Bean-grinding coffee machine with movable brewing head

A technology for a brewing head and a coffee machine, which is applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as unreliable performance and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

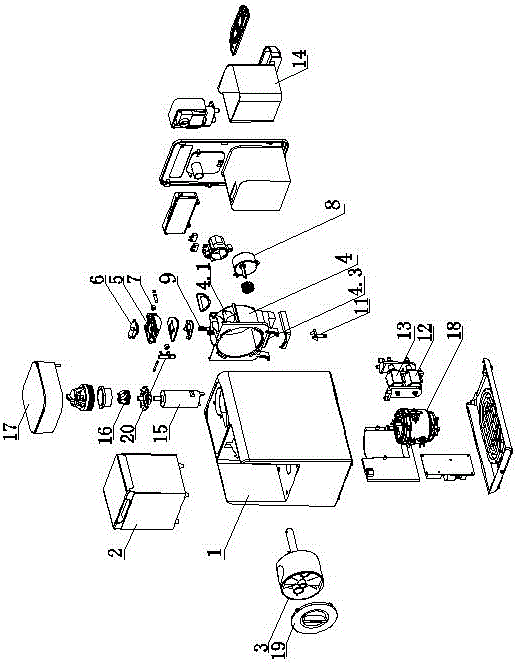

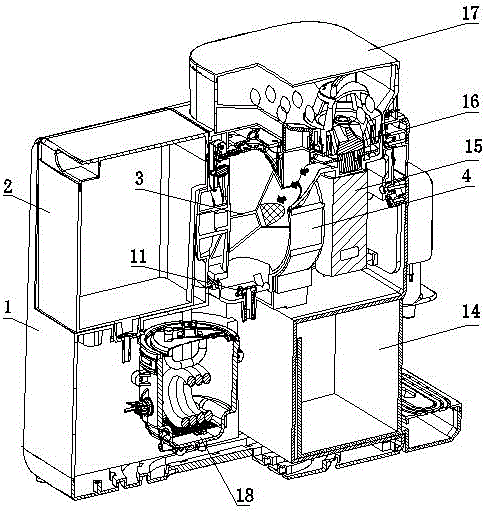

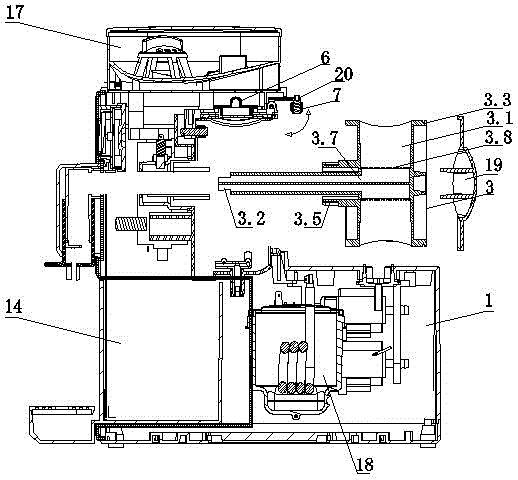

[0081] First embodiment (see Figure 1-Figure 12 , Figure 15-Figure 18 )

[0082] A bean grinder coffee machine with a movable brewing head, including a body 1, a water tank 2, a water supply assembly, an electric drive mechanism, a grinding assembly, and a brewing assembly; the body 1 is provided with at least a brewing chamber 3.1 and a grinding chamber, It is characterized in that: the brewing assembly includes a rotatable rotating part 3, and at least one brewing chamber 3.1 is arranged on the rotating part 3;

[0083] The brewing assembly is at least provided with a brewing head 5, and the opening of the brewing chamber 3.1 is connected to the brewing head 5 through relative movement, extruding and sealing by the force of the electric drive mechanism.

[0084] The brewing head 5 crosses the opening of the rotating bracket 4 and is sealed and connected with the brewing chamber 3.1, or the brewing head 5 is sealed and connected with the brewing chamber 3.1 across the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com