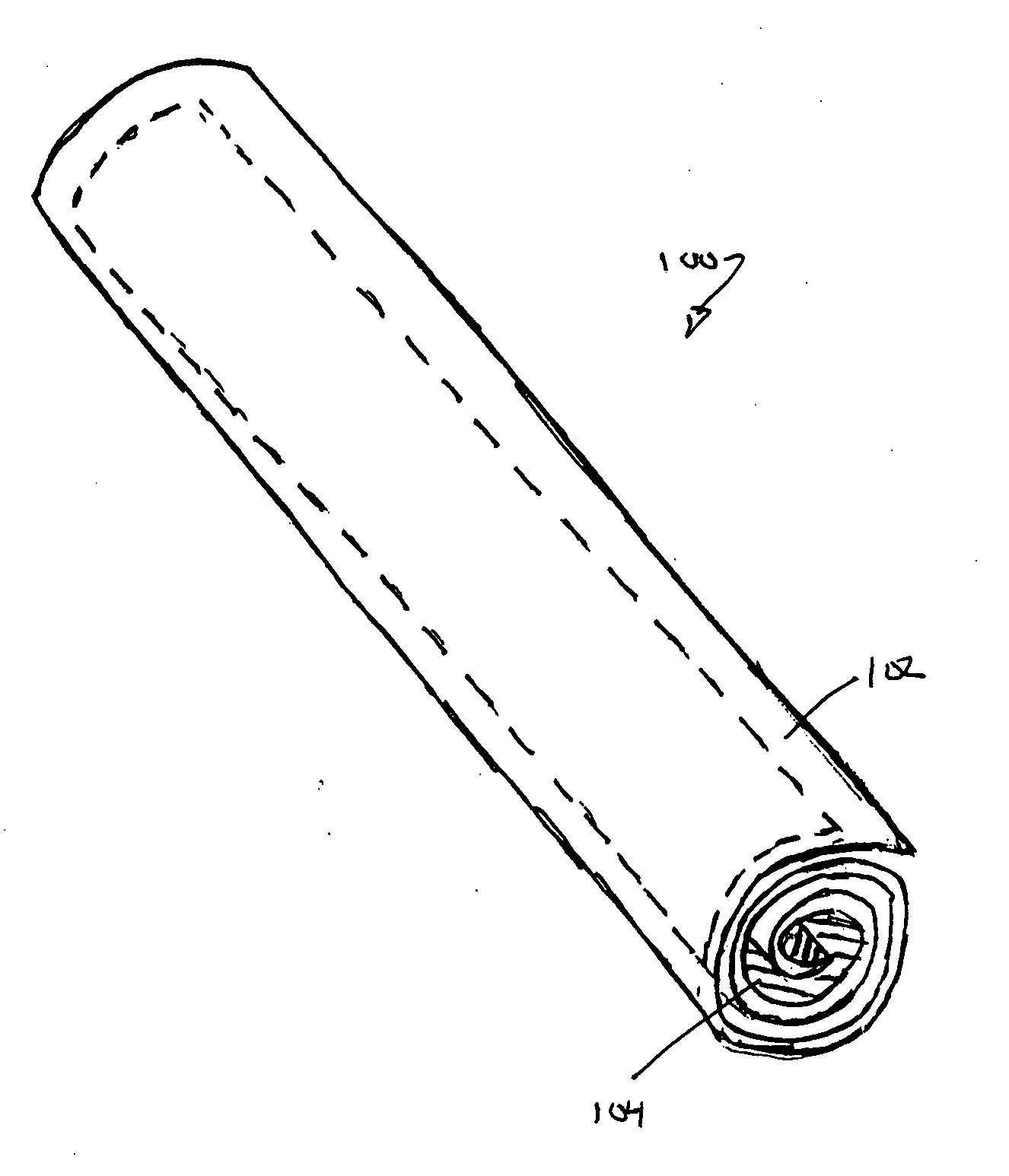

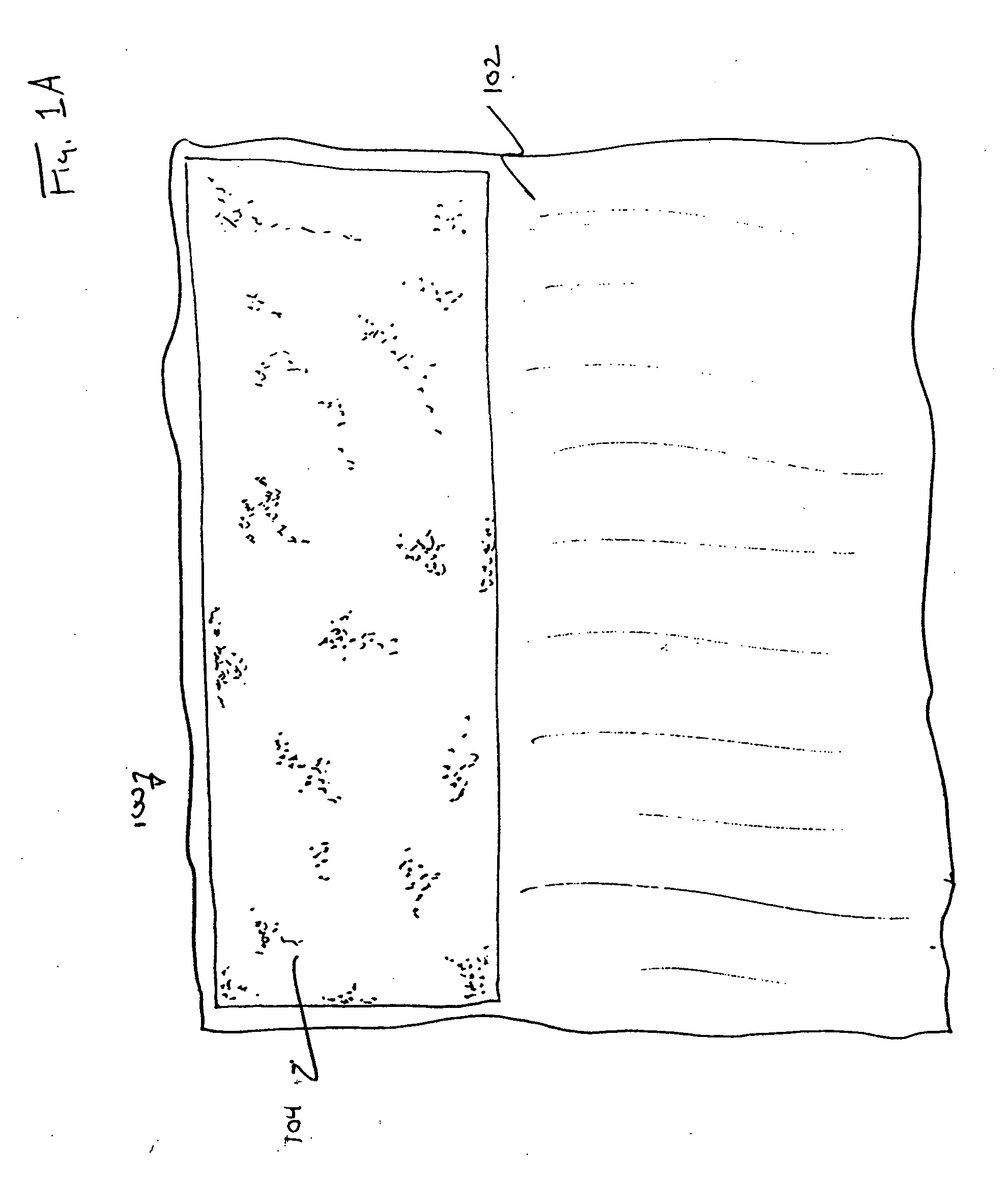

Flavor enhanced rawhide pet chew

A flavored rawhide pet chew. The rawhide pet chew is formed by adding a flavor additive to at least a portion of a rawhide strip, then forming the strip into a chew. An unflavored portion of the formed strip typically covers the flavored portion of the rawhide strip.

Owner:ASPEN PET PRODS

Rose extract liquid beverage and preparation method thereof

The invention relates to a rose extract liquid beverage which is made from the following raw materials in percentage by weight: 88.7% to 92.8% of first-grade reverse osmosis water and 7.2% to 12.7% of a rose flower mixed liquid. The rose flower mixed liquid contains the following components in percentage by weight: 36.3% to 58.1% of rose flower stock solution, 20.8% to 70.1% of oligosaccharides, 3.6% to 5.0% of citric acid monohydrate, and 7% to 10.0% of natural fruit juice. The invention also provides a preparation method of the rose extract liquid beverage. The invention has the advantages that: the formula is scientific; the rose extract solution, rose essential oil reduction liquid and rose cell solution in the rose flower stock solution which serves as the major material are obtained by different processes; the rose extract liquid beverage contains more than 54 kinds of rose active molecules, has fresh and slight fragrance and can effectively relieve mental stress, remove toxins in vivo and keep body healthy; the oligosaccharides and the natural fruit juice serve as sweetener additive and flavor additive respectively; and the rose extract liquid beverage is free of any pigment or synthetic chemical and conforms to the needs for backing to the nature.

Owner:GEOTHINK ECOTECH SHANGHAI

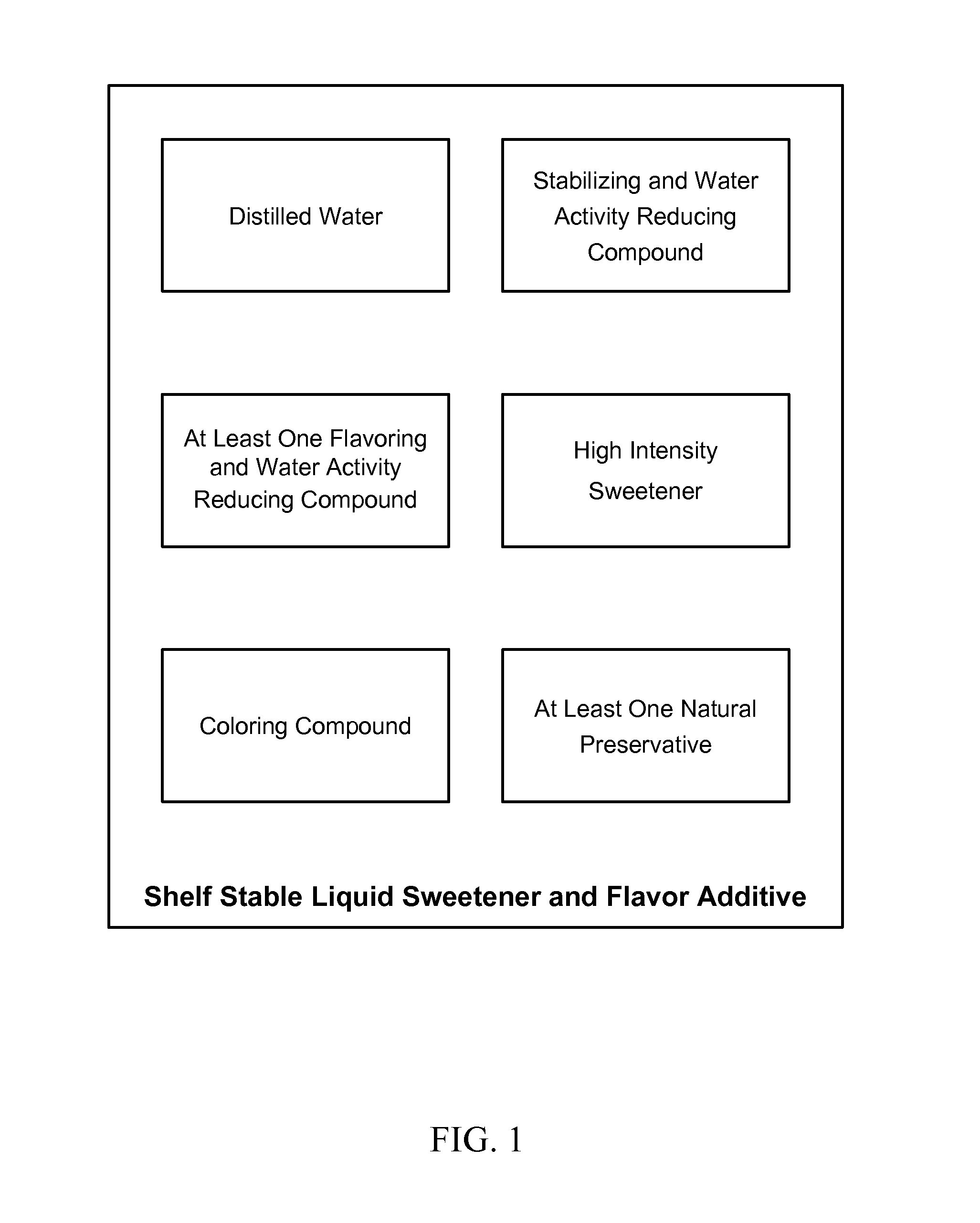

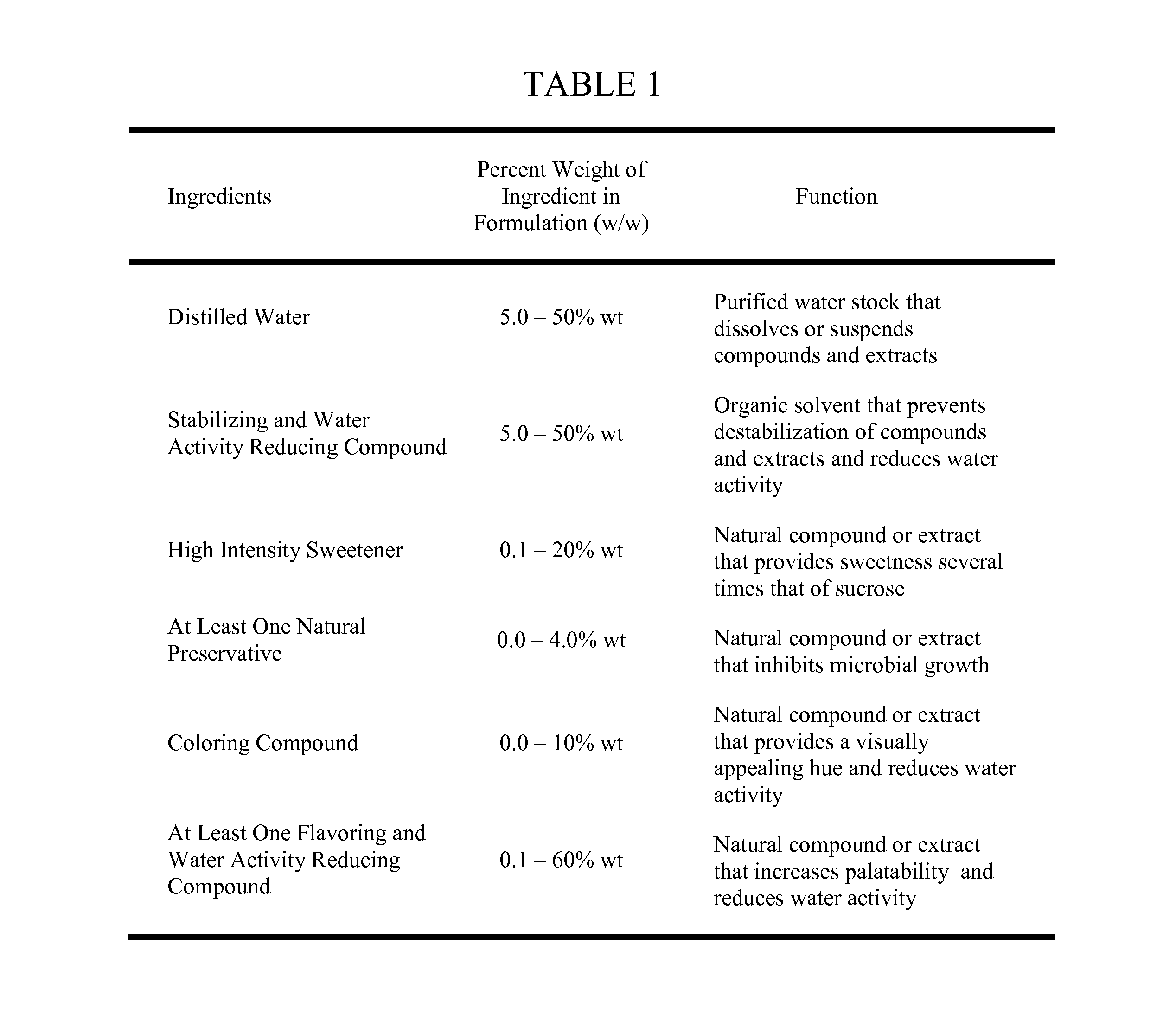

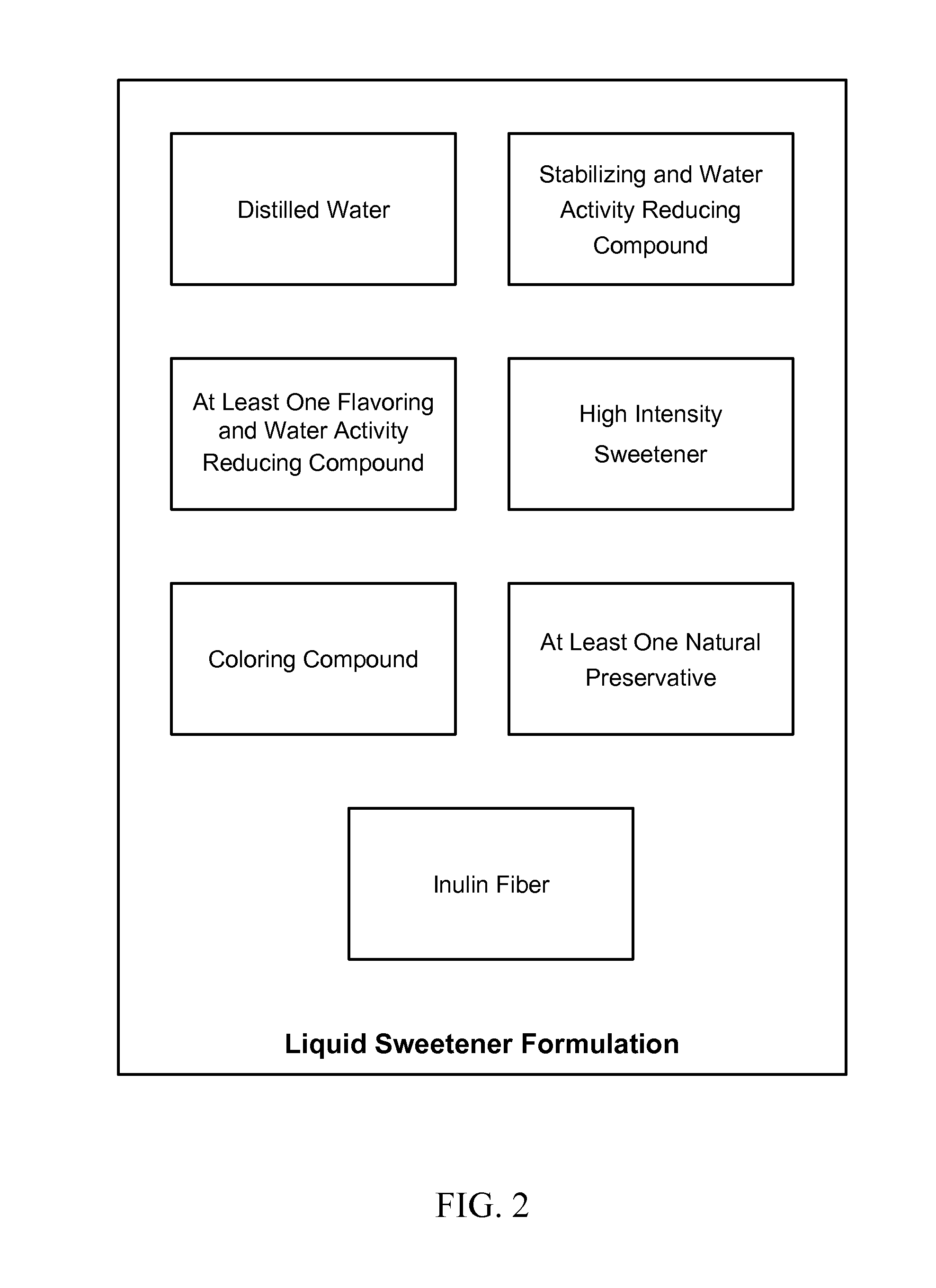

Shelf Stable Liquid Sweetener and Flavor Additive

A shelf stable liquid sweetener and flavor additive is a food additive that increases the palatability and sweetness of a plurality of food products. The shelf stable liquid sweetener and flavor additive is a formulation of various naturally occurring compounds and extracts that are obtained through non-chemically assisted means. The present invention enhances the sweetness and palatability of food product but contains a negligible caloric content. Additionally the present invention is able to be safely stored in a sealed container at ambient temperature for several months. The present invention comprises a plurality of natural compounds that function as water activity reducing compounds, stabilizing compounds, preservatives, and flavoring compounds as well as a natural high intensity sweetener. Through the formulation of the various natural components the present invention is able to maintain a water activity value that is below 0.8 and a pH value below 4.2.

Owner:INT FOOD NETWORK

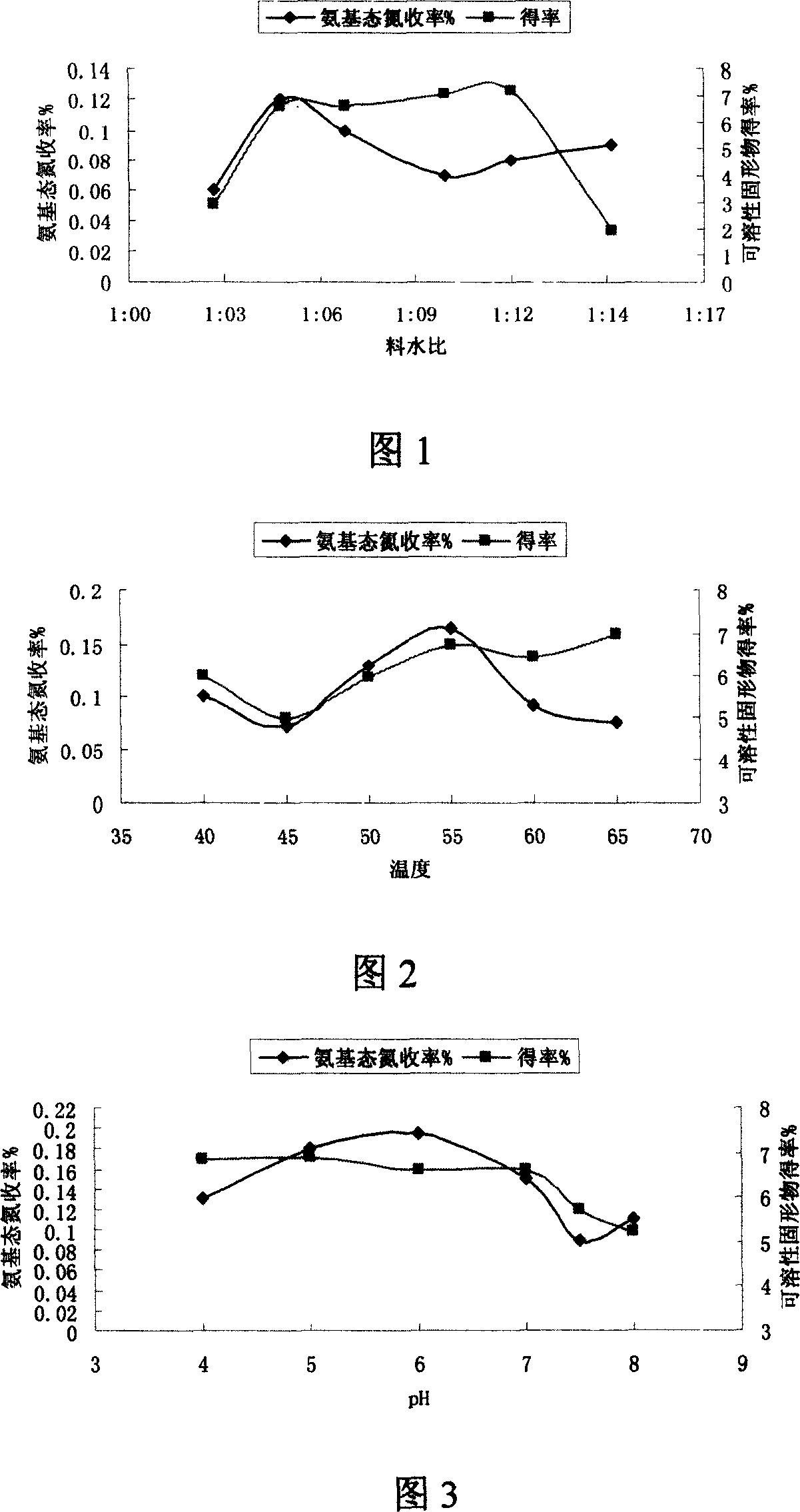

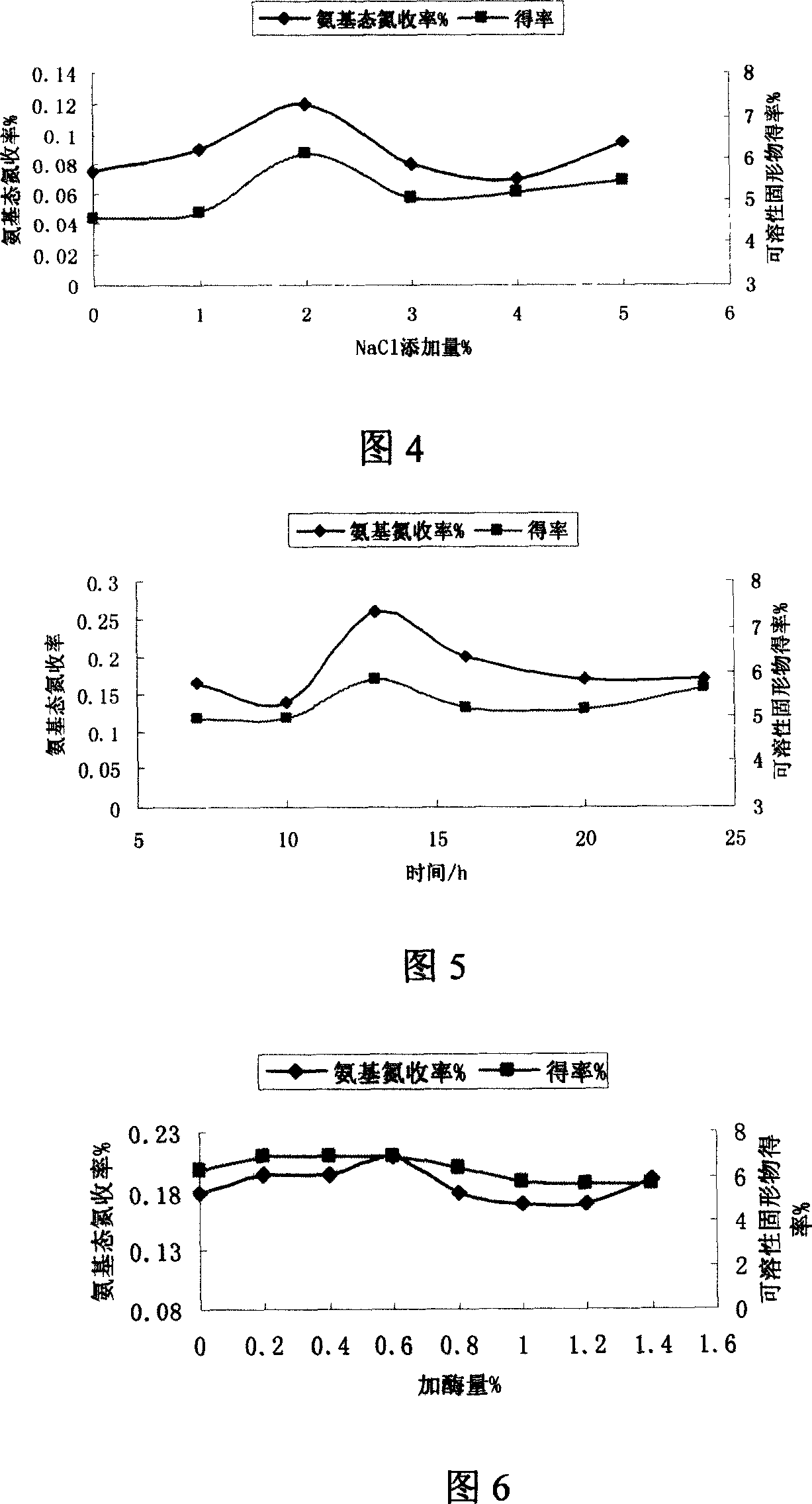

Process for preparing shiitake mushroom extract

The invention relates to a method for producing mushroom, which comprises that breaking mushroom and adding water, adding common salt to dissolve for 2-20h, adding some prolease to process enzymolysis, disinfecting enzyme and separating the filter solution; adding 5'-phosphodiesterase into filter solution to process the enzymolysis, disinfecting the enzyme and separating to obtain the filter solution; concentrating the filter solution into paste or atomizing and drying into powder. The invention processes two times of enzymolysis, while the product is abundant in amino acid, polypeptide, polysaccharide, or the like. And the invention has high solubility and stability in neutral or weak-alkali water solution, and some solubility in weak-acid water solution.

Owner:郝林

Meat pie and manufacturing method

InactiveCN101744306AReasonable variety configurationNutritional balanceBakery productsFood preparationEdible oilFlavor Additives

The invention relates to a meat pie which comprises a wrapper and pie fillings. The wrapper is formed by mixing the following materials by weight percentage: 50-60 of flour, 15-20 of shout, 0.1-0.3 of salt, 0.1-0.2 of sugar, 0.1-0.2 of five spice powder, 0.1-0.2 of custard powder and 1-3 of ferment powder and allowance water; the pie fillings are formed by mixing the following materials by weight percentage: 0.4-0.6 of salt, 0.2-0.3 of flavoring additives, 0.1-0.2 of edible oil, 3-5 of sauce, 0.2-0.5 of flavoring substances, 10-15 of vegetables and 20-25 of water and allowance meat; and the weight proportion of the wrapper and the pie fillings is 1:1-1.5. Therefore, the meat pie belongs to Chinese fast food with balanced nutrition and has the advantages of scientific manufacturing method, mechanical and massive production, convenient eating and easy package, carrying and storage.

Owner:褚景山 +1

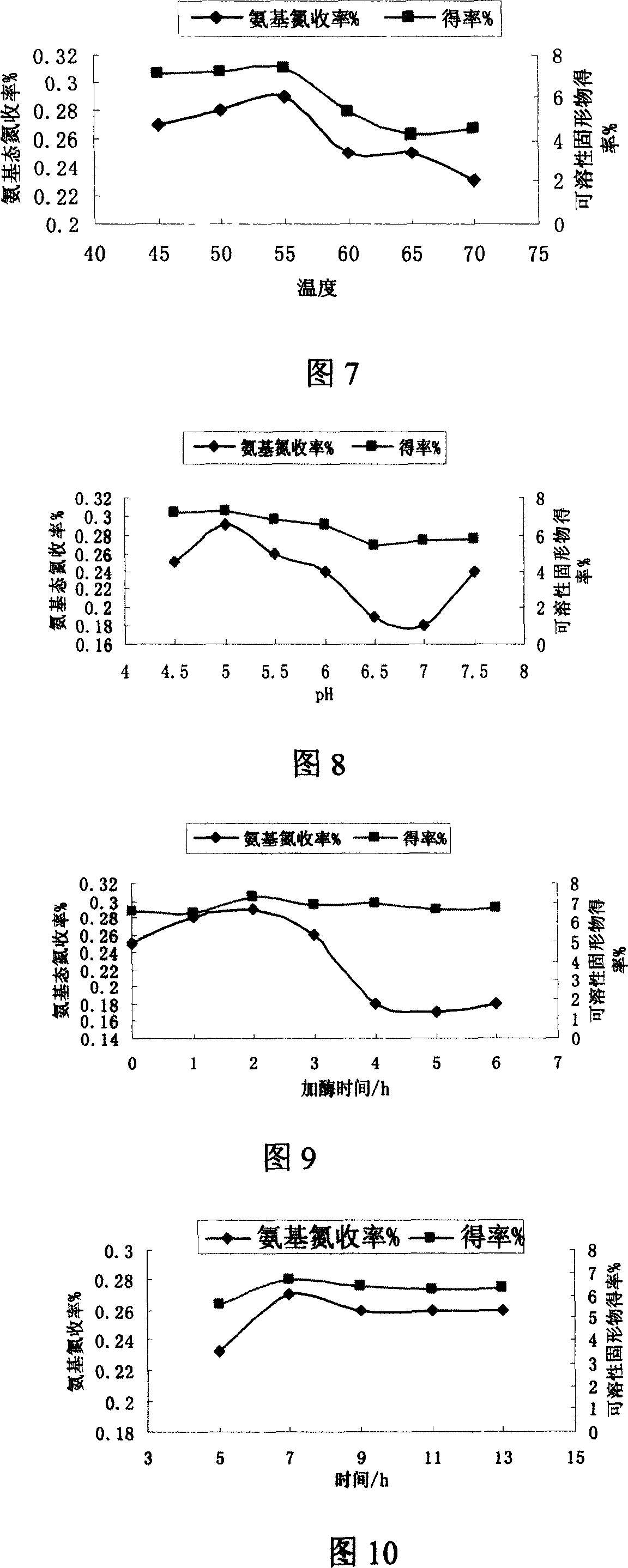

Nutraceutical method and additive for improving human physiology

ActiveUS7211279B1Improving energeticsReduced muscle responseOrganic active ingredientsBiocideGround-beanFat burning

A method for creating a coffee drink that having the addition of a nutraceutical additive composition of milk thistle; chromium picolinate, and carnitine. Milk thistle is present from about 50 to 99.7 parts by weight of the total composition, and preferably 50 to 60 parts by weight. Chromium picolinate is present from about 0.01 to 0.23 parts by weight of the composition and preferably from 0.01 to 0.1 parts by weight. Carnitine is present from about 0 to 50 parts by weight of the total composition, and preferably 40 to 50 parts by weight. The coffee drink can be created by an admixture of the composition with ground beans, sprayed and / or coated on the bean prior to grinding, or added to a brewed much the same as one would add sugar or other known flavor additives. The instant composition does not subtract from the flavor and improves human physiology by assisting in weight loss, body cleansing, weight loss, fat burning, and sugar regulation.

Owner:PEACHES & CREAM

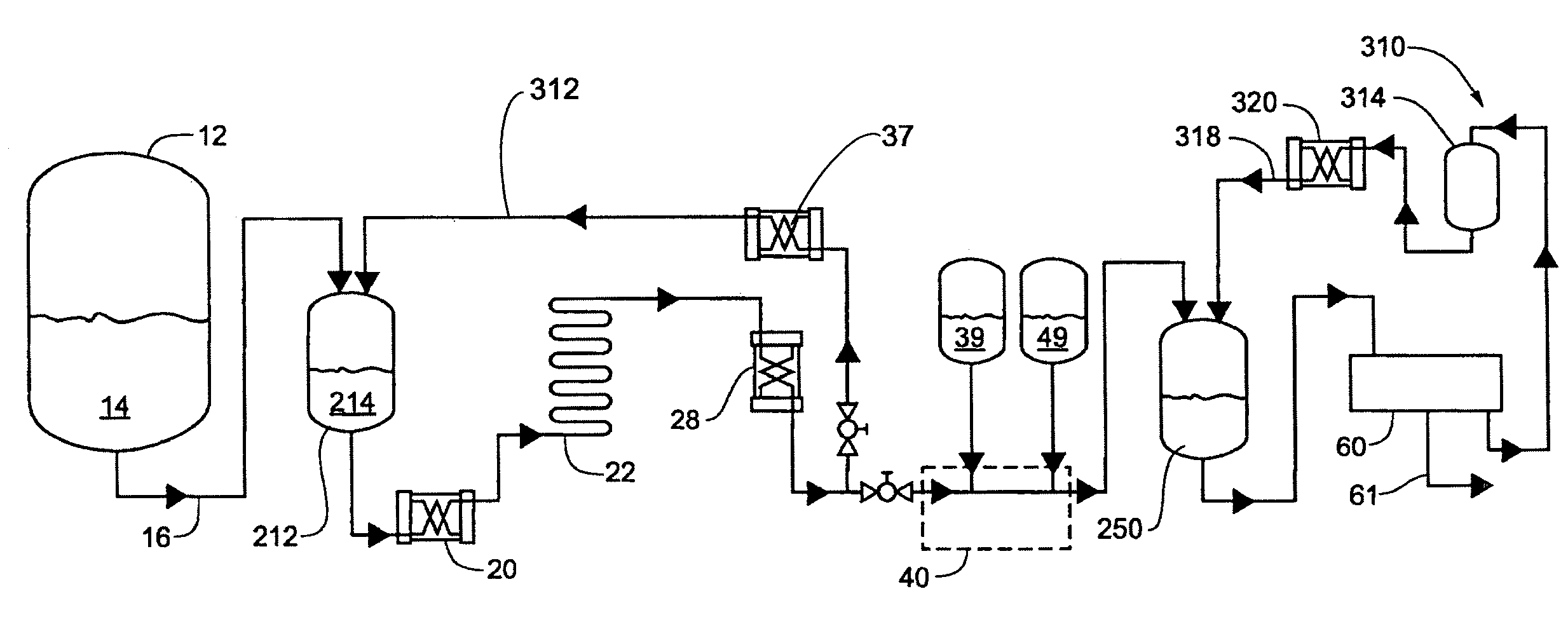

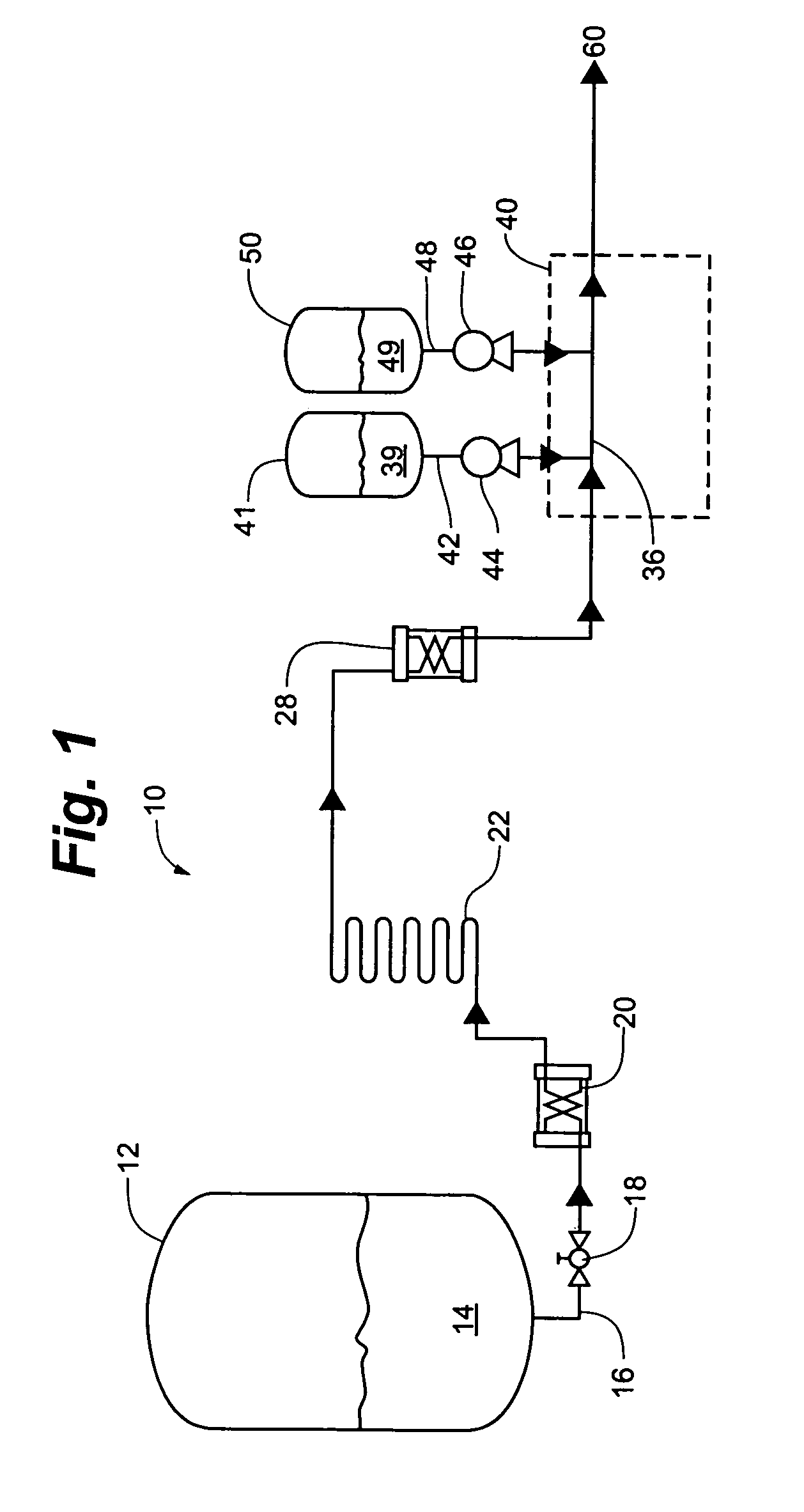

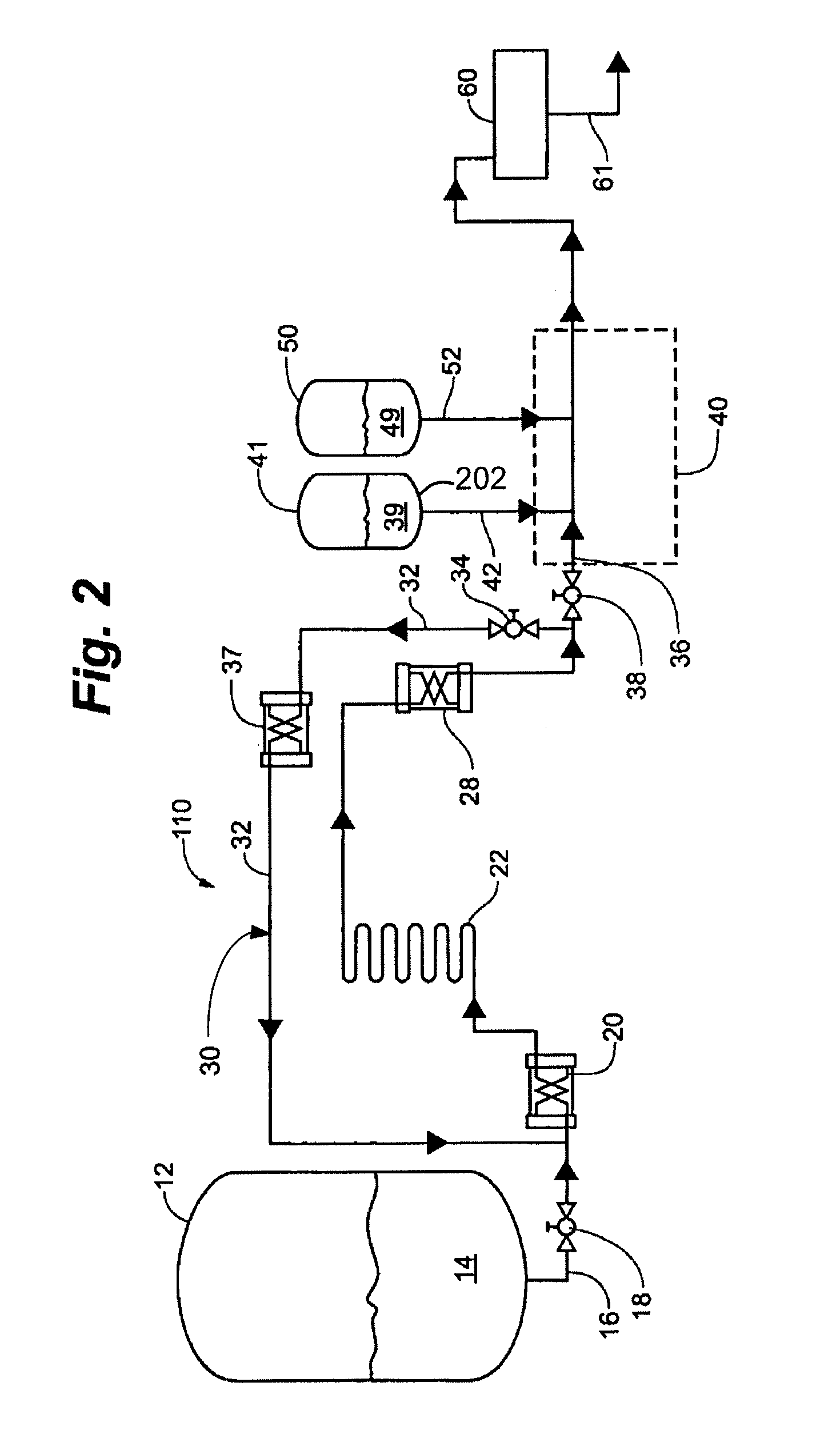

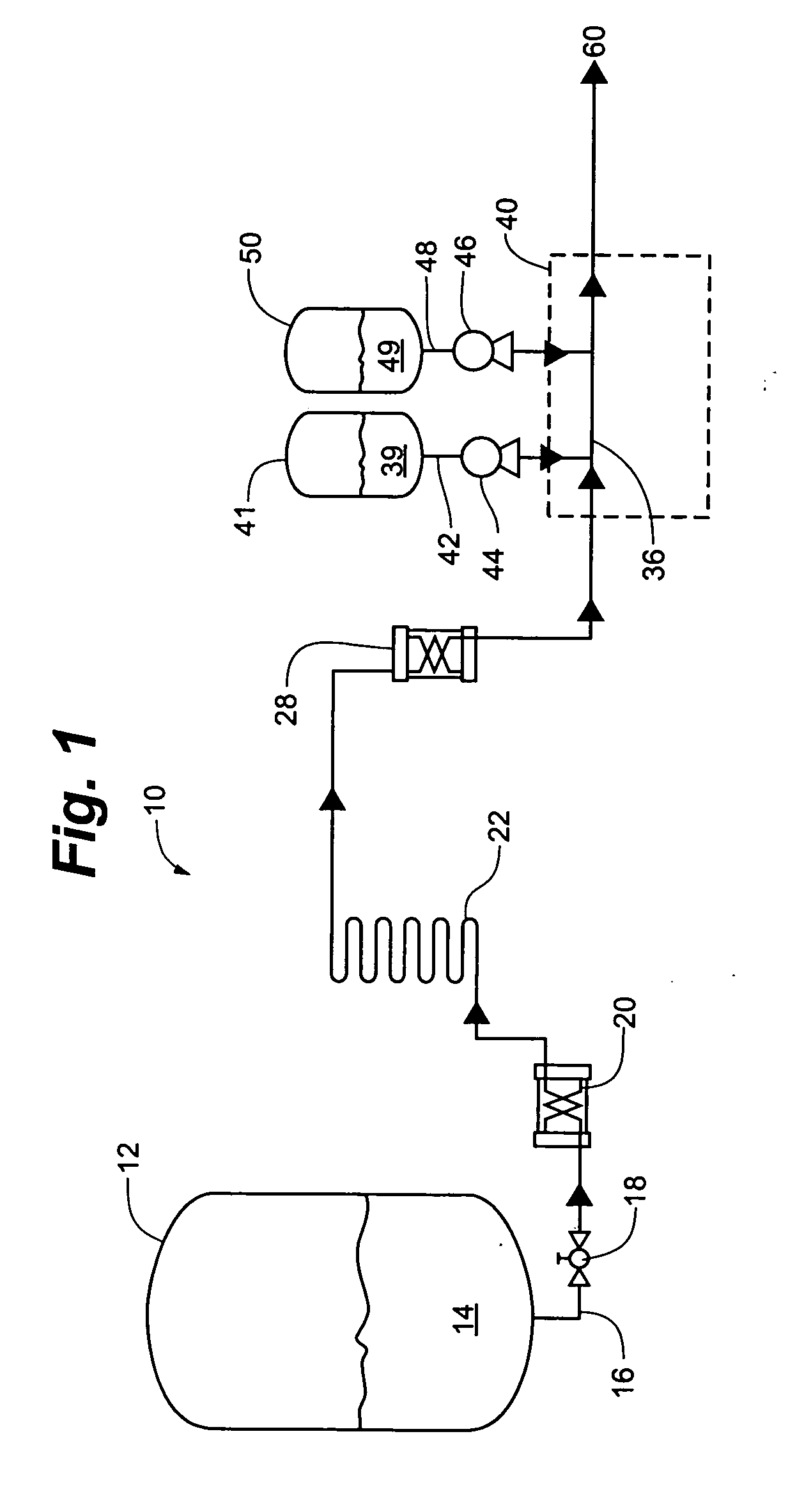

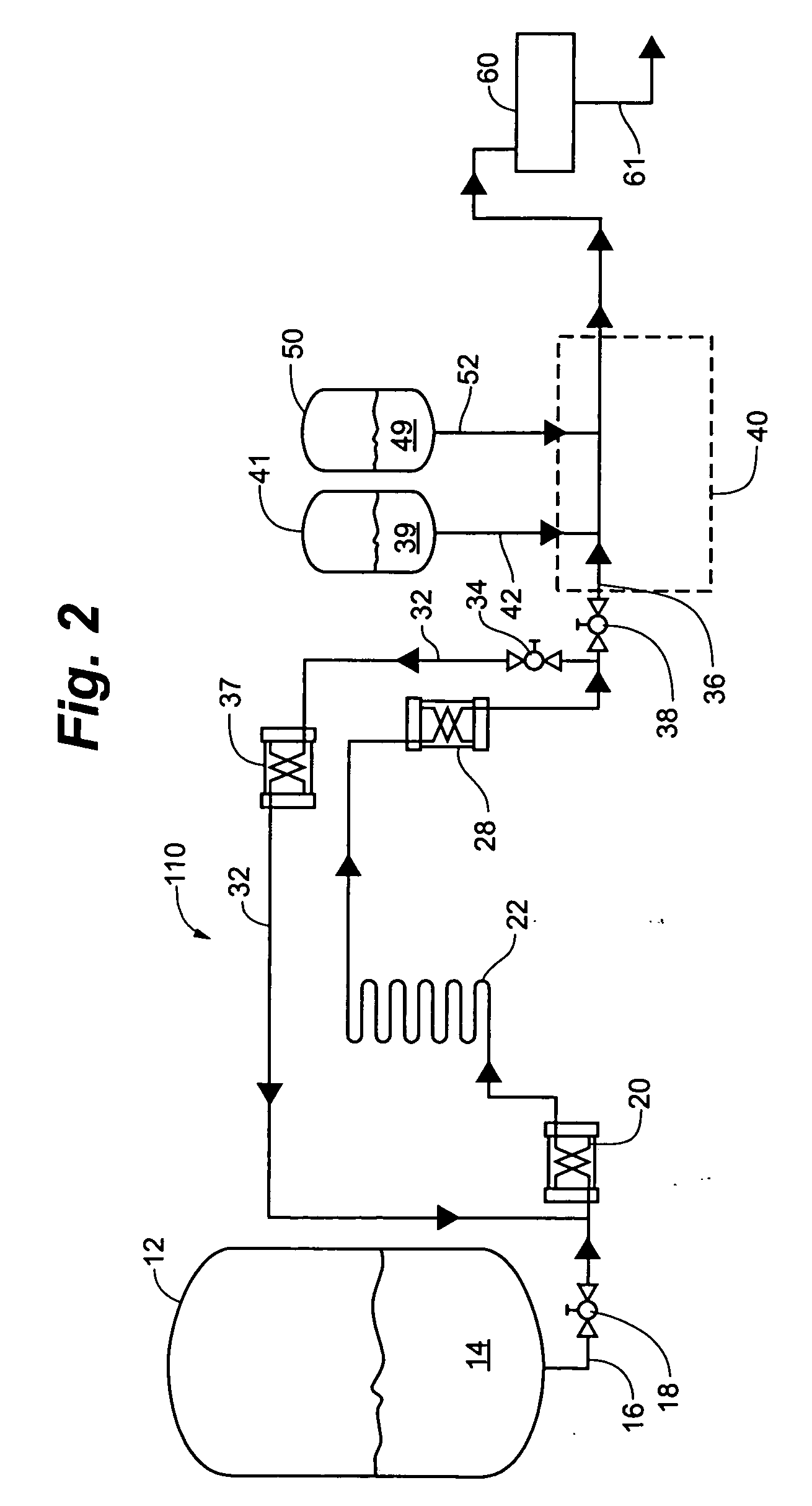

Hot-fill beverage production with flavor injection

InactiveUS8460733B2Reduce downtimeLess fresh water and energyLiquid fillingFood preservationStable stateFlavor Additives

A method and system for producing a flavored beverage wherein the flavor is added in a separate step to a combination of the base ingredients after the base liquid has been pasteurized by, for example, thermal heating. The flavor can be added to a continuous stream of the base liquid after a thermally processed hot-fill beverage base liquid is made up. A return loop conduit of the hot-fill beverage base liquid portion of the system is capable of diverting the heated hot-fill beverage base liquid in a stable state, that is, at the desired temperatures ready for continued beverage production, while the flavor may be switched over in a downstream flavor dosing portion of the system. The system may be used to produce a desired batch of flavored beverage by producing a first flavor, cleaning only that portion of the system to remove the first flavor and then changing over the flavor additive component to a desired second flavor.

Owner:THE QUAKER OATS CO

Blood glucose reducing, fat losing and health caring flour, fine dried noodles and preparation method thereof

The invention discloses blood glucose reducing, fat losing and health caring flour, fine dried noodles and a preparation method thereof, and belongs to the technical field of heath care food processing. The blood glucose reducing, fat losing and health caring flour comprises the materials, by weight, 15-25 parts of fiveleaf gynostemma herb, 15-25 parts of kudzu vine root powder, 15-20 parts of red beans, 15-25 parts of coix seed powder, and 60-150 parts of wheat flour. The fine dried noodles comprise the materials, by weight percentage, 60.5-72.2 % of blood glucose reducing, fat losing and health caring flour, 20-25% of soup-stock or water, 5-8% of mushroom, 1.8-3% of flavoring additives, 0.5-1.5% of ginger, and 0.5-2% of edible alkali. According to the concept of homology of medicine and food in traditional Chinese medicine, medicine and food homologous materials of fiveleaf gynostemma herb, kudzu vine root and red beans match with coix seed and wheat, and the flour and noodles are rich in nutrition, taste fresh and mellow due to the soup-stock and mushroom. Besides, the flour and noodles are convenient to carry and have the efficacies of reducing blood glucose, losing fat, strengthening immunity of the organism and the like.

Owner:刘巧霞

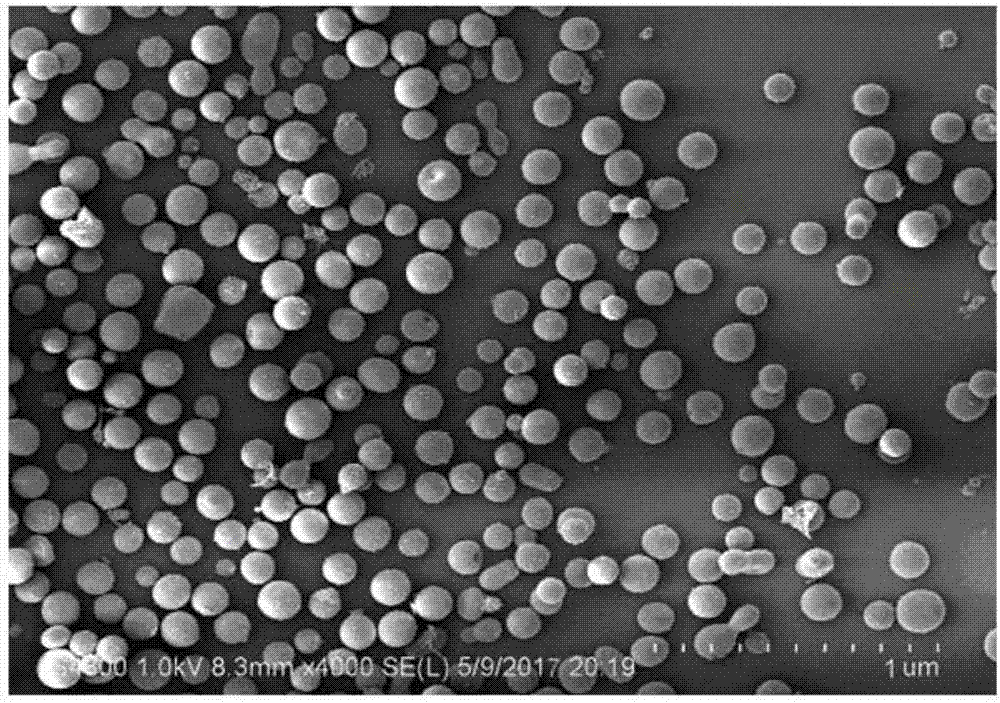

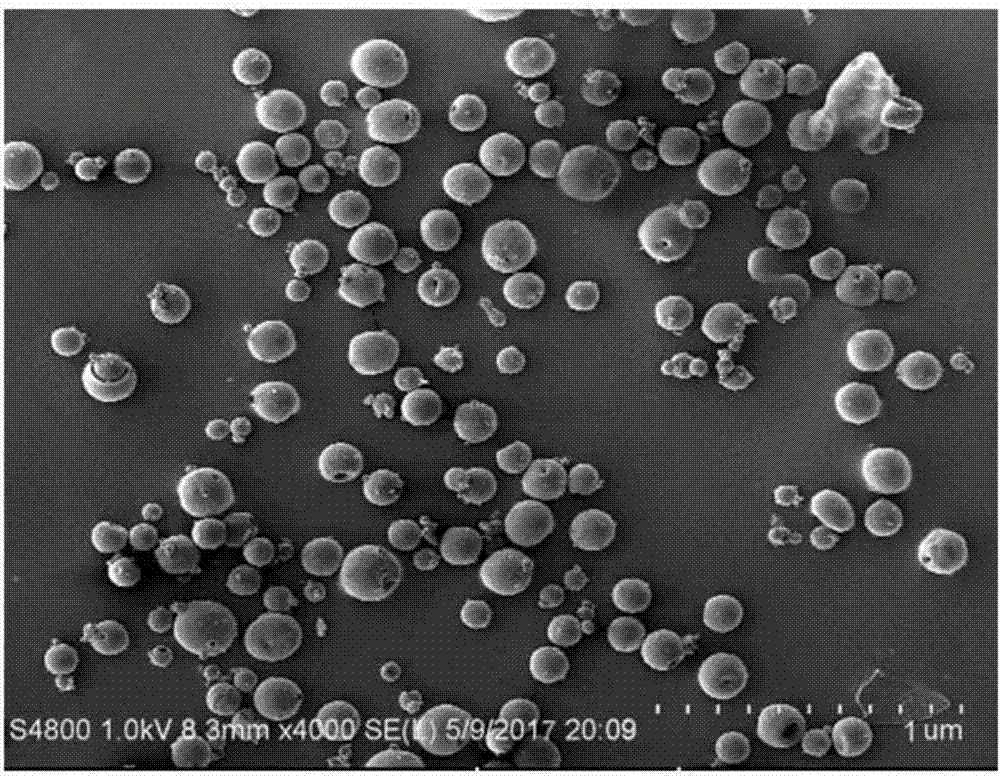

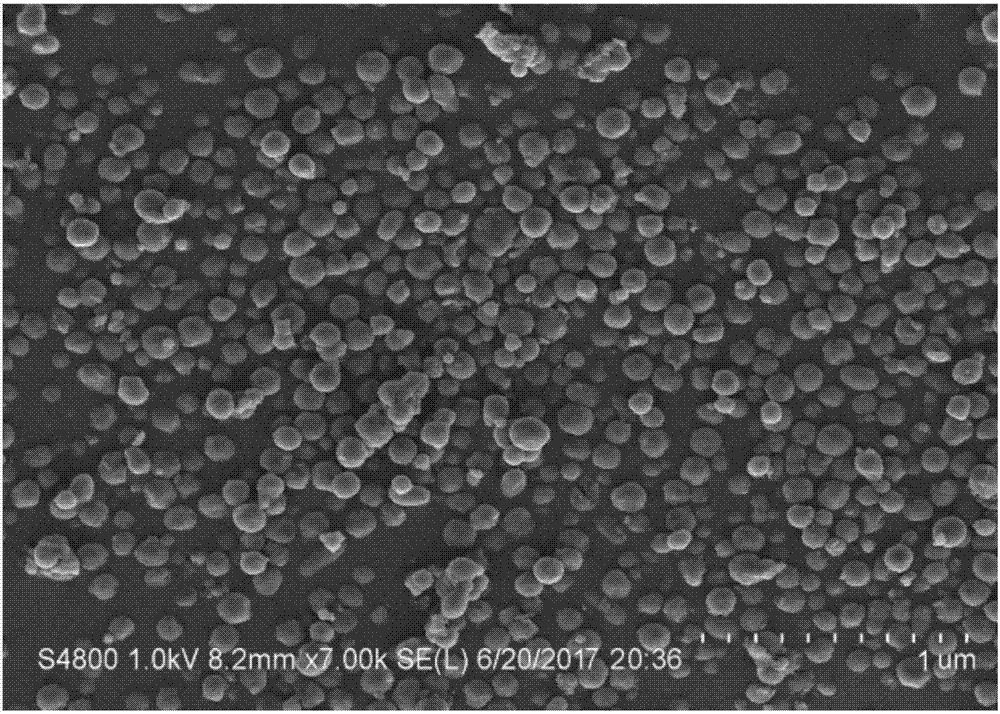

Nano-microcapsule with blumea balsamifera essential oil as well as preparation method and application of nano-microcapsule

ActiveCN107137714AReduce volatilityImprove light and heat stabilityCosmetic preparationsToilet preparationsCross-linkNon toxicity

The invention discloses a nano-microcapsule with blumea balsamifera essential oil. The nano-microcapsule comprises a core material and a wall material, wherein the core material is blumea balsamifera essential oil, the wall material is formed by carrying out cross-linked reaction between sulfhydryl modified chitosan and a cross-linking agent, and the wall material is coated with the core material. The invention also discloses a preparation method of the nano-microcapsule with the blumea balsamifera essential oil, i.e., the blumea balsamifera nano-microcapsule is prepared by adopting a controlled release technology of the nano-microcapsule and a nano-directional skin permeability absorption technology. The problems that active ingredients of the blumea balsamifera essential oil are unstable and efficacy action time of the blumea balsamifera essential oil is short are solved; the bioavailability of the blumea balsamifera essential oil is improved and an application range of the blumea balsamifera essential oil is widened; moreover, the nano-microcapsule has the advantages of non-toxicity, security, low cost and easiness for realization of industrial production and the like, so that the nano-microcapsule has wide application values in drugs, cosmetics, skin care products and spice and flavor additives.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

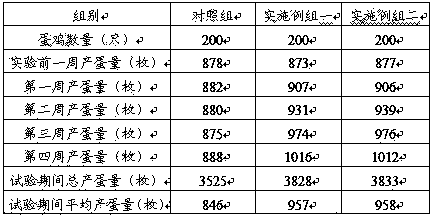

Feed for improving egg yield, traditional Chinese medicine additive and preparation method thereof

ActiveCN103749982AImprove feed conversionIncrease productionAnimal feeding stuffRadix OphiopogonisSoya bean

The invention provides feed for improving egg yield. The feed comprises basic feed components, vitamin D, vitamin A, lysine, methionine, sodium butyrate, calcium hydrophosphate, calcium carbonate, flavoring additives, bacillus subtilis microecologics, trace element additives and traditional Chinese medicine additives serving as additives, wherein the traditional Chinese medicine additives comprise rhizoma anemarrhenae, medical stone, ligusticum wallichii, Chinese angelica, Chinese-dates, herba aristolochiae, medlar, black soya bean, polished round-grained rice, hawthorn, pepper, black pepper, Radix Ophiopogonis, leaf of paniculate microcosm, longan aril, radix glehniae, American ginseng, lily, Ferula asafetida and liquorice. According to the feed provided in the invention, comprehensive absorption of nutrition of laying hens can be well promoted, and the egg laying performance of the laying hens is improved.

Owner:LIUHE FEED HUAIAN CO LTD

Hot-fill beverage production with flavor injection

InactiveUS20060286261A1Reduce downtimeLess fresh water and energyLiquid fillingBeverage vesselsStable stateAdditive ingredient

A method and system for producing a flavored beverage wherein the flavor is added in a separate step to a combination of the base ingredients after the base liquid has been pasteurized by, for example, thermal heating. The flavor can be added to a continuous stream of the base liquid after a thermally processed hot-fill beverage base liquid is made up. A return loop conduit of the hot-fill beverage base liquid portion of the system is capable of diverting the heated hot-fill beverage base liquid in a stable state, that is, at the desired temperatures ready for continued beverage production, while the flavor may be switched over in a downstream flavor dosing portion of the system. The system may be used to produce a desired batch of flavored beverage by producing a first flavor, cleaning only that portion of the system to remove the first flavor and then changing over the flavor additive component to a desired second flavor.

Owner:THE QUAKER OATS CO

High-calcium chicken flavor extract and production method thereof

ActiveCN103892227AMellow fragranceStrong fragranceLactobacillusFood preparationSucroseAdditive ingredient

The invention relates to a high-calcium chicken flavor extract and a production method thereof. The purposes of the invention are to provide the product with the characteristics of rich nutrition and good taste as well as provide the method with the characteristics of simplicity and convenience in production and low cost. The high-calcium chicken flavor extract comprises a high-calcium chicken flavor extraction liquid, hydrolyzed vegetable protein, edible salt, a flavoring additive, white sugar, spice essential oil, ethyl maltol, sucrose fatty ester, beta-cyclic dextrin, sodium diacetate and vitamin E. The method for producing the high-calcium chicken flavor extract comprises the following steps: (1) chicken bones are processed into chicken bone powder by sequentially washing, removing sundries, cutting into lumps, and pulverizing; (2) a high-calcium chicken flavor extraction liquid is formed by liquid fermentation; (3) the extraction liquid is mixed uniformly and reacts with the hydrolyzed vegetable protein and the like according to the proportion, and is prepared into a paste by concentration and weight reduction.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

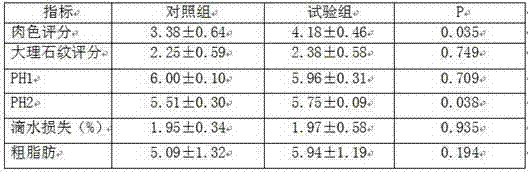

Method for producing pollution-free flavoured chilled pork

ActiveCN102511828AGuaranteed qualityGuaranteed flavorAnimal feeding stuffFood preparationAnimal scienceElectric shock

The invention discloses a method for producing pollution-free flavoured chilled pork, which belongs to raising processing method of livestock food and solves the problem that the quality of pork is not high and the tastiness is not good because of the disadvantages existing in the prior live pig raising and slaughtering technology. Animal welfare measures are brought in the two processes of raising and slaughtering processing, the ablactation time for piglets is increased to 28 days during the raising process, and dedicated cereal crops with full nutritional value is prepared, wherein, flavorenhancers are added in the dedicated cereal crops; light music is played; a temperature regulation and control device (comprising a heater and a water sheet cooling system) is arranged in a hog house; the herd management density that allows the activity space of at least 2 square meters for each pig is ensured; small toys are provided so as to satisfy foraging and searching behavior habits of thepigs; in addition, rest, feeding and water supply are ensured when the pigs are transported during the slaughtering and manufacturing process, the pigs enter a slaughter house when hearing the light music and are slaughtered through electric shock in an isolating manner, and then condensation, steaming, scalding, carcass opening, disemboweling, halving, cooling, refrigeration, acid discharge and examination are carried out. The method is suitable for batch production of commercial pork.

Owner:SICHUAN BAPIN AGRI PRODS DEV

Method for preparing bread natural flavor additive through sprouted wheat

The invention provides a method for preparing a bread natural flavor additive through sprouted wheat, and belongs to the technical field of food processing. According to the method, qualified wheat seeds which are subjected to strict quality screening are chosen, and the wheat seeds are subjected to cleaning, soaking, sprout cultivation, elutriation and drying, crushing and screening and baking to obtain the bread natural flavor additive. According to the additive, the sprouted wheat seeds are used as raw materials, so that the additive enables bread to have natural wheat aroma and scorch aroma and to be rich in flavor. Compared with common bread, the bread added with the additive is rich in dietary fiber, y-aminobutyric acid and the like, and nutritive value of the bread is improved.

Owner:广东鸿信食品有限公司

Groove feeding filter stick and smoke filter tip thereof

InactiveCN102754920ANovel structureImprove adsorption capacityTobacco smoke filtersCelluloseBiochemical engineering

The invention provides a groove feeding filter stick is characterized by being formed through firstly coating a layer of groove cellulose paper at the periphery of a filter core and then wrapping a layer of forming paper. The surface of the groove cellulose paper is formed by a through long groove section or combination of a groove section and a flat section, the filter core coated at the groove section contains adsorptive, filtering or flavored additive. The filter tip made by the groove feeding filter stick is formed by splicing a groove feeding small section and other small sections and finally coating an outer ring forming paper for compounding, and the lip close end of a cigarette is of other sections. The filter stick and the filter tip are novel and unique in structure, have the advantages of adsorbing, filtering or flavoring the feeding filter stick, and the advantages of good smoke ventilation, filter core strands and fully-played additive of the groove filter stick.

Owner:NANTONG CIGARETTE FILTER

Processing technology of lotus seed wine

InactiveCN103911247AHave physical fitnessAromaAlcoholic beverage preparationMicroorganism based processesKidneySpleen

The invention discloses a processing technology for lotus seed wine. A preparation method of the lotus seed wine comprises the following steps: selecting raw materials; grinding; mixing size; saccharifying; fermenting; distilling; and filtering to obtain finished wine. The processing technology disclosed by the invention has the following characteristics that the lotus seed wine is free from other sugars, traditional Chinese medicines and other flavoring additives; the prepared lotus seed wine is natural and mellow, fragrant in smell, pure and delicious in taste, clear and transparent, soft and fresh, and is well received by customers; the prepared lotus seed wine can nourish heart and smooth nerves, benefit kidney and induce astringency, invigorate spleen and stop diarrhea, has such functions as building body, promoting a regeneration function and nourishing, and is abundant in nutrition; the processing technology is simple in preparation process, short in cycle and applicable to industrial production.

Owner:陆滔

Maitake wine and preparation method thereof

InactiveCN102134549ARelieve painActivate immune functionAlcoholic beverage preparationBiotechnologyBULK ACTIVE INGREDIENT

The invention discloses a maitake wine and a preparation method thereof. The preparation method comprises the following steps of: weighting 50 to 120 weight parts of maitake, 30 to 100 weight parts of longan pulp, 30 to 100 parts of Chinese wolfberry, 30 to 100 parts of Chinese date and 20 to 100 parts of sweet osmanthus, drying for sterilization, crushing, adding white spirit in an amount which is 3 to 5 times total weight of raw materials, soaking for 15 to 20 days, performing percolation extraction and filtration, and adding flavoring additives. According to the compatibility of a medicinal formula, raw materials medicines are accurately mixed, and the maitake wine has obvious effects of activating organism immunity function, tonifying liver and qi, effectively relieving toxic and sideeffects after a cancerous person is subjected to chemotherapy, and the like. By the preparation method, active ingredients of medicines can be fully separated out, and the obtained maitake wine has mellow taste and typical sweet osmanthus smell and aroma, is smooth and coordinated, and has comfortable medicine scent; and the preparation method is simple and convenient, ensures stable product quality, and has wide application prospect.

Owner:云南大初酒业有限公司

Egg powder food

The invention relates to a food, in particular to an egg powder food produced from main raw materials of edible roughage starch and eggs. The egg powder food comprises the following materials in parts by weight: 65-90 parts of edible roughage starch, 10-35 parts of egg, 2-5 parts of walnut powder, 2-5 parts of peanut powder and 0-3 parts of flavoring additive. The product has the characteristics of wide source of raw materials, nutrient enrichment and huge consumer group (huge market), and contains minor elements, coarse fibers and vitamins required by human beings. Besides, the product also has the characteristics of high toughness, long-time cooking resistance, good elasticity, no separation, no adhesion, no gelation, no solubilization, softness, strong gluten, delicate, smooth and fresh mouth feel and bright and transparent appearance, and can meet the requirements of people for the roughage food, thereby providing a new platform for diversifying the producing method of the roughage food.

Owner:李全华

Coffee or Mocha Flavored Additive for Bakery Purposes

An anhydrous fat-based discrete flavoring additive is provided for incorporation into baked goods. The discrete flavoring additive product comprises from substantially 0% to 2% by weight of moisture, from about 3% to about 30% by weight of a finely ground natural flavoring agent comprising coffee and optionally cocoa, from about 25% to about 35% by weight of a bakery-compatible oil that is substantially liquid at about 35 degrees C. to about 40 degrees C., with the balance being sugar. The bakery-compatible oil is selected from the group consisting of vegetable oils, cocoa butter, liquid butter fats etc., and mixtures thereof, which exhibit a solid fat index curve characteristic which is preferably similar to that of cocoa butter. The bakery-compatible oil or fat system has finely ground coffee, optionally cocoa or other optional flavoring agents, held in suspension. This suspension is mixed with sugar, and is then cooled to effect solidification. The product, when solidified, will remain substantially solidified at temperatures below about 35 degrees C., and particularly at room temperature of about 20 degrees C., and forms a discrete final product which can be used as a coffee or mocha-flavored additive in the production of bakery goods.

Owner:MILLER VAN

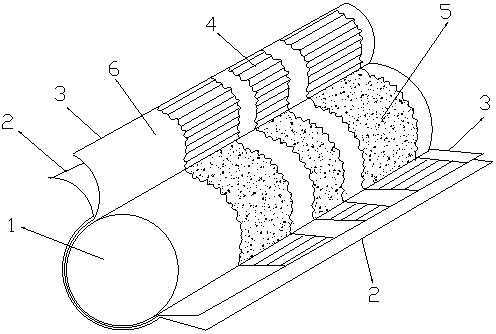

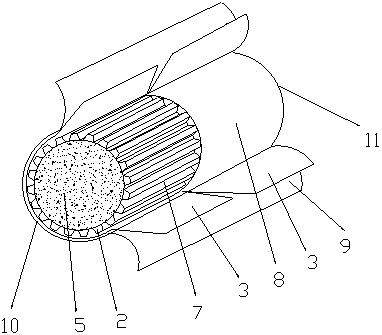

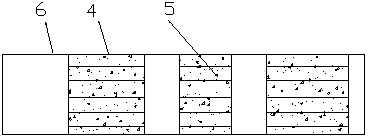

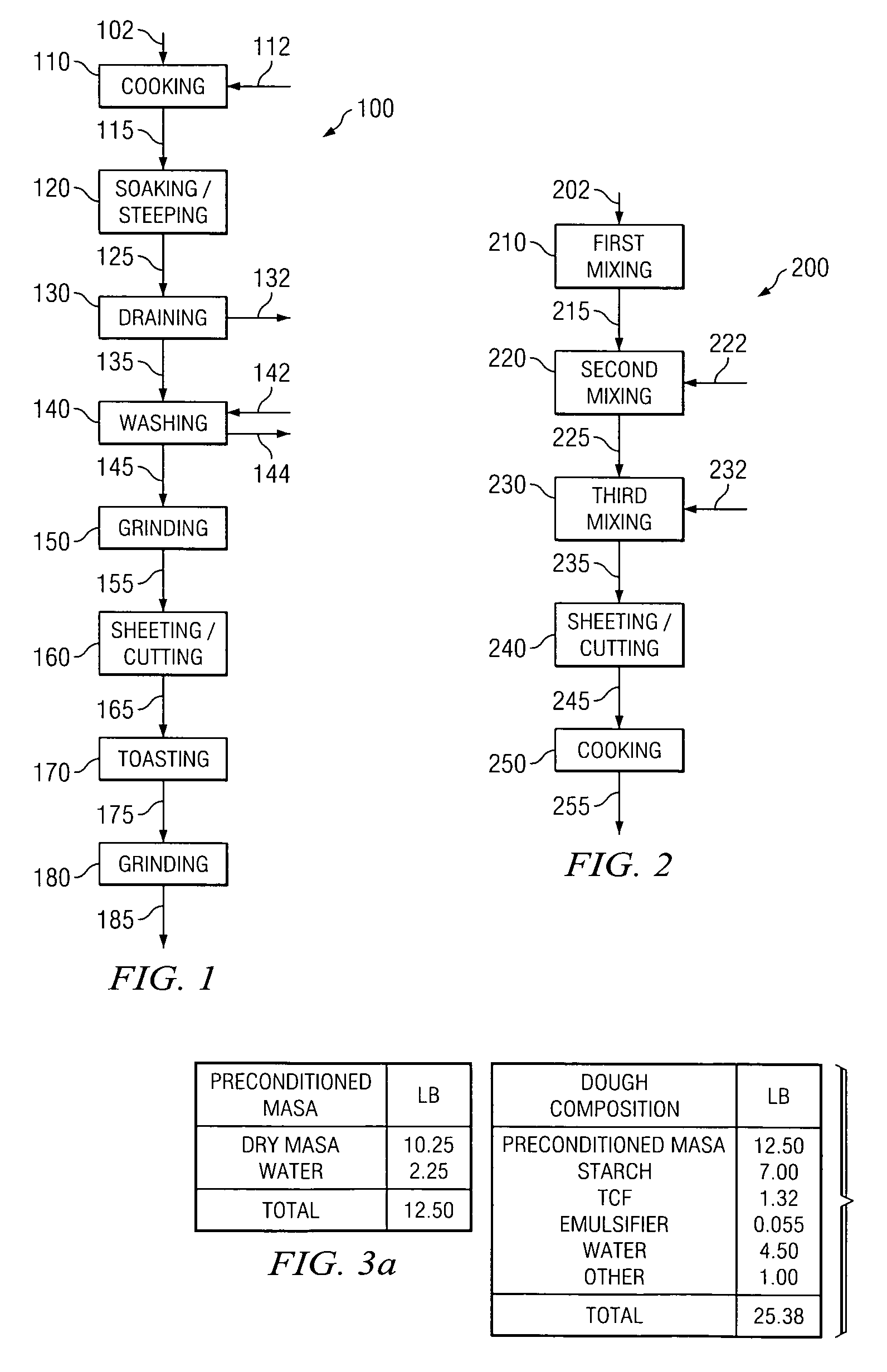

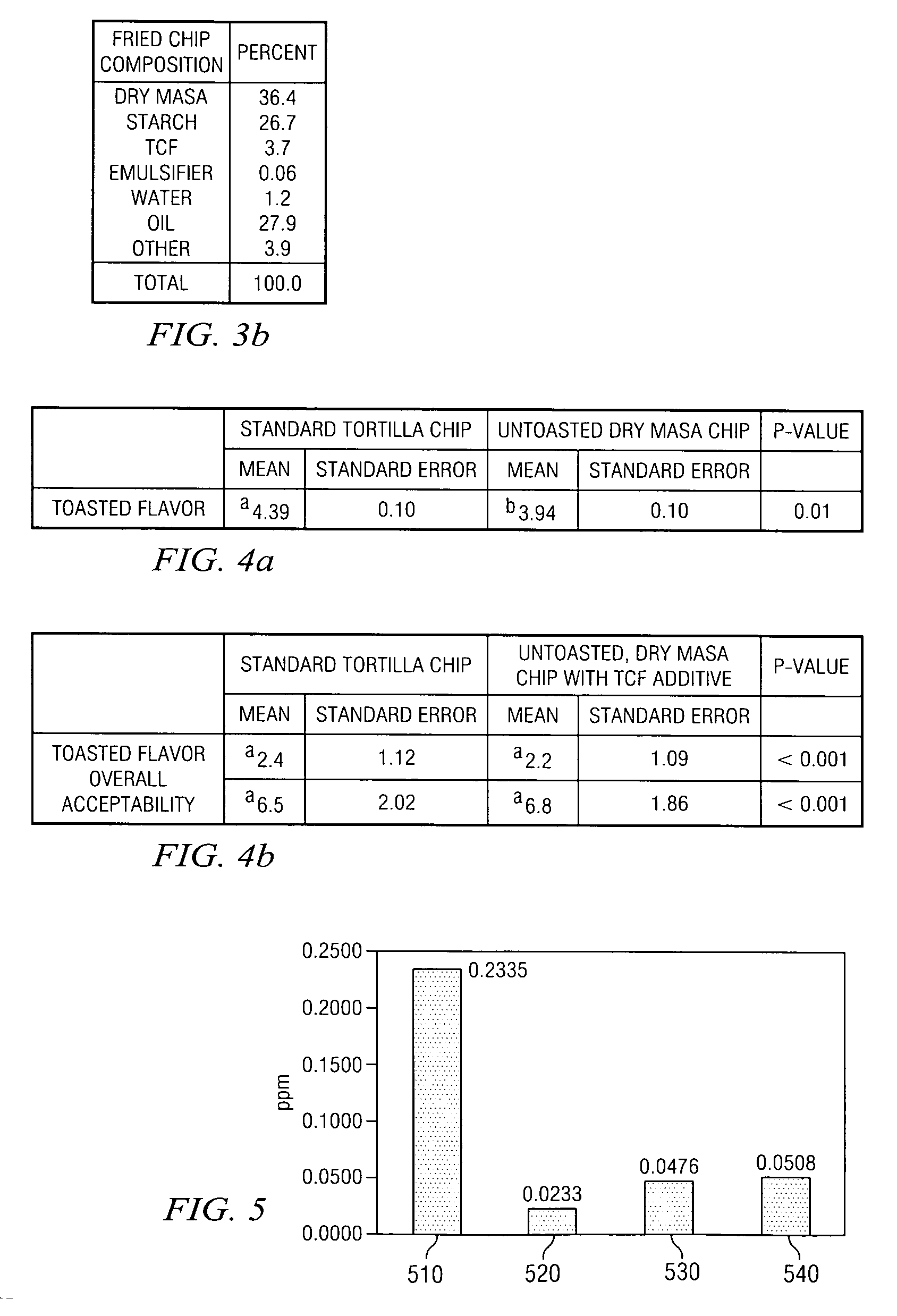

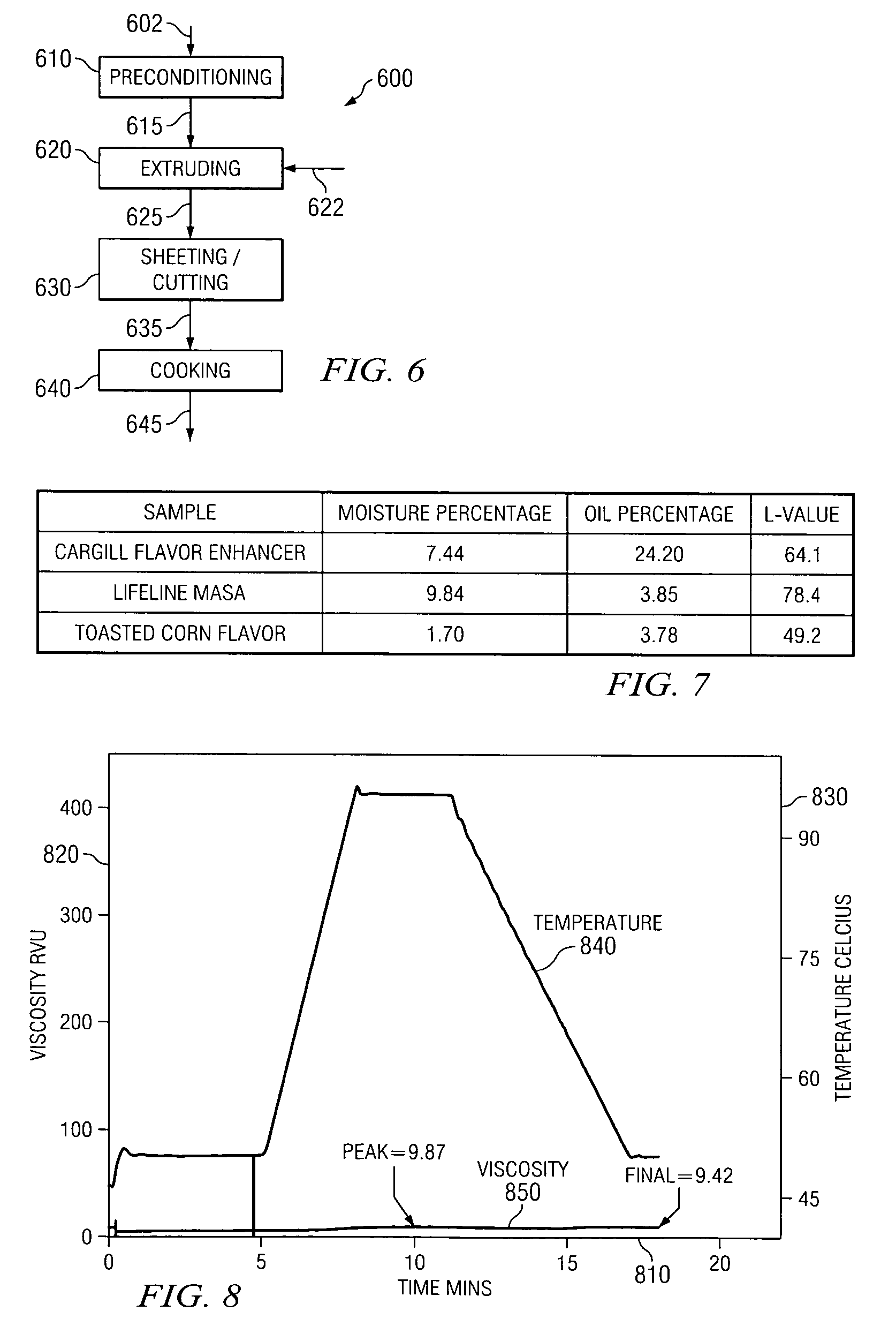

Toasted flavor additive

A novel toasted flavor additive for enhancing the toasted flavor and appearance of food products. In accordance with one embodiment of the present invention, toasted corn flavor additive (“TCF”) is made by the steps of cooking whole corn kernels in a solution of lime and water; steeping the corn; draining and washing the corn; grinding, sheeting and cutting the corn into pieces; toasting the pieces until significant browning has occurred beyond the level normally associated with consumed masa products; and grinding the toasted pieces into a powder that can be administered as toasted corn flavor additive.

Owner:FRITO LAY NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com