Operation method of bean grinding coffee machine for rotationally brewing

一种工作方法、旋转冲泡的技术,应用在饮料制备装置、家里用具、应用等方向,能够解决不能实现一次加水多次使用、性能不可靠、使用寿命短等问题,达到结构简单合理、性能可靠、降低操作难度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

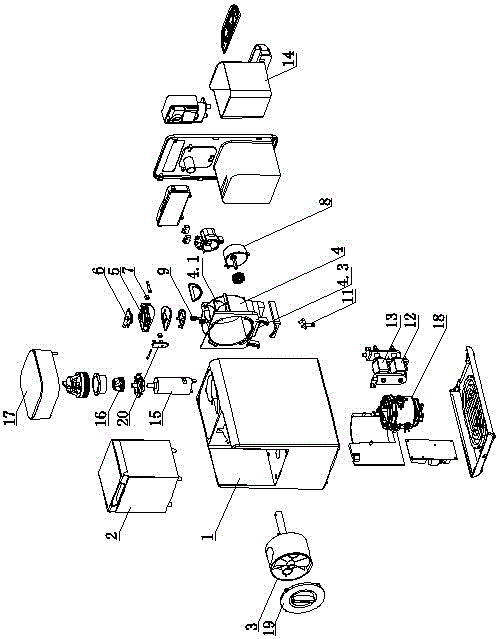

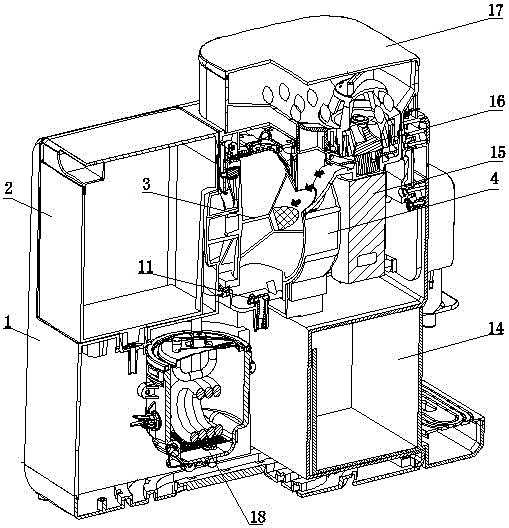

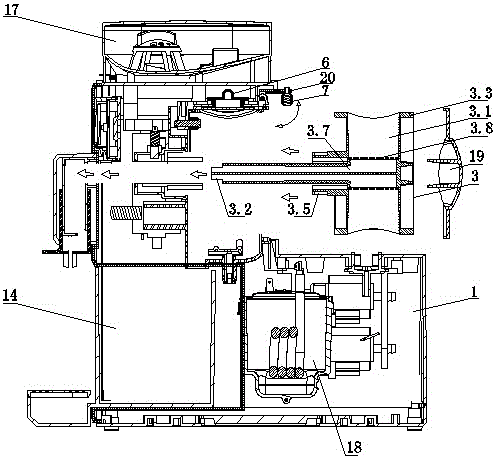

[0060] First embodiment (see Figure 1-Figure 15 , Figure 18 )

[0061] The working method of a coffee grinder with rotary brewing includes a body 1, a water tank 2, a water supply assembly, a grinding assembly and a brewing assembly; the body 1 is provided with a brewing chamber and a grinding chamber, and the brewing assembly and The grinding assembly is respectively placed in the brewing chamber and the grinding chamber; the brewing assembly includes a rotatable rotating part 3, and two brewing chambers 3.1 are symmetrically arranged in the rotating part 3, and the opening of the brewing chamber 3.1 rotates in a circular track The brewing component is provided with a brewing head opening 4.2 and a material outlet 4.1, the water outlet of the water supply component and the powder outlet of the grinding component respectively pass through the brewing head opening 4.2, the material outlet 4.1 and the opening of the barrel brewing chamber 3.1; The opening of the brewing cham...

no. 3 example

[0080] Third embodiment (see Figure 17 )

[0081] The working method of this rotary brewing bean grinder coffee machine is different from the first embodiment in that the grinding cutter 16 adopts a blade.

[0082] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

[0083] Fourth embodiment (see Figure 19 )

[0084] The working method of the rotary brewing bean grinder coffee machine is different from the first embodiment in that: one brewing chamber 3.1 is provided in the rotating member 3 and placed on one side of the axis.

[0085] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

[0086] Fifth embodiment (see Figure 20 )

[0087] The working method of the rotary brewing coffee grinder differs from the first embodiment in that: the rotating member 3 is fan-shaped, and a brewing chamber 3.1 is provided, and the brewing chamber 3.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com