Method for producing pollution-free flavoured chilled pork

A production method and technology of pork, which is applied in the field of livestock food feeding and processing, can solve the problems of poor quality and bad flavor of pork, and achieve the effects of ensuring hygienic quality, prolonging weaning time, and improving quality and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

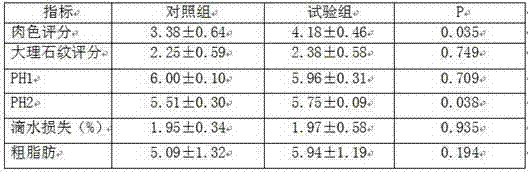

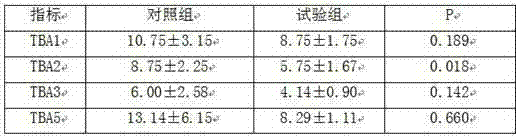

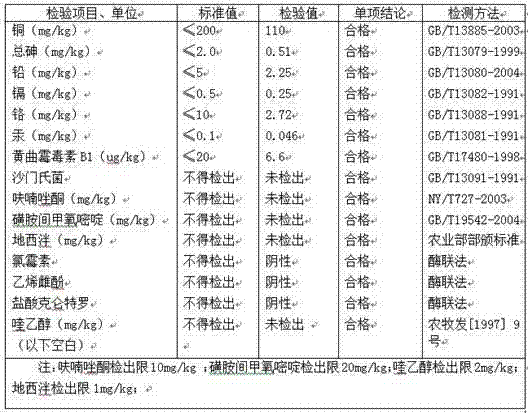

Examples

Embodiment 1

[0078] Example 1: Select piglets from hybrid commercial pigs above binary, and wean them after 28 days of age, and then put them into piggery for group breeding. The pig house is equipped with a music playback system, a water curtain cooling system, and heating. The density of group breeding is at least 2 square meters per head, and there are small balls, hanging baskets, and wooden sticks. The piglets are regularly fed with cleaned green and juicy feed and water every day, and the pigs are wiped with a hard brush once in the morning and evening, and the pigs are often bathed to keep the pigs clean, and light music is played from time to time.

[0079] Piglets start to feed the prepared full-price compound grain, the main components and weight content are:

[0080] Corn 64.8kg,

[0081] soybean meal 25kg,

[0082] Wheat bran 5kg,

[0083] Imported fish meal 2kg,

[0084] Calcium hydrogen phosphate 1kg,

[0085] Calcium carbonate 1.2kg,

[0086] Salt 0.3kg,

[0087] Beta...

Embodiment 2

[0182] Embodiment 2: The production method of pollution-free flavor chilled fresh pork. The processes are basically the same as in Example 1. The difference is that the prepared full-price compound grains are different:

[0183] Piglets start to feed the prepared full-price compound grain, the main components and weight content are:

[0184] Corn 62kg,

[0185] soybean meal 28kg,

[0186] Wheat Bran 4.5kg,

[0187] Imported fish meal 2.5kg,

[0188] Calcium hydrogen phosphate 1kg,

[0189] Calcium carbonate 1kg,

[0190] Salt 0.3kg,

[0191] Betaine 0.2kg,

[0192] Lysine 0.5kg.

[0193] After the piglets grow into medium pigs, they are replaced with new full-price compound grains, the composition of which is as follows:

[0194] Corn 65kg,

[0195] soybean meal 20kg,

[0196] Wheat Bran 12kg,

[0197] Calcium hydrogen phosphate 1kg,

[0198] Calcium carbonate 0.9kg,

[0199]Salt 0.4kg,

[0200] Betaine 0.2kg,

[0201] Lysine 0.5kg.

[0202] After the medium pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com