Coffee machine capable of achieving full-automatic water feeding and bean grinding

A fully automatic coffee machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of inability to add water for multiple uses at one time, short service life, unreliable performance, etc., and achieve a simple and reasonable structure and reduce operation. Difficult, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

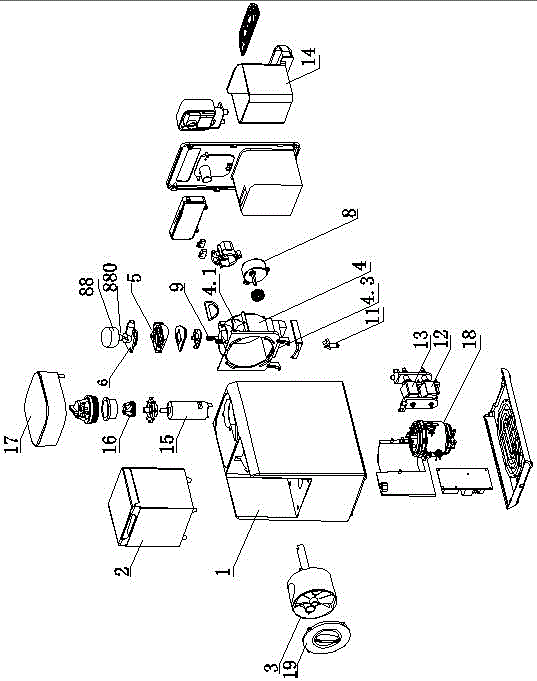

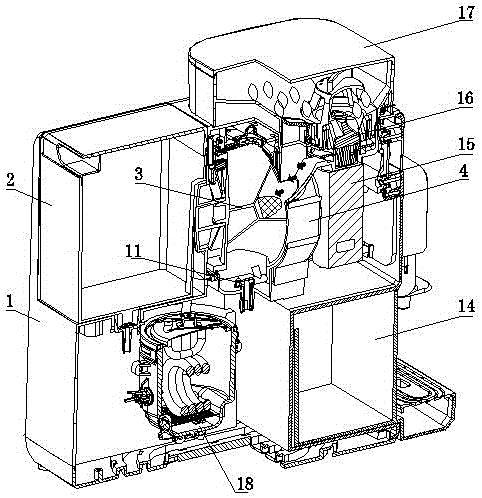

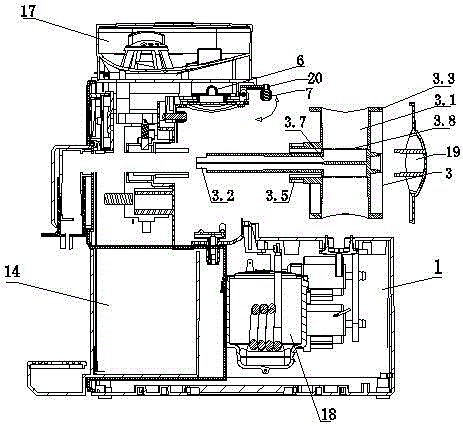

[0047] First embodiment (see Figure 1-Figure 15 , Figure 18 )

[0048] This fully automatic water-inlet grinder coffee machine includes a main body 1, a water tank 2, a water supply assembly, a grinding assembly and a brewing assembly; the main body 1 is provided with a brewing chamber and a grinding chamber, and the brewing assembly and the grinding assembly are respectively arranged correspondingly. In the brewing chamber and the grinding chamber; the brewing assembly includes a rotatable rotating member 3, and two brewing chambers 3.1 are symmetrically arranged in the rotating member 3, and the opening of the brewing chamber 3.1 rotates in a circular track; the brewing assembly is set There is a brewing head opening 4.2 and a material outlet 4.1, the water outlet of the water supply assembly and the powder outlet of the grinding assembly respectively pass through the brewing head opening 4.2 and the material outlet 4.1 and the opening of the barrel brewing chamber 3.1; t...

no. 3 example

[0131] Third embodiment (see Figure 17 )

[0132] This fully automatic water-inlet bean grinder coffee machine is different from the first embodiment in that the grinding tool 16 is a blade.

[0133] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

[0134] Fourth embodiment (see Figure 19 )

[0135] This fully automatic water-inflow coffee machine is different from the first embodiment in that: one brewing chamber 3.1 is provided in the rotating member 3 and placed on one side of the axis.

[0136] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

[0137] Fifth embodiment (see Figure 20 )

[0138] This fully automatic coffee machine with water inlet and bean grinder differs from the first embodiment in that: the rotating member 3 is fan-shaped, and a brewing chamber 3.1 is provided, and the brewing chamber 3.1 is located on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com