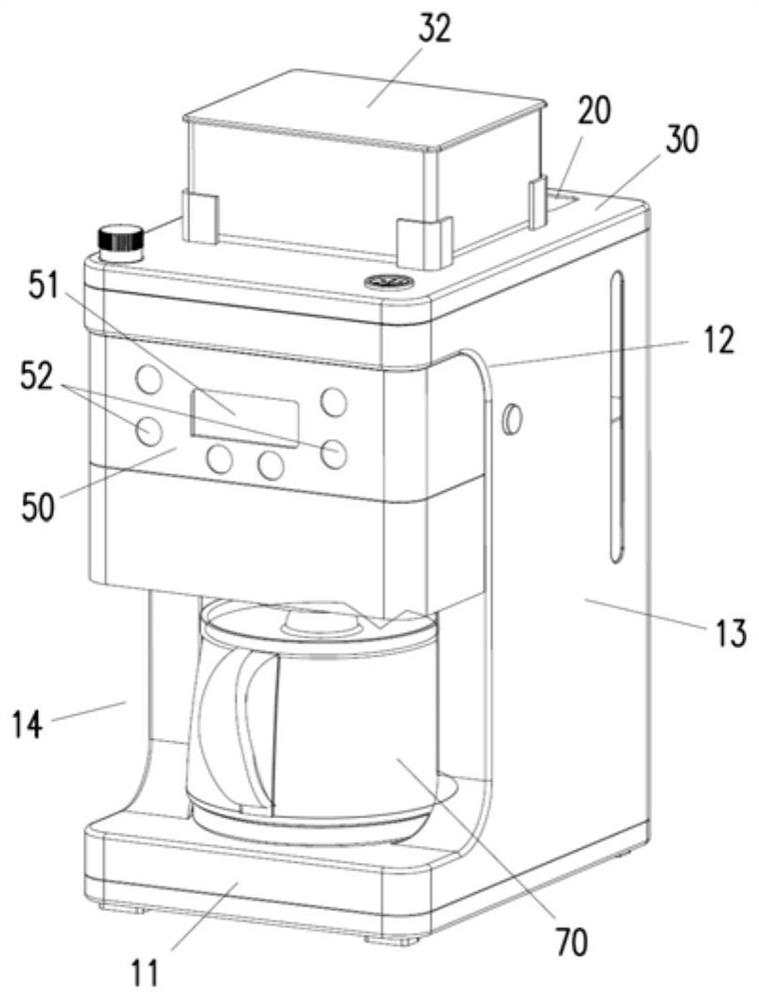

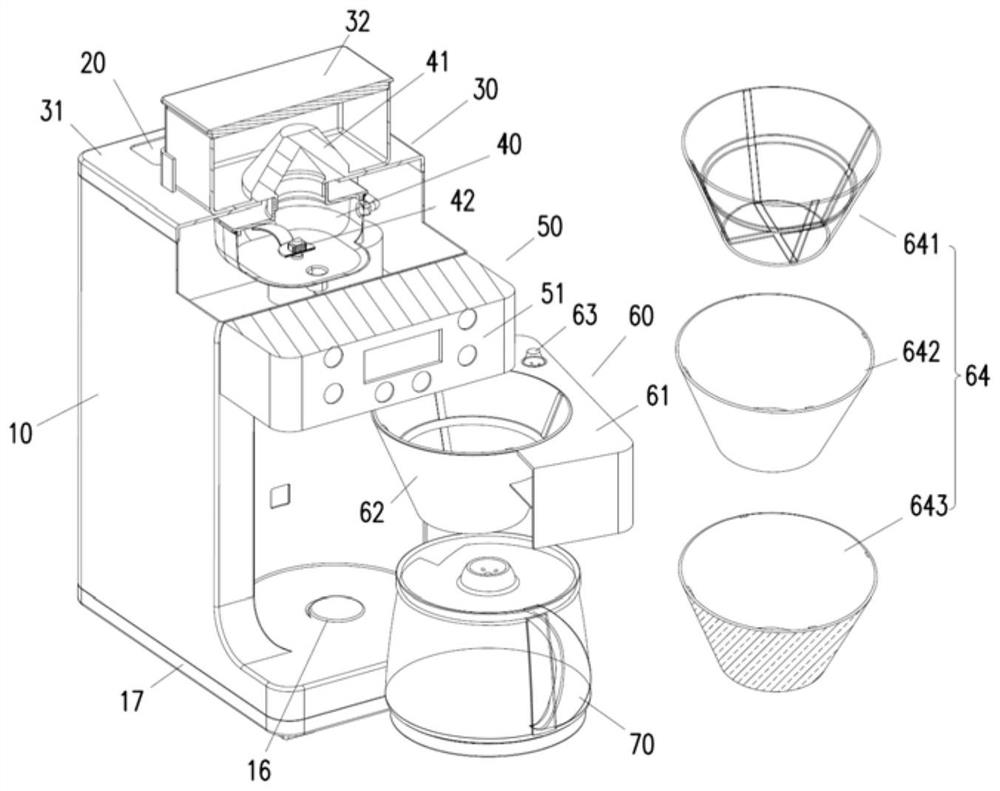

Automatic bean grinding and coffee brewing machine

A technology of coffee machine and bean grinder, which is applied in kitchen utensils, home utensils, beverage preparation devices, etc. It can solve the problems of coffee powder agglomeration, uneven brewing, falling, etc., and achieves easy manufacturing, improved coffee mouth, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In the following description, for the purpose of illustration rather than limitation, specific details such as a specific system structure and technology are proposed for a thorough understanding of the embodiments of the present application. However, it should be clear to those skilled in the art that the present application can also be implemented in other embodiments without these specific details. In other cases, detailed descriptions of well-known systems, devices, circuits, and methods are omitted to avoid unnecessary details from obstructing the description of this application.

[0027]It should be understood that when used in this specification and the appended claims, the term "comprising" indicates the existence of the described features, wholes, steps, operations, elements and / or components, but does not exclude one or more other The existence or addition of features, wholes, steps, operations, elements, components, and / or collections.

[0028]In order to make the drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com