Process for preparing shiitake mushroom extract

A technology of Lentinus edodes extract and production process is applied in the field of production technology of Lentinus edodes extract, and can solve the problems of single concentration of nutrients and poor extraction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

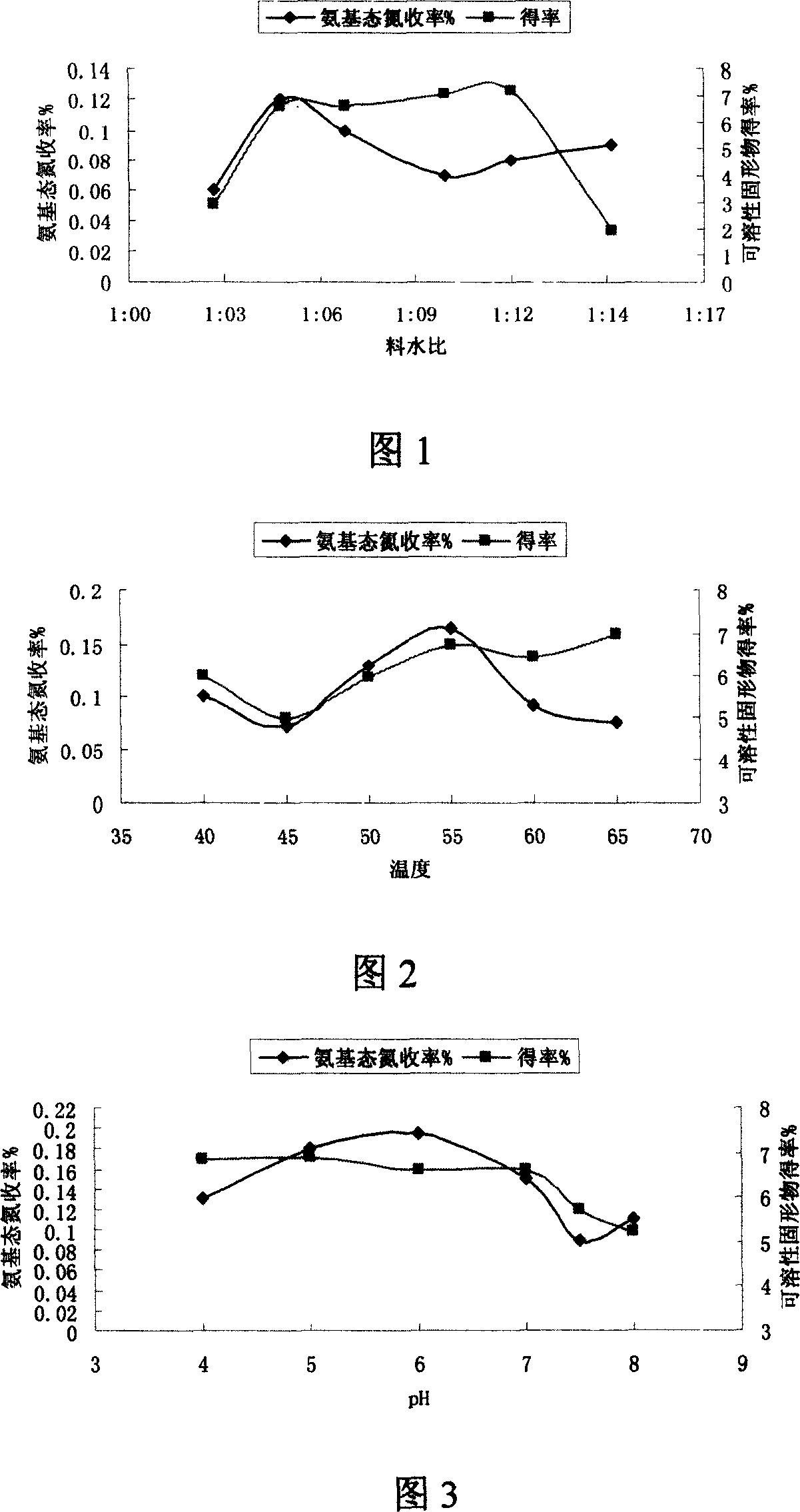

[0079] Embodiment 1: a kind of production technology of shiitake mushroom extract, comprises the following steps:

[0080] 1. Take shiitake mushrooms and crush them and add water with a weight ratio of 1:3.

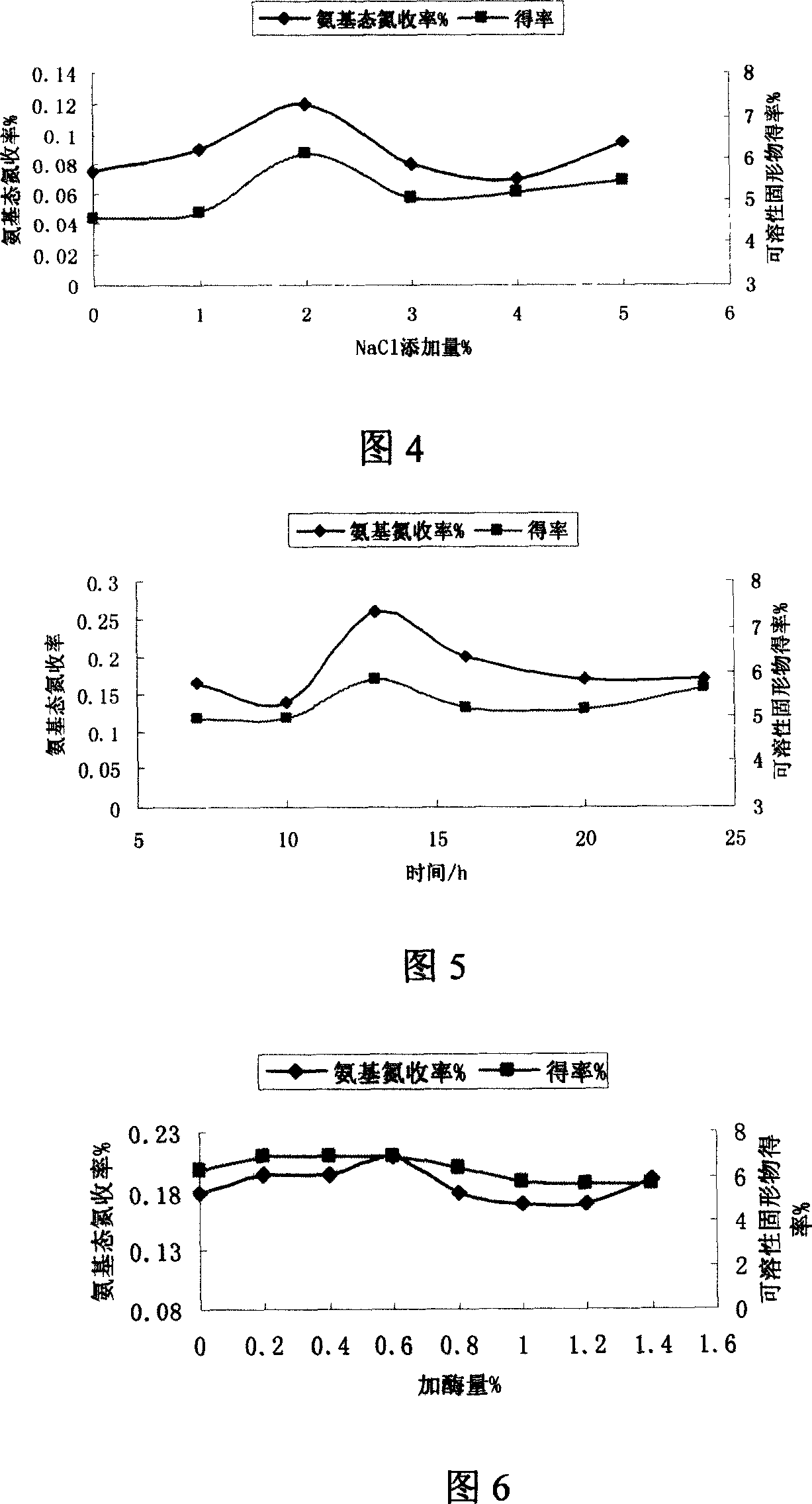

[0081] 2. Add 1% salt (NaCl) of the quality of the shiitake mushrooms and adjust the pH to 4, autolyze for 8 hours at a temperature of 40° C., and adjust the pH by using acetic acid or hydrochloric acid and sodium hydroxide solution.

[0082] 3. Add 0.2% protease of the mass of shiitake mushrooms, enzymatically hydrolyze for 1 hour under the condition of PH=4.5 and temperature of 45°C, and use papain or microbial protease as the protease;

[0083] 4. After deactivating the enzyme, separate the filtrate, which can be separated by centrifugation or filtration to remove the residue of the shiitake mushrooms to obtain a clear liquid; generally heat at 95°C for 15 minutes to deactivate the enzyme;

[0084] 5. Add 5'-phosphodiesterase enzyme solution with a volume of 1.25% of ...

Embodiment 2

[0087] Embodiment 2: a kind of production technology of shiitake mushroom extract, comprises the following steps:

[0088] 1. Take shiitake mushrooms and crush them and add water with a weight ratio of 1:14,

[0089] 2. Add 5% salt (NaCl) of the quality of shiitake mushrooms and adjust the pH to 8, and autodissolve for 20 hours at a temperature of 65°C.

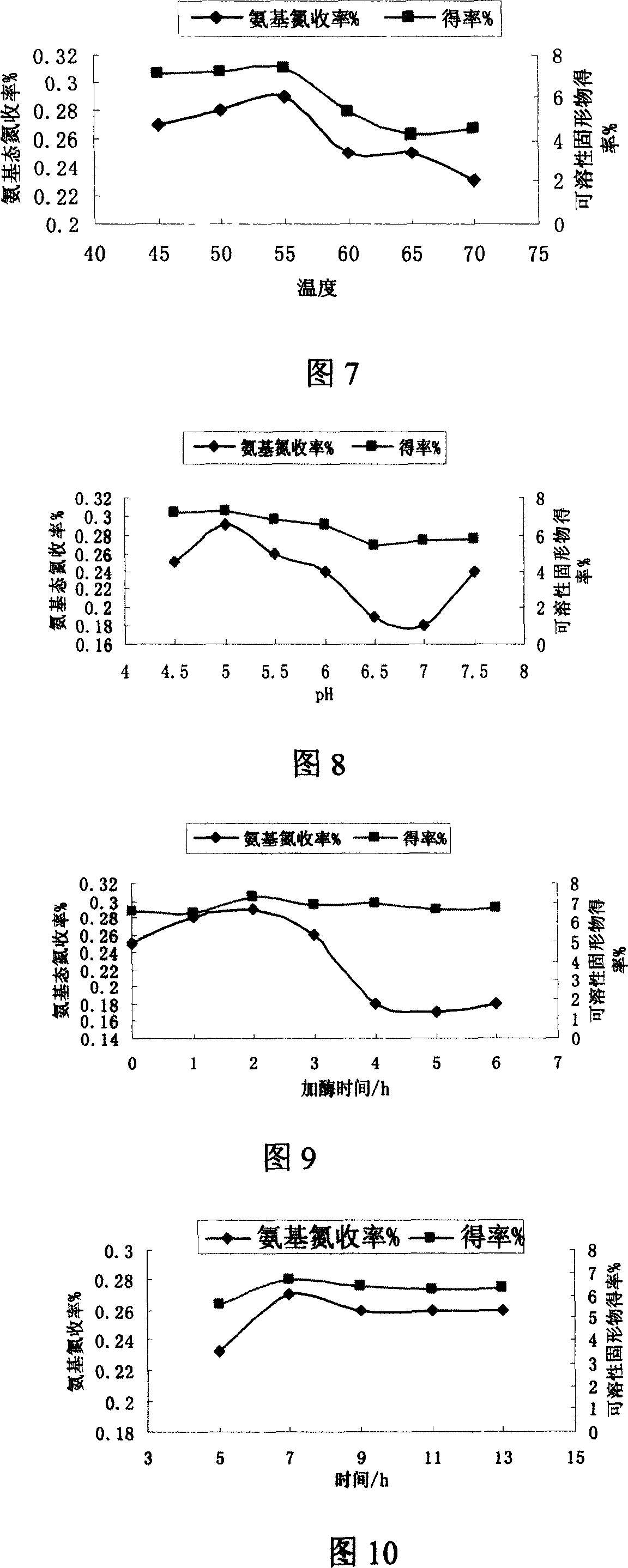

[0090] 3. Add 1.0% protease of the mass of shiitake mushrooms, and enzymatically hydrolyze for 6 hours under the conditions of pH = 7.5 and temperature of 75°C. The protease is papain or microbial protease;

[0091] 4. After deactivating the enzyme, separate the filtrate, which can be separated by centrifugation or filtration to remove the residue of the shiitake mushrooms to obtain a clear liquid; generally heat at 95°C for 15 minutes to deactivate the enzyme;

[0092] 5. Add 5'-phosphodiesterase enzyme solution with a volume of 4.25% of the filtrate to the filtrate, and perform enzymatic hydrolysis for 5 hours under the co...

Embodiment 3

[0095] Embodiment 3: a kind of production technology of shiitake mushroom extract, comprises the following steps:

[0096] 1. Take shiitake mushrooms and crush them and add water with a weight ratio of 1:5. Fresh shiitake mushrooms (water content 89.6%) are washed, drenched, crushed, added with 2 times the weight of fresh shiitake mushrooms, made into a homogenate with a beater, and then added with 3 times the weight of fresh shiitake mushrooms. 2. Add 2% salt (NaCl) of the quality of shiitake mushrooms and adjust the pH to 5, and autolyze for 14 hours at a temperature of 45°C.

[0097] 3. Add 0.4% protease of the mass of shiitake mushrooms, enzymatically hydrolyze for 2 hours under the conditions of pH=5.5 and temperature of 55°C, and use papain or microbial protease as the protease;

[0098] 4. After deactivating the enzyme, separate the filtrate, which can be separated by centrifugation or filtration to remove the residue of the shiitake mushrooms to obtain a clear liquid;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com